HAMMTRONIC

The Hammtronic electronic machine management system supports the operator in order to achieve optimum compaction without compromising on safety, cost-efficiency and fuel savings.

HAMMTRONIC - PERFECT MACHINE COORDINATION FOR OPTIMUM COMPACTION RESULTS

For earthworks or asphalt work, construction companies rely on achieving the most efficient use of machines possible in order to reduce their operating costs and achieve optimum compaction results. This is where the Hammtronic electronic machine management system comes in - it supports the operator in their day-to-day construction work in order to achieve optimum compaction without compromising on safety, cost-efficiency and fuel savings.

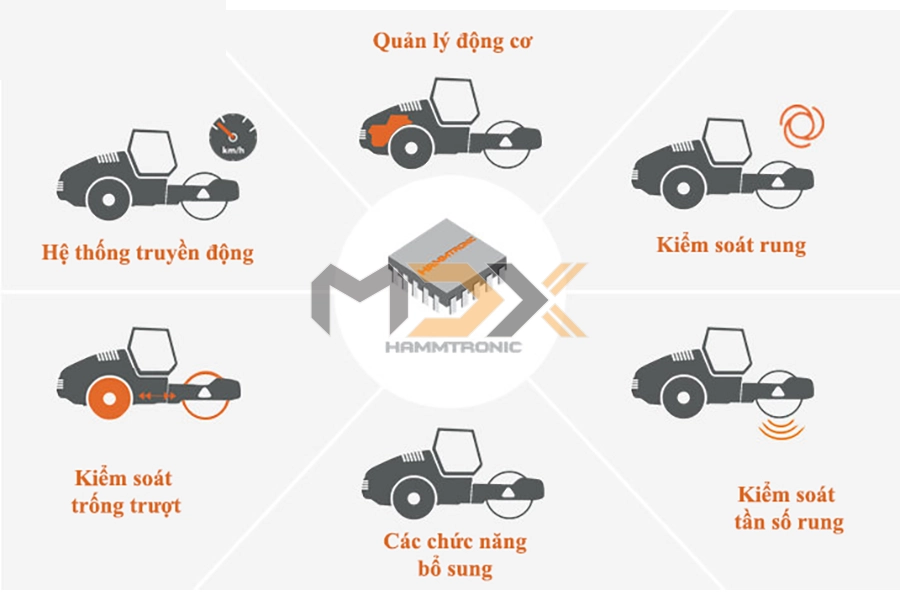

Hammtronic is an electronic machine management system that monitors and controls all key machine functions. The opportunities offered by Hammtronic include, for instance, automatic adjustment of the diesel engine speed to meet the power requirements of the individual drives (driving, vibration). What's more, Hammtronic controls start-up and braking and distributes the drive torque across the drum axle and/or rear wheels in accordance with real-time operating data (e.g. incline, driving speed, direction).

Hammtronic also controls the hydrostatic vibration drive and the various steering programmes (for DV+ series only), guaranteeing even, smooth movement of both drums. All information that the driver may need is shown on the display in the driver's platform. Depending on the model and equipment, additional functions may be controlled by Hammtronic (e.g. edge pressing and cutting device, water sprinkling, tyre-inflation system, chip spreader).

The electronic machine management system is available for models in the HD+, DV+, H, 3000 and HP series.

VIDEO SHARE BASIC KNOWLEDGE ABOUT HAMMTRONIC - INTELLIGENT CONTROL SYSTEM

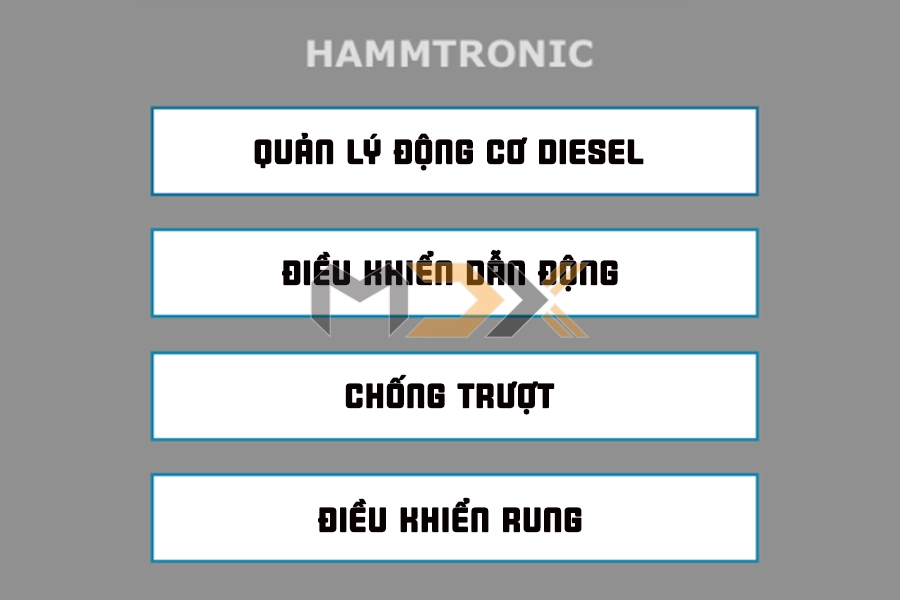

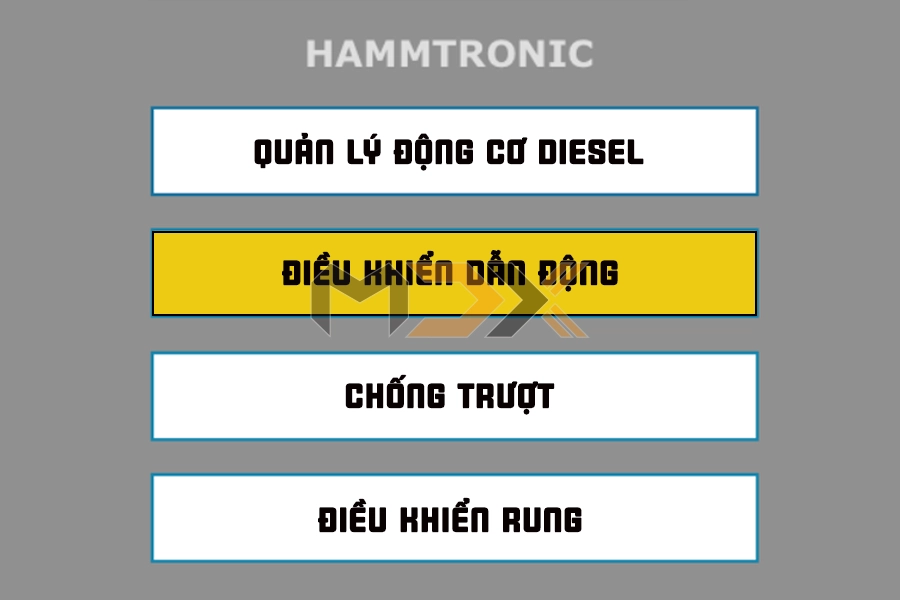

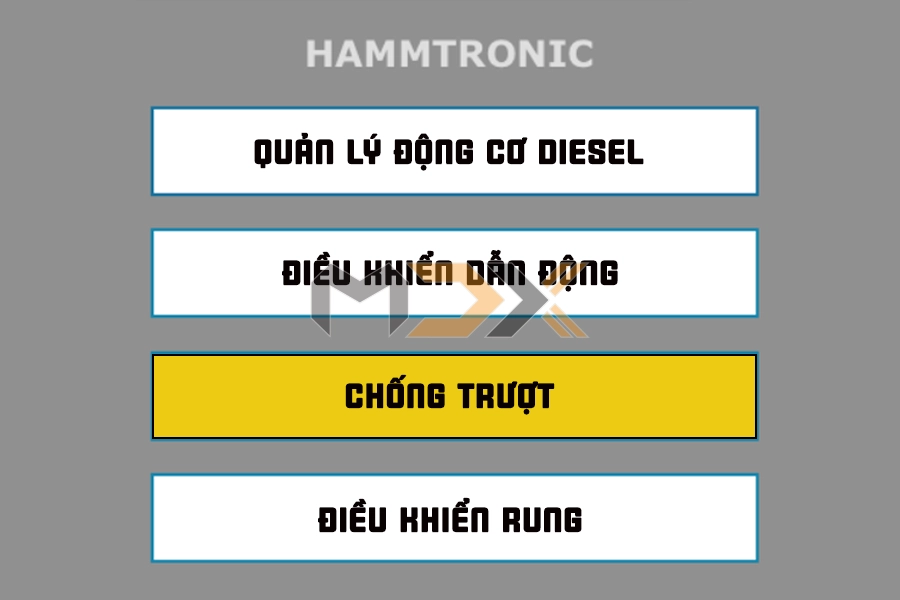

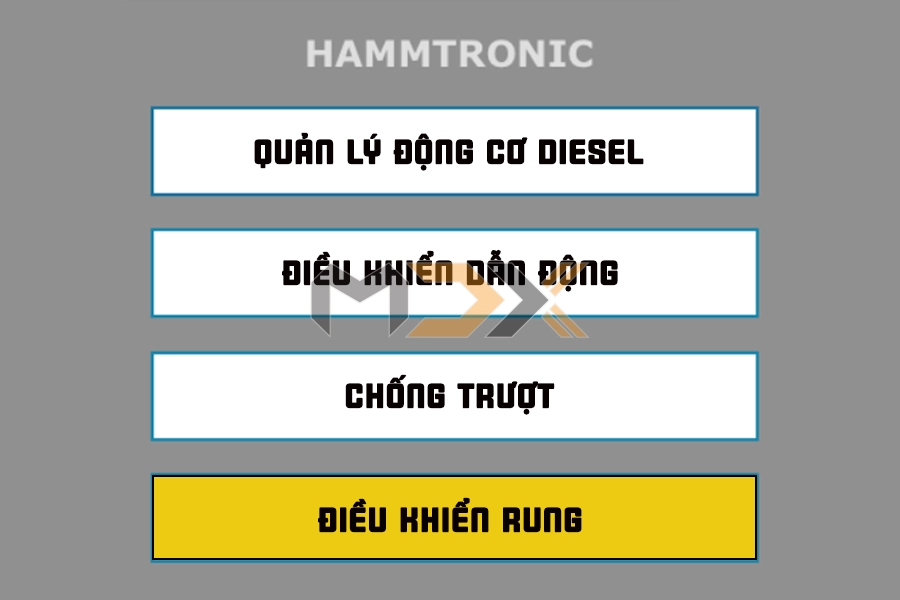

HAMMTRONIC MODULES

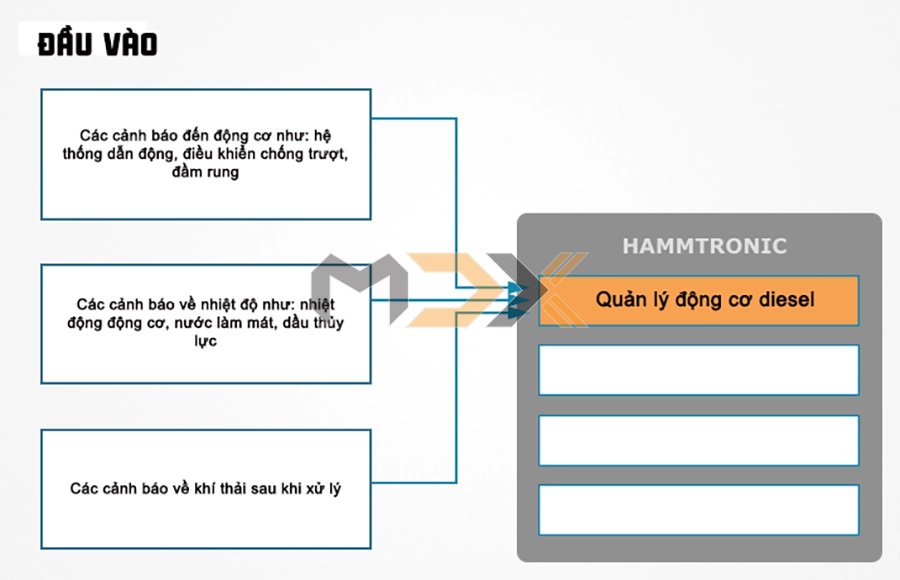

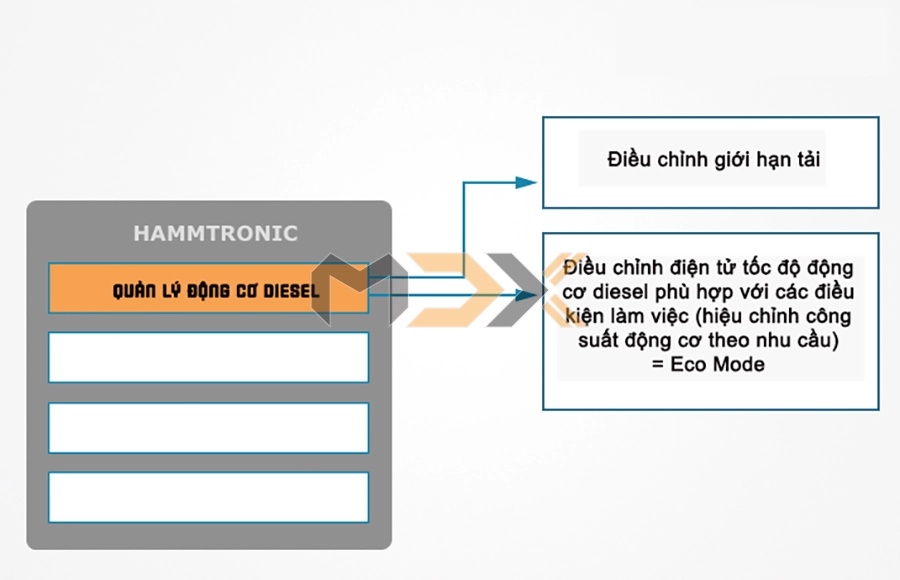

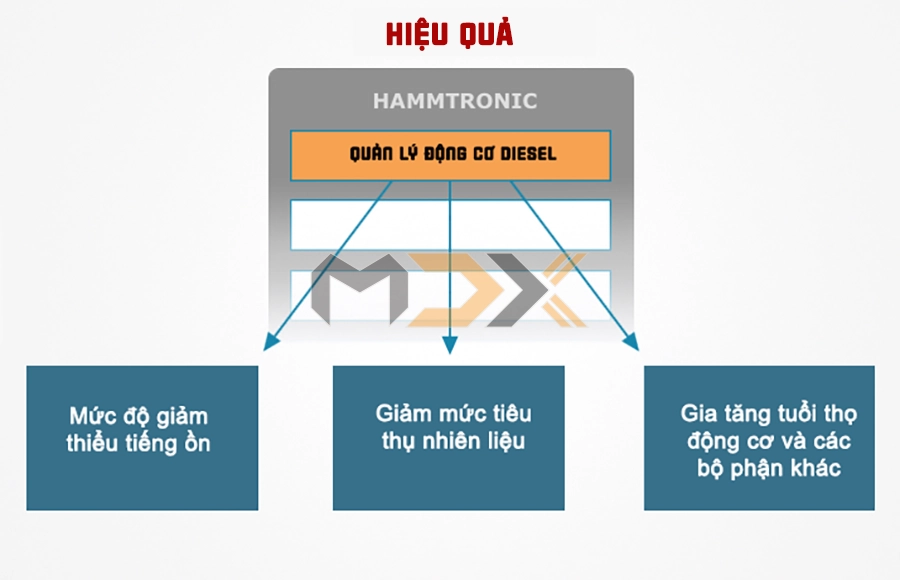

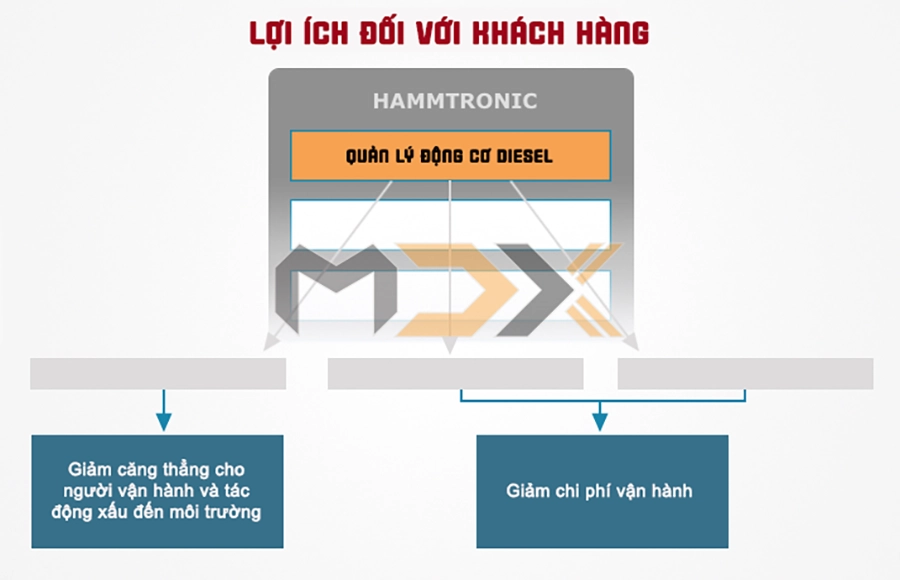

MODULE: DIESEL ENGINE (QUẢN LÝ ĐỘNG CƠ)

The first module is the diesel engine controller:

- Input to machine

- Output from machine: Limit-load regulation if the diesel engine reaches its power limit, the speed is automatically reduced to decrease the load on the engine.

- Customer benefits

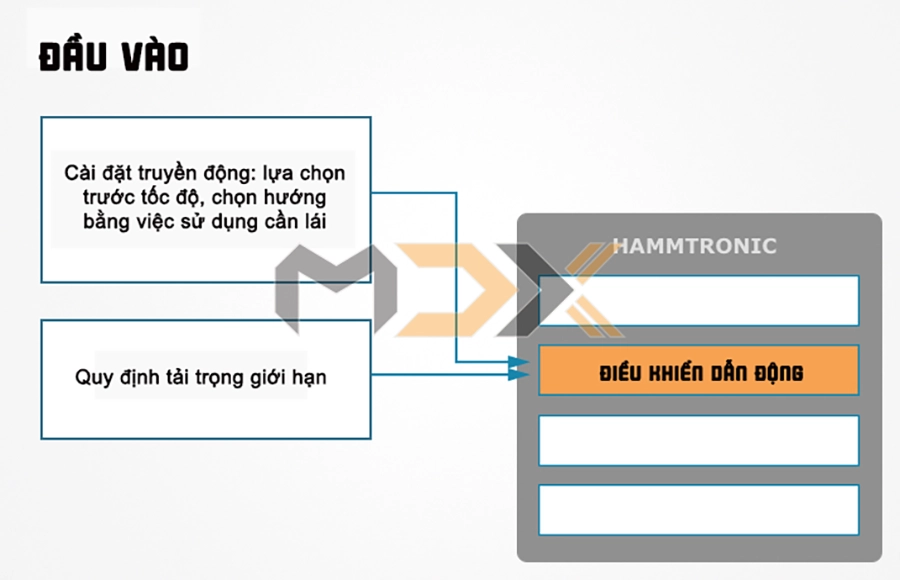

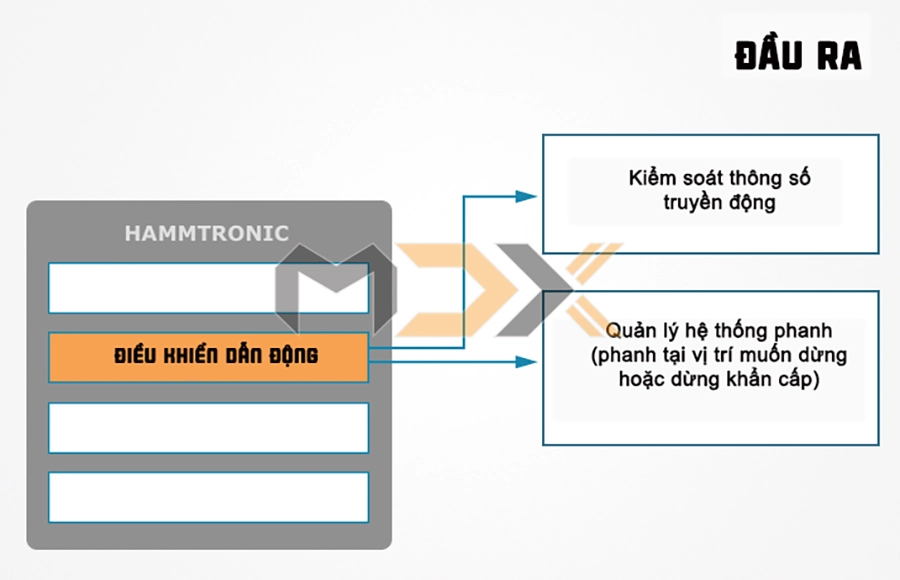

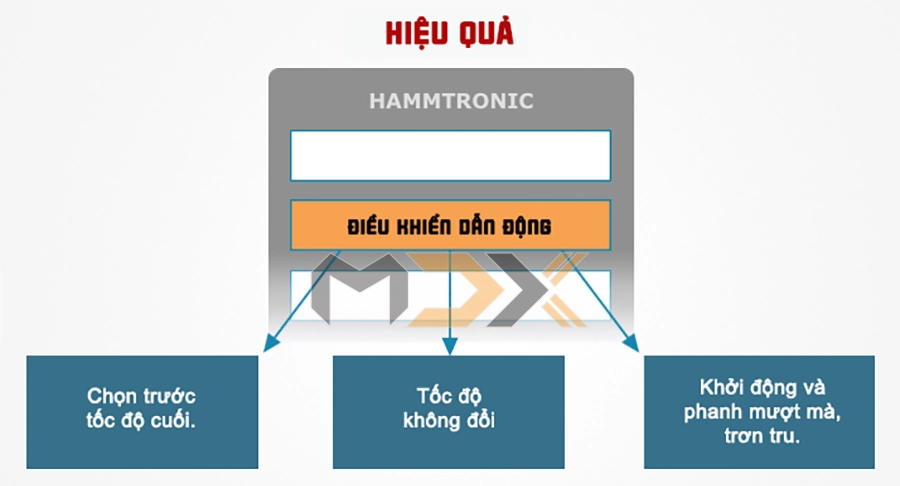

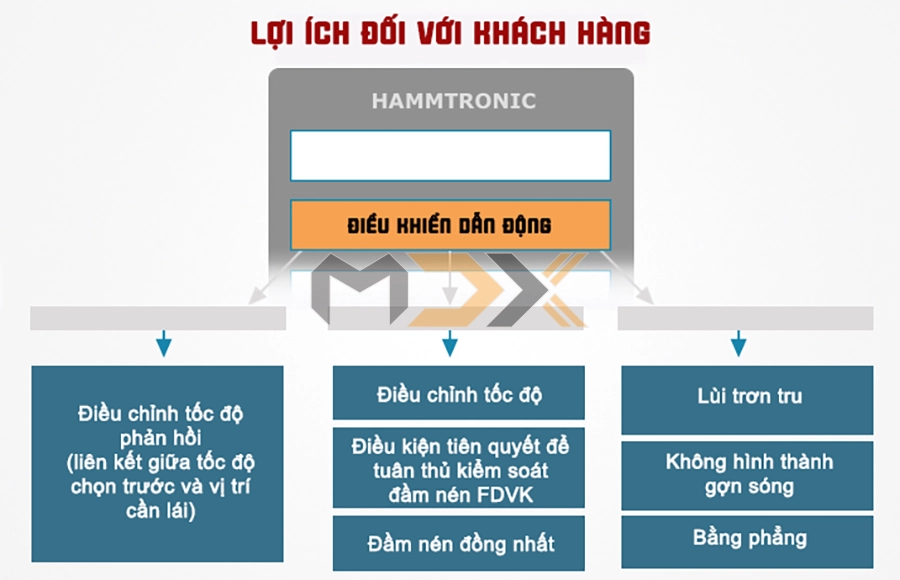

MODULE: DRIVE UNIT (QUẢN LÝ HỆ THỐNG DẪN ĐỘNG)

The second module is the drive unit:

- Input to machine.

- Output from machine

- Results

- Customer benefits

Increase in speed with preselected speed increased without changing position of drive lever (except in machines with manual gears)

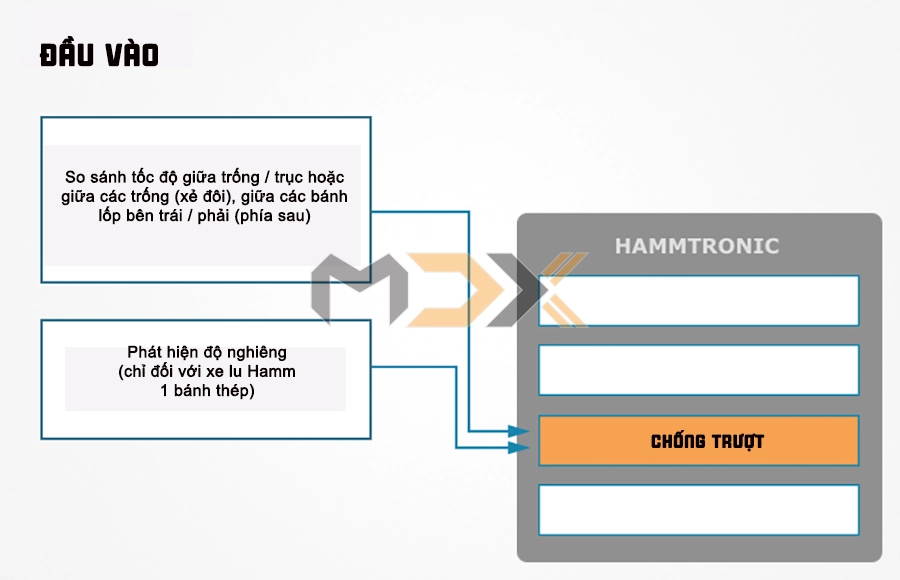

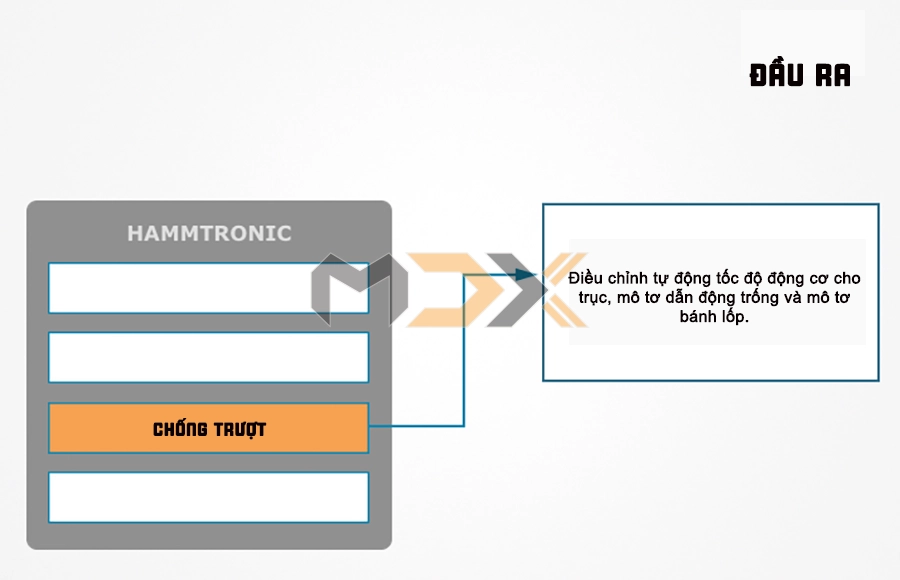

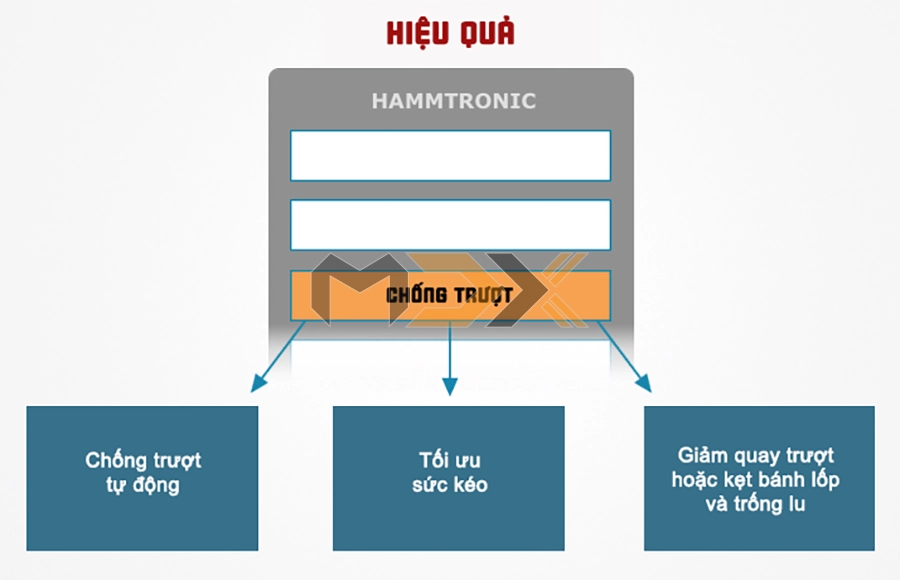

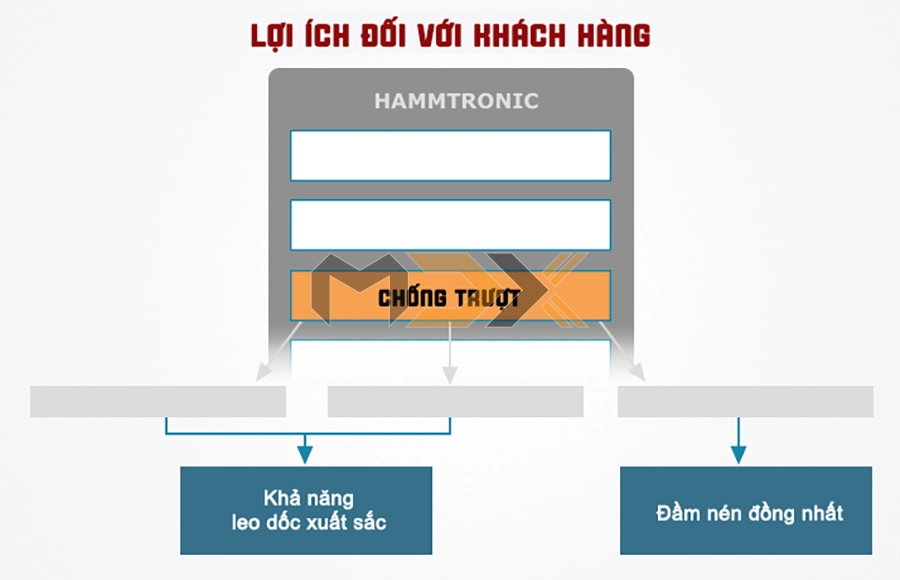

MODULE: ANTI-SLIP CONTROL (ĐIỀU KHIỂN CHỐNG TRƯỢT)

The third module is the anti-slip control:

- Input to machine

- Output from machine

- Results

- Customer benefits

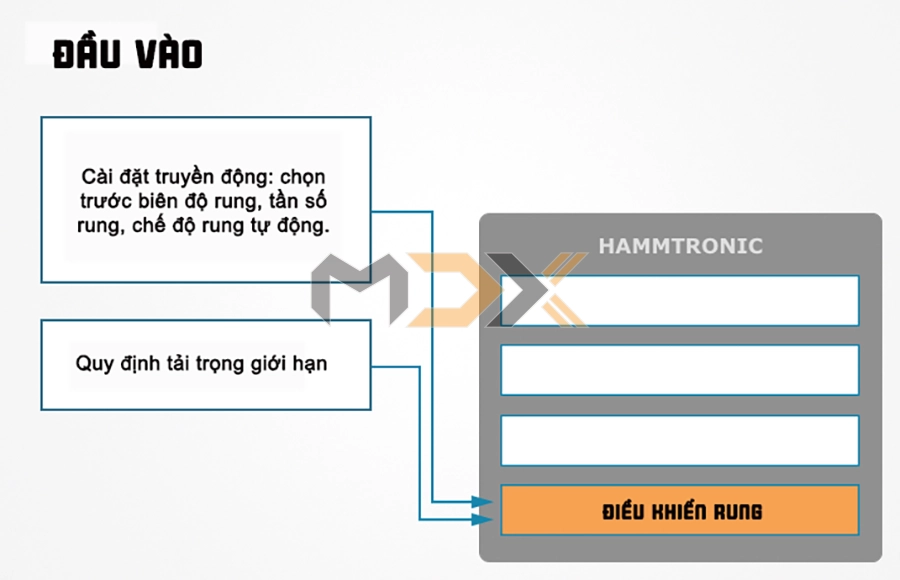

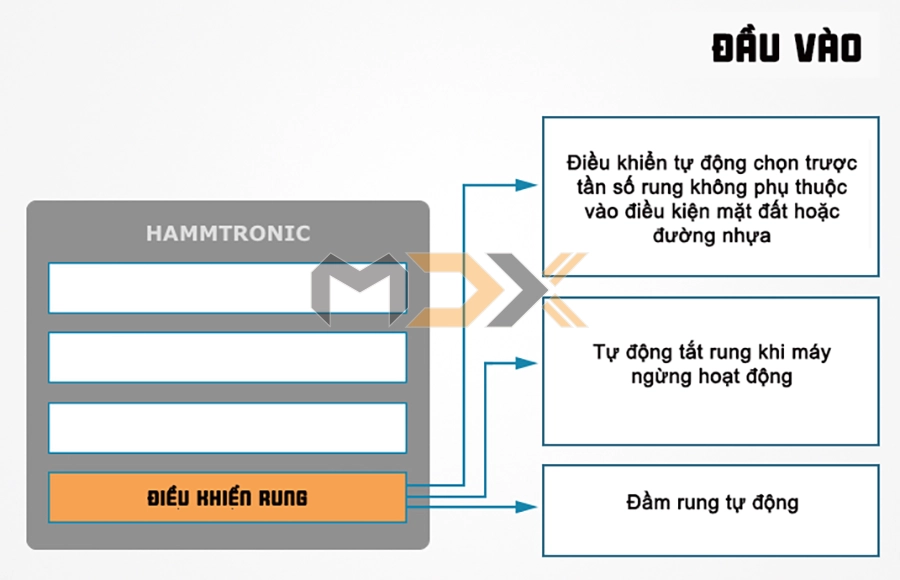

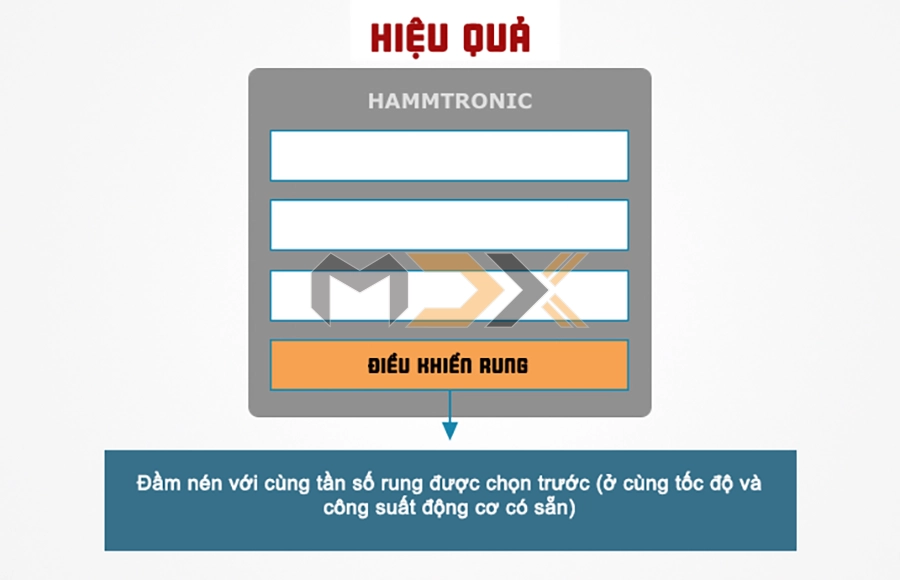

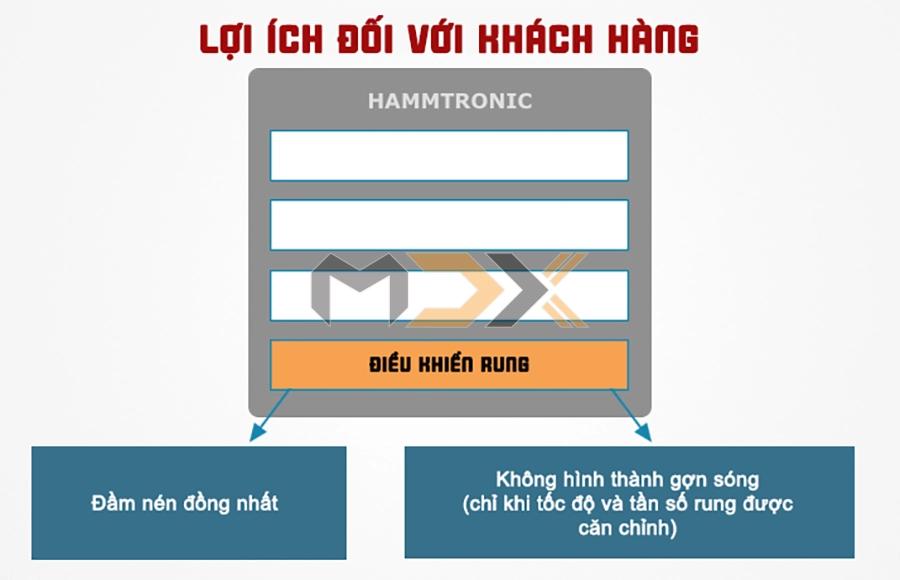

MODULE: FREQUENCY CONTROL (KIỂM SOÁT RUNG)

The fourth module is the frequency control:

- Input to machine

- Output from machine

- Result

- Customer benefits

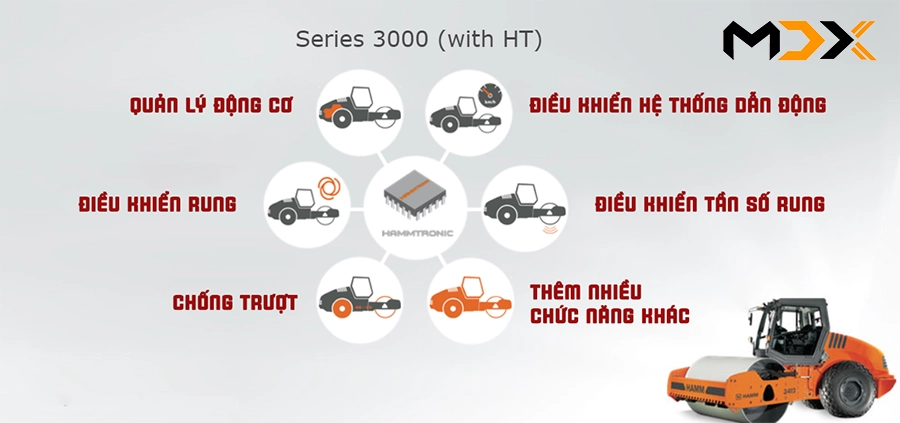

MODEL SERIES WITH HAMMTRONIC

HAMMTRONIC APPLICATION FOR HAMM ROLLER

SERIES HD+

Homogeneous compaction is achieved as a result of the speed and frequency control.

| Engine management |

ECO/MAX mode (button) |

| Limit-load regulator | Load-dependent engine speed |

| Protection function, engine |

|

| Vibration control |

Automatic vibration system Amplitude change |

|

Drive unit |

Soft acceleration and braking. Speed control. Speed preselect. Emergency stop (with drive lever pulled back rapidly) |

| Anti-slip control (with split drum) |

Slip and traction control |

|

Additional functions |

Water sprinkling system. Edge pressing and cutting equipment (option) Chip spreader (option). Track offset. Engine stop function (option). WIDIAG-capable (diagnostic capability) |

|

Frequency control |

Frequency control + variable adjustment (option) Frequency adjustment (TIER 3: option; TIER 4: standard) |

Check out Hamm's HD and HD+ series of road rollers at: HERE

SERIES DV+

| Engine management |

ECO/MAX mode (button) |

| Limit-load regulator | Load-dependent engine speed |

| Protection function, engine |

|

| Vibration control |

Automatic vibration system Amplitude change |

| Anti-slip control (with split drum) |

Slip and traction control |

| Drive unit |

Soft acceleration and braking Speed control Speed preselect Emergency stop (with drive lever pulled back rapidly) |

|

Additional functions |

Water sprinkling system. Edge pressing and cutting equipment (option) Chip spreader (option). Engine stop function (option). WIDIAG-capable (diagnostic capability) |

| Steering (electro-hydraulic) |

Track offset Steering |

| Frequency control | Frequency control + variable adjustment (option) |

SERIES H+

| Engine management |

ECO/MAX mode (button) |

| Limit-load regulator | Load-dependent engine speed |

| Protection function, engine |

|

| Vibration control |

Automatic vibration system Amplitude change |

|

Drive unit |

Soft acceleration and braking. Speed control. Speed preselect. Emergency stop (with drive lever pulled back rapidly) |

| Anti-slip control (with split drum) |

Slip and traction control |

|

Additional functions |

Engine stop function (option) Vibration plate (option) Dozer blade (option) Padfoot shells (option) WIDIAG-capable (diagnostic capability) |

| Frequency control | Frequency control + variable adjustment (option) |

SERIES 3000 (WITH HAMMTRONIC)

| Engine management |

ECO/MAX mode (hand wheel) |

| Limit-load regulator | Load-dependent engine speed |

| Protection function, engine |

|

| Vibration control |

Automatic vibration system Amplitude change |

|

Drive unit |

Soft acceleration and braking. Speed control. Speed preselect. Emergency stop (with drive lever pulled back rapidly) |

| Anti-slip control (with split drum) |

Slip and traction control |

|

Additional functions |

Engine-stop function Padfoot shells (option) WIDIAG-capable (diagnostic capability) |

| Frequency control | Frequency control + variable adjustment |

Check out the Hamm 3000 Series products at: HERE

SERIES HP

| Engine management |

ECO/MAX mode (button) |

| Limit-load regulator | Load-dependent engine speed |

| Protection function, engine |

|

|

Drive unit |

Speed control Speed preselect Emergency stop (with drive lever pulled back rapidly) Soft acceleration and braking |

| Anti-slip control (option) |

Slip and traction control |

|

Additional functions |

Water sprinkling system Tyre inflation system (option) Additive sprinkling system (option) Edge pressing and cutting equipment (option) Engine stop function (option) WIDIAG-capable (diagnostic capability) |

In addition, you can also see more pneumatic tyre roller products at: HERE

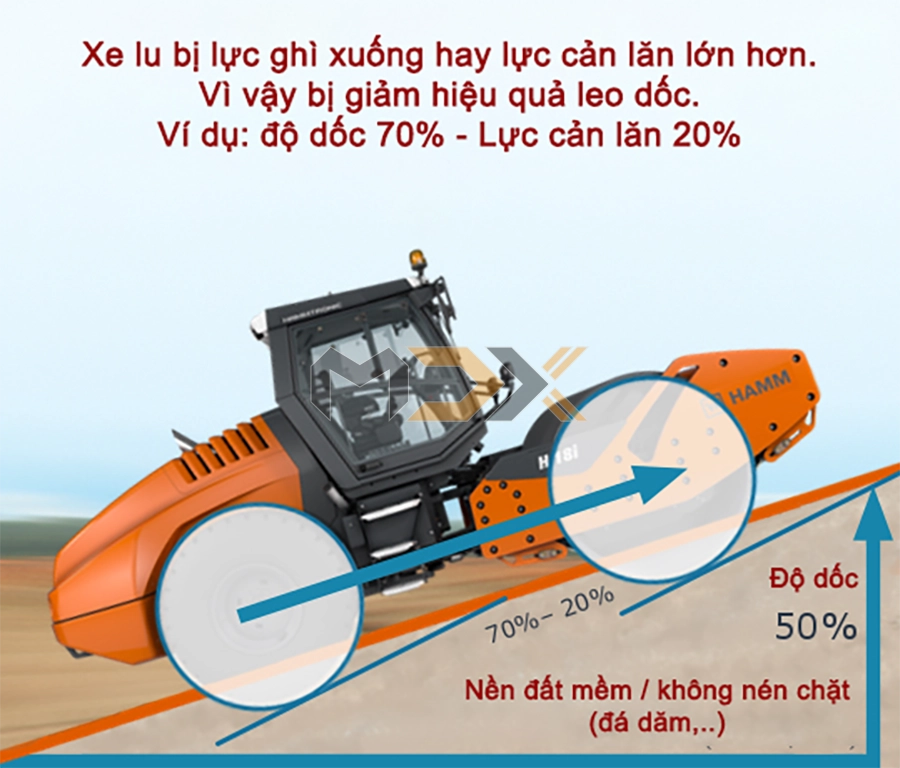

CLIMBING ABILITY

Advantages of Hammtronic Climbing ability Compactors with Hammtronic achieve maximum climbing ability thanks to perfect distribution of the drive force across the wheels and drum. What is the effect on different ground types?

- Hard / compacted ground.

- Soft / uncompacted ground.

DIESEL CONSUMPTION

Machines with Hammtronic also consume approx. 30% less diesel thanks to the latest diesel engine and control technology. The lower diesel consumption results in reduced handling costs on the construction site (fewer refuelling stops). Hammtronic thus saves costs.

OVERVIEW: ADVANTAGES OF HAMMTRONIC IN ASPHALT CONSTRUCTION AND EARTH WORK

| ADVANTAGE | ARGUMENTS |

|

Minimised diesel consumption |

- Diesel savings up to 30%. - Adjustment of diesel engine speed to specific load conditions |

| Soft acceleration and braking |

- Prevention of undulation forming |

| Reduced noise levels | - Lower emissions |

| Operational safety | - Supports driver and therefore prevents operator errors |

|

Anti-slip control |

- High traction. - Excellent climbing ability. - Reliable traction |

|

Lower operating costs |

- Longer service life of components. - Reduced service costs. - Diesel savings |

|

Constant speed and frequency |

- Homogeneous compaction. - Ideal for compaction measurement |

| Automatic vibration system | - Prevents vibration continuing when stationary |

| No engine overload | - Operational safety |

News Related

Tags: hammtronic, DV+ series, edge pressing and cutting device, water sprinkling, tyre-inflation system, chip spreader, 3000 series, hd+ series, hd series