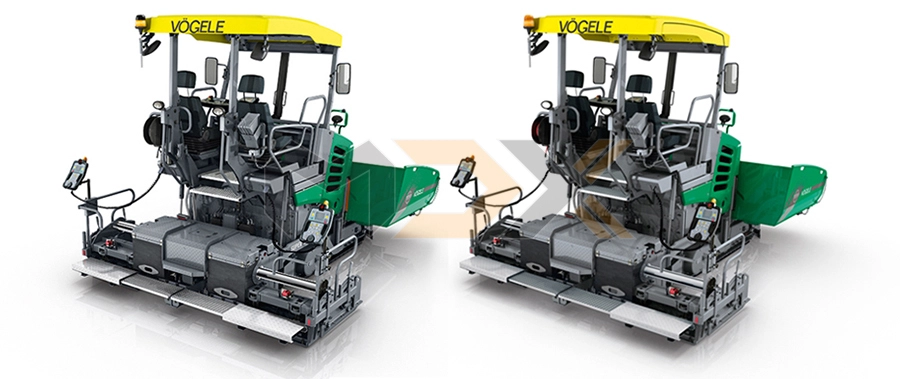

THE 6 HIGHLIGHTS OF VOGELE SUPER 1100-3 AND SUPER 1300-3

Vogele Super 1100-3 and Super 1300-3 are compact but still possess Vogele's most advanced design and technology. From optimal fuel consumption, simple and efficient operation with ErgoBasic to excellent paver performance. These are 2 models that are worth considering investing in for your business. The following article shares with readers the 6 most outstanding advantages of the Vogele S1100-3 and S1300-3. We hope you enjoyed this article!

VIDEO INTRODUCE VOGELE SUPER 1100-3 AND SUPER 1300-3

SOME IMPORTANT SPECIFICATIONS

| Specifications | S1100-3 | S1300-3 |

| Engine Power | 80 kW at 2 000 rpm | 80 kW at 2 000 rpm |

| Weight | 10 t | 10.6 t* |

| Basic Width | 1.85 m | 1.85 m |

| Pave width, max. | 4.2 m | 5 m |

| Laydown rate, max. | 300 t/h | 350 t/h |

| Layer thickness, max. | 20 cm | 25 cm |

| Pave speed, max. | 30 m/min | 30 m/min |

* Pave width 3,4m: 10,6t / 5m: 11,6t

View more at: HERE

THE 6 HIGHLIGHTS OF VOGELE SUPER 1100-3 AND SUPER 1300-3

1. COMPACT PAVERS FOR A LARGE RANGE OF APPLICATIONS

Lean machine design without protruding edges and a compact overall length of 4.95m. Paver easily gets in or out of confined working areas as push-rollers fold up together with the hopper sides. The hardtop of glass fibre reinforced polymer material can be folded down in a few swift moves for transport. "AutoSet Basic" function for quick and safe repositioning of the paver on the job site.

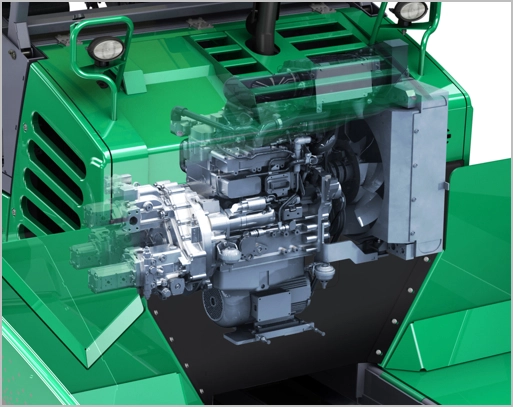

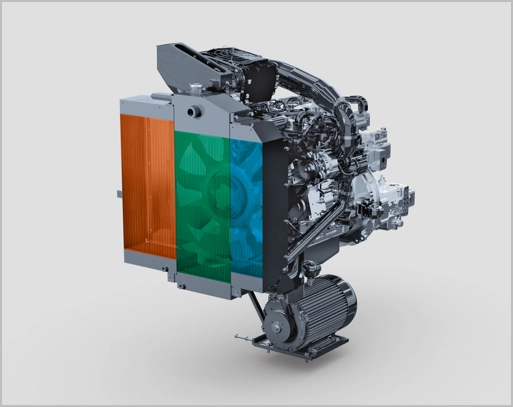

2. POWERFUL DEUTZ DIESEL ENGINE

|

Modern, powerful Deutz 4-cylinder diesel engine with ECO Mode for worldwide use. Exhaust emissions standards: 4 and EPA Tier 4f* as well as 3a and EPA Tier 3** engine output: - 74,4kW at 2,000 rpm - 68,7kW at 1,600 rpm (ECO Mode) * Europe / USA / Canada / Japan ** All other countries |

|

|

|

| The powerful three-phase AC generator ensures that the compacting systems heat up quickly. | The large cooler assembly provides for optimum cooling even when operating at full load, thus extending the service life of the paver systems. |

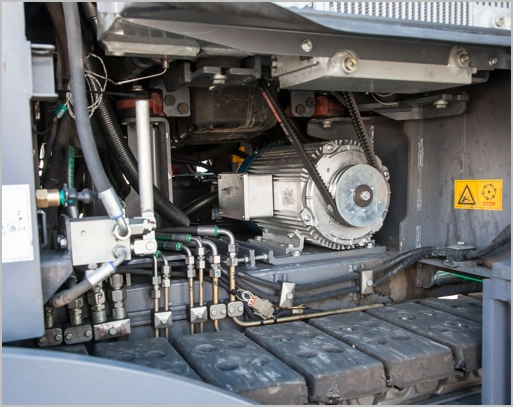

| Outstanding efficiency is achieved by high-quality separate hydraulic drives operating in closed circuits |  |

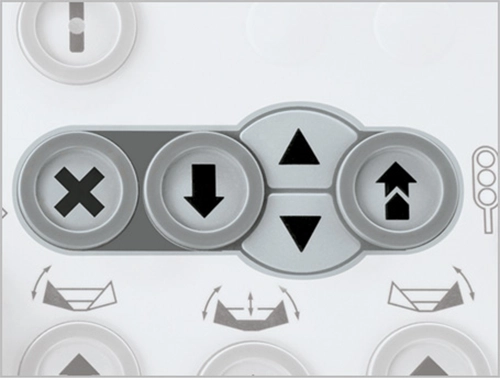

3. AUTOSET BASIC" REPOSITIONING FUNCTION

"AutoSet Basic" is particularly useful if the paver has to be repositioned frequently on a job site. Various settings are saved when the Execute button is pressed. These settings are retrieved when the button is pressed again after repositioning the paver. Advantages of "AutoSet Basic":

- Quick and safe repositioning of the paver on the job site

- Prevents damage to the augers and deflectors in front of the crawler tracks

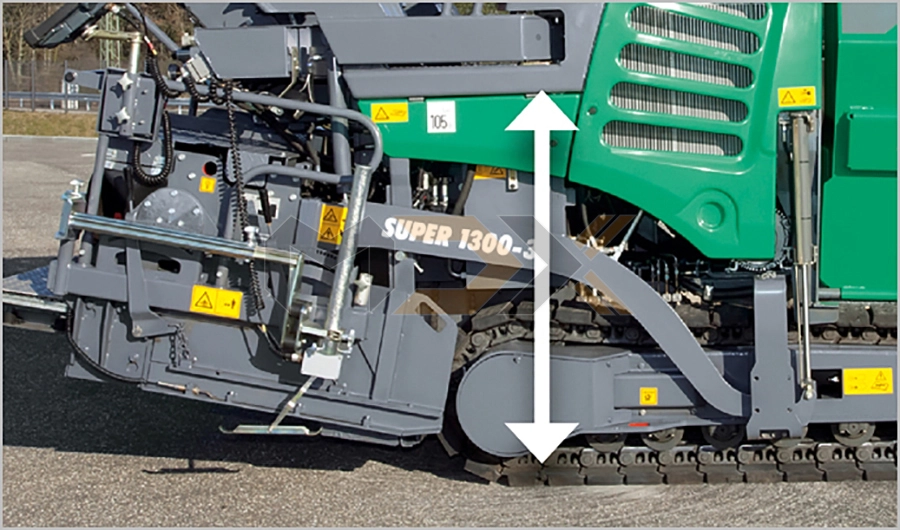

The "AutoSet Basic" function is activated simply by pressing the Execute button: Raise / lower screed, Raise / lower auger, Brief reversing of the conveyors, Raise / lower deflectors in front of the crawler tracks, Raise front of material hopper

"AutoSet Basic" repositioning function – what is the difference between "AutoSet Basic" and "AutoSet Plus"?

The "AutoSet Plus" repositioning function sets the screed tow point rams and auger to the stored position. In addition, paver and screed settings can be stored as "AutoSet Plus" paving programs and reactivated when required."AutoSet Basic", on the other hand, moves the auger to its mechanical limit position. The screed tow point rams are not adjusted, nor is the screed locked and unlocked.

AutoSet Basic" Repositioning Function

Raise / lower screed

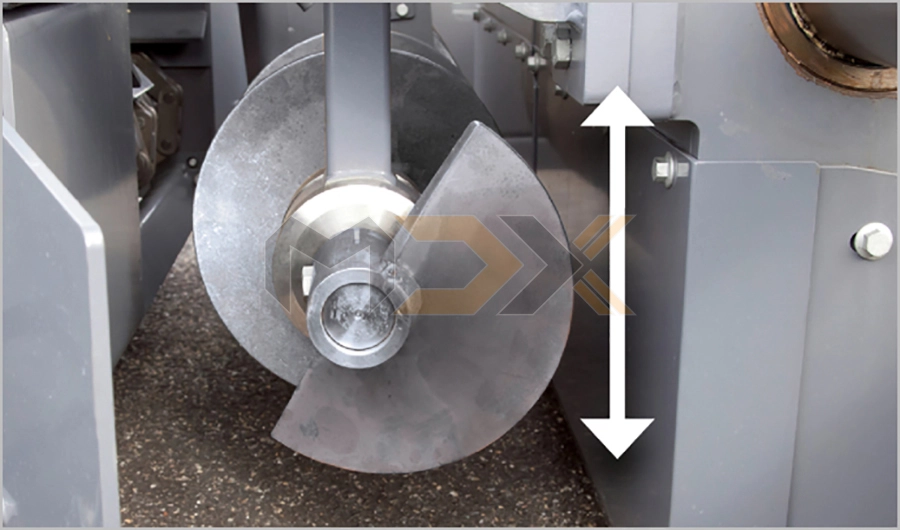

Raise / lower auger

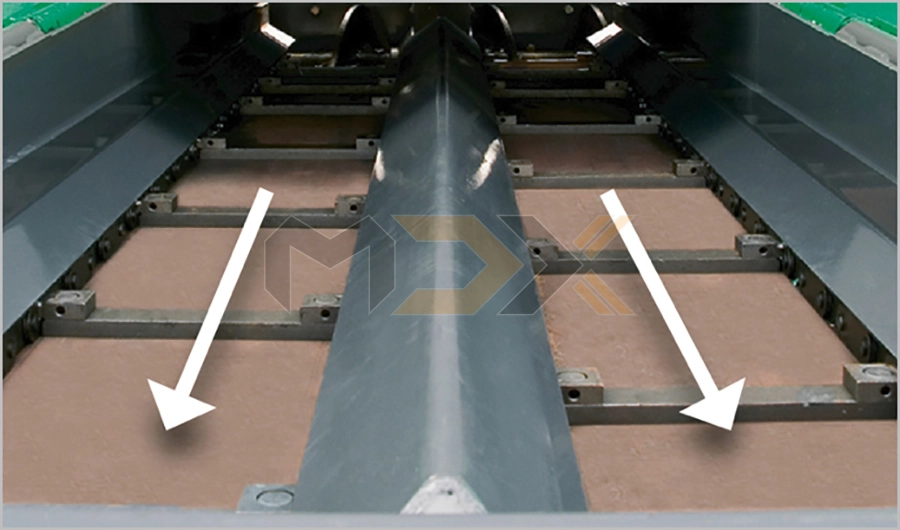

Brief reversing of the conveyors

Raise / lower deflectors in front of the crawler tracks

Raise front of material hopper

VIDEO AUTOSET BASIC - S1100-3 - S1300-3

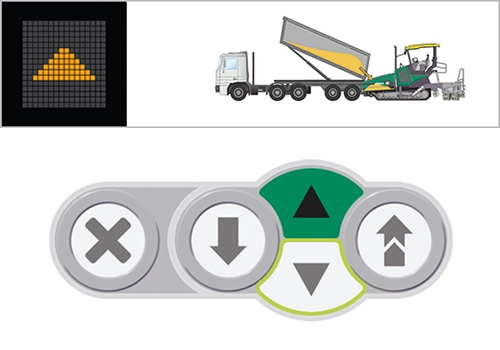

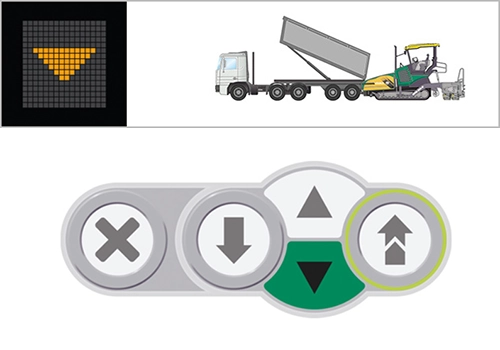

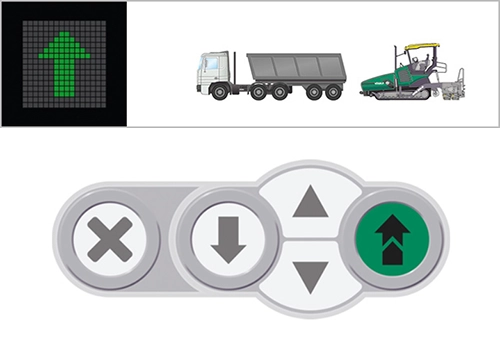

4. PAVEDOCK ASSISTANT

“PaveDock Assistant” is the communication unit between the paver operator and the feed vehicle driver. It allows particularly fast and reliable transfer of mix to the paver. The “PaveDock Assistant” components and process will now be explained in greater detail.

| The Components | |

|

|

| The control elements on the ErgoPlus paver operator's console. | The two signal lights mounted on the paver's hardtop indicate to the driver of the feed vehicle what needs to be done. |

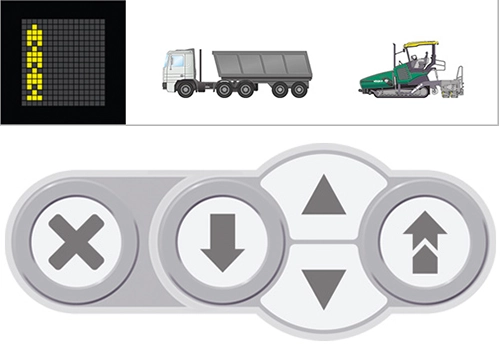

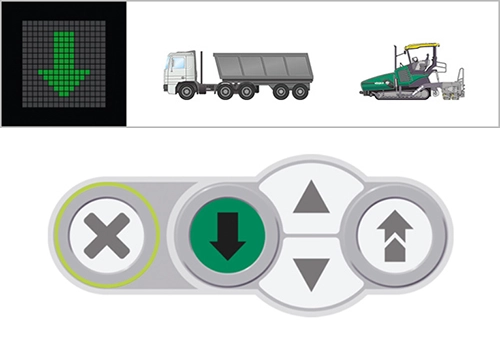

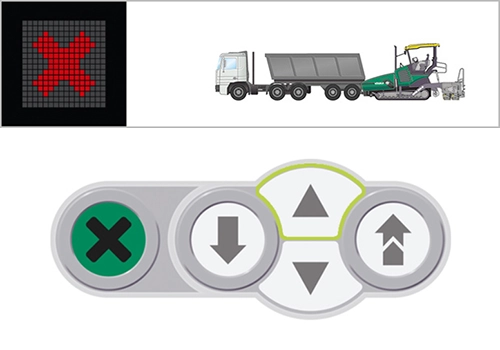

| The Process

The “PaveDock Assistant” facilitates communication between the paver operator and the driver of the feed vehicle. The paver operator first presses the appropriate button and the signal light is then activated. |

|

|

|

| The yellow line on the signal light indicates that the paver is moving. This symbol may appear in combination with all displays. |

Paver moving: This symbol may appear in combination with all displays. Dock: Lorry drives up to the paver and docks. |

|

|

|

Paver moving: This symbol may appear in combination with all displays. 1. Dock: Lorry drives up to the paver and docks. 2. Stop: Lorry must halt. It has docked. |

Paver moving: This symbol may appear in combination with all displays. 1. Dock: Lorry drives up to the paver and docks. 2. Stop: Lorry must halt. It has docked. 3. Raise dump box: Lorry raises the dump box. |

|

|

| Hạ thùng: Báo tài xế hạ thùng. |

Paver moving: This symbol may appear in combination with all displays. 1. Dock: Lorry drives up to the paver and docks. 2. Stop: Lorry must halt. It has docked. 3. Raise dump box: Lorry raises the dump box. 4. Lower dump box: Lorry lowers the dump box. 5. Drive off: Lorry drives away from the paver. |

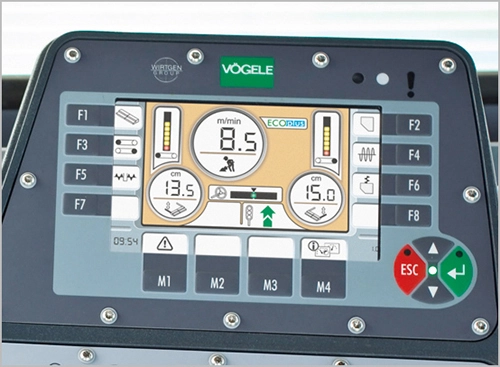

5. ERGOPLUS 3

|

|

| Colour display with a bright high-contrast display. | Backlit, language-neutral symbols on the operator's console for working in the dark and at twilight. |

|

|

| Glass side panelling protects the operator from the wind and rain. | “SmartWheel” for precise screed width control. |

|

|

| High-power LEDs on the screed console and material flow sensors for illuminating the area surrounding the screed. | Screed footstep and walkway allow operators to work safely and ergonomically. |

|

|

| “PaveDock Assistant” for perfect communication on delivery of the material. | “AutoSet Plus” relocation function for moving the paver quickly and safely at the touch of a button. |

|

|

| Crown adjustment at the press of a button for fast and direct access. |

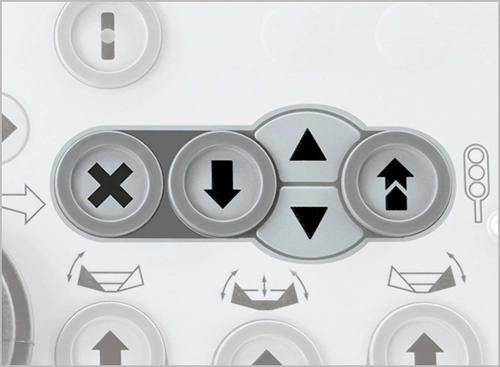

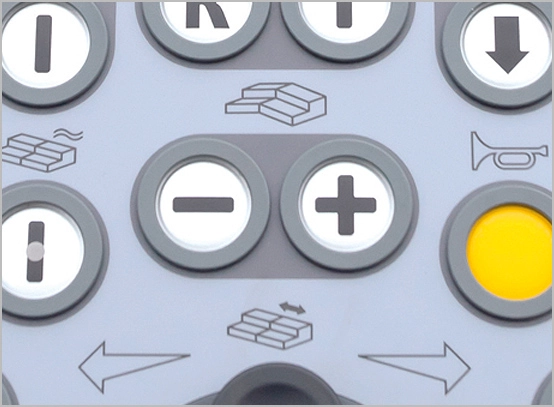

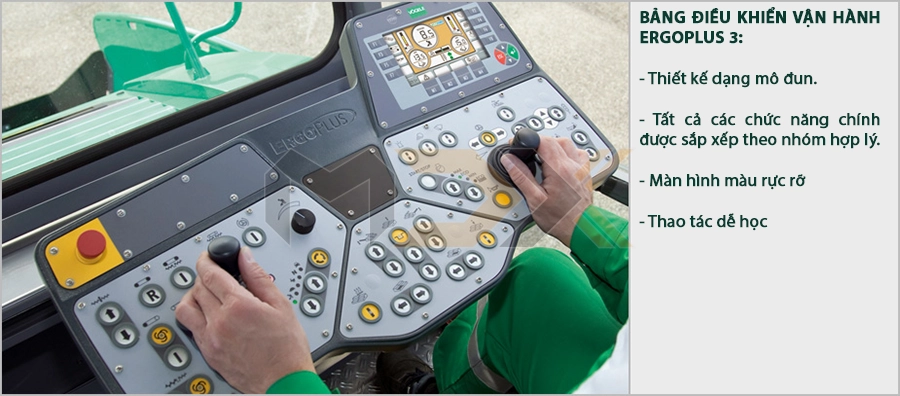

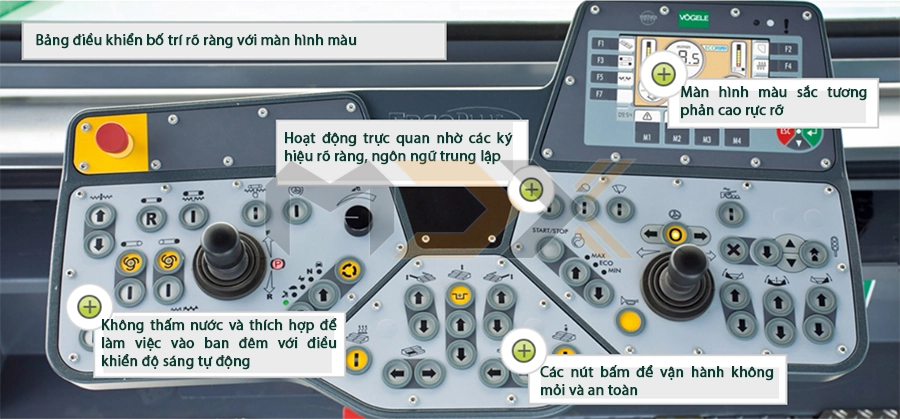

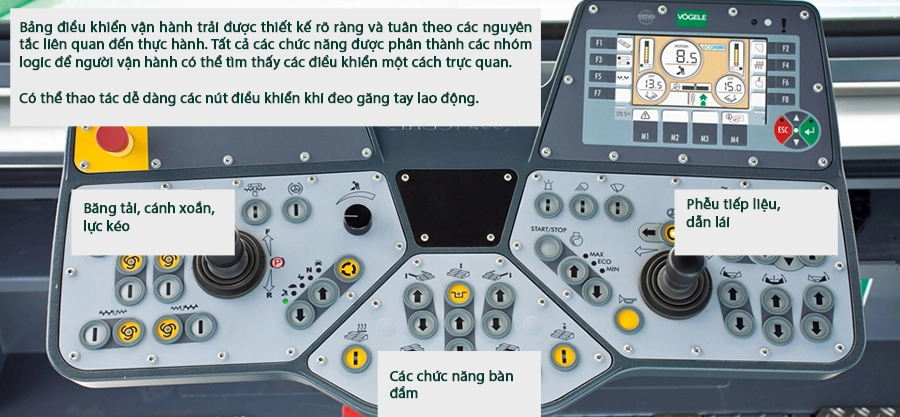

- ErgoPlus 3 paver operator's console: modular construction, all main functions arranged in logical groups, brilliant colour display, operation is easy to learn.

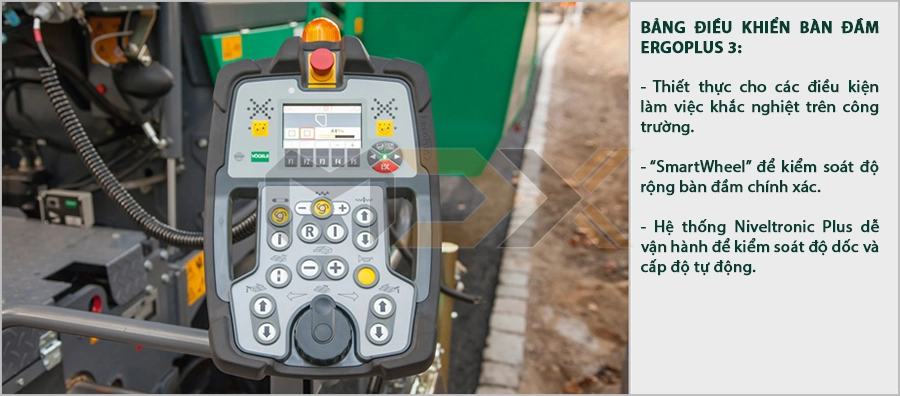

- ErgoPlus 3 screed console: robust for tough working conditions on site, “SmartWheel” for precise screed width control, easy-to-operate Niveltronic Plus system for automated grade and slope control

- Ergonomic workstations: clearly and neatly laid out operator's platform, glass side panelling affords protection from the wind and rain, hardtop for optimum protection against rain and sun, operator's seat and console can be adjusted separately, safe screed access with low footsteps

Operator's Platform

- Excellent all-round visibility: Unobstructed view of all crucial areas on the paver, such as the material hopper, steering guide and screed. It allows the paver operator to closely monitor the feeding process, for example. The seat arrangement and platform design provide an excellent view of the auger tunnel. As a result, the operator is able to monitor the head of mix in front of the screed at all times.

Video – ErgoPlus All-Round View

- Working comfort: The seat and console on the operator's platform are separately adjustable. The paver operator's console can be displaced across the full width of the operator's platform, swung out to the side and tilted. Side panelling affords effective protection from the wind and rain. When working with the seat swung out, the operator's console also swivels out. This ensures that an ergonomically optimum sitting position is guaranteed at all times.

Video – ErgoPlus Paver Operator's Console

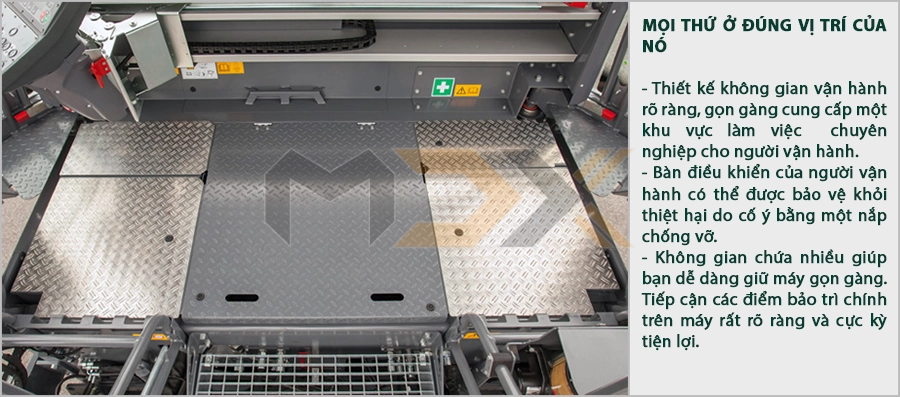

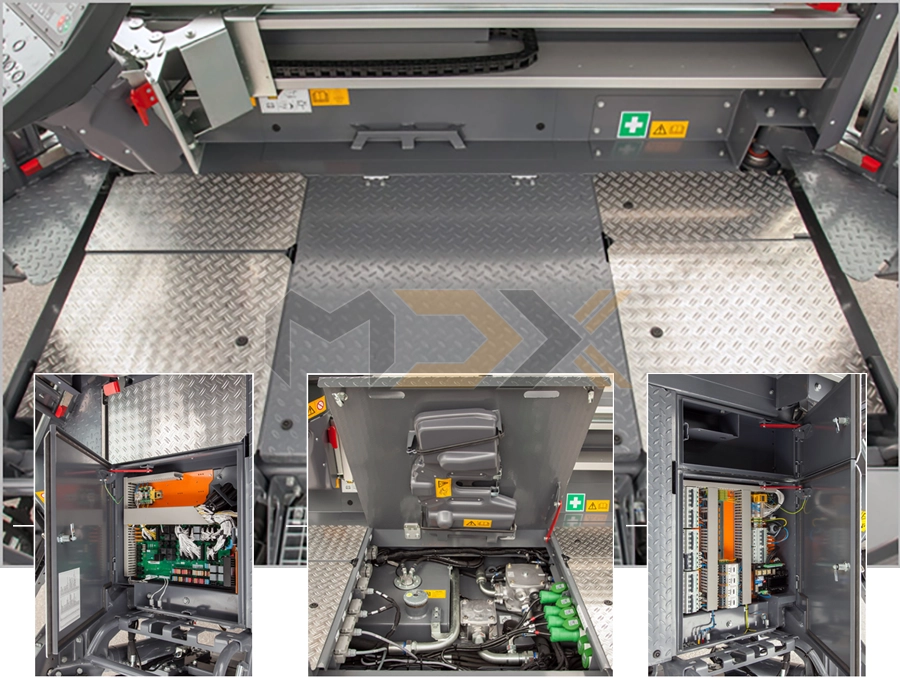

- Everything in its place: The clearly structured, neat operator's platform provides a professional workstation for the operator. The operator's console can be protected from wilful damage by a shatter-proof cover. Plenty of stowage space makes it easy to keep the machine tidy. Access to the key service points on the machine is very clear and extremely ergonomic.

- Hardtop gives excellent protection: The modern hardtop of glass fibre reinforced polymer material shelters the operator from rain and sun. The hardtop, including exhaust pipe, lifts up and lowers down quickly and effortlessly by means of a manually operated hydraulic pump. Wide sunshades which extend easily give the operator optimum protection when the seat is moved out. Six powerful working lights are built into the hardtop. As they are placed particularly high up, they provide excellent illumination for the job site.

Video – ErgoPlus Hardtop

ErgoPlus 3 – Screed

Paver Operator's Console

Screed Operator's Console

1. High-contrast colour display

2. “SmartWheel” for quick and infinitely variable screed width control

3. Screed console with crown control at the push of a button

4. Designed for use at night with backlit buttons. High-power LED illumination for optimum view of the side plates. Sturdy and weatherproof.

Video – ErgoPlus Screed Operator's Console

ErgoPlus 3 – Screed Operator's Console

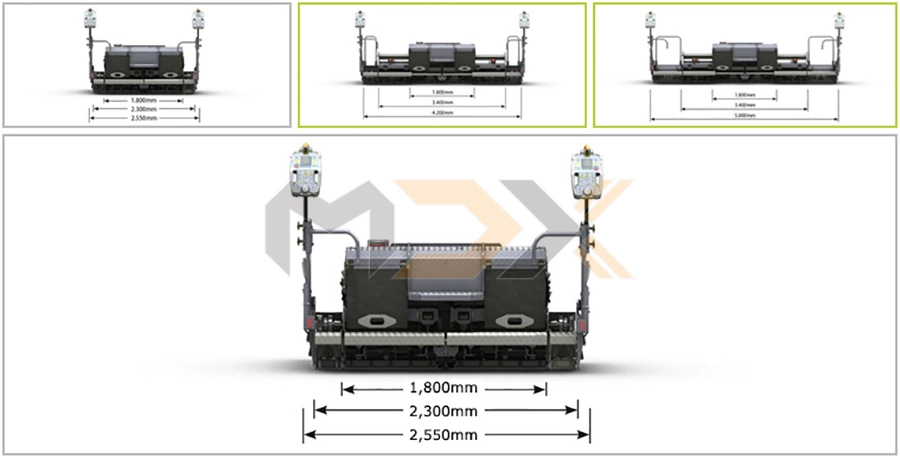

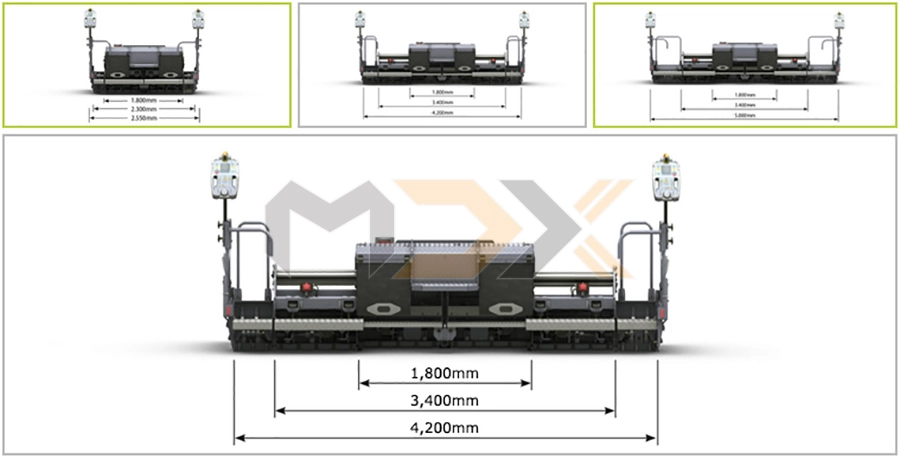

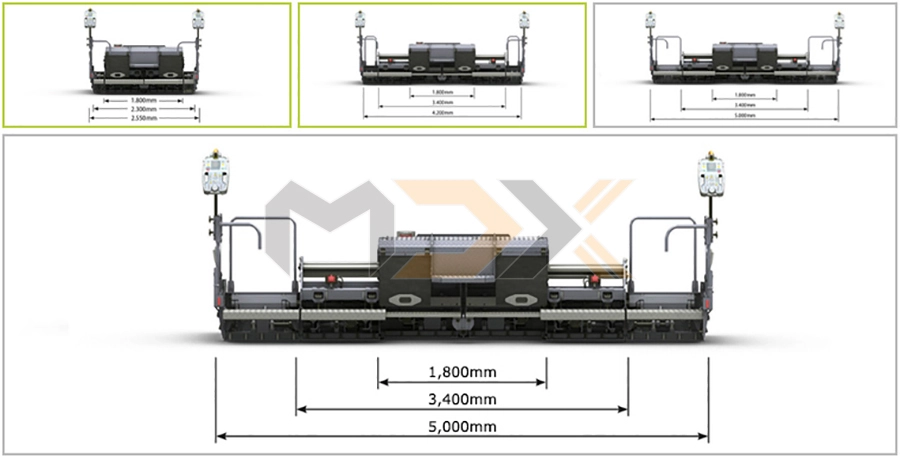

6. EXTENDING SCREED AB 340

Pave widths:

- Basic width: 1.8m

- Hydraulic extension: up to 3.4m

- Maximum pave width: 5m (with bolt-on extensions)

Compaction:

- 340 V: with vibrators

- AB 340 TV: with tamper and vibrators

SUPER 1100-3 and SUPER 1300-3 (with 25cm bolt-on extensions)

Easy transport: Even with bolt-on extensions and side plates fitted, the transport dimensions do not exceed 2.55m.

SUPER 1100-3 (with 40 cm bolt-on extensions)

SUPER 1300-3 (with 80cm bolt-on extensions)

Maximum precision and easer of use. The AB 340 in detail: powerful electric heating, single-tube telescoping system, high position of the guiding system, outstanding thermal insulation of the screed plate, uniform heating of the screed plate and tamper (AB 340 TV)

The AB 340 V Extending Screed (with vibrators) is available for the SUPER 1100-3. The SUPER 1300-3 can be combined with the AB 340 TV Extending Screed (with tamper and vibrators). The tamper stroke is invariably set to 4mm.

SOME OTHER ADVANTAGES

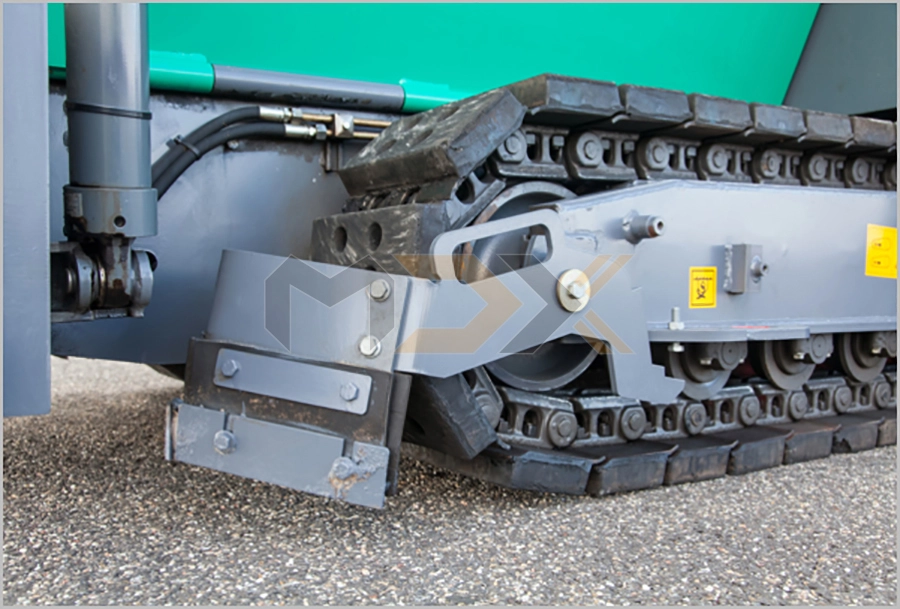

Crawler Tracks Provide Maximum Traction

Powerful separate drives directly fitted into the sprockets of the crawler tracks, for translating engine output into pave speed with maximum efficiency.

Long crawler tracks ensure maximum traction. This provides for a constant forward speed even when operating on difficult terrain.

Electronically controlled separate drives in both crawler tracks for sensitive speed control, positive tracking when moving straight ahead and accurate turning of radii.

Easy and Clean Feed with Mix

The large material hopper can hold 10t. This makes it easy to tide over situations where feeding with mix may be difficult (narrow places, for instance).

Oscillating push-rollers ensure convenient and shock-free docking, also by large feed vehicles.

Hydraulically folding hopper sides for a smooth feed with mix, avoidance of lateral obstacles as well as a targeted supply of mix even when paving in asymmetrical widths.

Perfect Conveyance and Spreading of Mix

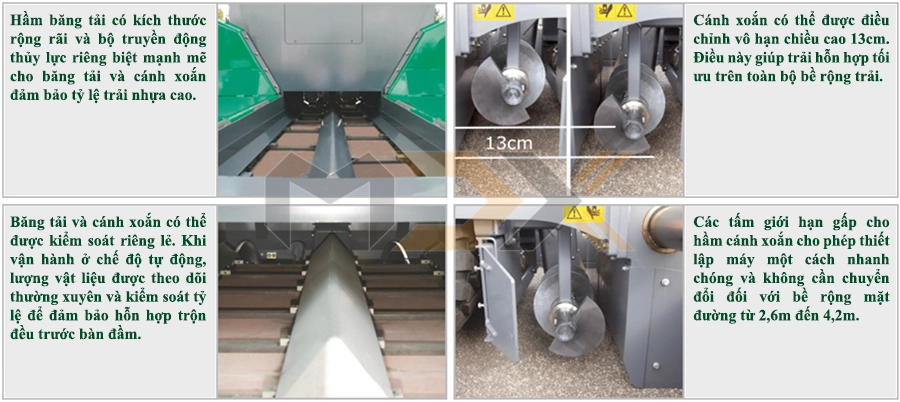

Generously dimensioned conveyor tunnel and powerful separate hydraulic drives for conveyors and augers ensure a high laydown rate.

The auger can be infinitely adjusted in height by 13cm. This provides for an optimum spread of mix across the entire pave width.

Conveyors and augers can be controlled individually. When operating in automatic mode, the amount of material is permanently monitored and proportionally controlled to ensure a constant head of mix in front of screed.

Folding limiting plates for the auger tunnel allow the machine to be set up quickly and without conversion for pave widths from 2.6m to 4.2m.

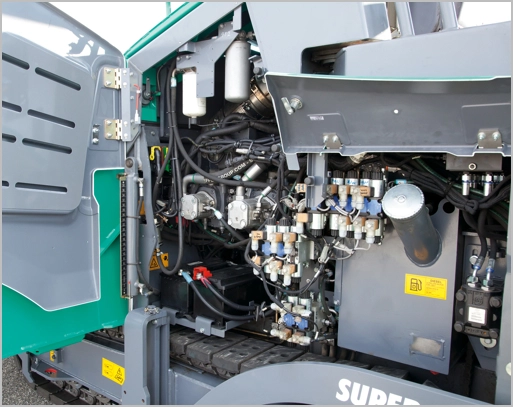

Maintenance – Quick and Simple

All service points are easily accessible via large hinged panels. All hydraulic pumps are located on the splitter gearbox, where they are clearly arranged and readily accessible. The bearings of conveyors and augers are maintenance-free. Sturdy, durable components made from highly resistant materials increase operational availability. A uniform service concept for all VÖGELE pavers simplifies maintenance.

All service points are easily accessible via large hinged panels. All hydraulic pumps are located on the splitter gearbox, where they are clearly arranged and readily accessible. The bearings of conveyors and augers are maintenance-free. Sturdy, durable components made from highly resistant materials increase operational availability. A uniform service concept for all VÖGELE pavers simplifies maintenance.

News Related

Tags: Vogele Super 1100-3, Vogele Super 1300-3