PRODUCT COMPARISON HAMM HD+ VS. BOMAG BW, STAGE IIIA / TIER 3

The following article shares with readers about the differences and competitive advantages between two brands of asphalt rollers: Hamm Series HD+ and Bomag, with the same Stage IIIA / Tier 3 standards. From that, we hope that you will be able to choose the most suitable brand. We hope you enjoyed this post!

HAMM VS. BOMAG – STAGE IIIA / TIER 3

HAMM, Stage IIIA/Tier 3

- Model: 17

- Weight range: 9 - 14 tons

- Drum width: 3

View Hamm Series HD+ at: HERE

BOMAG, Stage IIIA/Tier 3

- Model: 17

- Weight range: 8 - 13 tons

- Drum width: 4

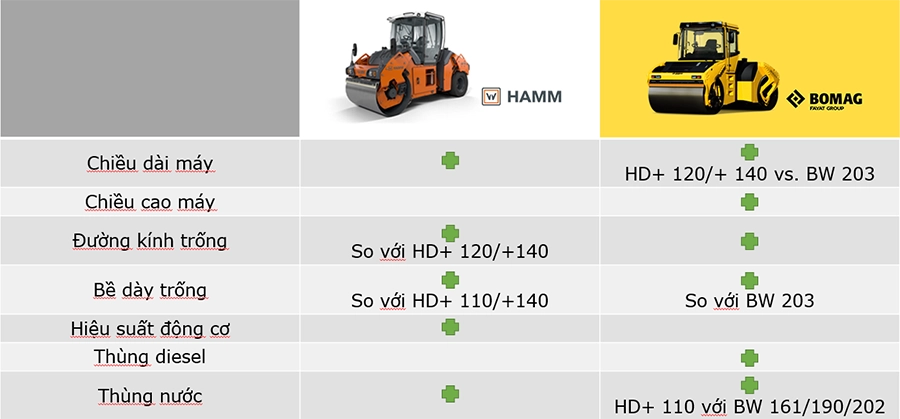

DETAILED COMPARISON

WIDE VARIETY

|

|

|

| Weight classes | 9 - 14 t. The HD series must be offered in the 7 - 8 t weight classes. | 8 - 13 t |

| Drum widths | 168/198/214 cm | - 150 / 168 / 200 / 213.5 cm |

| Application | City centre/parking lot, Universal/outside of built-up areas, Highway/airport | City centre/parking lot, Universal/outside of built-up areas, Highway/airport |

| Engine technology | Stage IIIB/Tier 4i, Stage IIIA/Tier 3 | Stage IIIB/Tier 4i, Stage IIIA/Tier 3 |

| Compaction systems | Vibration, Oscillation, Tyres, Split drum, High vibration frequency | Vibration, Tyres, Split drum (with BW 154 AD-4) |

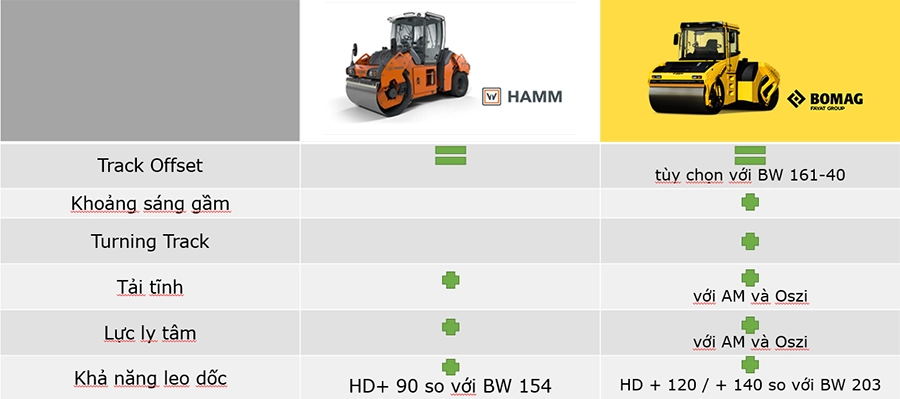

| Track Offset | - 170 mm | - 170 mm |

| Drum diameter |

- HD+ 90 / HD+ 110: 120 cm - HD+ 120 / HD+ 140: 140 cm Larger drum diameters prevent the movement of material. |

- BW 141 - BW 202: 122 cm - BW 203: 124 cm |

ASPHALT MANEGER (BOMAG)

Asphalt Manager (Bomag): Oscillation alignment system which enables stepless adjustment to the direction of compaction force between vertical and horizontal. The maximum possible output is provided, based on a calculation of the rigidity of the material being compacted. Compaction process is calculated continuously and displayed as an EVIB value on a special display, the BOMAG Operational Panel (BOP). The display also informs the operator of the current asphalt temperature, the rolling speed and the currently active amplitude.

Two operating modes:

+ Automatic mode: The roller operator does not need to make any manual settings. Amplitude is automatically adjusted to conditions.

+ Manual mode: The operator can preselect one of six oscillation directions between vertical and horizontal.

ERGONOMIC - EASE OF USE

| Dashboard | |

|

|

|

- Dashboard (movable)Classification in colour-coded functional groups - Self-explanatory pictograms that are clearly arranged - International symbols - Backlit |

- Fixed display - Operated by rotary knob - The display is located in the middle between the steering wheels, which means that the displays cannot be seen from every seating position - No ergonomic operation of the rotary knob |

| Steering wheel | |

|

|

| - Steering wheel and control panel - movable | - Two steering wheels, adjustable seat |

| Drive lever | |

|

|

|

- Drive lever with three positions: Stop (park), forwards and backwards - Button to activate vibration/oscillation, raising and lowering of the edge pressing and cutting equipment - Setting the track offset on the dashboard - 2 drive levers (2nd optional) |

- Drive lever with integrated vibration switches, crab steering and raising/lowering of the edge pressing and cutting equipment - 2 Drive lever |

| Comfort | |

|

|

|

- Very spacious ROPS-cabin - Boarding from both sides - Large rear storage area (incl. 12 V connector and bottle holder) - Storage for documents and tools - Compact design |

- Restricted cabin space due to two steering wheels, among others - Boarding from both sides - Little storage space |

| Seating conditions | |

|

|

|

- Seat can be moved seamlessly from left/right - 180° seat rotation - Seating comfort through individually adjustable seat - Steering column adjustment for comfortable seating - Split doors (optional) |

- Seat can be moved to the doors - Seat swivel - Instrument panel is fixed; the operator therefore sits either to the right or left beside the instrument panel, fixed grid positions - Steering consoles cannot be adjusted - Steering wheel with tilt adjustment |

| Working environment | |

|

|

|

- Excellent overview of drum and working environment - Large panoramic window for optimal view of the front and rear of the drum and of the working environment |

- Good view of drum and working environment |

WATER SPRINKLING SYSTEM

| Water tanks | |

|

|

|

- Large front and rear water tanks - Each water tank can be filled from both sides - Easy, secure access (on both sides - front and rear) to water tanks - Deep centre of gravity increases driving stability - Simple and quick emptying (three drainage points - right rear water tank + left drain plugs, drain at front water tank) - Water tanks are connected to each other for uniform emptying and weight distribution |

- Two rear water tanks (for non-uniform front and rear weight distribution) - Water tanks can be filled on both sides - Dual side access to water tanks - The hose connection on the swivel joint can be opened to empty the tanks - In addition, a second drain is attached in the pump area for faster emptying |

| Sprinkling | |

|

|

|

- Sprinkling settings on dashboard - Failure safety due to 2 water pumps (manual switching) - Manual switching from pump 1 to pump 2 (so that both pumps remain functional) - Indicator light for supporting water pump - Optical display of water level - 3-way filtration - 4 sprinkling levels (permanent sprinkling, 3 sprinkling intervals) and manual sprinkling - Speed-dependent water sprinkling |

- Operation via rotary knob which is connected to the left of the operator's seat in the driving lever console - Two water pumps (manual switching) - Optical and acoustic warning when water level is low - 12 interval stages - Preset interval stages, not regulated by speed |

| Spray bars | |

|

|

|

- Easy installation and removal of spray bars (quick coupling) + nozzles - Clear view of spray bars and nozzles - Sprinkling pipes protected from the wind - Scraper made of plastic - Frost protection and anti-theft protection |

- Spray bar is fixed and not easy to empty - Clear view of spray bars and nozzles - Sprinkler pipes protected from the wind - Scraper made of plastic - Radiator in the sphere of influence of the sprinkler, which results in a risk of contamination when dirt is sucked up |

OTHER FEATURES

|

|

|

| Engine management | ||

| Details about engine management |

Hammtronic: Minimal diesel consumption, Reduced sound level, Speed control, Traction control, Frequency control, Automatic vibration system View Hammtronic at: HERE |

Automatic vibration system |

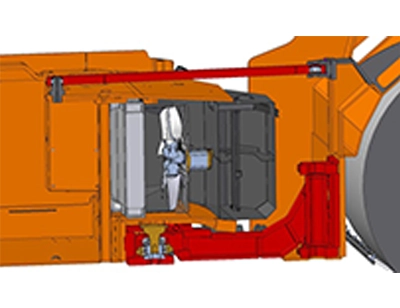

| Swivel joint | ||

| Details about the swivel joint |

3-point articulation: Driving stability and safety, Improved directional stability, No deformations in the asphalt when driving around curves View more at: HERE |

Articulated swivel joint: Strict directional stability, Deformations in curves |

|

|

|

| Application spectrum | ||

| Edge pressing and cutting equipment | Yes | |

| Chip spreader | Yes | |

| Track offset | Yes | Model dependent |

| Documentation system | HCQ. View more at: HERE | BCM 05 |

| Service | ||

| Details about service |

- Global service and distribution network - Easy access for routine maintenance - Maintenance-friendly arrangement of components - Engine room easily accessible - Engine room can be locked - Long intervals between services - Low operating and maintenance costs |

- Service points and diesel engine easily accessible from both sides - Auxiliary fuel pre-filter - Long replacement intervals |