HAMM COMPACTION METER (HCM)

Hamm Compaction Meter (HCM) is available on the 3000, H CompactLine, H, HD CompactLine, HD+, DV+ series. Module for measuring and displaying the rigidity of the substrate.

You can view the document at: HERE

OVERVIEW

- HAMM Compaction Meter, VIO: Option to measure the compaction in the vibration and oscillation mode; available for H 7i VIO and H 13i VIO.

- Automatic activation for dynamic compaction.

- Measurement via the acceleration sensor on the vibrating drum.

+ Recording the drum acceleration.

+ Evaluating the proportion of the soil reaction.

+ Continuous calculation of a relative rigidity value.

+ Display as a HAMM Measurement Value (HMV).

+ Calibration for continuous compaction control, e.g. via static or dynamic load plate.

To learn more about the HCQ module system, you can refer to the link: HERE

Advantages of HCM:

- No risk of over-compaction.

- Fast localisation of positions with high demand for compaction or material that cannot be compacted

- Reduction in overrunning and therefore in the work time thanks to the detection of sufficiently compacted positions = cost reduction.

- Reduced particle crushing, no re-loosening.

- Maximum, efficient and homogeneous compaction

INTRODUCTION OF HCQ APPLICATION ON HAMM ROLLER

HAMM COMPACTION METER - HCM

COMPACTION METER - DRUM LEFT

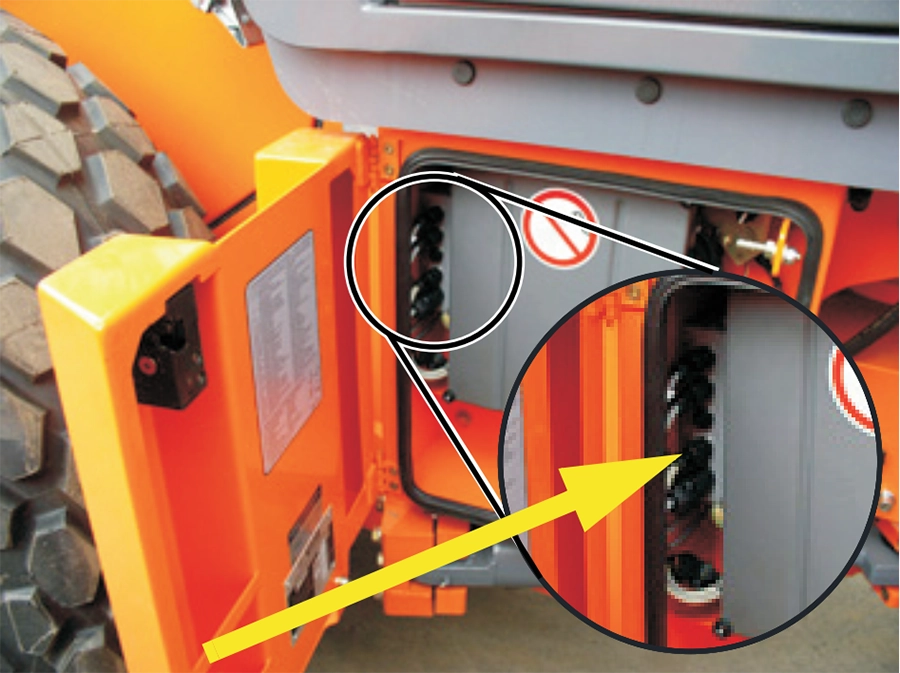

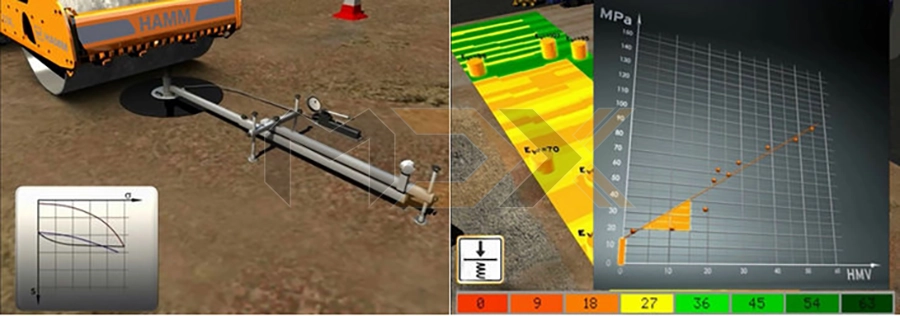

The HAMM Compaction Meter measures and displays the corresponding values for the rigidity of the subsoil via the acceleration sensor on the vibrating drum. Here you can see the components of the HAMM Compaction Meter.

HCM Sensor (for the accelerometer)

COMPACTION COMPUTER

VIDEO INSTRUCTIONS FOR INSTALLATION COMPACTION METER

ĐỒNG HỒ HIỂN THỊ TRÊN BẢNG ĐIỀU KHIỂN

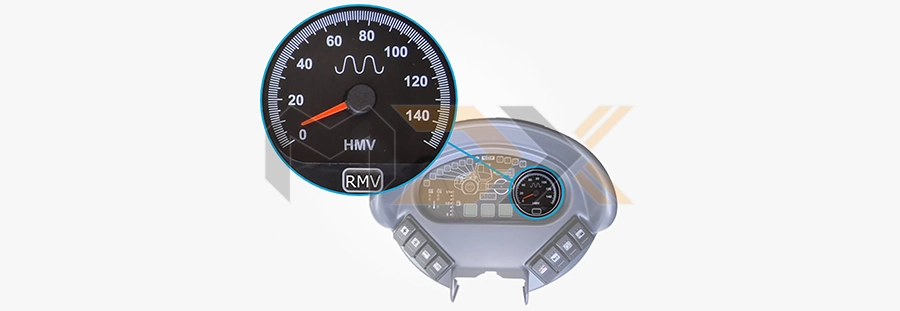

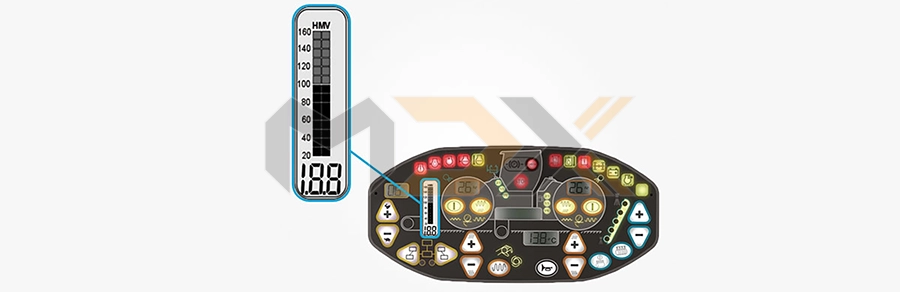

E.g. Series 3000 (earth work)

Display of the actual values during compaction

(HMV value) + warning Display

RMV (Resonance Meter Value - jump mode)

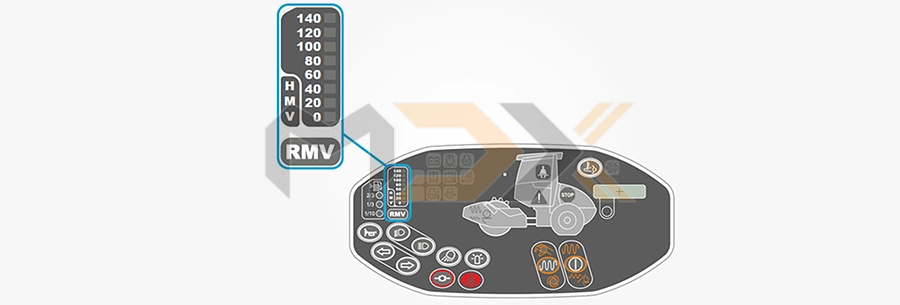

E.g. Series H CompactLine (earth work)

Display of the actual values during compaction (HMV value) + warning display RMV (Resonance Meter Value - jump mode)

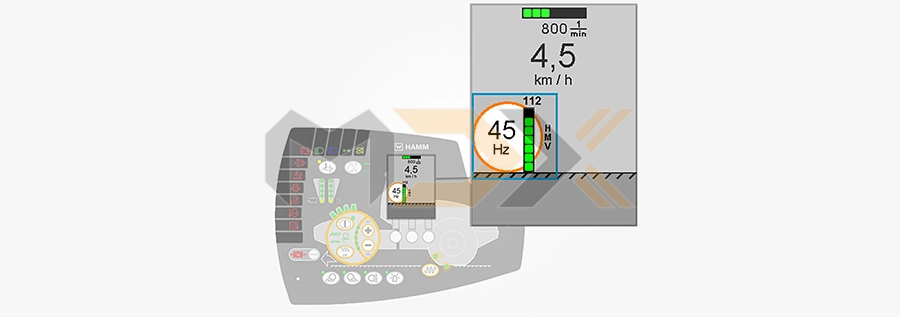

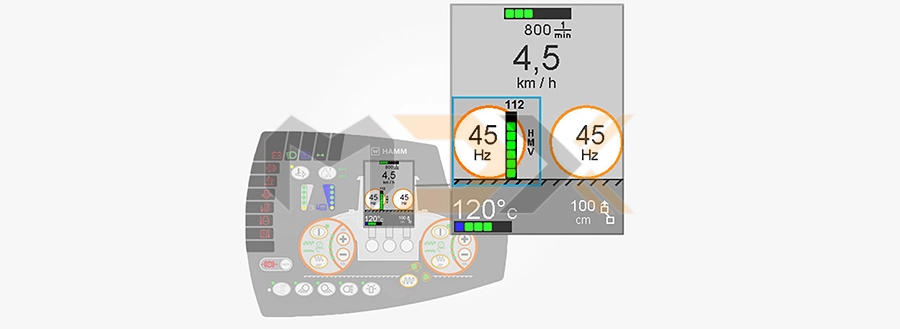

E.g. Series H (earth work)

Display of the actual values during compaction (HMV value) + warning display RMV (Resonance Meter Value - jump mode)

E.g. Series HD+ (asphalt construction)

Display of the actual values during compaction (HMV value) + warning display RMV (Resonance Meter Value - jump mode)

E.g. Series DV+ (asphalt construction)

Display of the actual values during compaction (HMV value) + warning display RMV (Resonance Meter Value - jump mode)

E.g. Series HD+ (asphalt construction)

Display of the actual values during compaction (HMV value) + warning display RMV (Resonance Meter Value - jump mode)

E.g. Series DV+ (asphalt construction)

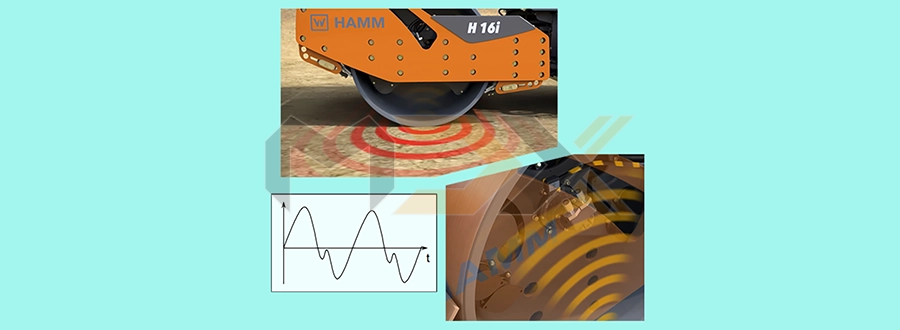

HAMM COMPACTION METER: RIGIDITY MEASUREMENT

Using the HAMM Compaction Meter (HCM), drum acceleration can be determined when vibration is switched on. This raw data reflects the reaction of the soil to the vibrations triggered by the roller, and the HCM Compaction Calculator continuously calculates the Hamm Measurement Value (HMV) of rigidity from this.

- Capture of drum acceleration.

- Evaluation of soil reaction component.

- Calculation of rigidity.

- HMV - Hamm Measurement Value.

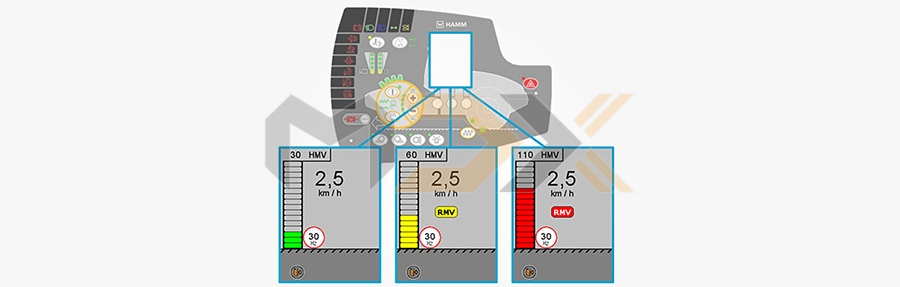

INTERPRETATION OF THE HMV VALUES

| High HMV values | 50 - 160 |

| Normal HMV values | > 20 |

| Low HMV values (uncompactable material, deeper soft layers) | 0 - 15 |

Using the HAMM Compaction Meter (HCM), drum acceleration can be determined when.

HMV RIGIDITY VALUE

| Increasing values | Material still able to be compacted |

|

Constant values |

Maximum compaction reached (using this roller). Switchover to small amplitude or oscillation, or stop compaction. Additional passes may result in re-loosening and destruction of the material. |

|

Decreasing values |

Re-loosening of the material. Material cannot be compacted (e.g. proportion of water is too high). Weaknesses can be detected, and measures can be taken |

|

Jump Mode |

Switchover to small amplitude or oscillation, or stop compaction.

|

HAMM COMPACTION METER: HMV RIGIDITY VALUE - TIPS AND GUIDELINE VALUES

| Types of ground |

Setting recommendation (last pass) |

HMV area |

Rigidity/ load capacity |

|

Silty/clayey soil with excessive water content |

- high amplitude - maximum frequency - speed: 2 - 2.5 km/h |

0 - 5 |

low |

|

Silty/clayey soil with correct water content |

- high amplitude - maximum frequency - speed: 2 - 2.5 km/h |

5 - 15 |

low |

|

Sandy/gritty soil |

- small amplitude - reduce frequency by 5 - 8 Hz (only possible for Hammtronic!) - speed: 2.5 - 3 km/h |

15 - 30 |

medium |

|

Frost protection/ bearing layer material/ HGT |

- small amplitude - reduce frequency by 5 - 8 Hz (only possible for Hammtronic!) - speed: 2.5 - 3.5 km/h |

30 - 50 |

high |

|

Rock |

- small amplitude - reduce frequency by 5 - 8 Hz (only possible for Hammtronic!) - speed: 2.5 - 3.5 km/h |

50 - 100 |

very high |

HAMM COMPACTION METER: HMV RIGIDITY VALUE AND CALIBRATION

A calibration can be run to evaluate the measured values determined at the building site. The reason and purpose of this calibration is to establish a correlation between the measured values determined by the roller (relative values) and the conventional control measurements. Calibration can be run e.g. using the compaction ratio or the load capacity.

Without calibration:

- Calculated values (dimensionless).

- Indication of increase or decrease in rigidity.

- Detection of inhomogeneities in the subsoil.

With calibration (A reference measurement value is assigned to the HMV value):

- Display of "genuine" values.

RECOMMENDED WORKING DEPTHS

|

This overview shows the working depths of the various types of vibration rollers at a large amplitude and maximum frequency.Note: - The working depths are correspondingly halved at a small amplitude. - The stated values must be regarded as guide values, and can vary widely under different soil conditions. |

|||

| Maschinentyp | Bodenart | ||

| Fels | Sand/Kies | Ton/Lehm/Schluff | |

| 3205 | 25 - 30 cm | 15 - 20 cm | |

| 3307 | 28 - 40 cm | 2 - 25 cm | |

| 3410, 3411 | 50 - 70 cm | 42 - 50 cm | 25 - 35 cm |

| 3412 | 70 - 85 cm | 50 - 65 cm | 28 - 40 cm |

| 3414 | 85 - 105 cm | 60 - 70 cm | 30 - 42 cm |

| 3516 | 97 - 125 cm | 67 - 80 cm | 30 - 40 cm |

| 3518 | 110 - 140 cm | 72 - 95 cm | 35 - 45 cm |

| 3520 | 125 - 155 cm | 90 - 115 cm | 37 - 52 cm |

| 3625 | 150 - 195 cm | 120 - 160 cm | 45 - 55 cm |

| Performance check and Troubleshooting | |

| Fault | Fault correction |

|

The needle of the HMV gauge does not deflect when the vibration is switched on. RMV indicator does not light up in jump operation.. |

1.Check whether the “HCQ Indicator” option is installed. 2.Check the fuse in the electrical systems box. 3.Check the plug connection on the HCQ Indicator computer. 4.Check the mounting of the sensor on the drum. |

| The HMV needle moves and the RMV indicator flashes during a transport drive without vibration. | This is not a fault, but a normal, physically induced reaction. |

| f the actions taken fail to correct a fault, please contact the Vinh Phu Service, and have the fault corrected by qualified Vinh Phuservice personnel. | |

BASIC REQUIREMENTS FOR CONTINUOUS COMPACTION CONTROL MEASUREMENTS

- Homogeneous and identical material.

- Constant water content.

- Constant working speed.

- Constant amplitude.

- Constant frequency.

- Constant dumping height.

- Measurement only in one direction of travel.

Note: Changing a parameter causes the measured values to be changed.

News Related

Tags: HCQ, Hamm compaction quality, hamm compactor, HCM