HAMM COMPACTION QUALITY (HCQ)

The more even and high-quality compaction is for earthworks and asphalt work, the more durable and long-lasting the streets and buildings constructed upon it will be. More and more frequently, invitations to tender and public projects therefore include demands for a detailed, comprehensive compaction measurement. To meet these specific requirements, HAMM offers a reliable solution in the form of the modular HCQ (HAMM Compaction Quality) system.

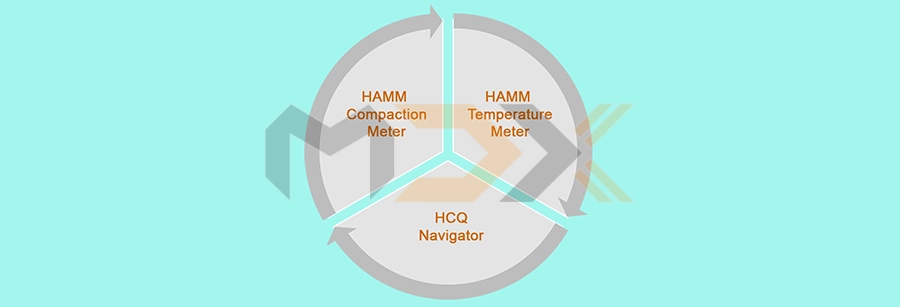

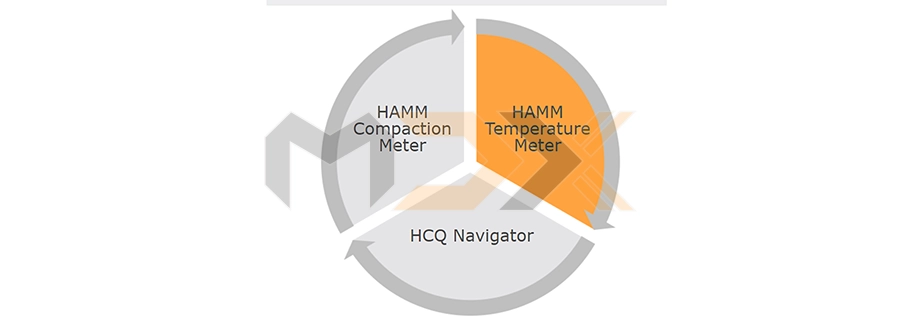

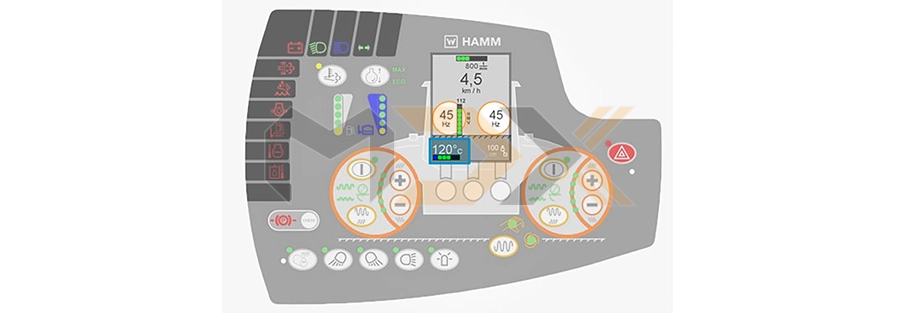

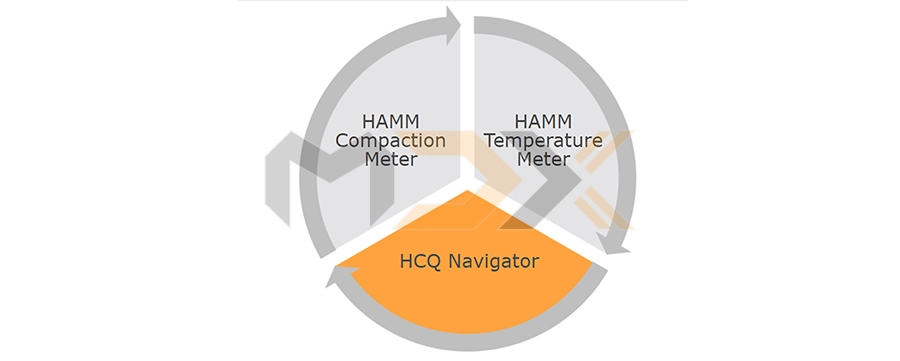

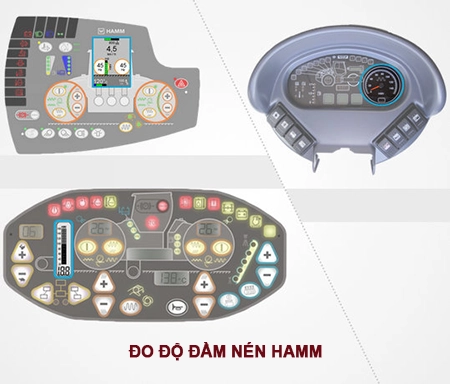

HCQ comprises a number of HAMM products designed to measure, monitor, document and control compaction and compaction processes. These include the HAMM Compaction Meter (available for earthworks and asphalt) for determining stiffness values, as well as the HAMM Temperature Meter (available for asphalt) for measuring the asphalt temperature. These two data points are shown for the driver on the display in the driver's platform.

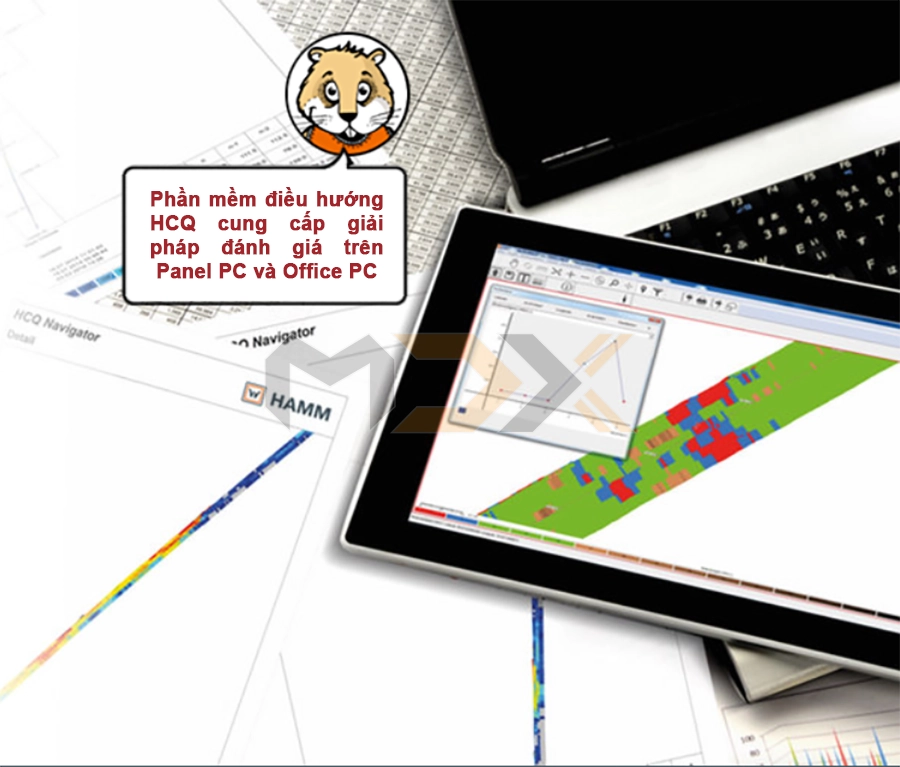

HAMM also offers the HCQ Navigator. This uses a GNSS receiver to continuously determine the position of the rollers and combines this data with the measured values that have been collected. A panel PC with a touchscreen in the driver's platform then displays all the data in a single package in the form of a real-time "compaction map" - this includes additional parameters such as current speed, amplitude and frequency.

Since the rollers are also able to communicate with each other via a WLAN connection, the display shows the separate passes and the overall compaction progress of the machine as a whole. This means that the roller driver can always see which areas have been sufficiently compacted and which areas require a further pass.

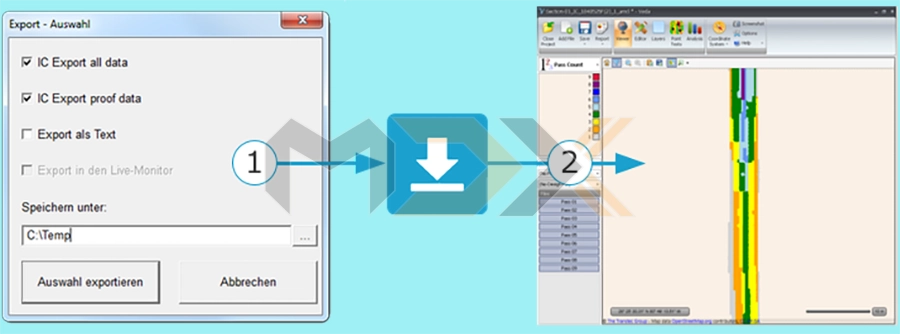

Using the HCQ Navigator software, the collected data can then also be displayed on graphs, analysed or exported in a format corresponding to the VETA standard. The data is transferred from the panel PC using a USB stick. The HCQ Navigator is available in the following versions: HCQ Navigator Asphalt, HCQ Navigator Earthworks and HCQ Navigator Premium (asphalt and earthworks).

INTRODUCTION - HCQ SYSTEMS IN EARTH WORK AND IN ASPHALT CONSTRUCTION

ONE SYSTEM FOR ALL MODEL SERIES

CONVENTIONAL COMPACTION CONTROL

Conventional measuring methods are used at many building sites. Here are a few examples:

Check during asphalt construction:

- Density/compaction ratio.

- Void content.

Check during earth work:

- Density/compaction ratio.

- Load capacity.

Selective compaction control. Ratio of point checks to installed material:

- In asphalt construction and earth work about 1: 50,000.

Disadvantages of conventional, selective compaction control:

- Selective measurements (random).

- Time consuming.

- Small number of samples.

- Samples usually only taken near to the surface

- Standstill times of construction machinery.

- Interference in the construction process.

- Measurement only possible after work is completed.

- Labour intensive.

CONTINUOUS COMPACTION CONTROL

To avoid the disadvantages of conventional measuring methods, the goal is to measure the entire building site continuously. Criteria for continuous compaction control:

- Continuous compaction control.

- Graphic display.

- Must ensure homogeneous, high-quality compaction.

- Documentation of the entire compaction process

FDVK / FDVK-A

- FDVK = Continuous Dynamic CompactionControl (earth work).

- FDVK-A = Continuous Dynamic CompactionControl in Asphalt.

In Anglo-American context, this is referred to and abbreviated as Continuous Compaction Control (=CCC).

CONTINUOUS COMPACTION CONTROL: USE OF ROLLERS

During the progress of construction, the compaction quality can be influenced most easily and quickly. The roller is both compacting equipment and measuring device at the same time.

HCQ MODULES IN EARTH WORK AND IN ASPHALT CONSTRUCTION

Measured in earth work:

- Rigidity / load capacity.

- Passes.

Measured in asphalt construction:

- Temperature.

- Passes.

- Rigidity

HCQ MODULES

HCQ is a measurement, planning and documentation module for monitoring and controlling compaction and the compaction processes. In the USA, the term "Intelligent Compaction (IC)" is used in conjunction with the HCQ Navigator.

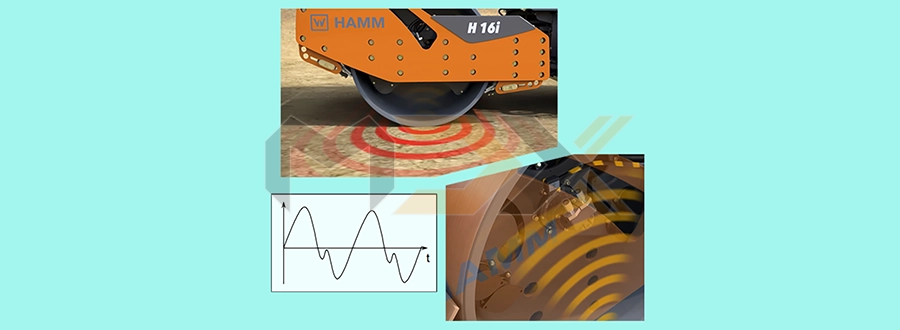

HAMM Compaction Meter

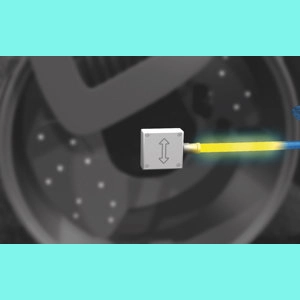

Measurement and display of the rigidity of the subsoil by utilising the acceleration sensor on the vibrating drum.

HAMM Temperature Meter

Measurement and display of the upper surface temperature of the asphalt to be compacted.

HCQ Navigator

Satellite-supported documentation system for capturing and displaying all major compaction parameters and the compaction progress of one or several rollers.

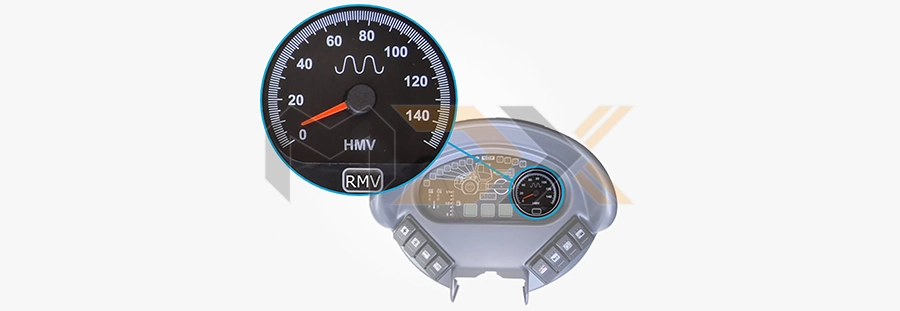

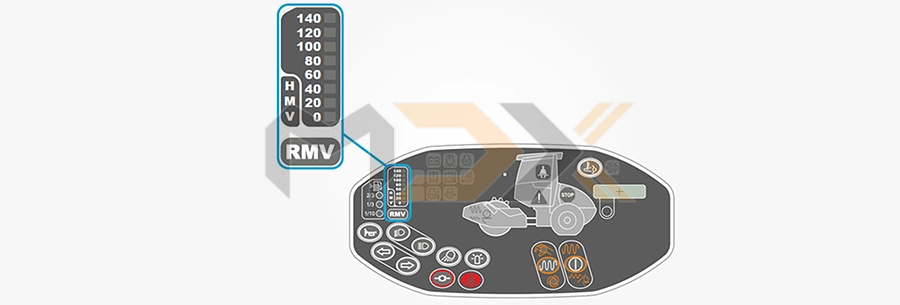

HAMM COMPACTION METER: COMPONENTS

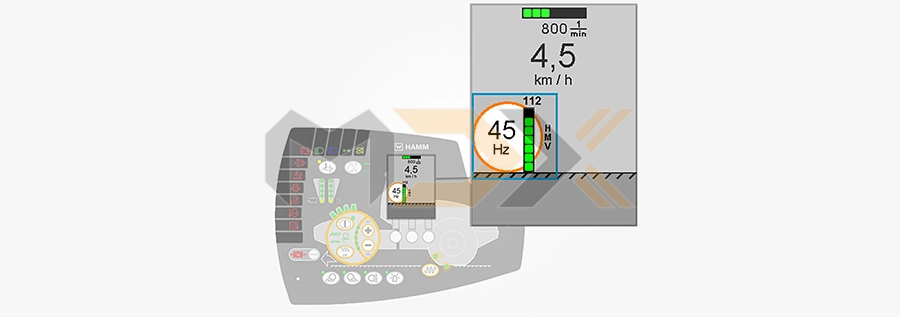

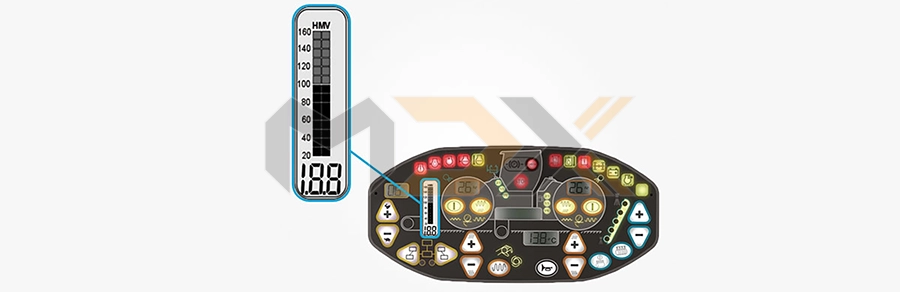

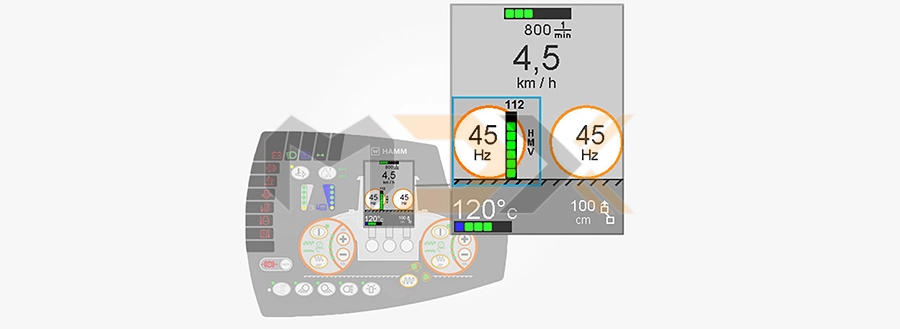

The HAMM Compaction Meter measures and displays the corresponding values for the rigidity of the subsoil via the acceleration sensor on the vibrating drum. Here you can see the components of the HAMM Compaction Meter.

HCM Sensor (for the accelerometer)

E.g. Series 3000 (earth work)

Display of the actual values during compaction

(HMV value) + warning Display

RMV (Resonance Meter Value - jump mode)

E.g. Series H CompactLine (earth work)

Display of the actual values during compaction (HMV value) + warning display RMV (Resonance Meter Value - jump mode)

E.g. Series H (earth work)

Display of the actual values during compaction (HMV value) + warning display RMV (Resonance Meter Value - jump mode)

E.g. Series HD+ (asphalt construction)

Display of the actual values during compaction (HMV value) + warning display RMV (Resonance Meter Value - jump mode)

E.g. Series DV+ (asphalt construction)

Display of the actual values during compaction (HMV value) + warning display RMV (Resonance Meter Value - jump mode)

E.g. Series HD CompactLine (asphalt construction)

Display of the actual values during compaction (HMV value) + warning display RMV (Resonance Meter Value - jump mode)

E.g. Series H with Easy Drive: HAMM Compaction Meter display

HAMM COMPACTION METER: RIGIDITY MEASUREMENT

Using the HAMM Compaction Meter (HCM), drum acceleration can be determined when vibration is switched on. This raw data reflects the reaction of the soil to the vibrations triggered by the roller, and the HCM Compaction Calculator continuously calculates the Hamm Measurement Value (HMV) of rigidity from this.

- Capture of drum acceleration.

- Evaluation of soil reaction component.

- Calculation of rigidity.

- HMV - Hamm Measurement Value.

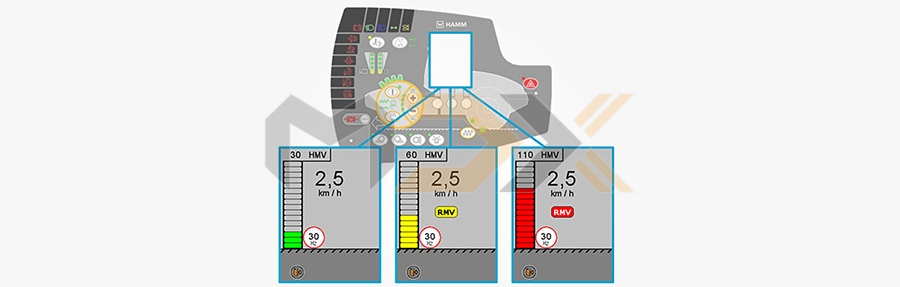

INTERPRETATION OF THE HMV VALUES

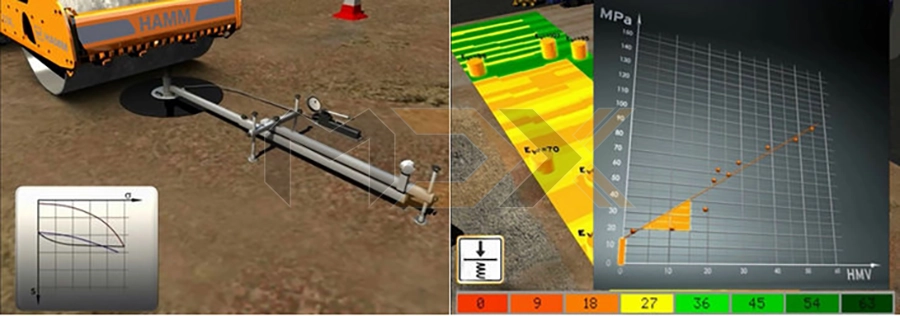

| High HMV values | 50 - 160 |

| Normal HMV values | > 20 |

| Low HMV values (uncompactable material, deeper soft layers) | 0 - 15 |

Using the HAMM Compaction Meter (HCM), drum acceleration can be determined when.

HMV RIGIDITY VALUE

| Increasing values | Material still able to be compacted |

|

Constant values |

Maximum compaction reached (using this roller). Switchover to small amplitude or oscillation, or stop compaction. Additional passes may result in re-loosening and destruction of the material. |

|

Decreasing values |

Re-loosening of the material. Material cannot be compacted (e.g. proportion of water is too high). Weaknesses can be detected, and measures can be taken |

|

Jump Mode |

Switchover to small amplitude or oscillation, or stop compaction.

|

HAMM COMPACTION METER: HMV RIGIDITY VALUE - TIPS AND GUIDELINE VALUES

| Types of ground |

Setting recommendation (last pass) |

HMV area |

Rigidity/ load capacity |

|

Silty/clayey soil with excessive water content |

- high amplitude - maximum frequency - speed: 2 - 2.5 km/h |

0 - 5 |

low |

|

Silty/clayey soil with correct water content |

- high amplitude - maximum frequency - speed: 2 - 2.5 km/h |

5 - 15 |

low |

|

Sandy/gritty soil |

- small amplitude - reduce frequency by 5 - 8 Hz (only possible for Hammtronic!) - speed: 2.5 - 3 km/h |

15 - 30 |

medium |

|

Frost protection/ bearing layer material/ HGT |

- small amplitude - reduce frequency by 5 - 8 Hz (only possible for Hammtronic!) - speed: 2.5 - 3.5 km/h |

30 - 50 |

high |

|

Rock |

- small amplitude - reduce frequency by 5 - 8 Hz (only possible for Hammtronic!) - speed: 2.5 - 3.5 km/h |

50 - 100 |

very high |

HAMM COMPACTION METER: HMV RIGIDITY VALUE AND CALIBRATION

A calibration can be run to evaluate the measured values determined at the building site. The reason and purpose of this calibration is to establish a correlation between the measured values determined by the roller (relative values) and the conventional control measurements. Calibration can be run e.g. using the compaction ratio or the load capacity.

Without calibration:

- Calculated values (dimensionless).

- Indication of increase or decrease in rigidity.

- Detection of inhomogeneities in the subsoil.

With calibration (A reference measurement value is assigned to the HMV value):

- Display of "genuine" values.

HAMM COMPACTION METER: BASIC REQUIREMENTS FOR MEASUREMENTS

Parameters for the measurement:

- Homogeneous material.

- Constant water content.

- Same driving speed.

- Same amplitude.

- Same frequency.

- Constant dumping heights.

- Only possible with vibration.

- Only measure in one driving direction.

The measured values change if a parameter changes! The measured values can then no longer be compared.

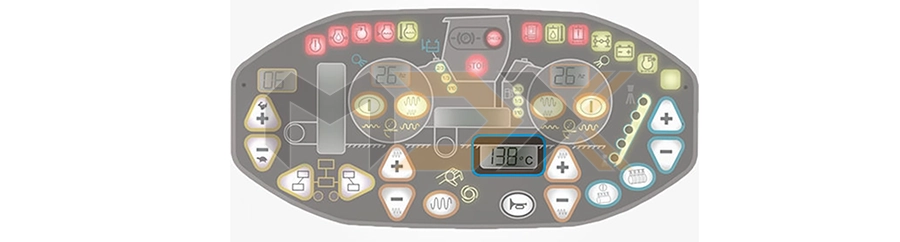

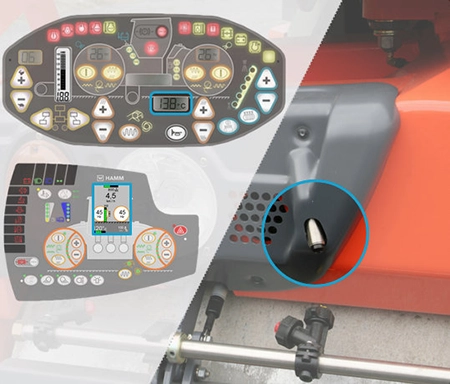

HAMM TEMPERATURE METER: COMPONENTS AND VALUES

The HAMM Temperature Meter measures the surface temperature of the asphalt to be compacted and then displays the corresponding values. Display of:

- Asphalt surface temperature in °C or °F.

- Measurement with infrared sensor.

- Display of actual values during compaction

HAMM TEMPERATURE METER: COMPONENTS AND VALUES

Asphalt temperature sensor (infrared)

Temperature measurement in °C or °F

E.g. Series HD+

E.g. Series DV+

E.g. Series HD CompactLine

E.g. Series GRW 180/280

HCQ NAVIGATOR

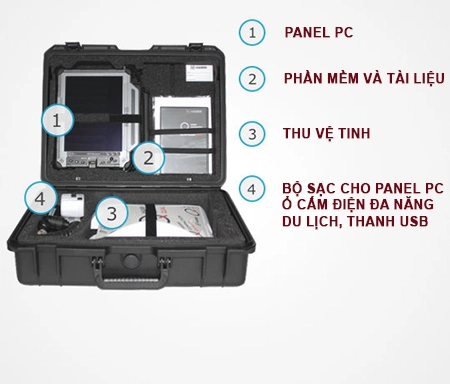

HCQ Navigator is a satellite-supported documentation system for capturing and displaying all major compaction parameters and the compaction progress of one or several rollers. You will learn about the components that comprise the HCQ Navigator and which aspects of this system play an important role. The HCQ Navigator is available for earth work and asphalt rollers.

The HCQ Navigator...

- is satellite-supported and continuous.

- measures and displays relevant parameters.

Satellite-supported and continuous

- measurement.

- display

- Documentation.

Measurement and display of all relevant parameters such as:

- number of passings.

- rigidity.

- temperature.

- global position and much more.

HCQ NAVIGATOR: COMPONENTS IN EARTH WORK AND ASPHALT CONSTRUCTION - OVERVIEW

The HCQ Navigator is only functional when the machine has been fitted with the HCQ Navigator preparation (optional). This can also be retrofitted. The HCQ Navigator must be ordered and configured separately. If the HCQ preparation is to be retrofitted at a future time, then the preparation should be installed immediately when possible, because the components of the HAMM Compaction Meter single option cannot be used.

|

|

|

| HCQ Navigator central unit (incl. wiring) | HCQ Navigator case | Docking Station |

|

|

|

| HAMM Compaction Meter | HAMM Temperature Meter (only asphalt construction) | HCQ Navigator office software |

|

|

|

| Panel PC with software | HCQ satellite receiver |

HCQ NAVIGATOR: COMPONENTS

|

|

| HAMM Compaction Meter, HAMM Temperature Meter, Docking Station, HCQ Navigator central unit, HCQ Navigator case, Panel PC | HAMM Temperature Meter (only asphalt construction) |

|

|

| Docking Station | HCQ Navigator central unit (no HCQ Navigator central unit for DV+; the components are installed in the roof lining). |

|

|

| HCQ Navigator case | Panel PC |

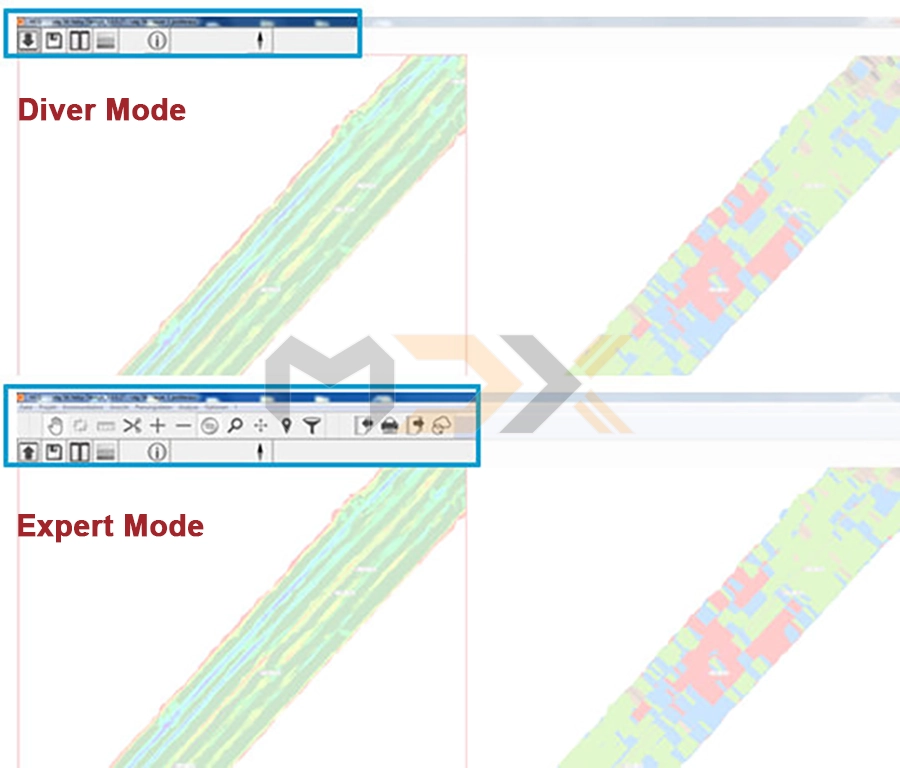

HCQ NAVIGATOR: COMPONENTS - PANEL PC

Features:

- Touch screen operation.

- Display and storage of all values.

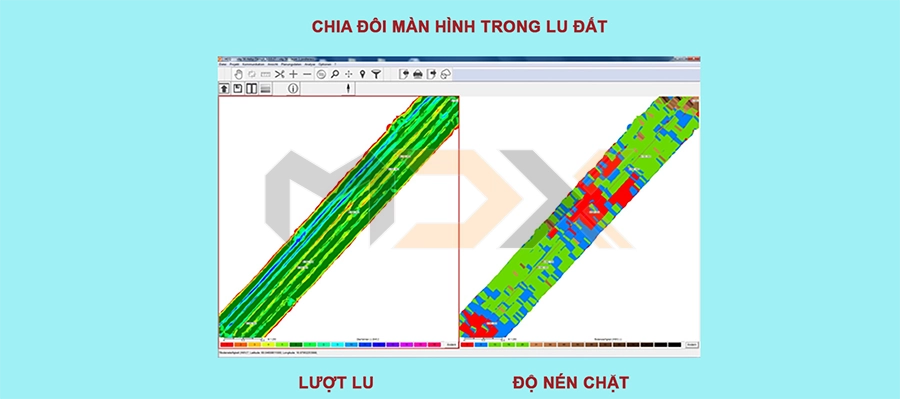

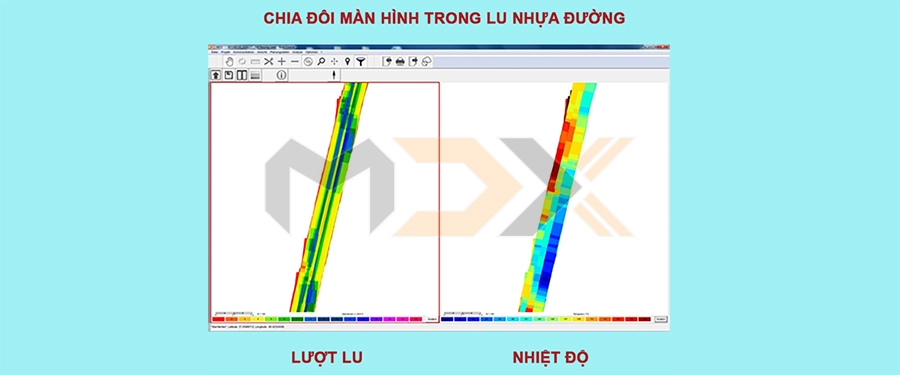

- Split screen function.

- Protection class IP67 (dust-tight and water-jet proof).

- Operating temperature range -36 ºC to +60 ºC.

- WLAN, bluetooth.

- Fast and powerful SSD drive.

The software provides:

- Analysis functions to optimise the compaction process.

- Automatic detection of machine number and type, machine parameters, installed sensors.

- Recording of roller drum positions and measured values.

- Accurate display of pass positions include quantity.

- 2D map display of all measured values.

- Calibration functionality.

- Creation of projects, sections, soil layers.

- Embedding of e.g. maps, geolines, measuring points.

Driver and expert mode

Split screen earth work

Split screen asphalt construction

HCQ SATELLITE RECEIVER

This receiver provides a high level of satellite reception and therefore stable position detection.

HCQ satellite receiver:

- High-precision detection of roller position.

- Display and recording on the panel PC is impossible without receiver or without a signal

Advantage of the HCQ satellite receiver:

- Plug & play function.

- In addition to GPS (US-American), it also receives GLONASS (Russian) satellites.

- No need for base station.

Adapter kits for receivers from third parties:

- Adapter kit for Topcon HiPer II.

- Adapter kit for Topcon HiPer SR

- Adapter kit for Trimble MS972/MS992

Adapter kit for Topcon HiPer II = adapter cable to connect Topcon HiPer II receivers

- Adapter kit for Topcon HiPer SR

Adapter kit for Topcon HiPer SR = adapter cable to connect Topcon HiPer SR and HiPer SR Cell receivers.

- Adapter kit for Trimble MS972/MS992

- wiring harness, installation kit and metal box to connect Trimble receivers MS972 and MS992 to SNM920, SNM940 or a comparable wireless modem.

Adapter kits for receivers from third parties

Using the adapter kit, even DGNSS systems/receivers from other manufacturers can be connected. The kits normally comprise an adapter cable to connect to the DGNSS interface of the HCQ Navigator on the roller and a connection documentation. Configuration and start-up of the respective hardware must be carried out by the third-party supplier.

Hamm helps to connect receivers/GNSS systems from other manufacturers. In most cases, customers have their own measuring equipment. In this case, often all that is required is a short call with Hamm to find the suitable adapter kit for the correct configuration.

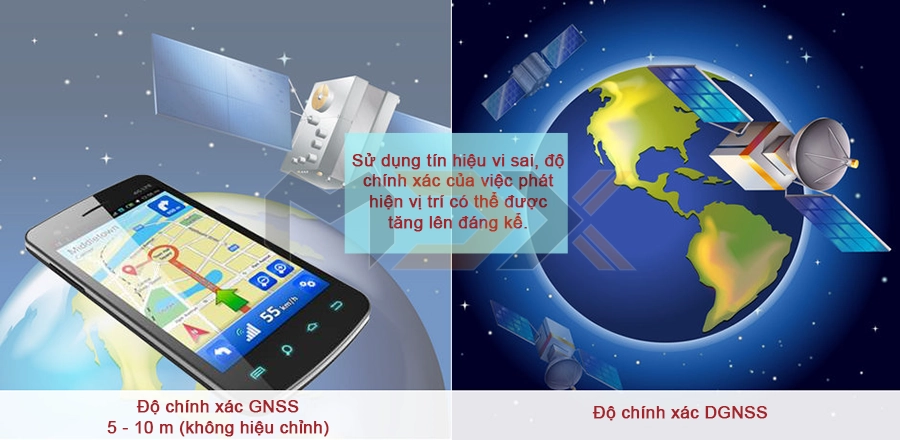

HCQ NAVIGATOR: GNSS VS. DGNSS ACCURACY

GNSS accuracy: 5 - 10 m (without correction), DGNSS accuracy, satellite correction 10 cm (when using a ground station or access to correction data via cellular: 1 - 2 cm), signal reception and correction:

- 24 satellites in 6 orbits.

- Direct visual contact with at least 6–7 but ideally 8 satellites is required.

- Accuracy ~ 10 cm for satellite-supported correction signals.

- Accuracy ~ 1.5 cm using local ground stations/RTK systems.

How does correction calculation work?

Correction calculation:

- The correction calculation of a GPS signal is via a geostationary reference station (Hamm provides correction services WAAS/EGNOS or Trimble/Omnistar as standard). The correction signal is transmitted via communication satellite to the DGNSS receiver.

- The accuracy of position detection therefore depends on the correction signal (license).

CORRECTION SIGNALS

| DGNSS | RTK |

|

|

| SBAS signal* accuracy to within at least 95 cm | RTK signal accuracy to within at least 2.5 cm |

| VBS signal accuracy to within at least 78 cm | Modem GPS / GNSS - Modem GPS-RTK (EU) |

| HP/XP signal accuracy to within at least 10 cm | |

| *The SBAS signal (e.g. EGNOS, WAAS) is free of charge; all other correction signals are with costs. | |

| Licenses are provided by HAMM Customer Support. | |

HCQ NAVIGATOR: WITH AND WITHOUT HCQ SATELLITE RECEIVER

Visualization on the panel PC without position data is impossible without receiver. In this case, only the HAMM Compaction Meter or the HAMM Temperature Meter can be used.

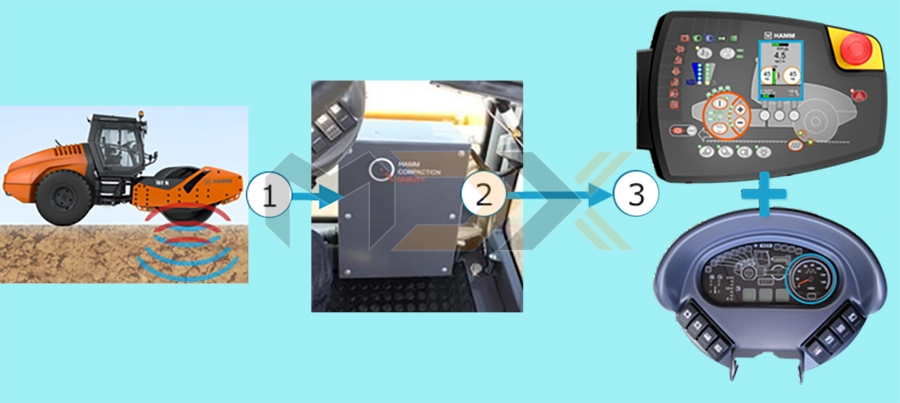

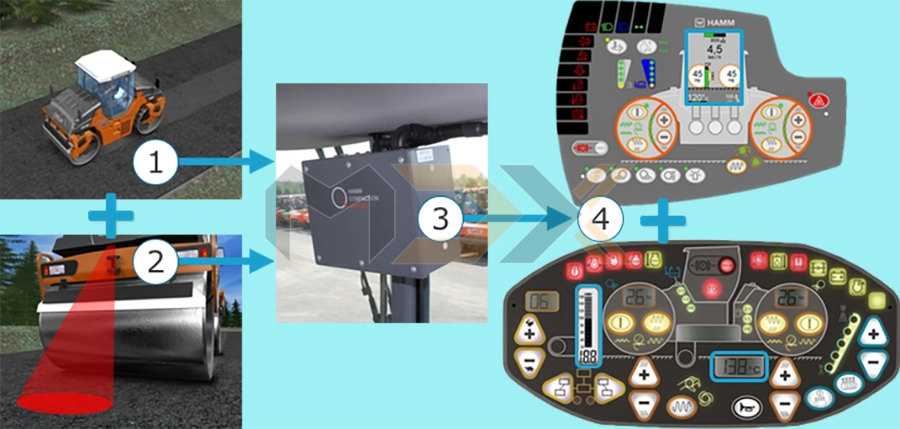

Display for earth works roller without HCQ satellite receiver

1. Acceleration sensor delivers the raw data for the HMV value.

2. HCQ Navigator central unit calculates the HMV value.

3. Display of HMV value on the display.

Display for asphalt construction roller without HCQ satellite receiver

1. Acceleration sensor delivers the raw data for the HMV value.

2. Temperature sensor measures the asphalt temperature.

3. HCQ Navigator central unit calculates the HMV value.

4. Display of HMV value and temperature.

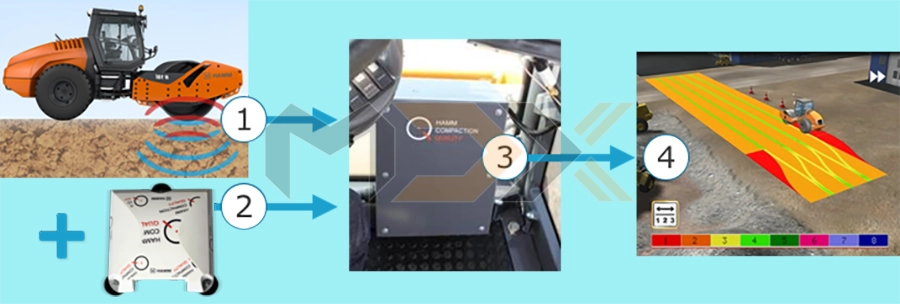

Recording for earth works roller with HCQ satellite receiver

1. Acceleration sensor delivers the raw data for the HMV value.

2. HCQ satellite receiver delivers the position.

3. HCQ Navigator central unit calculates measured values and forwards them to the panel PC.

4. Panel PC: Compaction map with number of passes, HMV value, etc.

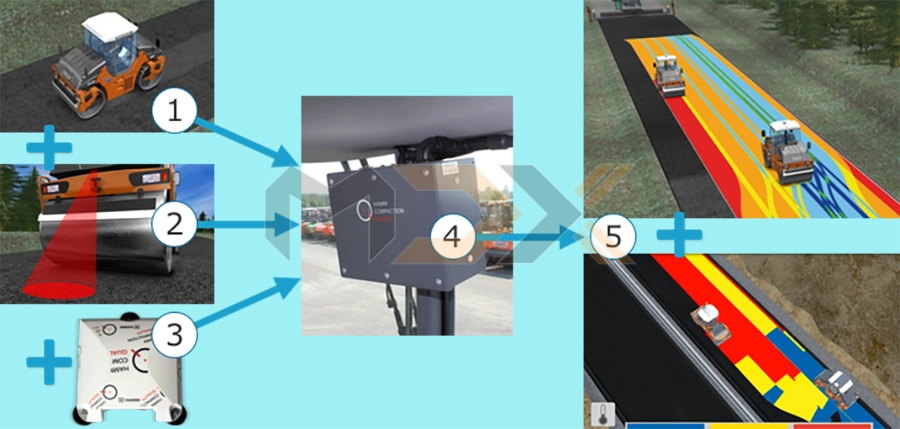

Recording for asphalt construction roller with HCQ satellite receiver

1. Acceleration sensor delivers the raw data for the HMV value.

2. Temperature sensor measures the asphalt temperature.

3. HCQ satellite receiver delivers the position.

4. HCQ Navigator central unit calculates measured values and forwards them to the panel PC.

5. Panel PC: Map of passings + temperature map

HCQ NAVIGATOR: DATA EXCHANGE VIA WLAN

Networking of up to 5 machines. Several tandem rollers often compact at the same time on asphalt sites and therefore generate the compaction map together. Your own machine is marked with a +. Additional machines can be seen by the change in colour of the map. The joint compaction work can be seen on every screen.

HCQ NAVIGATOR: SOFTWARE

There are 2 different programs for evaluating the data.

1. HCQ Navigator office software

- Project preparation.

- Analysis functions.

- User-friendly interface.

- Multilingual documentation.

- Animations, resources and links.

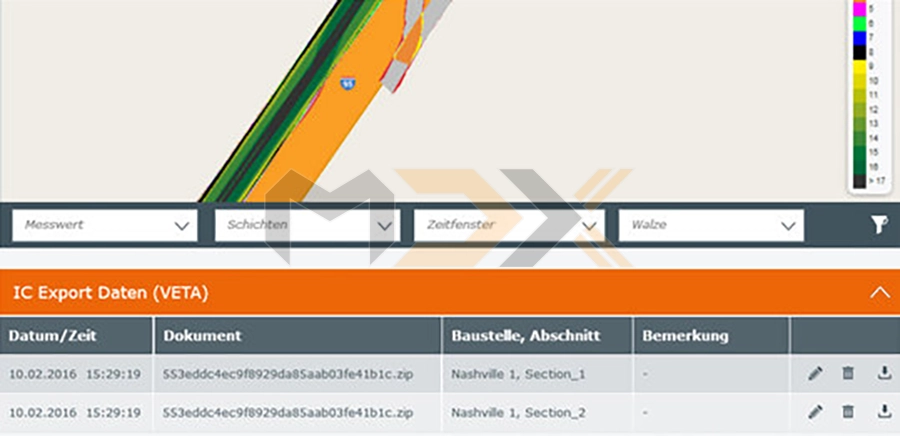

2. VETA software

What is VETA? - VETA visualizes the compaction information in a prepared format with diagrams and maps. VETA is a uniform analysis software of US authorities and is required in the IC specifications of the US-American “Federal Highway Administration” road authority and the AASHTO for earth work and asphalt construction.

Additional information is available at www.intelligentcompaction.com

What is VETA?

VETA is a software mainly developed for the US-American region. Data export for further analysis of the IC data:

- Export in Veta format *.vexp (1) for import into Veta software (2).

- Export of the recorded data in scaled tiles of 30 cm x 30 cm.

- Export of compaction history with each pass

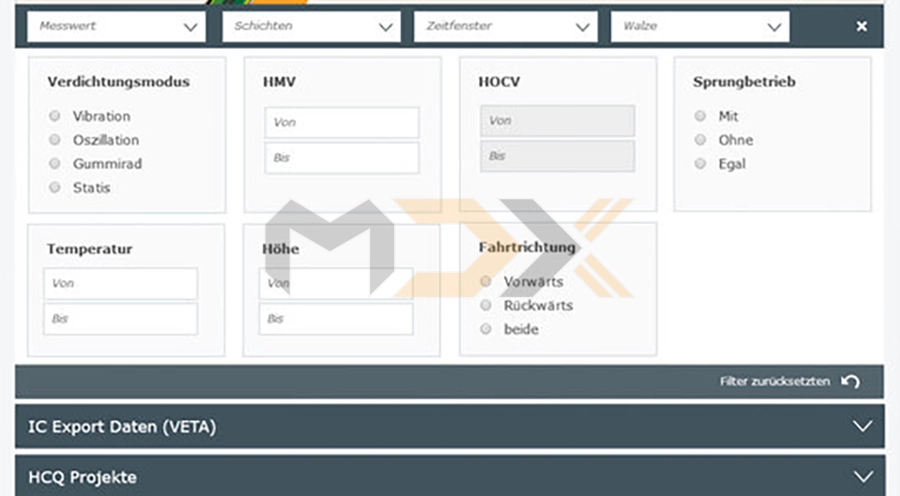

HCQ NAVIGATOR: SOFTWARE ANALYSIS

Filter functions

E.g. for the evaluation of the number of passes with dynamic or static compaction.

Point analysis

Displays the achieved HMV value, the number of passes, temperature etc. at a given point.

Replay function

Displays the compaction processes in fast increments => Support for the analysis and optimization of the processes

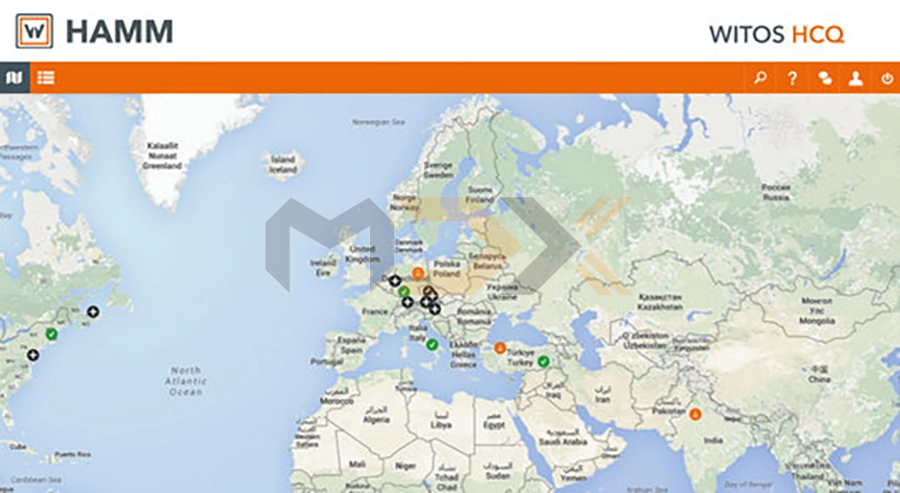

WITOS HCQ (OPTION)

WITOS HCQ process module incl. 3-year validity period. Data can be transferred from the machine via USB stick, although there is also an online-based solution: the WITOS HCQ. Expansion of the HCQ Navigator for real-time data transfer to the WITOS HCQ process module.

The system allows the measured data of the HCQ Navigator to be called up and processed via the WITOS HCQ online portal. Data is transferred via the WITOS SIM card (can be retrofitted from panel PC model generation C5). The package includes the connection required for the Wirtgen Group Portal and access to the WITOS HCQ Portal.

WHY WITOS HCQ?

Starting position

- HCQ Navigator: Previously only local networking on the building site with data transfer per WLAN between machines.

- Repeated interest shown by customers for online functionality.

- Requirement from the USA: Data transfer in cloud storage, at the latest 15 minutes after the recording – use of USB sticks by authorities is very risky.

With WITOS HCQ

- Expansion of the existing HCQ Navigator by cloud storage as well as data transfer and display in real time.

- Integration in the WITOS environment for later networking with other WITOS modules

WITOS HCQ: POSSIBILITIES

WITOS HCQ provides a whole range of useful options.

1. Building site overview

- Overview of all available building sites with geographical allocation.

- Direct jump to live monitor by clicking on the required project.

- Display of project status by symbols (project without any data yet, live data recorded, project closed)

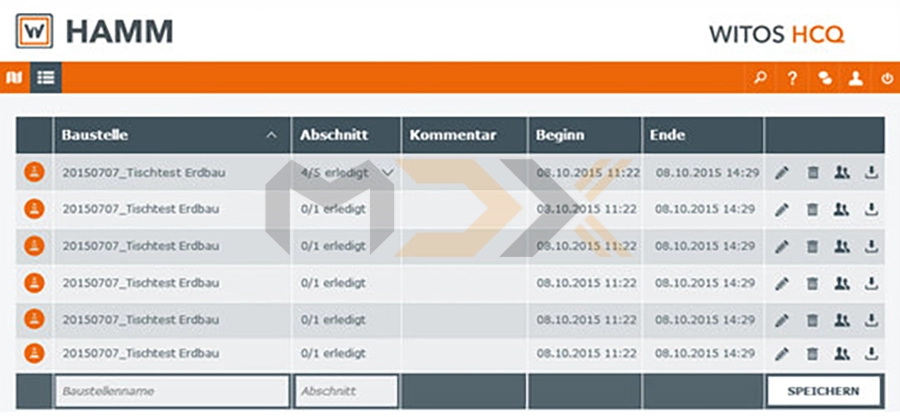

2. Project list

- Display of all projects and sections in a table.

- Detailed information such as comments and recording periods.

- Call up of the live monitor.

- Comment on and delete projects.

- Release projects and sections

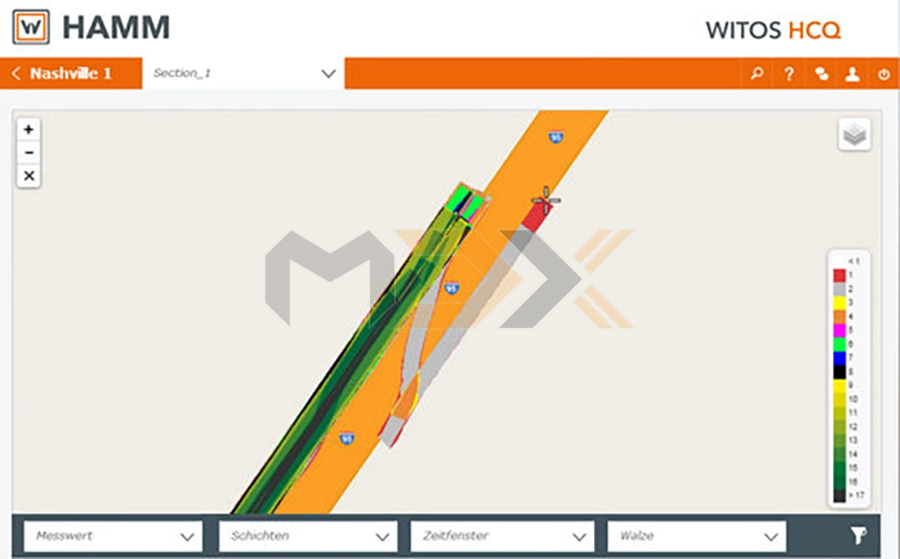

3. Live monitor

- Real-time display of the compaction process.

- Visualization of passes, temperature and compaction

4. VETA export

- Can be created at any time, even during the recording.

- Manual triggering.

- Can be downloaded after creation

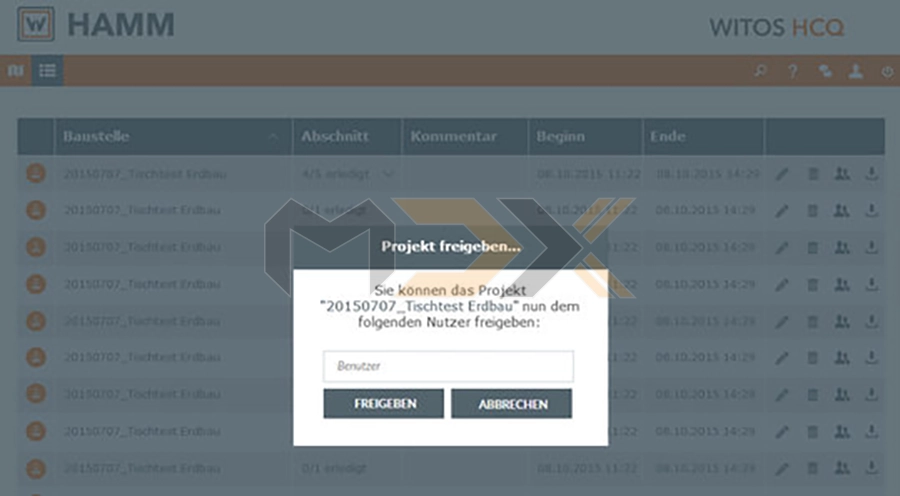

5. Project release

- Targeted release of projects and sections for other users such as officials.

- Creation and management of users using the corresponding functions in the Wirtgen Group Portal (self service)

6. Filter and analysis functions

7. View of all layers and machines

HCQ NAVIGATOR: ADVANTAGES

Using the HCQ Navigator, there are no standstill times of construction machinery during the measurements!

Quality

- Level of compaction and load capacity can be controlled in a targeted manner during the compaction process.

- Ensure homogeneous compaction over the entire area.

- Prevent over-/under-compaction

- Check the preceding work in asphalt construction

Cost-effectiveness

- Avoid unnecessary passes.

- Efficient use of combined rollers

- Reduced investment due to modular system.

- Machine-independent system components

- High quality of tasks = less damages, additional claims

Documentation

- Continuous, clear, secure

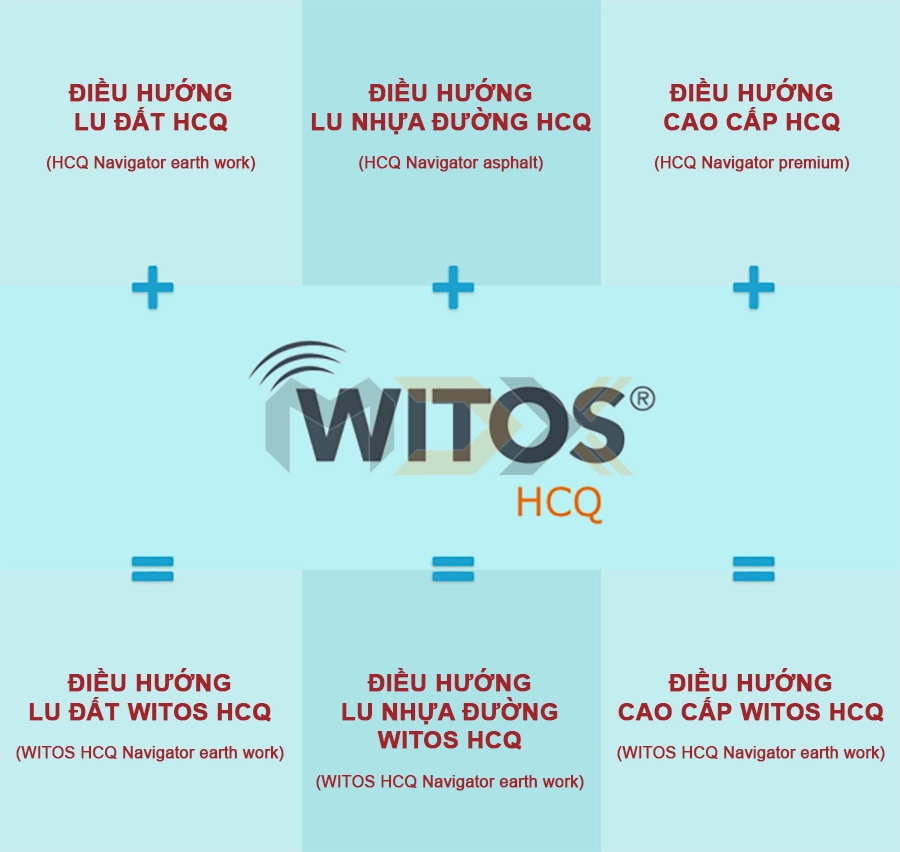

HCQ NAVIGATOR: SALES VARIANTS

The HCQ Navigator is available in the following sales variants:

- HCQ Navigator earth work.

- HCQ Navigator asphalt.

- HCQ Navigator premium - earth work and asphalt construction

Equipment variant "WORLD": The current panel PCs are fitted with a cellular modem at the factory. This variant is suitable for all regions except North America.

- The USA has its own variant.

- The HCQ Navigator premium.

combines both documentation systems and makes the system more flexible. All application-relevant settings are thereby unlocked and can be freely selected by the user.

OPTIONS IN COMPARISON

| HCQ Navigator earth work |

HCQ Navigator asphalt |

HCQ Navigator premium |

|

| Passes | yes | yes | có |

| Rigidity | yes | yes | có |

| Change in compaction | yes | no | có |

| Amplitude | yes | yes | yes |

| Frequency | yes | yes | yes |

| Jump mode (RMV) | yes | yes | yes |

| Speed | yes | yes | yes |

| Absolute height* | yes | yes | yes |

| Section | yes | yes | yes |

| EV1/2 | yes | yes | yes |

| EVd | yes | no | yes |

| Temperature | no | yes | yes |

| * The accuracy of the elevation depends on the positional accuracy used. | |||

HCQ: ANIMATION

There is a DVD on this topic incl. animation with additional information.

CHECK LISTS FOR USE WITH THE HCQ NAVIGATOR

Building site and position

- Where is the building site?

- Are there limitations in the reception of the signals?

- For example: Forest, mountain, houses, bridges, tunnels, …

- What positional accuracy is required?

- Is a license required and if yes, which?

- For how long should the license be valid?

- How many machines should be incorporated into the system?

- Is instruction for the machine assured on site?

Technical requirements

- Are all machines fitted with HCQ Navigator preparation?

- Are there sufficient systems?

Documentation

- In what form and scope must the data be transmitted?

- Should the machines be networked?

News Related

Tags: HCQ, Hamm compaction quality, hamm compactor, HCM