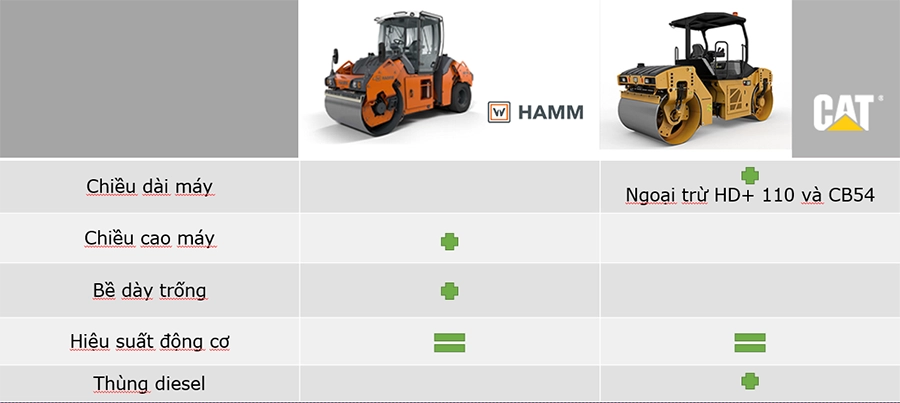

PRODUCT COMPARISON HAMM HD+ VS. CAT BW, STAGE IIIA / TIER 3

The following article shares with readers about the differences and competitive advantages between two brands of asphalt rollers: Hamm Series HD+ and Cat, with the same Stage IIIA / Tier 3 standards. From that, we hope that you will be able to choose the most suitable brand. We hope you enjoyed this post!

HAMM VS. CAT – STAGE IIIA / TIER 3

HAMM, Stage IIIA/Tier 3

- Model: 17

- Weight range: 9 - 14 tons

- Drum width: 3

View Hamm Series HD+ at: HERE

BOMAG, Stage IIIA/Tier 3

- Model: 3

- Weight range: 11 - 13 tons

- Drum width: 3

DETAILED COMPARISON

WIDE VARIETY

|

|

|

| Weight classes | 9 - 14 t. The HD series must be offered in the 7 - 8 t weight classes. | - 11 - 13 t |

| Drum widths | 168/198/214 cm | - 170 / 200 / 213 cm |

| Application | City centre/parking lot, Universal/outside of built-up areas, Highway/airport | - Universal/outside of built-up areas, Highway/airport |

| Engine technology | Stage IIIB/Tier 4i, Stage IIIA/Tier 3 | - Stage IIIB / Tier 4i - Stage IIIA / Tier 3 - Stage II / Tier 2 |

| Compaction systems | Vibration, Oscillation, Tyres, Split drum, High vibration frequency | - Vibration, Split drum. CB64 only available with the five-amplitude vibratory system or the Versa Vibe vibratory system. |

| Track Offset | - 170 mm | - 170 mm |

| Drum diameter |

- HD+ 90 / HD+ 110: 120 cm - HD+ 120 / HD+ 140: 140 cm Larger drum diameters prevent the movement of material. |

- CB54: 130 cm - CB54 XW: 130 cm - CB64: 130 cm |

- Dual amplitude/dual frequency system (standard) (CAT): two amplitudes, two frequencies, automatic link between amplitude and frequency, switch activated

- Five-Amplitude Vibratory system (CAT) (Option for CB44B/CB54B): one frequency, five amplitudes, hand wheel on the drum for adjusting amplitude

- Versa Vibe Vibratory System (CAT) (Option for CB54B): four amplitudes, two frequencies, high-frequency or high-amplitude settings, frequency adjusted using a switch in the control panel, two settings for light compaction with higher working speed and, two settings for heavier compaction with slower working speed, amplitude adjustment using hand wheel on the vibrator housing outside

ERGONOMIC - EASE OF USE

| Dashboard | |

|

|

|

- Dashboard (movable)Classification in colour-coded functional groups - Self-explanatory pictograms that are clearly arranged - International symbols - Backlit - Instrument panel covering (for ROPS version) |

- Instrument panel - Clear layout and simple control switch - Instrument panel cov |

| Steering wheel | |

|

|

| - Steering wheel and control panel - movable | - Steering wheel and control panel - movable |

| Drive lever | |

|

|

|

- Drive lever with three positions: Stop (park), forwards and backwards - Button to activate vibration/oscillation, raising and lowering of the edge pressing and cutting equipment - Setting the track offset on the dashboard - 2 drive levers (2nd optional) |

- Drive lever with the functions: Speed, in/out vibration, on/off water sprinkler system, horn and crab steering (optional) - 1 drive lever |

| Comfort | |

|

|

|

- Very spacious ROPS-cabin - Boarding from both sides - Large rear storage area (incl. 12 V connector and bottle holder) - Storage for documents and tools - Compact design |

- Only ROPS/FOPS version - No cab version - Boarding from both sides - 4 rubber bumpers to reduce vibrations |

| Seating conditions | |

|

|

|

- Seat can be moved seamlessly from left/right - 180° seat rotation - Seating comfort through individually adjustable seat - Steering column adjustment for comfortable seating - Split doors (optional) |

- Individually adjustable seat - Seat can be moved to left/right, seat with middle position and fixed grid positions for seat adjustment - 180° seat rotation - Tiltable steering console for easy entry and exit |

| Working environment | |

|

|

|

- Excellent overview of drum and working environment - Large panoramic window for optimal view of the front and rear of the drum and of the working environment |

- Severely restricted visibility of drum edges (only with max. adjustment of the seat outwards), rear working environment and drum - High noise emission due to the arrangement of the engine and fans in the rear half of the machine |

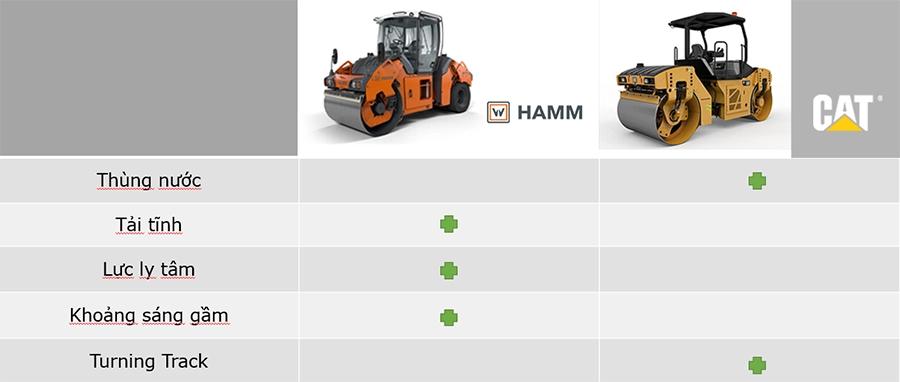

WATER SPRINKLING SYSTEM

| Water tanks | |

|

- Large front and rear water tanks - Each water tank can be filled from both sides - Easy, safe access to water tanks |

- One water tank with filling connections - Restricted accessibility of the filler neck (only larger operators can fill the water tank without additional help) - Operator must bend over the drum when filling the water tank - No side access to the water tank |

| Sprinkling | |

|

|

|

-Sprinkling settings on display - 4 sprinkling levels (permanent sprinkling, 3 sprinkling intervals) and manual sprinkling - 1 spray bar and 2 water pumps - Failure safety due to second pump |

- On/off sprinkler at drive lever - Sprinkler stages can be adjusted on instrument panel - Permanent sprinkler or steplessly adjustable sprinkler - 2 spray bars and 2 water pumps |

| Spray bars | |

|

|

|

- Spray bars can be supplied by both pumps - Manual switching from pump 1 to pump 2 (so that both pumps remain functional) - Indicator light for supporting water pump - Easy installation and removal of spray bars (quick coupling) + nozzles - Clear front and rear view of spray bars - Clear front and rear view of drum - Easy to empty - Scraper made of plastic |

- 2 function cycles: Function mode 1, Function mode 2 - Spray nozzles oriented upwards - Spray bars can be installed and removed only by loosening the screws - Clear view of spray bar towards the front but not towards the rear - Clear view of drum towards front but not towards rear - Water distribution mats (coconut or rubber) - Scraper made of plastic |

OTHER FEATURES

|

|

|

| Engine management | ||

| Details about engine management | Hammtronic: Minimal diesel consumption, Reduced sound level, Speed control, Traction control, Frequency control, Automatic vibration system. View Hammtronic at: HERE | Automatic speed regulation, auto Vibe function |

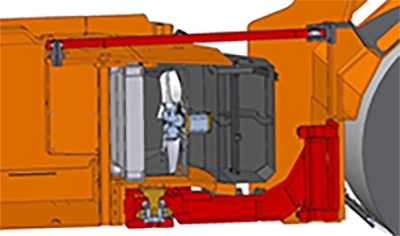

| Swivel joint | ||

| Details about the swivel joint | 3-point articulation: Driving stability and safety, Improved directional stability, No deformations in the asphalt when driving around curves. View more at: HERE | Articulated swivel joint: Strict directional stability, Deformations in curves |

|

|

|

| Application spectrum | ||

| Edge pressing and cutting equipment | Yes | |

| Chip spreader | Yes | |

| Track offset | Yes | Yes |

| Documentation system | HCQ. View more at: HERE | |

| Service | ||

| Details about service |

- Global service and distribution network - Easy access for routine maintenance - Maintenance-friendly arrangement of components - Engine room easily accessible - Engine room can be locked - Long intervals between services - Low operating and maintenance costs |

- CAT service network - Engine and maintenance points easily accessible (major repairs difficult due to engine room design) - Engine room can be locked - Long intervals between services |

News Related

Tags: hamm roller, cat roller