VIBRATION AND OSCILLATION BY HAMM - BASIC

Dynamic compaction with vibrating or oscillating rollers has proved particularly effective in earthworks, as it compacts the soil through the combination of vibrations from the roller drum and the weight of the roller.

Dynamic compaction with vibrating or oscillating rollers has proved particularly effective in earthworks, as it compacts the soil through the combination of vibrations from the roller drum and the weight of the roller.

Compacting a gravel layer in oscillation mode: This gentle method of dynamic compaction needs just a few roller passes to achieve high degrees of density. Trapezoidal studs on the drum produce impressions in the soil, increasing the total surface and enabling the soil to dry.

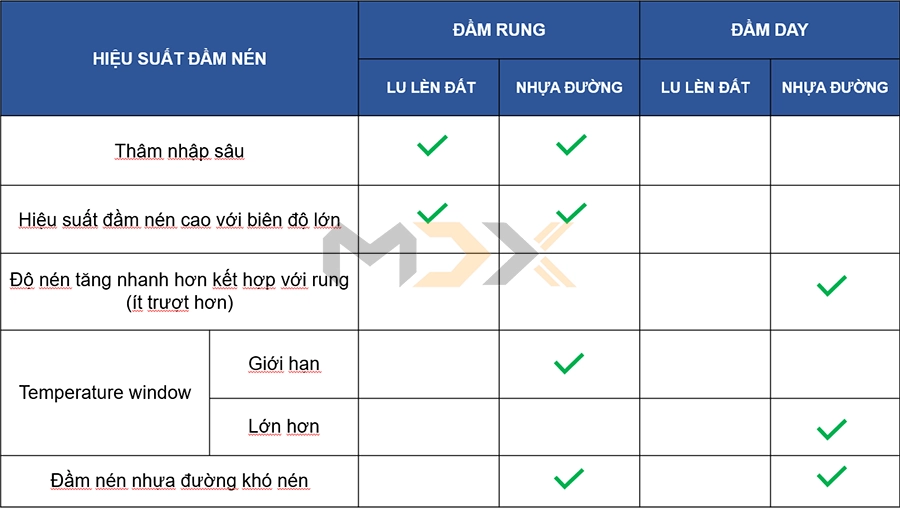

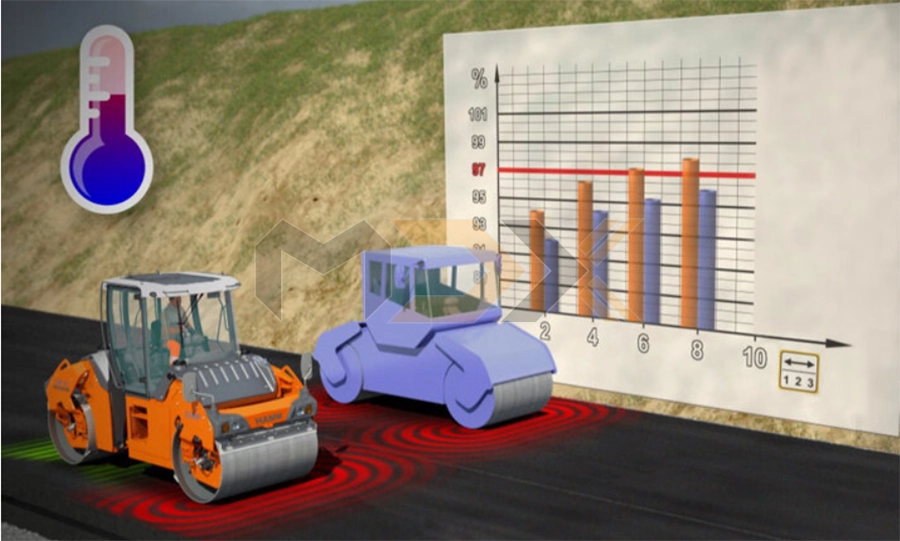

The intensity of compaction is governed by three influencing factors: displacement of the roller drum, meaning the amplitude of the vibration or oscillation, rate of recurrence of the vibration or oscillation, meaning the frequency, and duration, meaning the roller’s travel speed. When these parameters are set correctly, the specified density can be achieved in considerably less roller passes.

VIDEO SHARE BASIC KNOWLEDGE ABOUT VIBRATION AND OSCILLATION

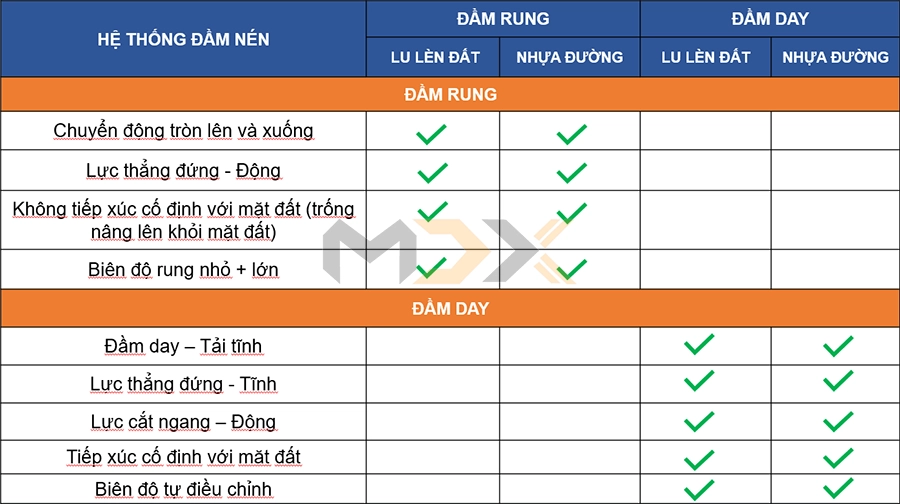

WHAT KINDS OF COMPACTION SYSTEMS ARE THERE?

Compaction systems:

- Static

- Dynamic: vibration and oscillation

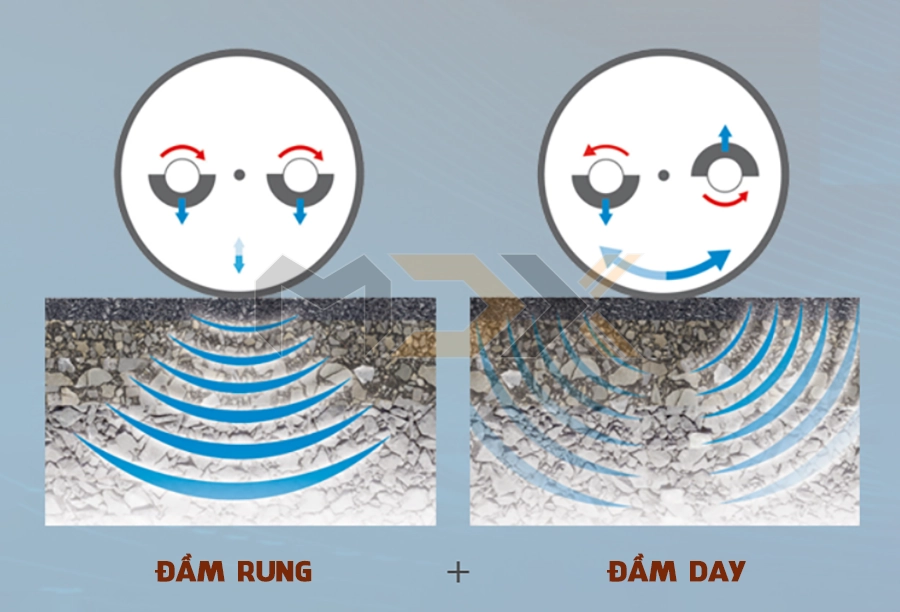

VIBRATION

HOW THE DRUM WORKS?

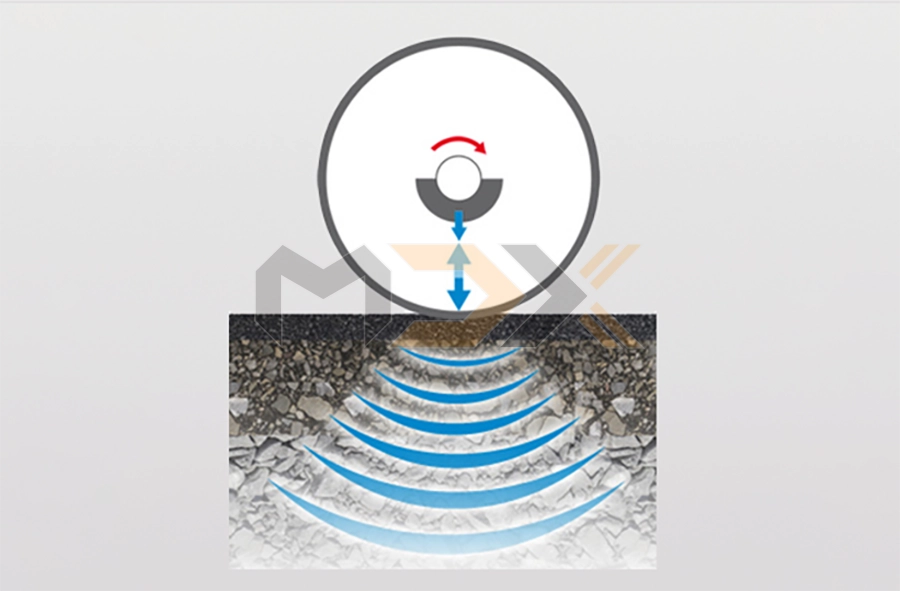

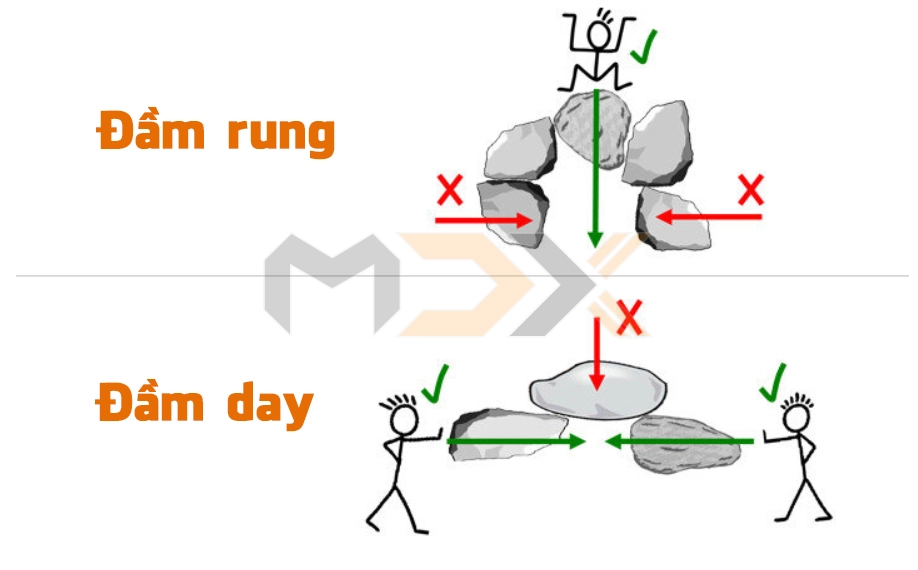

The drum moves in a circular motion that is induced by a rotating unbalanced mass. This causes the drum to impact the material being compacted and directs vertical centrifugal forces into the subsoil. Compaction can occur at large or small amplitudes.

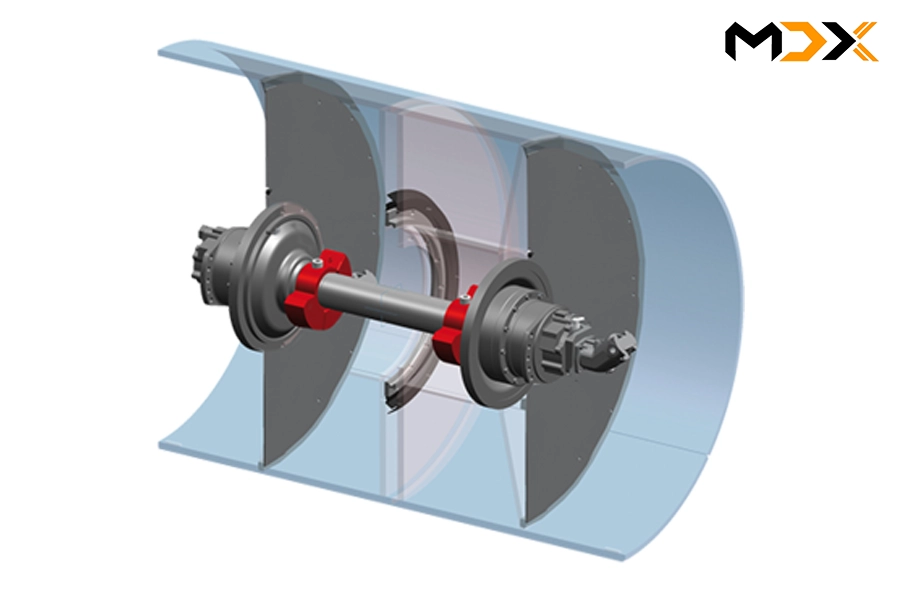

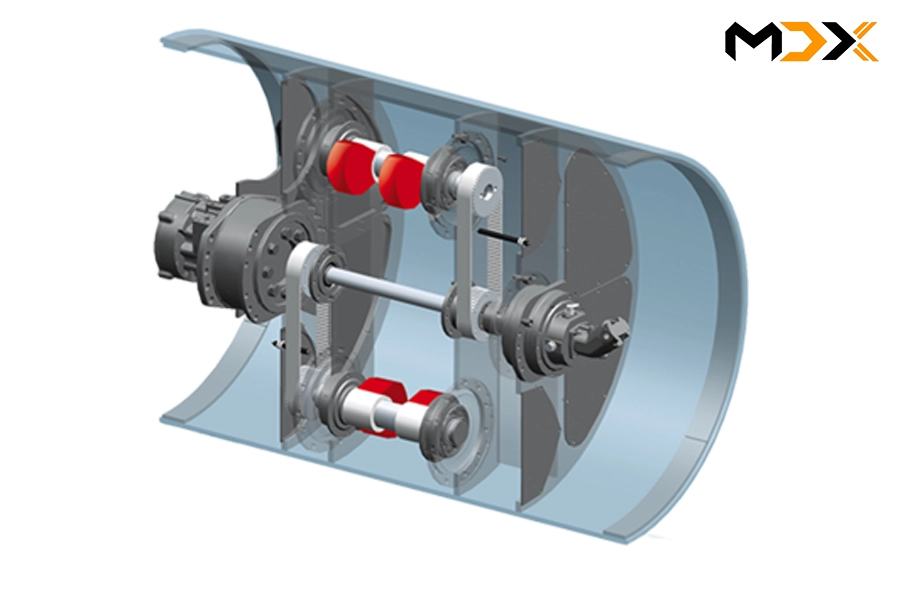

CROSS-SECTION OF A DRUM

The vibrating roller drum consists of an axle with one or two imbalance masses.

ANIMATION OF HOW IT WORKS

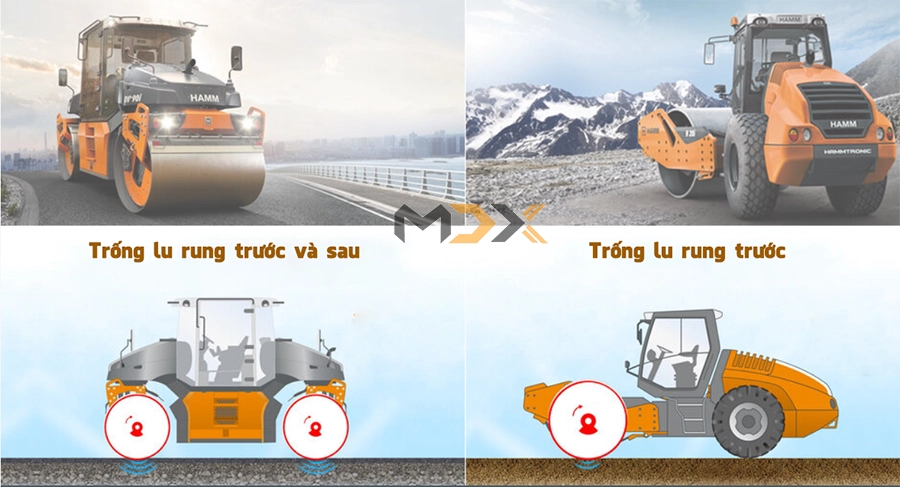

VIDEO FRONT AND REAR VIBRATING ROLLERS DRUMS

View products of Tadem roller at: HERE

VIDEO FRONT VIBRATING ROLLER DRUM

View products of Compator roller at: HERE

FIELDS OF USE FOR VIBRATORY COMPACTION

- Classical compaction system for virtually any asphalt and earth application.

- Compaction of thick layers.

- Deep penetration in earth work

OSCILLATION

HOW THE DRUM WORKS?

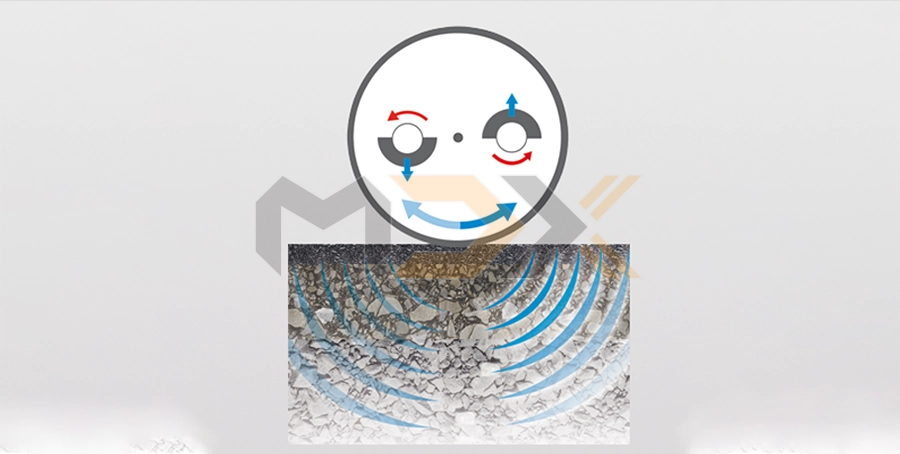

Two eccentric imbalance masses - aligned at 180° from each other - rotate synchronously in the same direction. This imparts a rapid back-and-forth rotational movement on the drum. As it rotates, the drum does not lift up from the subsoil. It remains in constant contact with the subsoil, causing static compaction in addition to the dynamic shearing forces. The oscillation drum is made of extremely wear-resistant steel in order to increase its service life.

CROSS-SECTION OF A DRUM

Two eccentric (external) axles are driven by a centre axis using toothed belts. The imbalance masses are aligned opposite each other (180°).

ANIMATION OF HOW IT WORKS

ANIMATION OF HOW IT WORKS

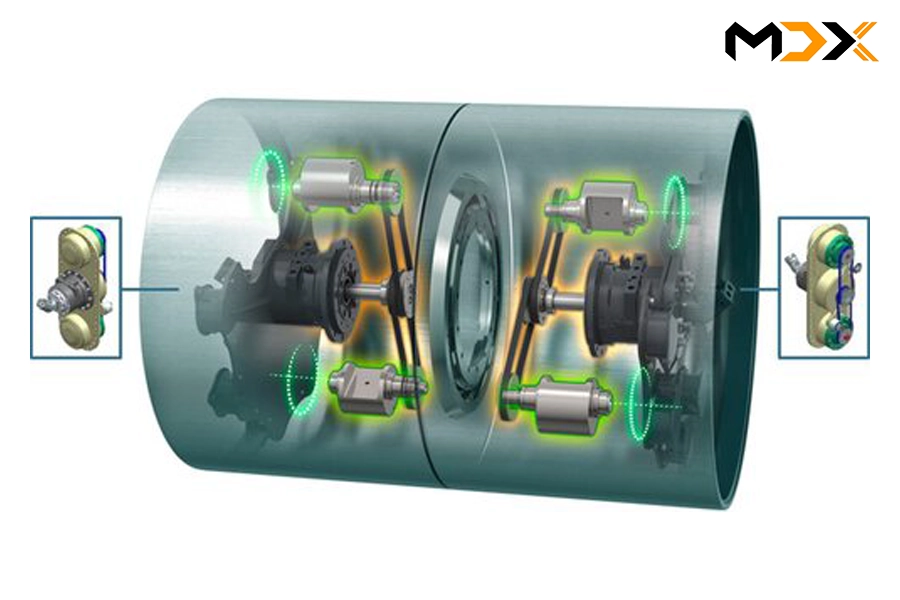

SPLIT OSCILLATION

The principle of HAMM's split oscillation:

Two completely mechanically independent oscillation units work in the split drum. An integrated control system quickly and precisely adjusts the position of the unbalances to the position of the drum halves. Synchronisation is effected by means of a digital hydraulic system. It ensures that both drum halves - despite their different rotational speeds in curves - oscillate synchronously at all times. This minimizes the shear stress in the asphalt to be compacted.

ADVANTAGES FOR CUSTOMERS WITH SPLIT OSCILLATION AT A GLANCE

- Experience for over 35 years with oscillation.

- Same compaction technology as with the proven HAMM oscillation.

- Higher compaction quality in curves and roundabouts.

- Compaction of materials sensitive to displacement (e.g. stone mastic asphalt or polymer-modified mixes).

- No change for the driver in terms of application (driver does not need to be trained).

- Maintenance-free belt drive through highly wear-resistant steel.

- Avoidance of material displacement and surface cracks in the asphalt by minimizing the shear stress in the asphalt.

- Optimum compaction results due to perfect synchronization.

- Low noise emissions.

- Economic and efficient compaction due to higher compaction

ONE MECHANICALLY INDEPENDENT OSCILLATION UNIT PER DRUM HALF

SOME WAYS THAT OSCILLATION SUPPORTED COMPACTION IS USED

- Compaction of difficult-to-compact asphalt.

- Compaction of thin layers.

- Compaction of seams.

- Compaction of areas sensitive to vibration.

- Compaction at low temperatures

Some models of Hamm Tandam rollers equipped with oscillation:

- Hamm HD O75V: https://mdx.vn/xe-lu-hamm-hd-o75v

- Hamm HD O90V: https://mdx.vn/xe-lu-hamm-hd-o90v

VIO

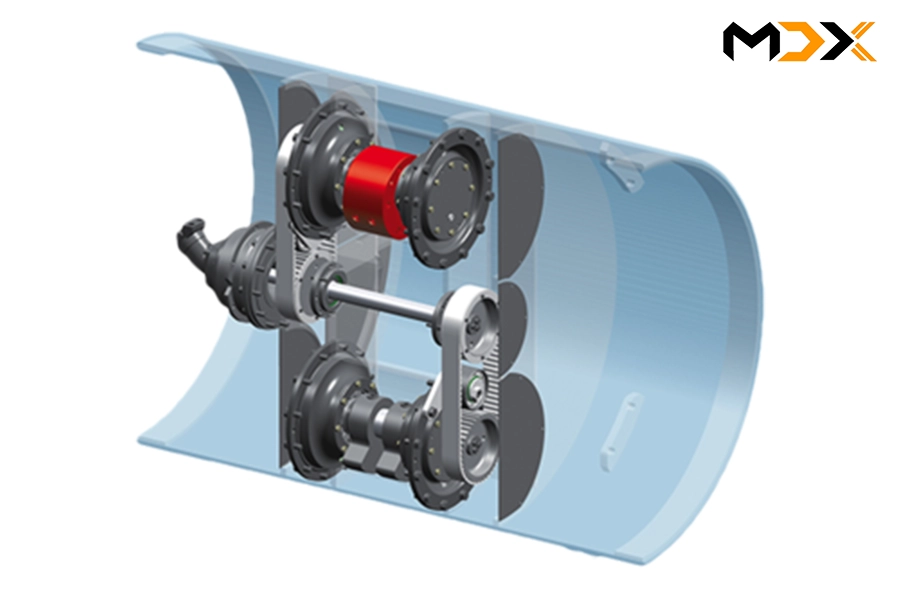

HOW VIO-DRUMS WORK

VIO stands for the combination of Vibration and Oscillation. The system is available only for earth compactors.

IMBALANCE SYSTEM ON VIO

The imbalance system combines both dynamic compaction systems (vibration and oscillation) in a single drum. The VIO-drum can operate either as a vibratory or an oscillation drum. You cannot use both systems simultaneously.

ANIMATION OF HOW IT WORKS

CONTROLLING THE VIO-DRUM

Two systems are brought together in the VIO-drum: oscillation and vibration. The operator actuates a switch to switch from vibration to oscillation.

Switching changes the centre shaft's direction of rotation. It is not possible to use both system simultaneously.

SOME WAYS THAT VIO COMPACTION IS USED

- Surface compaction (except sand).

- Areas sensitive to vibration, e.g. above gas lines.

- Compaction in urban areas

Some models of Hamm Compactor equipped with VIO drum:

COMPACTION IN EARTH WORK

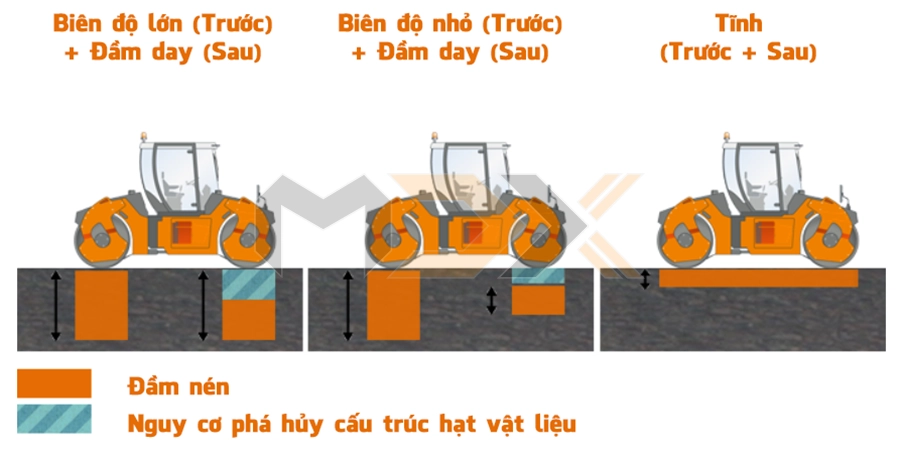

Which compaction steps are recommended with the various compaction systems when compacting earth work?

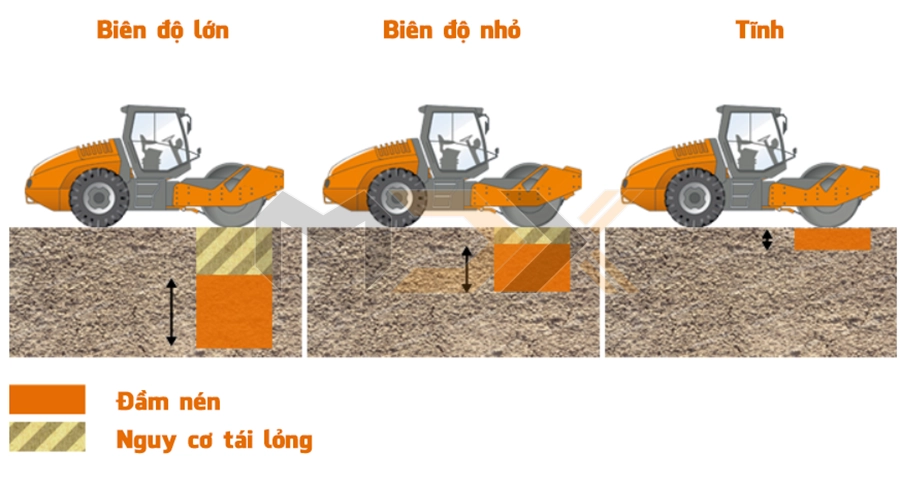

- Vibration: first compact with a large amplitude (1), then use a small amplitude (2), and then static (3).

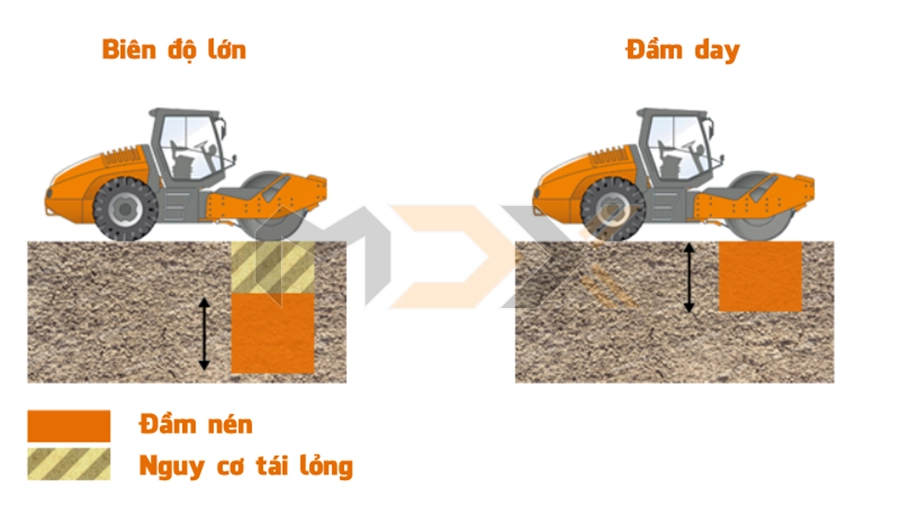

- VIO: first compact with vibration (1), then with oscillation (2).

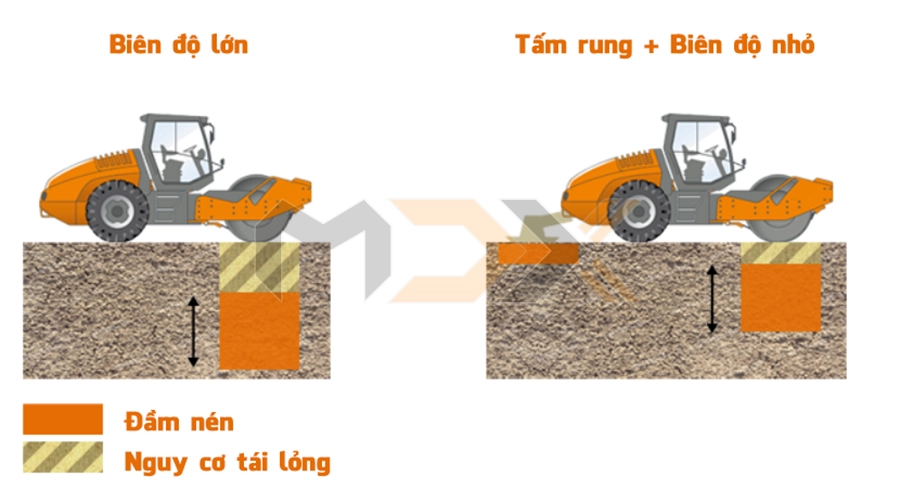

- Vibration Plate: first compact with vibration (large amplitue) (1), then with vibration (small amplitude) (2) and similataneous use of the vibration plate.

COMPACTION STEPS FOR ASPHALT CONSTRUCTION

Which steps are recommended when compacting asphalt construction?

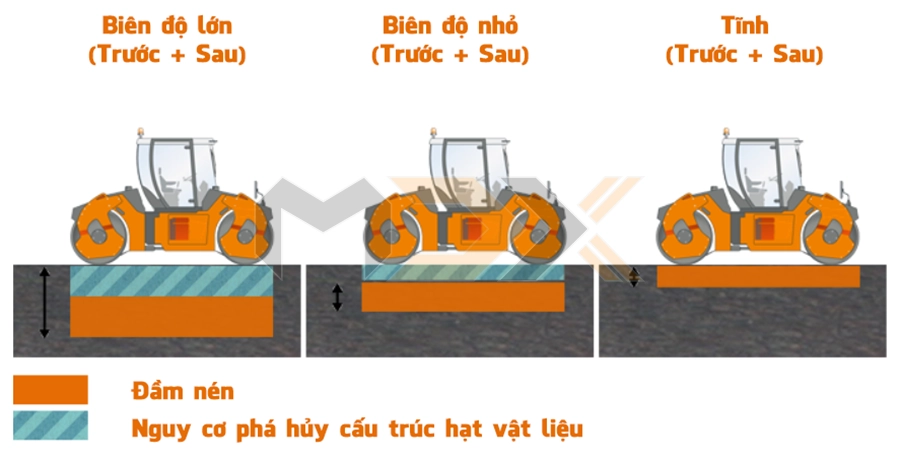

- Double vibration: when compacting thicker layers, first compact with a large amplitude (1), then use a small amplitude (2) and then static (3). When compacting thinner layers, skip step 1.

- Vibration + oscillation: when compacting thicker layers, first compac with a large amplitude and oscillation (1), then use a small amplitude and oscillation (2), and then static (3). When compacting thinner layers, skip step 1.

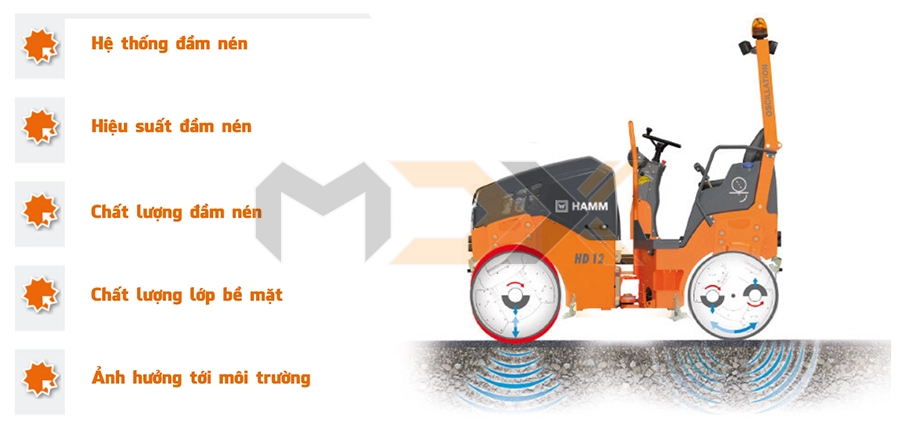

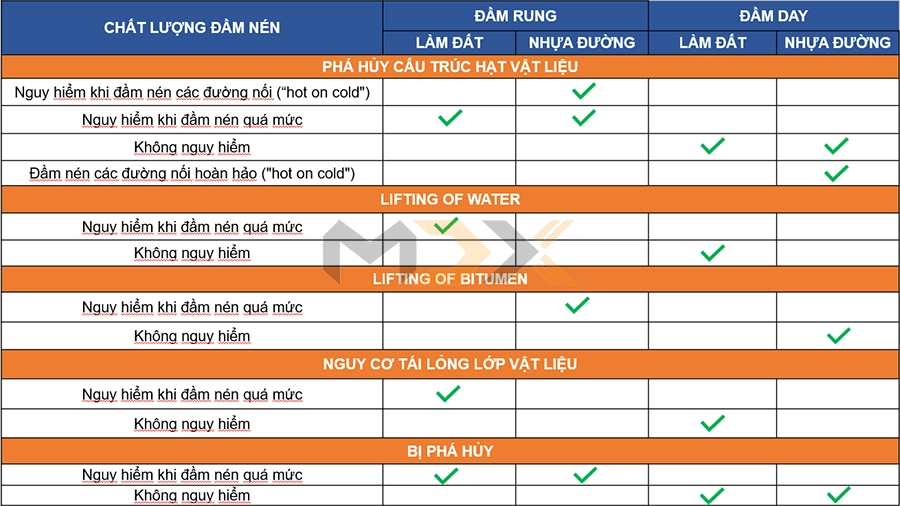

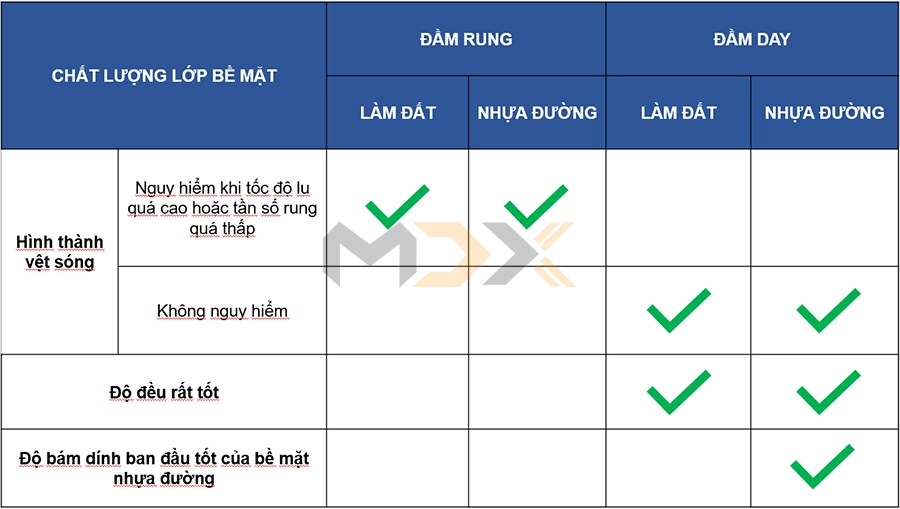

HOW ARE VIBRATION AND OSCILLATION DIFFERENT FROM EACH OTHER?

MAIN BENEFITS OF OSCILLATION - COMPACTION WITH VIBRATION IN COMBINATION WITH OSCILLATION

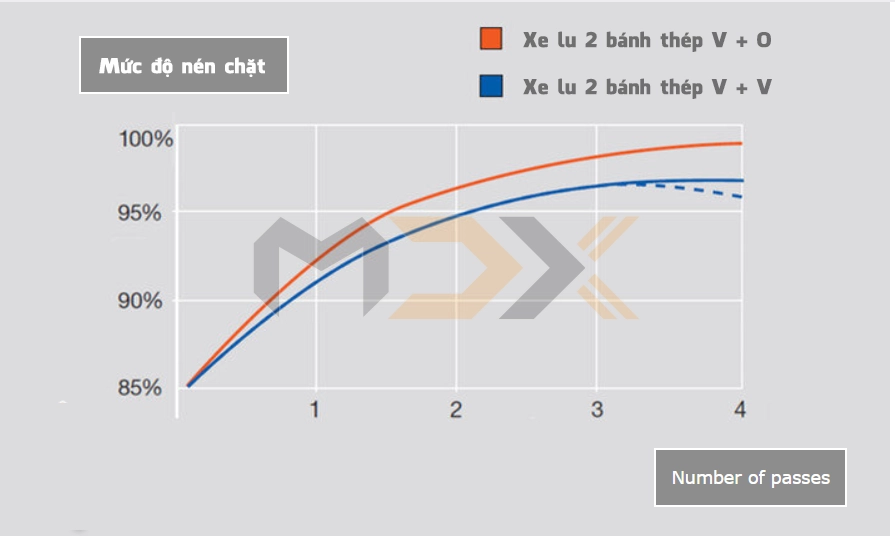

Oscillation has two large benefits.

1. Compaction increases faster with vibration when simultaneously combined with oscillation (V+O).

THE BENEFITS OF COMPACTION WITH V+O

- Faster and continuous increase of compaction.

- The level of compaction increases continuously through oscillation.

- No re-loosening or grain destruction occurs.

- Fewer passes when compacting with V+O than with V+V

MAIN BENEFITS OF OSCILLATION - OSCILLATION DISPERSION

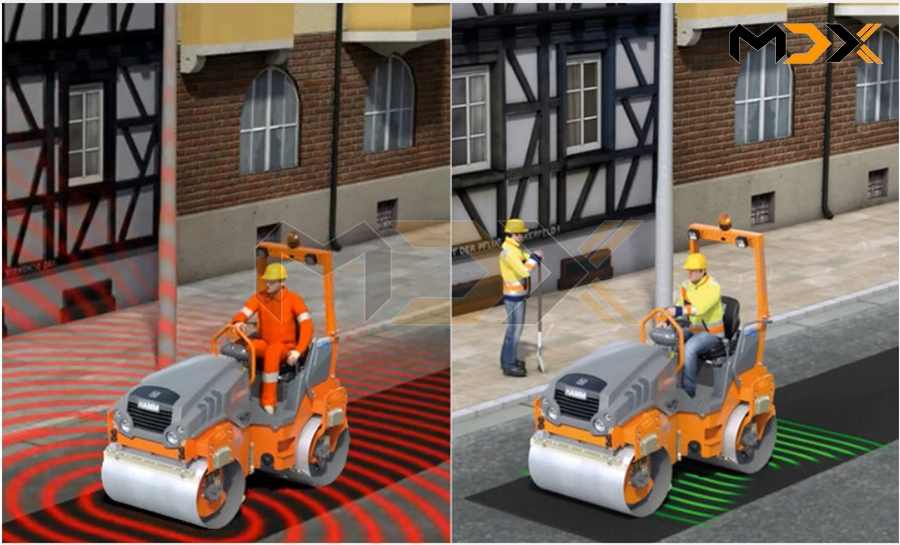

2. Minimal environmental vibrations

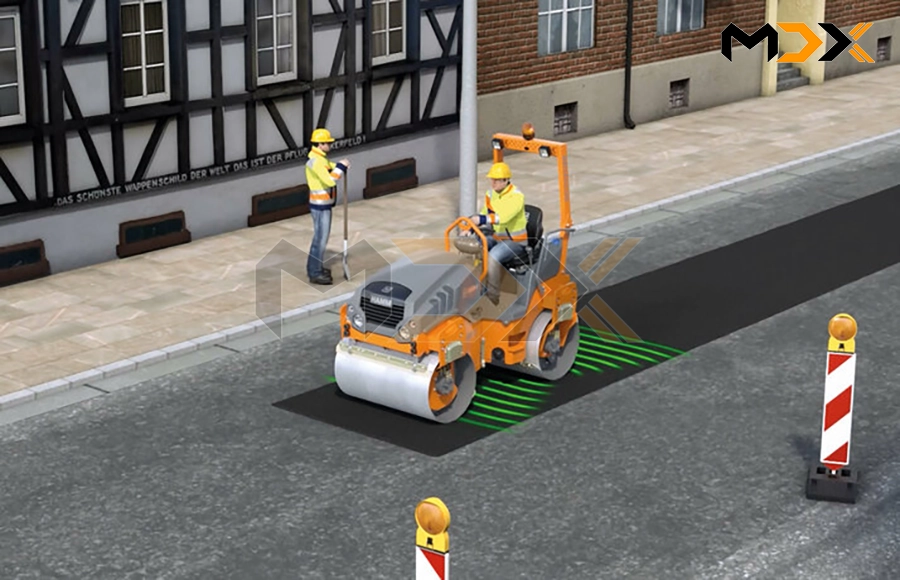

Spreading of vibrations with vibration (left) and oscillation (right).

The minimal ground motion of oscillation makes it ideal for use around vibration-sensitive buildings and bridges.

News Related

Tags: Oscillation, oscillation drum, soil compactor, Tandem roller