WITOS PAVING - ROAD CONSTRUCTION SOLUTION 4.0

Road construction 4.0 is gradually becoming a top priority solution in modern life today. It meets all stringent construction requirements such as the best paving quality, interconnected tasks within the asphalt paving process, clear information, and tight time tolerances.

Most contractors are interested in increasing paving efficiency and reducing downtime costs as much as possible. To meet these desires, Vogele offers customers three modern technological solutions: WITOS Paving Plus, WITOS Paving Docu, and RoadScan, which help optimize the entire process, facilitate documentation, or monitor paving temperature. At the same time, they provide suitable digital solutions for every need.

SUMMARY

| 1 | Advanced paving management software - WITOS Paving Plus | 2 | Basic paving management software - WITOS Paving Docu |

| 3 | Non-contact temperature measurement system - RoadScan |

1. WITOS PAVING PLUS

|

|

|

WITOS Paving Plus from Vogele is a comprehensive asphalt paving process management solution, based on a software platform with five integrated modules. This solution connects all parties involved in the process, from the mixing plant to the paver operator, helping to optimize efficiency and coordination in construction. Vogele has developed WITOS Paving Plus as a solution to optimize the asphalt paving process, using data for more efficient, transparent, and faster planning. This solution helps minimize machine downtime and optimize the main stages in the paving process, thereby increasing productivity and construction efficiency. WITOS Paving Plus creates a seamless network, bringing together all parties involved in the road paving project. This solution directly connects the mixing plant supervisor, the truck drivers, and the construction team at the job site, helping them to coordinate smoothly and exchange information effectively in real-time. As a unique solution developed by Vogele, a leading machine manufacturer and long-term partner in the road construction industry, WITOS Paving Plus offers customers maximum reliability. This solution is built on Vogele's extensive expertise in asphalt paving, along with support from the Wirtgen Group's global consulting and service network, ensuring that customers are always supported and have peace of mind throughout the process. |

The system provides road construction engineers and site managers with a complete overview of the current project. Potential disruptions and obstacles in the paving process are detected more quickly, providing those in charge with various intervention options. This allows them to take immediate action to optimize the work site. They can also correct deviations from the planned workflow in real-time. Some of the prominent advantages of WITOS Paving Plus: - Planning and controlling all processes from the mixing plant to paving. - Quick detection of deviations in the paving process. - Immediate notification to all parties involved in case of incidents and deviations. - Timely and cyclical material supply. - Database for all parties involved in the paving process. - Analysis and statistics tools to optimize process flows. - Data from Hamm HCQ rollers can also be imported for documentation. - Machine stops and compaction are highlighted. - Integration of Vogele's RoadScan temperature measurement system to clearly record and display paving temperatures. |

WITOS PAVING PLUS MODULES

|

WITOS Paving Plus operates simply and intuitively. Everyone can participate in operating the module that suits them. For example, before construction work begins: - The site manager prepares the project using the Control module (WITOS Paving Control). - The mixing plant supervisor uses the Material module (WITOS Paving Material). - Trucks automatically transmit their exact location, including the estimated time of arrival, to the system via the Transport module (WITOS Paving Transport). - The paving supervisor and the paver operator locally operate the JobSite module (WITOS Paving JobSite) on site. - When the project is completed, the construction manager has all the data available for evaluation in the Analysis and Documentation module. |

| Planning and Control Module (WITOS Paving Control) | |

|

|

|

The Planning and Control module allows you to conveniently plan projects based on the geometry of the job site. All key information is collected simply and quickly: - The mixing plant is selected from the master database. - Paving parameters are recorded, including paving width, paving speed, etc. - The number of machines and materials required, including their availability over time. This module is an important source of information during project execution and supports the monitoring and analysis of the ongoing project. The construction manager can use it to monitor paving progress in real-time. The Planning and Control module is a crucial source of information for the construction manager. They can use this module to track paving progress, always in real-time, and stay updated on the status of material transfers. Furthermore, information about the operating status of the machine operators is always available to the construction manager and helps them monitor and analyze the current project. With this module, even the temperature of the freshly paved asphalt layer can be displayed and monitored in real-time. |

Overall, they ensure that site operations run in perfect cycles. At the same time, they optimize the planning of time and the timely provision of suitable materials. Highlights of the Control module: - Clear and detailed presentation of the project in real-time. - Easy machine scheduling avoids double assignments. - Logical job site planning. - Provides information on the operating status of the paver. - Coordination and data exchange with the mixing plant. - Calculates the number of mixing trucks needed. - Paving progress is displayed and can also be considered when planning subsequent orders. - Displays the temperature of the freshly laid asphalt layer measured by the Vogele RoadScan system. |

| WITOS Paving Material | |

|

Highlights of the Material module: - Displays actual material requirements to prevent overproduction and excess material. - The mixing plant delivers material to the job site on time thanks to dynamically updated cycles for material transport vehicles. - Easier communication between the mixing plant and the job site, especially in case of deviations from the plan. - The mixing plant supervisor receives information on quantity and transport efficiency. - Continuous display of paving progress as well as the positions of the mixing trucks. - Reduces the number of unnecessary mixing trucks. - Immediate notification to the mixing plant supervisor in case of rejection of a transfer due to poor material quality. - Delivery notes can be recorded via the digital interface to the server at the mixing plant. |

|

|

|

| The number of mixing trucks calculated by the WITOS Paving Control module is linked to the relevant data from the mixing plant. This information is the basis for calculating the mixing truck cycle and the material transfer time on site. | The mixing plant module uses a convenient interface for direct data exchange between the server at the asphalt mixing plant and the WITOS Paving Plus server. The system accurately records the number of mixing trucks in transit, how much volume is going to the site, and from which mixing plant. |

| Mô đun Vận chuyển (WITOS Paving Transport) | |

|

|

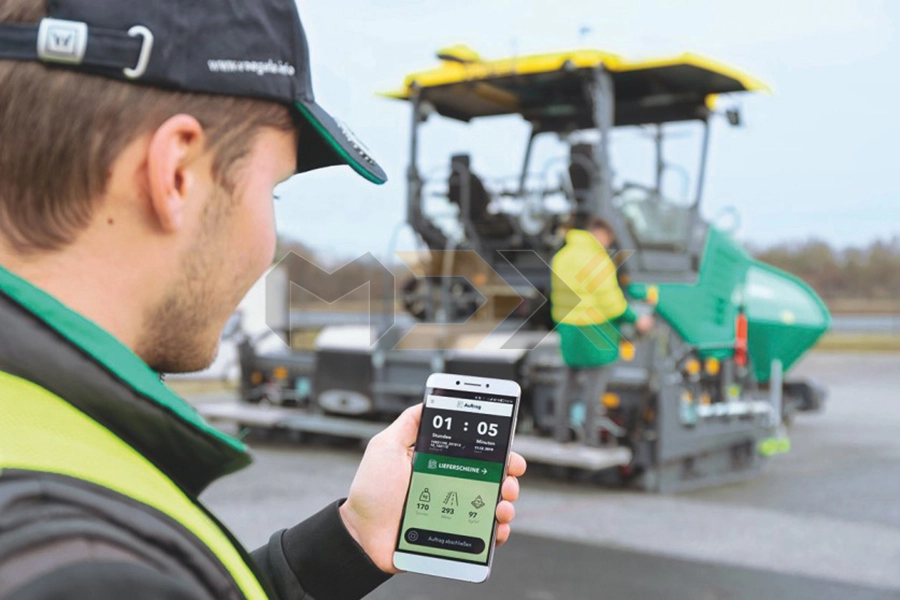

| The Transport module allows for more economical and efficient use of material trucks. Truck drivers are provided with important job-related details, such as scheduled arrival times, and regularly transmit the truck's GPS location to WITOS Paving Plus via an Android app. |

A map displays the exact locations of both the job site and the mixing plant. This allows the system to continuously update the estimated time of arrival (ETA) and provide reliable information to all parties involved in the project. Thanks to the WITOS Paving Transport module, the paving team, site management, and the mixing plant receive real-time information about the arrival of mixing trucks at the site throughout the entire construction phase. As a result, projects can be handled much more reliably today. |

|

Accurate planning also has an impact on paving quality, as waiting times for mixing trucks are reliably avoided, preventing the possibility of the paving material cooling down. Highlights of the Transport module: - Supports the economical use of mixing trucks delivering asphalt to the job site. - Informs all parties involved in the process about the arrival time of the material transport vehicle. - An app is available for standard smartphones (Android), offering maximum flexibility for the logistics company supplying the material. - The app shows the truck driver a map with the location of both the mixing plant and the job site. |

| WITOS Paving JobSite | |

|

The JobSite module is like the pacemaker of WITOS Paving Plus. It provides the paving supervisor and the site manager with a visual overview of the project, ensuring efficient process management throughout the paving process. This module provides important real-time information on paving progress, paving performance, or the number of mixing trucks. This is combined with the display of planned and actual values for paving time, paving distance, and the amount of paved material. This allows immediate identification of deviations from the plan, such as higher material consumption. As a result, continuous paving is ensured. |

|

|

|

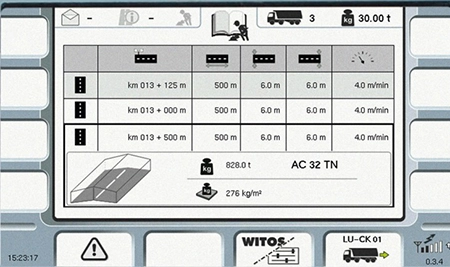

The JobSite module allows for the entry of delivery notes with just one button press. If QR codes are used, they can be entered into the system quickly and conveniently using a handheld scanner. WITOS Paving JobSite Highlights: - The entire project is clearly displayed for the paver operator and site manager. - Important information is displayed on the paver operator's ErgoPlus 3 console. - Information on the current volume and transport status. - Displays planned and actual values for paving time, paving distance, and the amount of paved material. - Simple entry of delivery notes. - Special orders are noted directly on the software. - Real-time updates on paving progress. - Early detection of deviations from the plan and quick initiation of corrective measures. The paving manager uses the JobSite module on a tablet or outdoor PC on site, giving them an overview of all key information about the job site. |

Mixing truck / Accept delivery note: The transfer of the mix can be conveniently entered into the overall system with just the push of a button by using the "mixing truck / accept delivery note" function. This information is then provided in real-time to all those participating in the project. This function can also be initiated by the paver operator via their ErgoPlus 3 display. Project progress: Displays the foreman's project progress with a comparison of specified/actual values by: paving time, paving section, amount of paved material, and area density. Supply chain: This module provides a convenient overview of all mixing trucks, whether they are en route to the job site or have already arrived. Integration with ErgoPlus 3: The JobSite module is an integral part of Vogele ErgoPlus 3 and offers the paver operator a unique system for controlling and optimizing the asphalt paving process. |

|

The paver operator is linked to the JobSite module by the ErgoPlus 3 display. For example, they can access current information about the job site and paving progress at any time. Thanks to clearly arranged and easy-to-understand diagrams, they can immediately identify any deviations of the actual situation from the plan. |

| Display of job data | Monitoring paving progress |

|

|

| Material type, material quantity, project duration, or expected paving progress. All information relevant to the current project is available to the operator. | Paving time, paved section, and paving progress. The paver operator can directly read the paving time, the section that has been paved, and the paving progress. They are also informed of the amount of material that has been planned, has been paved, and still needs to be placed. |

| Monitoring the supply chain | Display of asphalt temperature |

|

|

| Truck and load monitoring: The number of mixing trucks approaching the site and their loads are continuously displayed. The operator can accept the delivered quantity of mix with the push of a button. | Real-time temperature monitoring: The RoadScan non-contact temperature measurement system is an integral part of WITOS Paving Plus, allowing the paver operator to monitor the temperature quality of the paving material in real-time. |

2. WITOS PAVING DOCU

|

|

|

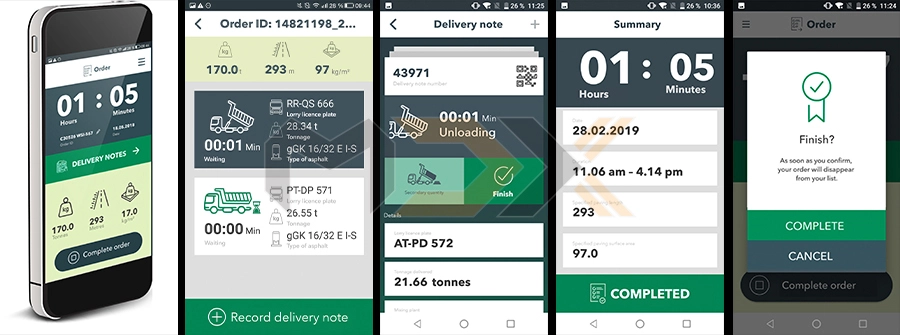

Customers are increasingly demanding the use of intelligent process management systems for paving. WITOS Paving Docu is a reliable and simple solution for digital documentation and analysis of small to medium-sized projects. It is the ideal tool where accurate data recording is required, but operational process optimization is not needed. This system complements Vogele's two existing products for job data documentation and analysis - RoadScan (non-contact temperature measurement system) and WITOS Paving Plus (comprehensive process management solution). When faced with more demanding customer requirements for larger-scale projects, contractors can upgrade from WITOS Paving Docu to the full version of WITOS Paving Plus at any time with just an activation code. |

Highlights of WITOS Paving Docu: - Simple documentation of both paver data and paving work. - Immediate start of recording jobs on site without prior planning. - Delivery notes are entered digitally. - Its WLAN capability allows it to be used even without a mobile signal. - Daily job reports via the WITOS Paving server. |

|

Data Loop for All Process Participants The paver establishes a WLAN network on the job site. All relevant personnel on site can dial into the network using the WITOS Paving Docu app, with the paver acting as the server and ensuring that data is exchanged between the machine and the mobile devices. This way, everyone on site has access to the same information. At the end of the day's paving operations, the recorded data is automatically sent to the WITOS Paving server and stored there. Job reports can also be sent via email to selected recipients. |

| WITOS Paving Docu: A Brief Overview | |

|

|

|

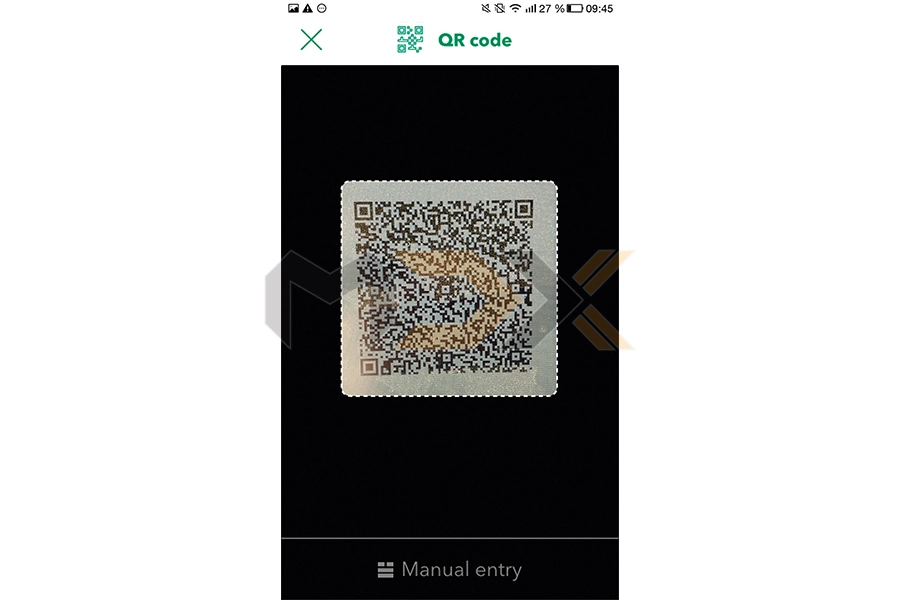

WLAN network: The paver creates a WLAN network with a range of around 50m and acts as a server on the job site. In other words, data can be recorded even in dead zones. As soon as the Vogele paver returns to an area with mobile phone coverage, it transmits all recorded data and parameters to the WITOS Paving server. Entering delivery notes: Delivery notes can be scanned using a QR code or recorded manually for entry into the app. This has the advantage that these slips are stored digitally as well as in analog form. |

JobSite Note App: Connecting to the paver's WLAN network is done by scanning a QR code on the paver's control panel display. The JobSite Note app can then be used to start the job and record job data. The daily paving rate is specifically planned. The app features intuitive menu navigation, so users can quickly familiarize themselves with the app, even without specific knowledge or in-depth training. |

|

Convenient paving control: WITOS Paving Docu continuously records the paved surface area, the amount of paving material, and uses this data to calculate the area density. Accurate recording and fast data analysis: This application allows recording and analyzing various paver and paving data including paving width, speed, and paving interruption times, as well as effective paving time. If the project is using Vogele RoadScan, the paving temperature can also be recorded and analyzed. Daily job reports: Include job site location data, such as deployment locations, and key paving parameters. If RoadScan is used, temperature measurement data compiled for the asphalt temperature is also included. At the end of a day, a PDF of the report can be automatically sent via email to selected recipients through the WITOS Paving server. |

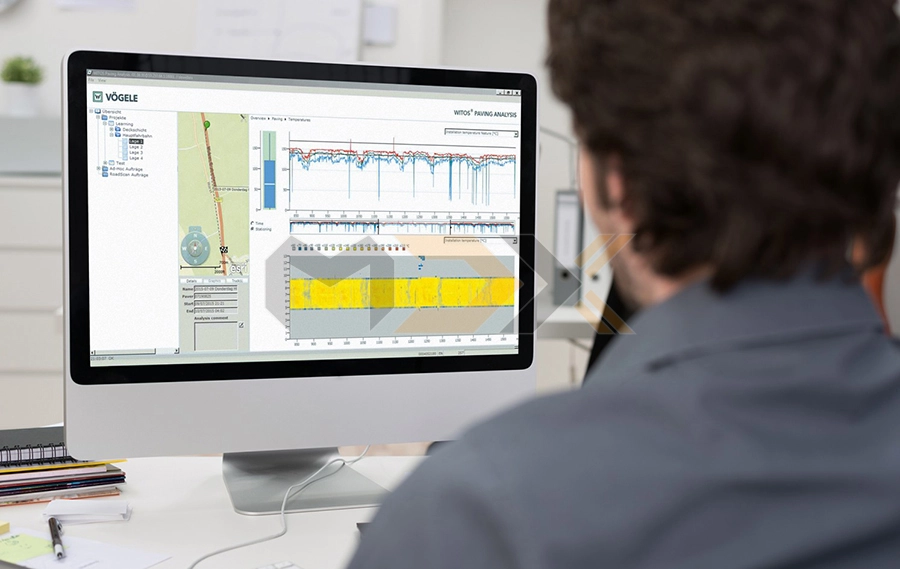

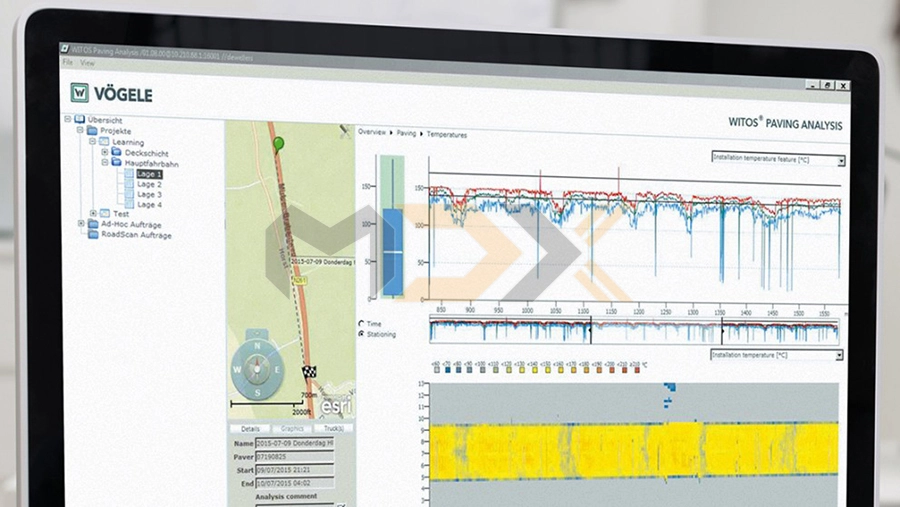

| WITOS Paving Analysis | |

|

|

| This module facilitates objective project evaluation by providing data for various assessments and analyses. Easy-to-understand and clearly arranged diagrams and charts allow the site manager or planning engineer to draw important conclusions from a completed project. |

If RoadScan is used, the temperature measurement data compiled from the asphalt temperature is transmitted along with the process data immediately after paving. Monitoring active job sites has never been easier or more convenient. Frequently asked questions in job site analysis: - Where did the mixing trucks unload the material? - What was the paving speed? - Where did the paver operator wait? - How many mixing trucks were on the job site? - How long were the waiting times, and can the number of mixing trucks be reduced? - What costs are incurred due to waiting times? The Analysis and Documentation module provides the necessary information to answer all of these questions. |

|

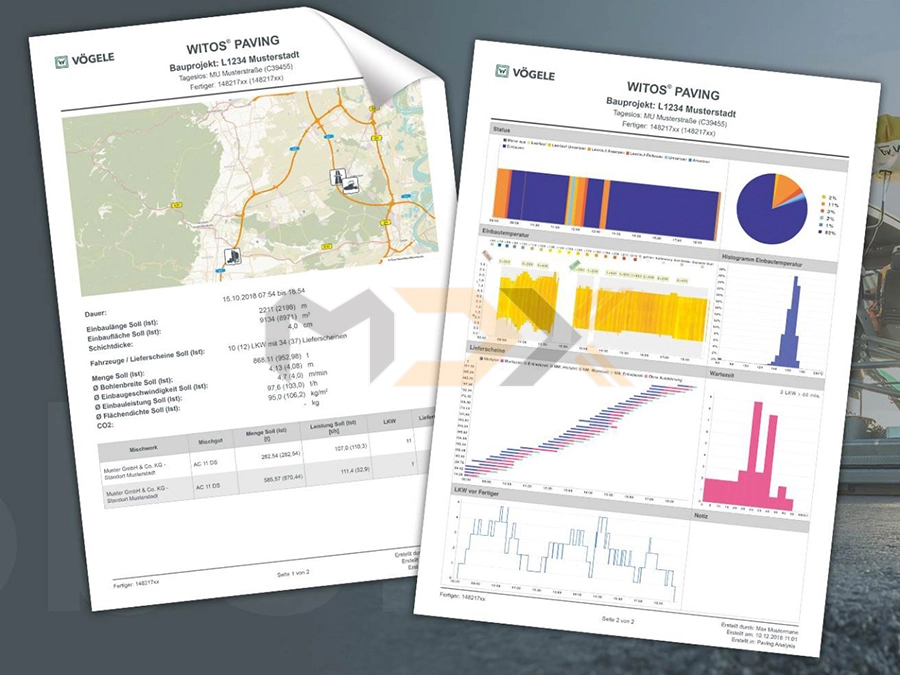

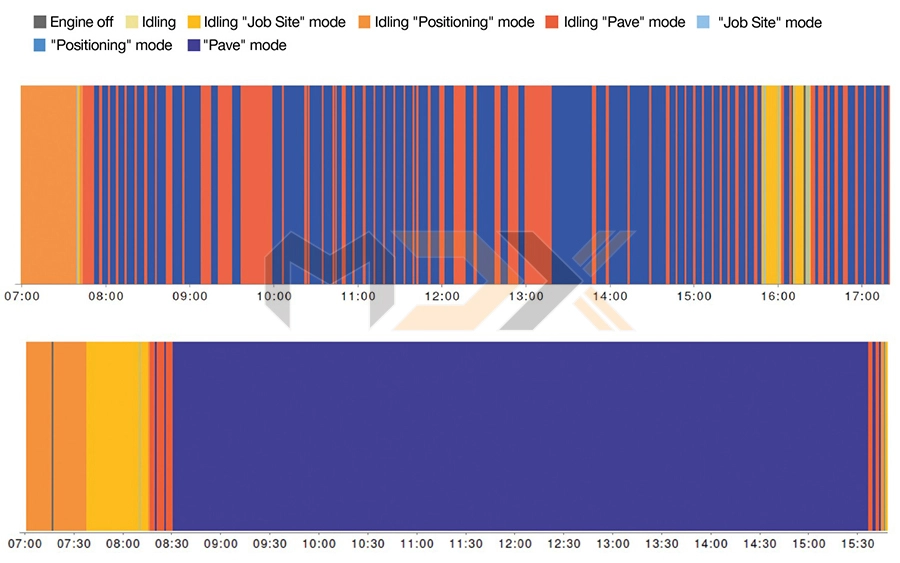

WITOS Paving Analysis has an interface that accepts HCQ data from Hamm rollers, allowing the compaction process to also be analyzed and optimized. Therefore, WITOS Paving Plus offers the option of detailed documentation of the entire process chain, from asphalt paving to compaction. Highlights of WITOS Paving Analysis: - Objective evaluation of projects based on informative diagrams and analyses. - Documentation of empirical values to promote a best-practice approach. - Examination of interruptions in the paving process to identify possible optimization measures for a continuous improvement process. - Evaluation of the paver's operating efficiency (downtime phases vs. production phases). - Precise documentation as proof of quality (when using the RoadScan system to measure asphalt temperature). - Daily job reports in PDF format can be sent via email. |

| Overview of Paving Parameters | |

|

|

|

Job-site Report At the end of a day's paving operations, or some other user-defined interval, the system automatically generates a job-site report. This report includes data on project progress (with a comparison of target/actual values), information on paving efficiency and the material truck delivery chain, as well as temperature measurement data (if RoadScan is used). All of this information is stored in the WITOS Paving Analysis module. The report can also be emailed as a PDF to relevant parties, such as the site manager. The first page of this report provides a summary of all the paving parameters. These include the job site location, time, paving performance data, mixing plant delivery performance, and more. |

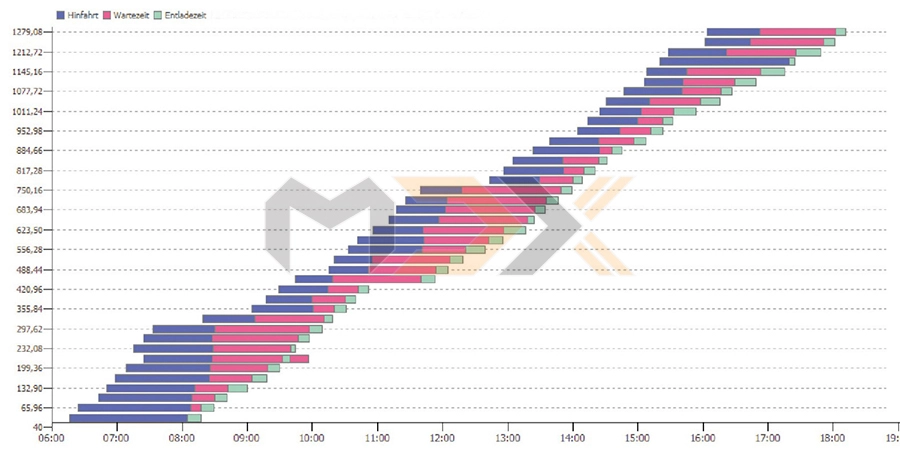

Paving Efficiency The starting point for optimizing job site operations is analyzing paving efficiency. Users need to be able to see how many hours of pauses and non-productive time a completed job had in order to identify potential for improvement in the value chain and initiate the necessary measures. In the example shown, it is possible to increase paving efficiency from 62% to 82%. Regular analysis of logistics processes and paving measures helps to improve operational efficiency, increasing economic efficiency for the customer. |

|

|

|

Material Truck Delivery Chain Transport logistics is a decisive factor in job site organization. If the delivery chain is running on time, the paver operator always has a sufficient supply of mix. The continuous flow of material avoids waiting times caused by machine stops, idling, repositioning, etc. The continuous paving process creates optimal conditions for maintaining a homogeneous mix. This ensures that the paved surface is perfectly prepared for subsequent rolling. The result is a durable road base with high load-bearing capacity. Comparing the arrival, waiting, and unloading times of the mixing trucks with the paving temperature data allows for the identification of weak points in the transport chain. Why was the paving material too cold? Did a mixing truck arrive at the job site too late? Or did it wait too long after arriving? These questions suggest approaches to optimize logistics. |

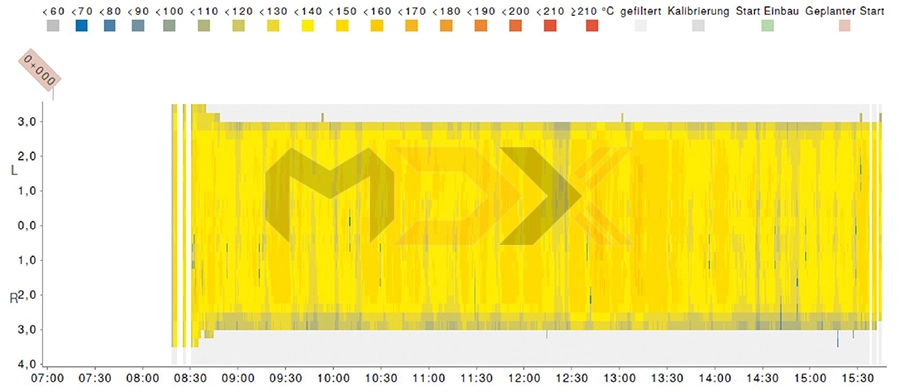

Paving Temperature Data Making quality measurable is one of the major challenges facing contractors and clients worldwide. In road construction, it is particularly important to verify that a constant paving temperature has been maintained. 1 This is because it is a key criterion for ensuring the quality and durability of the road. This is due to the fact that only a homogeneous layer can also be compacted evenly. The temperature range in the diagram shows a very homogeneous overall temperature. There are very few deviations into colder areas (blue), and these are more visible at the edges of the paved section. |

3. VOGELE ROADSCAN NON-CONTACT TEMPERATURE MEASUREMENT SYSTEM

|

Vogele's RoadScan non-contact temperature measurement system is an economical and innovative solution for the road construction industry. Making quality measurable is one of the major challenges facing contractors and clients worldwide. In road construction, continuous monitoring of the paving temperature is a crucial aspect. You can see the details of Vogele RoadScan through the article: HERE |