-

Model:

SLB-8/10/15/20/30

- Năm sản xuất: 2025

- Thương hiệu: TTM

- Xuất xứ: Trung Quốc

- Địa điểm: Toàn Quốc

Model SLB-8, SLB-10, SLB-15, SLB-20, SLB-30 Loại Trạm trộn bê tông nhựa nóng di động Công suất 8 - 30…

-

Model:

YLB

- Năm sản xuất: 2025

- Thương hiệu: TTM

- Xuất xứ: Trung Quốc

- Địa điểm: Toàn Quốc

Model YLB1500 Loại Trạm trộn bê tông nhựa nóng di động Công suất 120 tấn/giờ Thương hiệu TTM Xuất xứ…

-

Model:

PLB

- Năm sản xuất: 2025

- Thương hiệu: TTM

- Xuất xứ: Trung Quốc

- Địa điểm: Toàn Quốc

Model LB800, LB1000, LB1200, LB1500, LB2000, LB3000, LB4000, LB5000 Loại Trạm trộn asphalt (với thùng…

-

Model:

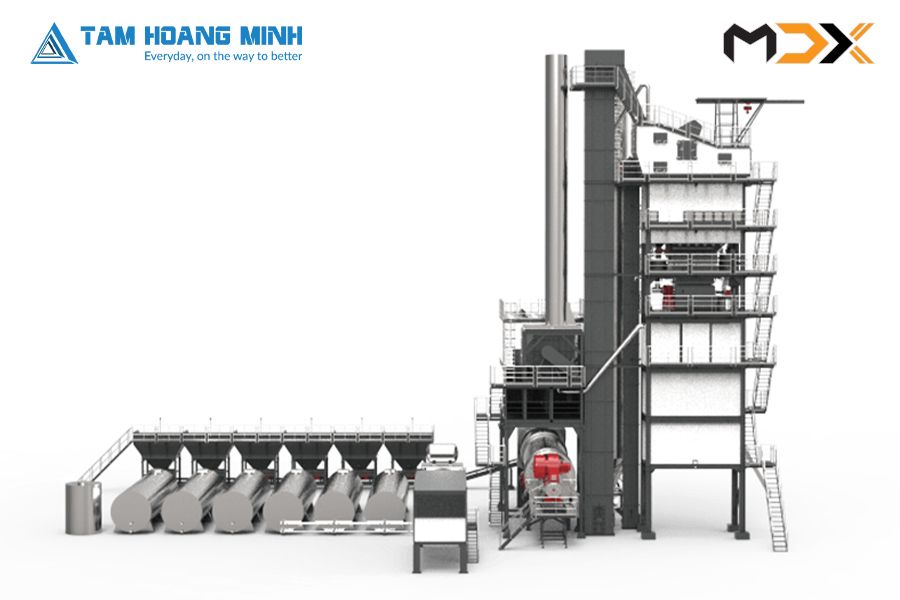

GLB

- Năm sản xuất: 2025

- Thương hiệu: TTM

- Xuất xứ: Trung Quốc

- Địa điểm: Toàn Quốc

Model LBE1000, LBE1500, LBE2000, LBE3000, LBE4000, LBE5000 Loại Trạm trộn asphalt cố định (với thùng…

-

Model:

GLBE

- Năm sản xuất: 2025

- Thương hiệu: TTM

- Xuất xứ: Trung Quốc

- Địa điểm: Toàn Quốc

Model LBE1000, LBE1500, LBE2000, LBE3000, LBE4000, LBE5000 Loại Trạm trộn asphalt thân thiện với môi…

-

Model:

LB

- Năm sản xuất: 2025

- Thương hiệu: TTM

- Xuất xứ: Trung Quốc

- Địa điểm: Toàn Quốc

Model LB800, LB1000, LB1200, LB1500, LB2000, LB3000, LB4000, LB5000 Loại Trạm trộn asphalt (không thùng…

-

Model:

LBE

- Năm sản xuất: 2025

- Thương hiệu: TTM

- Xuất xứ: Trung Quốc

- Địa điểm: Toàn Quốc

Model LB800, LB1000, LB1200, LB1500, LB2000, LB3000, LB4000, LB5000 Loại Trạm trộn bê tông nhựa nóng…