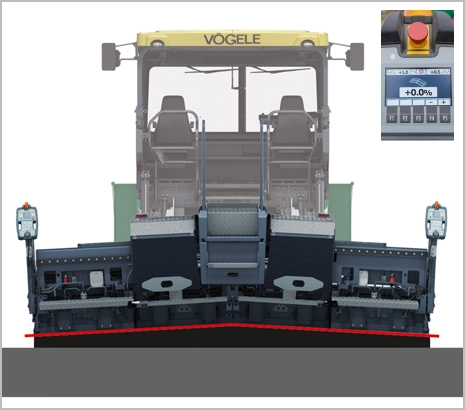

PRODUCT COMPARISON VOGELE S1800-3 VS DYNAPAC SD2500CS, VOLVO ABG 6820 C, CAT AP655 D

In this article, you will learn about our key competitors and products. The comparisons demonstrate our strengths vis-à-vis the products supplied by DYNAPAC, VOLVO and CAT. They will provide you with key arguments to use in discussions with customers.

You can view the product catalog at the following links:

- Vogele S1800-3: HERE

- Dynapac SD2500CS: HERE

- Volvo ABG 6820 C: HERE

- Cat AP655 D: HERE

PRODUCT COMPARISON

Specification

| VOGELE S1800-3 | DYNAPAC SD2500CS | VOLVO ABG 6820 C | CAT AP655 D |

|

|

|

|

|

Engine output: 127 kW Laydown rate:700 t/h Transport width: 2.55 m Pave width (max):10 m Screed heating: electric |

Engine output: 142 kW Laydown rate:800 t/h Transport width: 2.55 m Pave width (max):10 m Screed heating: gas or electric |

Engine output: 140 kW Laydown rate:700 t/h Transport width: 2.55 m Pave width (max):10 m Screed heating: gas or electric |

Engine output: 129 kW Laydown rate: no information available Transport width: 2.5 m Pave width (max):8 m Screed heating: gas or electric |

Ergonomics and Overview

| VOGELE S1800-3 | DYNAPAC SD2500CS | VOLVO ABG 6820 C |

|

|

|

| Clear platform design | Platform difficult to lock in place | Unclear platform with multiple operating units |

|

|

|

| Designed for a quick change of working position from right to left. | Awkward for changing working position quickly | Console can be pivoted at point of rotation. Locking device difficult to access. |

|

|

|

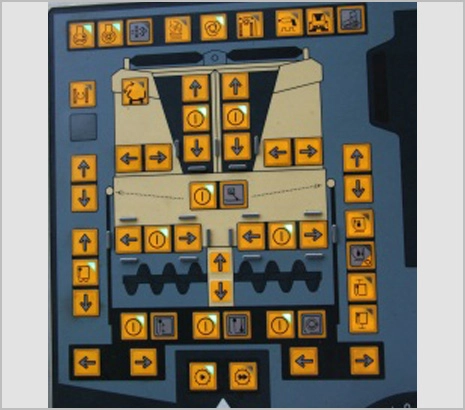

| Ergonomic and convenient to operate | Poor ergonomic design. Not designed for the operator's convenience. | No emergency off function within visual range of the operator. |

Operation

| VOGELE S1800-3 | DYNAPAC SD2500CS | VOLVO ABG 6820 C |

|

|

|

| Individually adjustable swivelling seat. Heated seat available as an option. Plenty of legroom for the operator. | Uncomfortable working position. | Slightly lateral operation. Console has to be constantly repositioned. |

|

|

|

| Colour display with easilly identifiable symbols | Highly reflective display especial when the sun is shining on it. | Membrane keypad with tactile strips. Activation of funtions not clearly tangible. Slipping can result in operating errors. |

|

|

|

| High-contrast display with good readability. Only vital information is displayed. | Overloaded menu graphics. Too much information on each page. | Overloaded and unclear menu graphics. No possibility of storing paving programmes. |

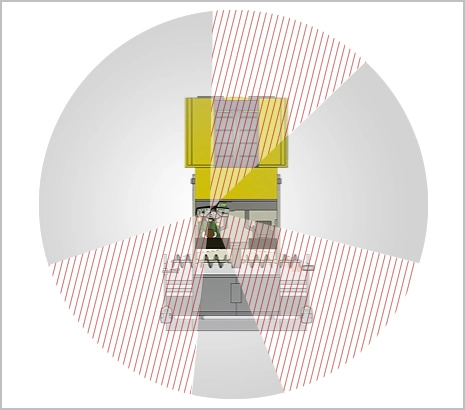

Visual Range

| VOGELE S1800-3 | DYNAPAC SD2500CS | VOLVO ABG 6820 C |

|

|

|

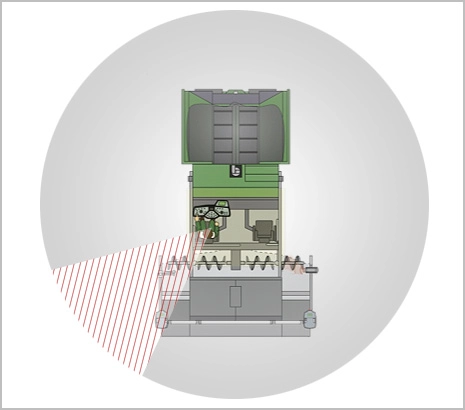

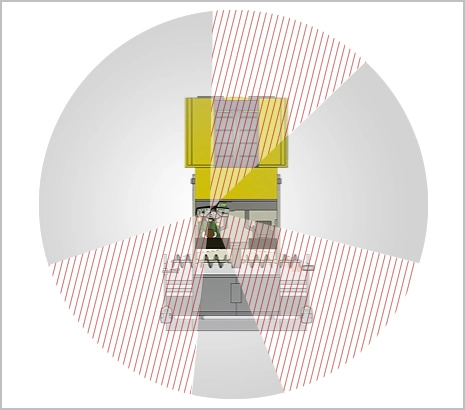

| Very good all-round view | Limited visual range | Limited visual range |

|

|

|

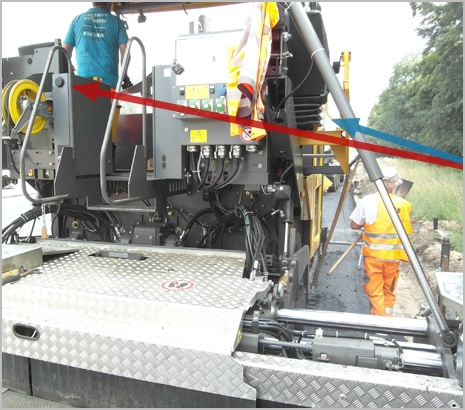

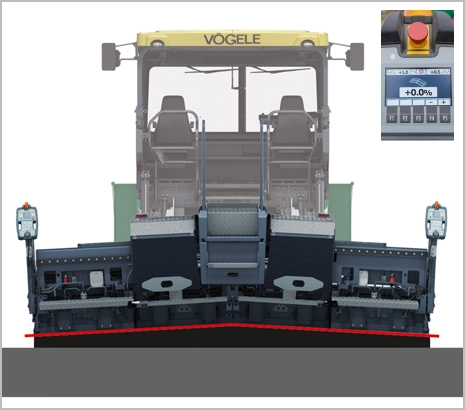

| Operator has an optimized view of the material hopper, direction indicator and screed. | Limited view to the front due to high engine contour | Screed tow point is displayed mechanically. Only the paver operator can see both indicators. The screed operator can only see the indicator on their side (blue arrow). The indicator on the opposite side cannot be read off (red arrow). |

|

|

|

| Unobstructed view of auger tunnel for monitoring the head of mix and the screed. | View of screed impaired by gas cylinders and heating box. | View of screed impaired by gas cylinders and heating box. |

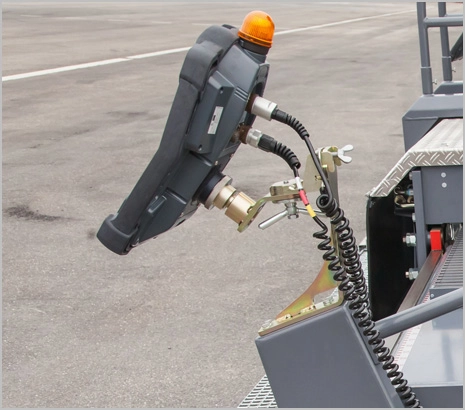

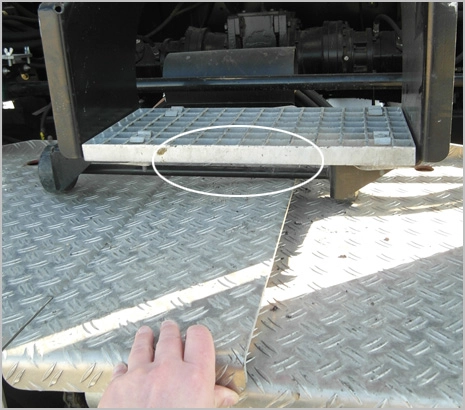

Safety

| VOGELE S1800-3 | DYNAPAC SD2500CS | VOLVO ABG 6820 C |

|

|

|

| Voluntary audit for "Conformity with the Essential Health and Safety Requirement of 2006/42/EC Machinery Directive. | Danger of operator being crushed between screed arm and chassis. | No type testing. Internal controls only |

|

|

|

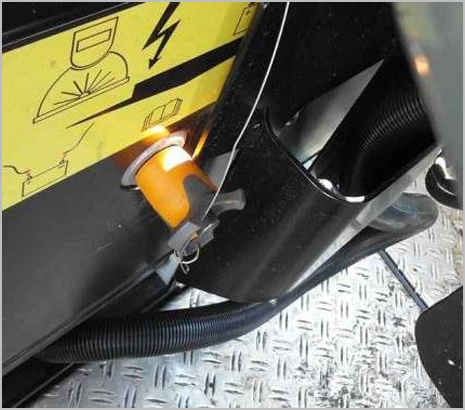

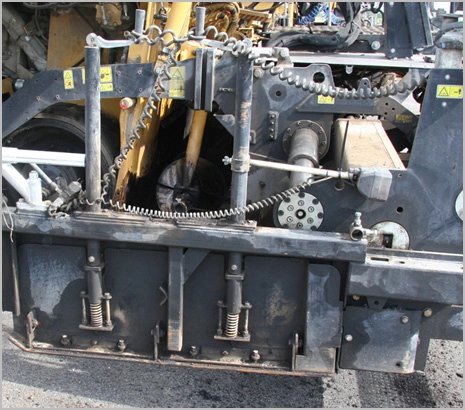

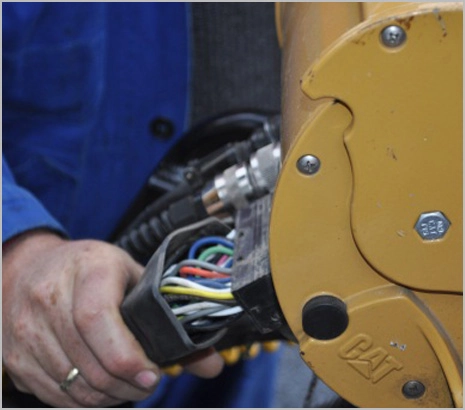

| No danger to screed personnel from snagging. Accidental damage is prevented. | Unfavourable cable routing and arrangement of plug connectors. Risk of damage, loss of contact and snagging. | Warming light obscured |

|

|

|

| Smart routing prevents tripping over cables and hydraulic hoses | Dangerous routing of the gas line in the area of the screed's descent | Tubing and cables secured with cable ties. |

Screed and Crown

| VOGELE S1800-3 | DYNAPAC SD2500CS | VOLVO ABG 6820 C | CAT AP655 D |

|

|

|

|

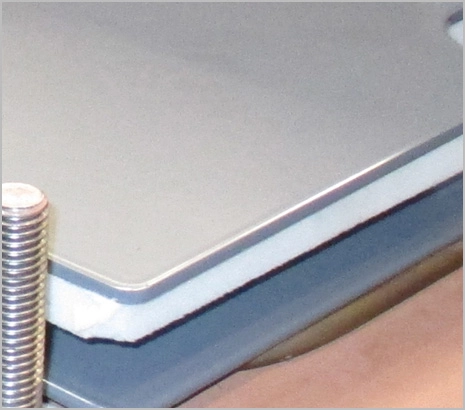

| Side plates high and robust. Material does not overflow to the outside | Low, thin-walled side plates. Overflowing material. Height adjustment jams due to the pressure of the material from the inside. | Material overflows on account of low and unstable side plates. If the material then presses from the inside, the height adjusting mechanism becomes blocked. | Material overflows on account of low and unstable side plates. If the material then presses from inside, the height adjusting mechanism becomes blocked. |

|

|

||

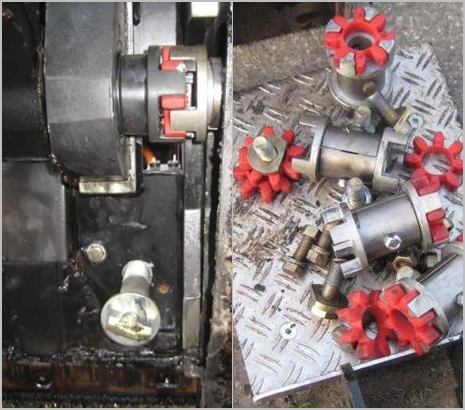

| Sliding coupling ensures that bolt-on extensions are quick and easy to fit | Extensions comprise lots of loose parts with danger of loss during transport of assembly. | ||

|

|

||

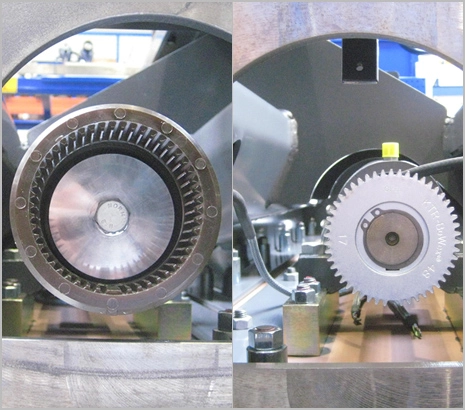

| Khả năng bịt kín cao giữa bàn đầm cơ bản và bộ phận mở rộng. Sẵn có các phiên bản bàn đầm: TV, TP1, TP2, TP2 Plus. | Poor seal between basic screed and extending unit. Maximum sceed version: TV = tamper and vibrators | ||

|

|

||

| Thanh gia nhiệt áp lực tuyệt vời lên bề mặt các tấm bàn đầm. Dẫn nhiệt tốt bên dưới do có vỏ bọc và lớp cách nhiệt. | Heating rod applies no surface pressure to the screed plate. The gaps need to be made flush using thermally conductive paste. No insulation on top - loss of head. | ||

|

|

|

|

| At least 25mm overlap between extending unit and basic screed. Smooth surface texture when screed is fully extended. | No residual overlap between extending unit and basic screed. Strips form when screed is fully extended. | As there is no overlap when the screed is fully extended, there is a gap between the basic screed and the extending unit, resulting in the formation of streaks in the pavement surface. | |

|

|

|

|

| Hydraulic crown adjustment. Adjusted from the screed operator's console. | Crown adjustment cover blocked by steps. Narrow handle - risk of injury. | As only the auger is adjustable in height, paving material can egress via the limiting plates for the auger tunnel, as these are locked in place. | |

|

|||

| The head of mix in front of the screed is uniformly spread over the full pave width. Adjusting the auger and the limiting plates for the auger tunnel in height ensures the paving material remains in the auger tunnel when paving layers of varying thickness. |

Brand Comparison

| VOGELE S1800-3 | DYNAPAC SD2500CS | VOLVO ABG 6820 C |

|

|

|

|

A brand within a group of companies that is involved exclusively in the road and mineral technologies industry. Worldwide network of authorized dealers and branches. Rapid availability of parts and service technicians worldwide. The ultimate in product quality developed and produced in Germany |

Only a niche within a group of companies that is not established in the road construction industry (Atlas Copco). Receding market shares worldwide; declining customer confidence in products and brand. Quality problems with SD series were never consistently resolved. Problems in the on-site provisioning of parts and service. Staff downsizing/migration at Wardenburg plant, Germany |

Many employees left after integration into the VOLVO Group Central service and parts centre in Belgium No direct point of contact at factory Problems in the on-site provisioning of parts and service Virtually no expert consultants for pavers in the VOLVO branch offices |

Application

| VOGELE S1800-3 | VOLVO ABG 6820 C | CAT AP655 D |

|

|

|

| Screed console with built-in grade and slope control. Large display. Information displayed on both screed consoles. | Separate consoles for grade and slope control and for screed operator. Small display. Infomation displayed on the respective console. | Separate consoles for grade and slope control and for screed operator. Small display. Infomation displayed on the respective console. |

|

|

|

| Screed console with high-pwer LED for illuminating the pavement edges | Addittional magnet-mounted working light can shift position during operation. | Cables and connections are not weatherproof of dustproof. No built-in lighting. Poor pavement edge illumination. |

|

Hydraulic crown control via additional operating unit (optional). |  |

| Hydraulic crown control. Simple adjustment directly from the screed consoles. | Hydraulic crown control optional. Adjustment via a separate control box, not from the screed console. |

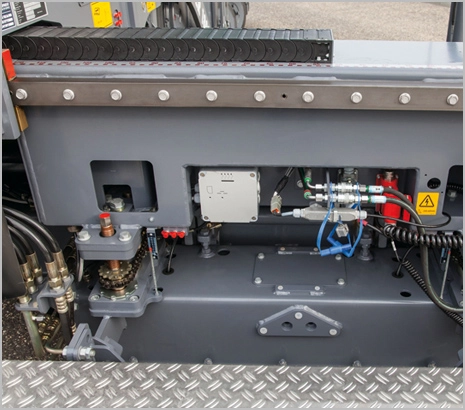

Service

| VOGELE S1800-3 | VOLVO ABG 6820 C | CAT AP655 D |

|

|

|

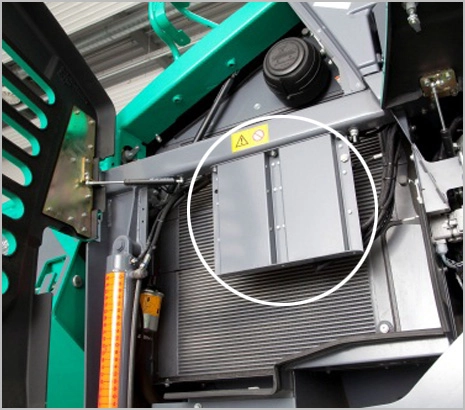

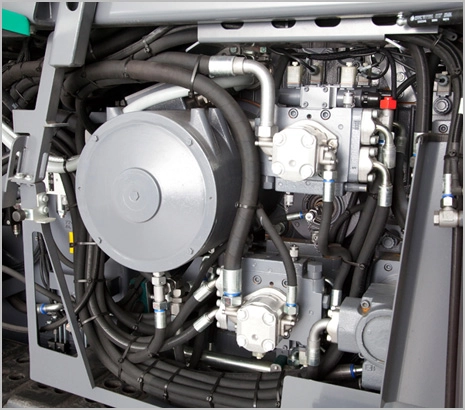

| Clear arrangement of all components. Maintenance-free liquid-cooled generator flange-mounted directly on the splitter gearbox. V-belt-free generator drive. | Generator housed in the centre of the engine compartment. V-belt drive. Cooling air supply via low-quality hose, danger of heat built-up. | Unstructured hose routing. Generator driven by hydraulic motor. Generator drive difficult to access. Generator exposed to dirt and dust. |

|

|

|

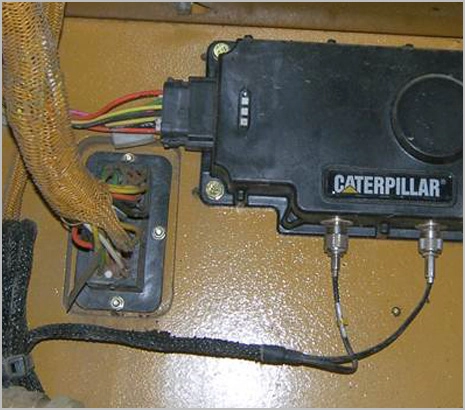

| Replaceable controllers. Automatic reprogramming when controllers are replaced. | Replaceable controllers | Controller positioned immediately above the engine compartment. Only one controller provided. Machine shuts down when the controller is defective. |

|

|

|

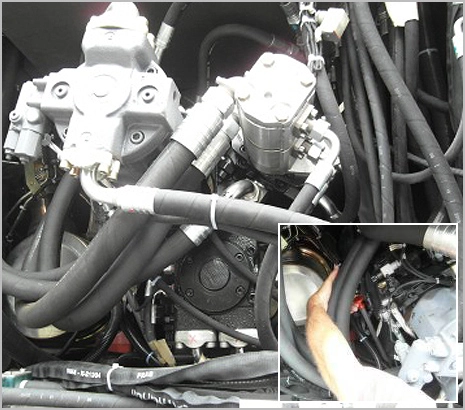

| Clear arrangement and hose routing. Quick and simple maintenance. | Unstructured hose routing. Poor access to maintenance points. | Maintenance points are difficult to access. Risk of injury if operators come into contact with low open panel. |

News Related

Tags: Vogele S1800-3, Dynapac SD2500CS, Volvo ABG 6820 C, Cat AP655 D