PRODUCT COMPARISON HAMM HP 180/280 VS. BOMAG BW 28 RH

Here we will compare the competitive features between the Hamm and Bomag of Pneumatic tyre roller, through 2 models: HP 180 / 280 and BW 28 RH. We hope you enjoyed this post!

PRODUCT COMPARISON HAMM HP 180/280 VS. BOMAG BW 28 RH

1. TECHNICAL DATA

| HP 180 / 280 | BW 28 RH |

|

|

|

Working width: 2.084 mm. Engine Power: 85 kW (115.6 HP). Emission standard: EU Stage IIIA / EPA Tier 3. Operating weight: - HP 180: 8, 10, 12, 16, 18 tons. - HP 280: 10, 12, 16, 18, 20, 24, 28 28 tons. |

Working width: 2.042 mm. Engine Power: 92 kW (123.4 HP). Emission standard: EU Stage IIIA / EPA Tier 3. Operating weight: 8.6, 10, 12, 16, 18, 20, 24, 28 28 tons |

You can view the side-by-side comparison (HP 180/280 vs BW 28 RH): HERE

Product reference:

- Hamm HP 180 at: HERE

- Hamm HP 280 at: HERE

2. DRIVER'S PLATFORM

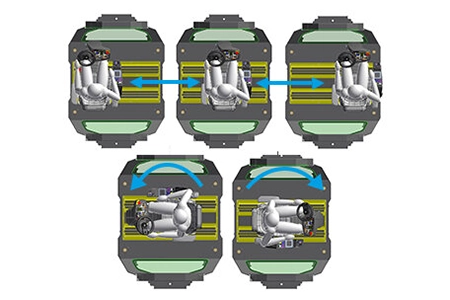

| Seat shift and rotation | |

| HP 180/280 | BW 28 RH |

|

|

| Mechanically adjustable seat (standard). Mechanical seat rotation (optional). Rotation to the left and right by 90° each. It is unlocked via a lever to the left of the seat. | Mechanically adjustable sideways and rotating seat (standard). Rotation to the left by 15° and right by 75°. It is unlocked mechanically via a lever below the seat |

| Steering column | |

|

|

| The steering column follows every seat movement (seat operating unit). When rotating the seat, the driver has the dashboard, steering wheel and brake pedal always in view and within reach. Operational safety | The steering column does not follow the seat when rotating. When rotating the seat, the dashboard, steering wheel and brake pedal are out of the driver's field of vision and reach. Reduced operational safety |

| Display inclination/easy exit | |

|

|

| Tilt of the steering column for comfort exit (optional). The tilt of the dashboard with steering wheel can be adjusted individually (standard). Can be adapted to the driver's needs | Tilt of the steering column not possible since it is rigid. No possibility of tilting the dashboard. Cannot be adapted to the needs of the driver |

| Ascent and descent | |

|

|

| Entry from both sides possible, wide steps, easy ascent, as first step is 365 mm (14") | Entry from both sides possible, narrow steps, difficult ascent, as first step is 610 mm (24") |

| Operator control | |

|

|

| The steering column, steering wheel and dashboard form a seat operating unit. At the same time, the dashboard, steering wheel and brake pedal always remain in the driver's field of vision and under control, even when the seat is rotated. The brake can always be reached, it does not disturb the driver during work. Sensitive braking is possible. High demands on safety | The display and dashboard are rigid and therefore detached from the seat. The dashboard, steering wheel and brake pedal are out of the driver's sight and control while rotating the seat. The brake pedal extends over the entire width of the cabin. There is therefore little space for the driver's feet. The brake pedal only has an emergency brake function. Very sensitive braking with the brake pedal is not possible |

| Operating concept overview | |

|

|

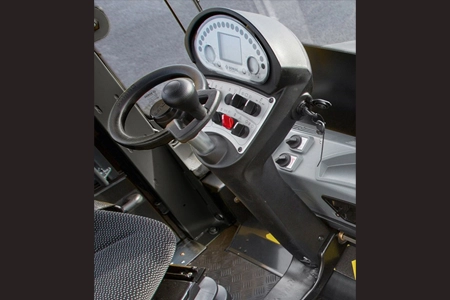

| Display and dashboard | |

|

|

| Membrane display, illuminated, membrane buttons (backlit), displays are very easy to see, even with little light, language-neutral design, clear assignment, facilitates operation, no dashboard is used | Monochrome display, displays that are difficult to see with little light, classic dashboard, language-neutral design |

| Classic dashboard | |

|

Rotary switches. Switch without illumination and therefore difficult to see at night |

|

| Steering wheel | |

|

|

| Large steering wheel, centrally arranged | Large steering wheel, centrally below the display |

| Multifunction armrest | |

|

|

| Multifunction armrest can be folded up on the right (optional). Can be swung out to the side (standard) Rigid armrest, but can be folded out and used as a shelf for a smartphone. Swivel armrest for more comfortable work with cutting wheel and pressure roller |

Right-hand multifunction armrest cannot be folded up or swung out to the side. Armrest can be moved forward and back |

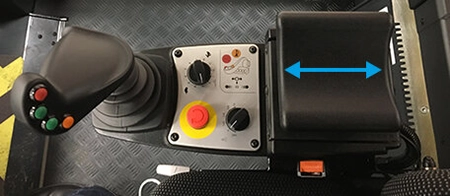

| Multifunction armrest with joystick | |

|

|

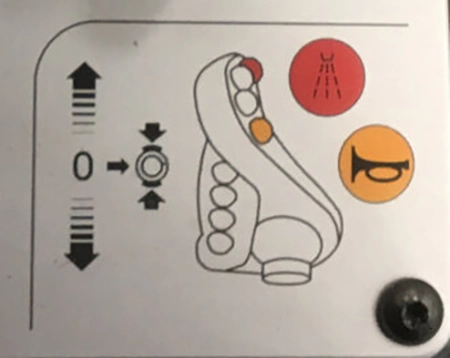

| Self-explanatory symbols. Explanatory diagram provided below the joystick. Standardised colour coding. Fast learning. Explanatory diagram provided below the joystick. Clearly structured design | Joystick is overloaded with too many control buttons. No self-explanatory symbols. No standardised colour coding. Control buttons in the right-hand section of the picture are located on the back of the joystick and cannot be seen by the driver. No clearly structured design |

| Self-explanatory symbols |  |

|

Explanatory diagram provided below the joystick |

| No self-explanatory symbols (BW 28 RH) |  |

| Visibility | |

|

|

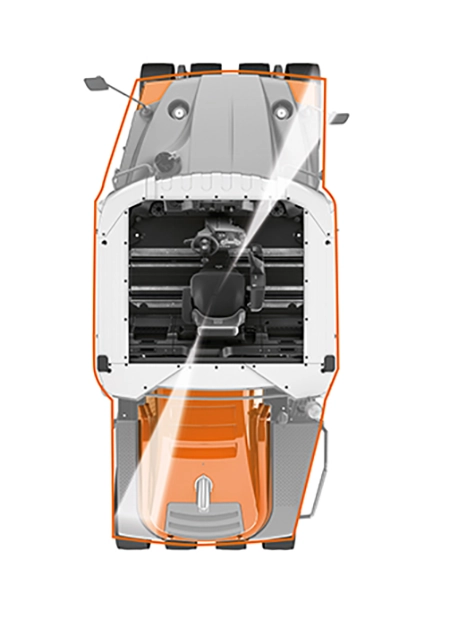

| Asymmetrical frame allows a view of outer wheel edges. Optimal visibility to the front and rear even in the immediate vicinity. Direct view of working equipment such as the cutting and pressure roller. Best view of the working environment in every seating position, and the steering wheel, dashboard and brakes are always under control | Shark design allows visibility of the front, right and left tyre surface. Restricted visibility due to reduced seat rotation |

| Doors | |

|

|

| Split doors (optional). Both doors open to the rear. Lower door segment is completely glazed and thus offers an excellent view of the surroundings | Split doors (standard). Cabin doors open in opposite directions, left to the front and right to the rear. Lower door segment covered with plate; this hinders a clear view of the surroundings |

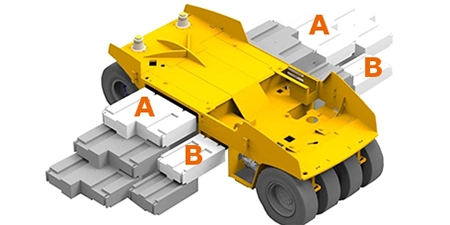

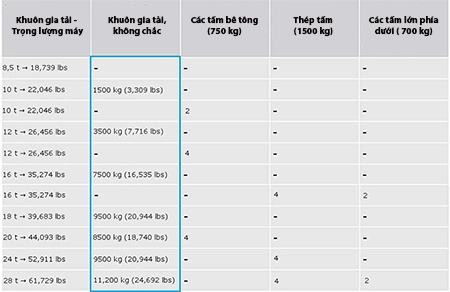

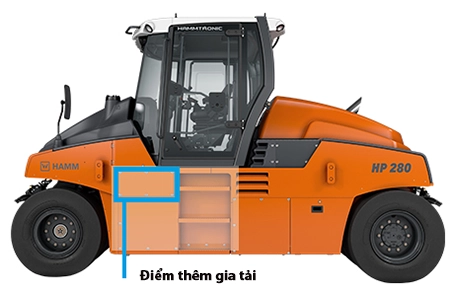

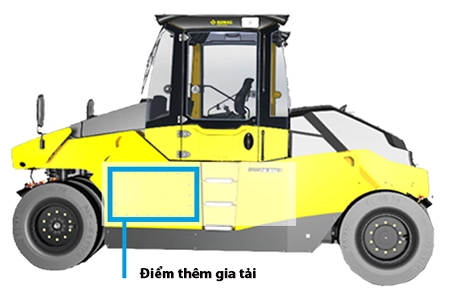

3. BALLASTING

| HP 180/280 | BW 28 RH |

| Ballast spaces | |

|

|

|

Two ballast spaces, left and right (A, B) Ballast elements made of concrete, heavy concrete and steel A – Can also be used for self-ballasting No steel weights for HP 180, since the max. operating weight is 18 t (39,683 lbs) Simple and flexible ballasting since all ballast weights can easily be changed using a forklift truck |

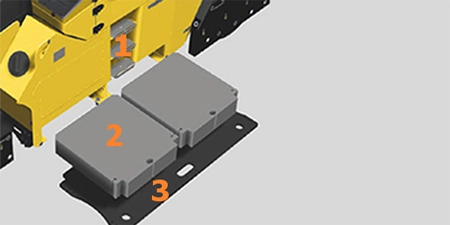

Three ballast spaces, left and right 1. For self-ballasting 2. Inserts for concrete, heavy concrete or steel 3. Underbody panels More or less fixed weights. Limited ballasting options with a forklift truck. Ballasting only possible with great effort |

| Ballasting | |

|

|

| Maximum flexibility and safety. No fixed ballasting. Quick and simple change of the operating weight by approx. 16.8 t / 37,038 lbs (8 t / 17,637 lbs HP 180). Front axle disc brake from 20 t / 44,093 lbs (HP 280 | Partial flexibility and safety. Ballast inserts only from 8.6 t - 16 t (18,960 lbs - 35,274 lbs) operating weight, flexible to use. Fixed and non-fixed ballasting |

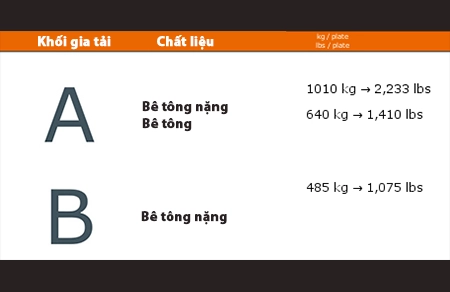

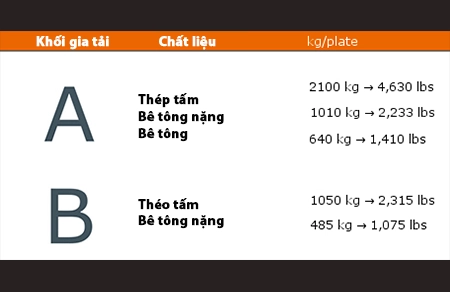

| Materials and weights | |

|

|

| Easy and quick handling with the forklift truck. Clear ballasting structure. HP 180 no steel weights, since the max. operating weight is 18 t (39,683 lbs). All weight classes can be achieved through the targeted use of different ballast weights. | Change only possible with great effort or not at all. Ballast elements ex works or can be retrofitted. Maximum ballasting, from 18 t (39,683 lbs) can only be achieved by using loose ballast material. |

|

|

| Easy and quick handling with the forklift truck. Clear ballasting structure. All weight classes can be achieved through the targeted use of different ballast weights. | Change only possible with great effort or not at all. Ballast elements ex works or can be retrofitted. Maximum ballasting, from 18 t, can only be achieved by using loose ballast material. |

| Own ballasting | |

|

|

| Ballast space A: 2 m³ possibility of self-ballasting* with other materials, such as sand (approx. 4.2 t / 9,259 lbs) or scrap metal (* option, two base plates are fitted at the factory). Six screws must be loosened at the filling point, then filling can take place | Ballast space: 3 m³ option to self-ballast with other materials, such as sand or scrap. 22 screws must be loosened, then filling can take place |

| Water ballasting | |

|

|

| Additional water tank (optional). 1500 l (396,2 gal lqd) Additional water volume as additional weight. Quick filling via pressure tanking connection. Can be used for sprinkling since it is connected to main water tank | Water ballasting if ordered as waterproof (optional). 2600 l (686,8 gal lqd) Additional water volume as additional weight. No pressure filling, since there is no connection provided. Cannot be used for sprinkling, since there is no connection to the main water tank |

4. DRIVE

| HP 180/280 | BW 28 RH |

| Engine output: 85 kW (115.6 HP) | Engine output: 92 kW (123.4 HP) |

| Exhaust emission standard:Stage IIIA/Tier 3 | Exhaust emission standard:Stage IIIA/Tier 3 |

|

Hydrostatic drive – HAMMTRONIC HAMMTRONIC Electronic machine management for monitoring all engine and driving functions. Automatic adjustment of advance drive and engine speed to the current operating conditions. Significant reduction in fuel consumption, exhaust and noise emissions ASC ANTI-SLIP CONTROL (optional) for optimal traction on different substrates, e.g. in earthworks > increases the traction and at temperature differences, e.g. (hot to cold) View more at: HERE |

Hydrostatic drive – BOMAG ECOMODE Monitors and controls the engine |

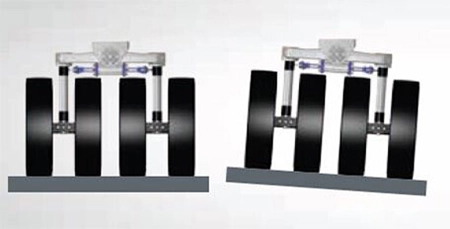

5. STEERING

| HP 180/280 | BW 28 RH |

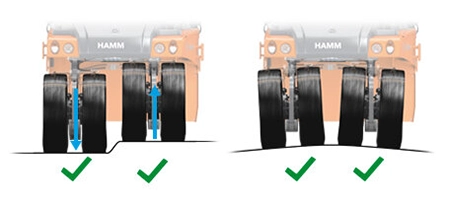

| Wheel suspension for levelling | |

|

|

| Both pneumatic tyre rollers have two-point steering for the four front wheels. The four wheels on the rear axle are rigid on both. | |

|

|

| Special wheel suspension ensures even pressure distribution, regardless of the ground conditions. Optimal levelling of the front wheel suspension via two swing-arms between the front wheel pairs. Optimal substrate adaptation, whether an asphalt building or earthworks. Each pair of front axle wheels adapts perfectly | Pairs of wheels move via a pivot point on the cross member. Wheel suspension without optimal levelling. Insufficient to moderate adaptation to the substrate |

6. OPERATION

| Water tank - Filling the water tank | |

| HP 180/280 | BW 28 RH |

|

|

| Water tank with a capacity of 650 l (171,7 gal lqd). Water sprinkling system adjustable in three stages. Gravimetric water tank filling. Pressure refuelling water tank (optional). Very large water tank volume. Continuous sprinkling possible without problems. Quick filling of the water tank possible | Water tank with a capacity of 340 l (89,8 gal lqd). Water sprinkling system adjustable in five stages. Gravimetric water tank filling. Pressure refuelling not possible. Relatively small water tank. Since the filling is exclusively gravimetric, this is time consuming. Continuous sprinkling empties the water tank very quickly |

| Water tank - Emptying the water tank | |

|

|

| A central drain outlet below the water tank. Unscrew the drain plug and the entire water tank is emptied. Easy access to the water drain plug. Open the drain plug without running the risk of getting wet | The drain outlet is located under the frame. Detach the water hose (2) from the drain cover. Unscrew the drain cover (1); the entire water tank is emptied. Poor access to the drain cover. Since you are working with your hands upwards, the water that emerges flows off via the elbow |

| Fuel refuelling | |

|

|

| The tank nozzle can be reached if the service levels are used. Comfortable ascent, as first step is 365 mm (14,4"). Handhold optimally positioned near the filler neck. Optimal safety is therefore guaranteed | Tank nozzle can be reached if the service level below is used. No comfortable ascent, as first step is 610 mm (24"). As the tank filler neck is placed in the middle of the water tank, the driver can only reach it with great difficulty |

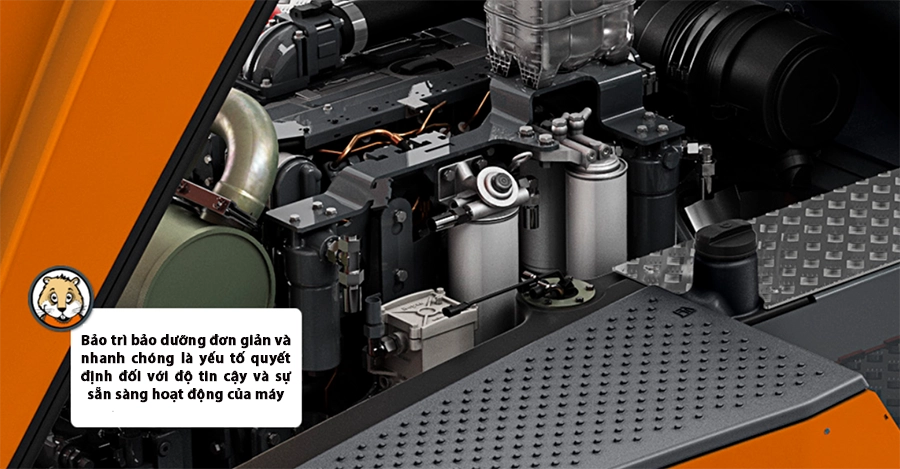

7. SERVICE

| Engine hoods | |

| HP 180/280 | BW 28 RH |

|

|

| Engine hood can be swivelled upwards by more than 100° (away from the cabin). Compactly designed hood. Two gas pressure springs assist in opening the engine hood and keep it open. Due to the engine hood's direction of opening, the working lights can illuminate the maintenance area in darkness | The engine hood can be swivelled upwards by approx. 90° (towards the cabin). Relatively voluminous engine hood. The locking lever prevents unintentional closing. The rollo belt assists in closing the hood. The working lights cannot be used since the engine hood's direction of opening prevents illumination |

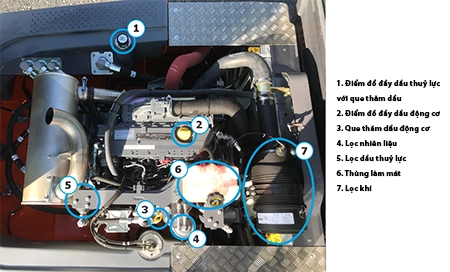

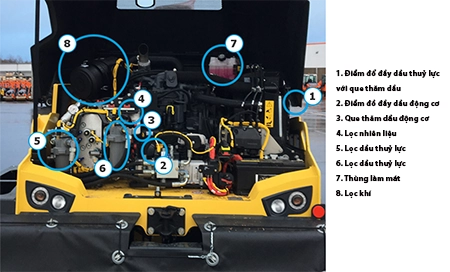

| Engine compartment/fill level/filter | |

|

|

| Engine compartment very easily accessible. Since almost all maintenance points are located on one side, they are easy to locate | Engine compartment or maintenance points only partly accessible with ladder. Since the maintenance points are distributed over the entire engine compartment, they are difficult to locate |

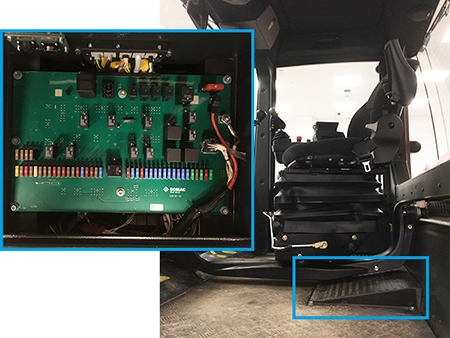

| Central electrical system | |

|

|

| Central electrical system is very compact and clearly laid out. Relays and fuses on a board slotted into the electronics box. The description is located on the cover of the e-box, which can be easily opened with the ignition key. The board can be pulled forwards as required. Very easy to reach. Relays and fuses can be replaced without great effort | The central electrical system is located in the driver's floor. The seat must be pushed to the side. Four screws must be loosened. No information on relays and fuses. Very costly, replacing relays and fuses. Increased demands on sealing the cover. Risk of dust and water penetration, especially on open driver platforms |

| Diagnostics interface | |

|

|

| WIDIAG interface below the armrest | No diagnostics interface |

8. OPTIONS

| Edge pressing and cutting device | |

| HP 180/280 | BW 28 RH |

|

|

| Edge pressing and cutting device. The water pump supplies the tyres, edge pressing and cutting device with a water film. Edge pressing and cutting device enable clean roadway closure at the side edges | Edge pressing and cutting device not available |

| Additive-sprinkling system | |

|

|

| Simple and safe filling of the additive tank from the ground. Automatic mixing (setting via the display). Constant mixing ratio. No preparation time required. Additive fill level control via display. Protection against theft and solar radiation | No simple additive handling. The driver needs a ladder to position the canister. Automatic mixing (setting via rotary switch). Constant mixing ratio. Preparation time is necessary to connect hoses and vent the emulsion mixing plant. Visual fill level control of the canister, no indication on the display. No protection against theft and solar radiation |

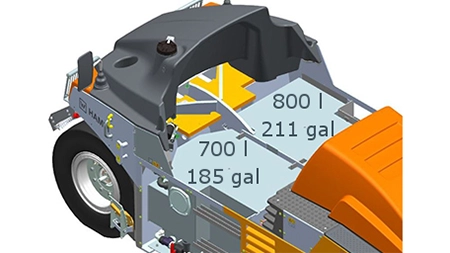

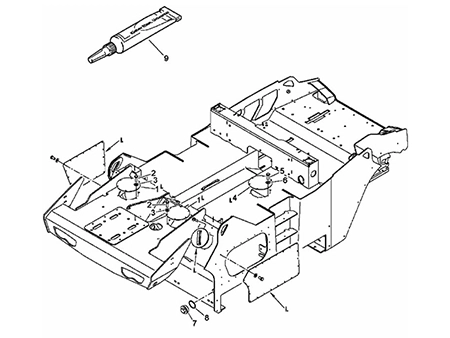

| Additional water tank | |

|

|

| Optional additional water tanks, right and left. Quick filling via the pressure tanking connection (C-pipe connection). The standard water tank is also filled above this. Additional weight (1500 l / 396,2 gal lqd). Can also be used as sprinkling water | Frame can be "glued" at the factory. Exclusive gravimetric water ballast filling. Relatively time-consuming filling since there is no pressurised water connection (C-pipe connection). Additional weight (2600 l / 686,8 gal lqd). Water is used exclusively for ballasting. Cannot be used for the spray bar |

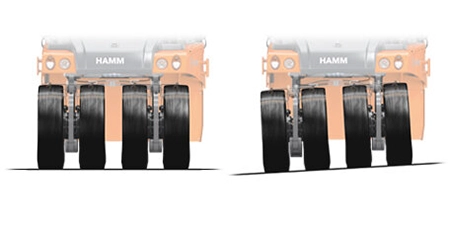

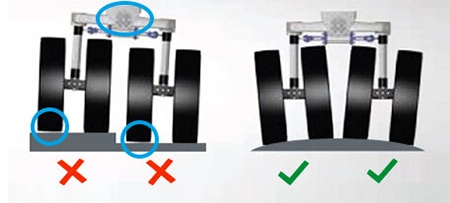

| Thermal aprons | |

|

|

| The effect of the thermal aprons on both wheel axles is optimal. Since the tyres are completely enclosed and the aprons are not divided. Heat can hardly escape | The tyres are not optimally enclosed with the thermal aprons and there are too many openings. A lot of heat is lost due to the split design. Higher risk of heat loss in windy and cold conditions |

News Related

Tags: hp 180, hp 280, BOMAG BW 28 RH