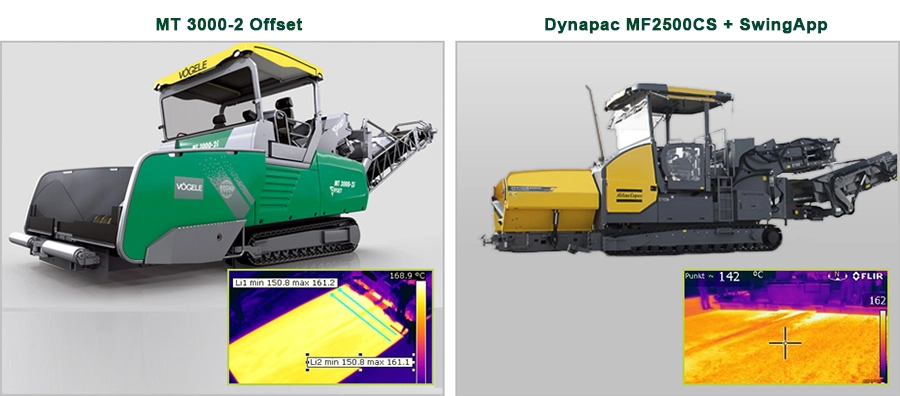

PRODUCT COMPARISON VOGELE MT 3000-2 OFFSET VS DYNAPAC 2500CS + SWINGAPP

The following article introduces you to the competitive advantages of the Vogele MT 3000-2 Offset material feeder with Dynapac 2500CS + Swingapp. These are competitors of the Vogele MT 3000-2 Offset material feeder. The comparisons show Vogele's strengths compared to Dynapac. They also give you their advantages when talking to customers. We hope you enjoyed this article!

You can see in detail the outstanding advantages of the MT 3000-2 Offset: HERE. Or refer to product specifications at: HERE

DIMENSIONS AND WEIGHT

| MT 3000-2 Offset | DYNAPAC 2500CS + SWINGAPP | |

| ENGINE | ||

|

|

|

| Engine | Deutz engine, 6 cylinders, water cooled. | 6 cylinders |

| Version | TCD 6.1 L6 | Cummins QSB 6.7 C 260 |

| Engine Power | 160 kW at 2 000 rpm (ECO: 150 kW at 1 800 rpm) | 194 kW (264 HP) at 2 200 rpm |

| Fuel tank capacity | 450 liter | 300 liter |

| Emission standards | EU 3b, US EPA Tier 4i | EU 3A/3B, US EPA Tier 3/4i |

| Travel speed | up to 4.5 km / h,infinitely variable | up to 4 km / h |

| Working speed | up to 25 m / mininfinitely variable | up to 25 m / min |

| UNDERCARRIAGE | ||

|

|

|

| Tracked | Tracked | |

| Ground contact | 3 060 x 305 mm | 3 600 mm |

| Traction drive | separate hydraulic drive and electronic control provided for each crawler track | separate hydraulic drive and electronic control provided for each crawler track |

| Steering | by alteration of track travel speeds | by alteration of track travel speeds |

| Ground contact | multiple-disk brake locked on automatically without oil pressure | multiple-disk brake locked on automatically without oil pressure |

| RECEIVING HOPPER | ||

|

|

|

| Holding capacity | 16 t (18 tons – US) | 12 t |

| Width | 3 680 mm | 3 345 mm |

| Feed height | 600 mm (from the bottom of the supply hopper) | 523 mm |

| Push-rollers | Oscillation | Oscillation |

| Holding capacity (Extra material hopper) | 20 – 24 t | approximately 20 – 22 t |

| Total capacity of the whole system (feeder and paver) | up to 40 t | 24 t |

| AUGER | ||

|

|

|

| Quantity | 2 horizontal auger in the receiving hopper (optional homogenous cone hoppers) |

There are no auger, only folded hopper faces that separate the material and release heat. |

| Auger drive | hydraulic | |

| Auger speed | infinitely variable | |

| Diameter | 400 mm | |

| CONVEYOR | ||

|

|

|

| CONVENIENTS WITH RUBBER BELT | CONVENIENTS WITH RUBBER BELT | |

| Quantity | 2 continuous rubber conveyor belt with hydraulic actuator | 2 rubber belts screwed onto metal rods |

| Ability to rotate | can rotate ±55° hydraulically | can be rotated horizontally ±55° |

| Discharge height | 3 900 mm (max) | 2 900 mm |

| Conveyor Width | 1 100 mm | |

| Conveyor heating | Diesel heating (infrared heating plate) | Unavailable |

| MT 3000-2 Offset | DYNAPAC 2500CS + SWINGAPP |

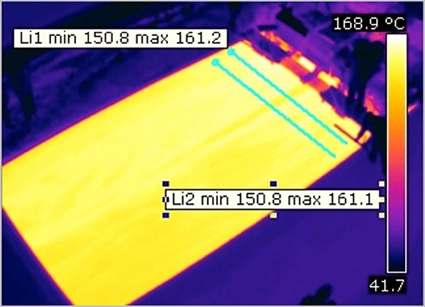

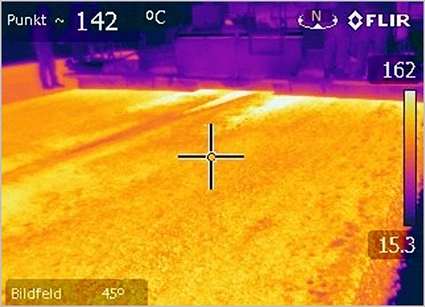

| THERMAL SYNC | |

|

|

|

|

|

The use of conical torsion blades resists mechanical and thermal separation. Heated trough conveyors with rubber belts ensure stable, non-separable conveying of materials. The average temperature measured in the material feeder is 3.3 °C The optimal shape of the filler hopper in the spreader (60° curved wall) prevents additional segregation. Thermal imaging clearly shows positive homogenizing effects. Uniform temperature distribution in the material when spreading provides better and uniform compaction later. |

There is no uniformity measure of any kind. The wiper is often embedded in the material and heavily soiled (limited effectiveness and laborious cleaning) |

| ENGINE TECHNOLOGY | |

|

|

|

The ECO mode reduces engine wear and fuel consumption, allowing for economical operation. Lower engine speeds result in quieter operation and reduced noise emissions, benefiting both the crew and the surrounding environment. Measured fuel consumption: 10 liters / h at 300 t / h. The low position of the power supply unit combined with the crawler units ensures high stability during movement and the machine is stationary. The power supply unit is in a maintenance-friendly location. |

ECO mode with variable engine speed. Measured fuel consumption: 12 liters / h at 300 t / h. |

| KHẢ NĂNG KIỂM SOÁT | |

|

|

|

Chain handling runs smoothly and stably even when the offset conveyor is rotated to one side. Low ground pressure. Ease of working on limited construction sites: almost starting the machine on the spot. Easy to locate and manage on site. |

The chain runs bumpy. Make high noise when operating. Limited stability on horizontal slopes due to narrower blade width. Difficult to drive due to long chain. The long running chain limits the opening of the machine on the construction site. |

| OPERATOR'S PLATFORM | |

|

|

|

Comfortable working space. Individually adjustable driver's seat with ample leg room The driver's seat is optimally designed, heat-resistant as an option. The control panel can be adjusted horizontally and vertically. The rotating conveyor is sensitively controlled via the joystick on the armrest of the operator's seat. One to two operators, depending on work conditions. |

The lack of height adjustment for the seats and the operator console limits legroom. The operator's control panel is not adjustable, making driving uncomfortable. Good visibility only with the lift (option). |

| OPERATION PLATFORM | |

|

|

| The design of the operating space is spacious and clear. Access to key service points is extremely driver-friendly and convenient | The operating space is narrow, there is no storage space. |

| VIEW | |

|

|

| All-round visibility thanks to the driver's seat that can be moved beyond the edge of the material feeder. Great view of the entire work area. | Extremely uncomfortable sitting position. Overall visibility is severely limited. |

| CONTROL PANEL | |

|

|

|

Intuitive, user-friendly design with logically grouped functions. The function buttons can also be operated while wearing work gloves. The operator panel has a modular design, so that it can be replaced individually in the event of damage. Intuitive, language-neutral ErgoPlus operating system for all Vogele machines, cutting training costs Backlight automatically when it starts to get dark. |

The main control panel is taken from the SD series and retrofitted only for the material feeder functions. Arrange activities without logic and clarity No touch on slim keyboard. The keys are very close together. |

| DISPLAY | |

|

|

| Large, easy-to-read display panel shows important information on level 1 menus. For example current operating speed and mixing level in the feed hopper of the spreader. Feeder capacity and distance to the spreader can be set directly on the screen. The operator can access important additional information such as fuel consumption or working hours through the display. | Small screen, hard to read. The screen is reflective. Complex, integrated menu instructions. Unintelligible characters. Messy menu graphics. |

| MATERIAL RECEIVED | |

|

|

| The large load width of 3.68 m provides easy access to the truck. Large capacity auxiliary hopper for pavers with a capacity of up to 24 tons | Hopper receives material up to 12 tons. Material overflows through the feed hopper due to unsightly design. Design the receiving hopper based on the material hopper of the spreader. Increased material separation. |

| CONVEYOR | |

|

|

|

Conveyor heating. Conveyor belt has rubber belt to prevent heat loss. Low surface load due to the sprocket set. Continuous material transfer through trough-shaped rubber belt There is hardly any segregation thanks to stable material transport. Conveyor belt can be rotated horizontally. |

Lack of conveyor heating causes the material to stick to the guide plates. Significant material separation on the left and right sides of the conveyor belt due to the adhesive material. Flat conveyors cause additional separation. Conveyor can be rotated through 55° The material is not guided at the sides. Limited stability on horizontal slopes due to narrower track width. |

| TRANSFER MATERIAL | |

|

|

|

The material transfer process is optimized. Three transfer points: having fewer transfer points helps to prevent separation. Stable material conveying thanks to conveyor belts with rubber troughs. The material is less prone to cooling due to the heat-insulating rubber belt. |

The receiving hopper is poorly designed, dirty continuously due to material falling out. Unfavorable hopper shape for rapid material discharge cycles Material adheres to left and right cold guide plates (risk of material separation) Material overflows significantly at the point of passing to SwingApp. |

| IMPACT PROTECTION | |

|

|

| Mechanical impact protection stops the pavers if there is a risk of a collision. | Option of impact protection (ram) |

| CONTROL DISTANCE | |

|

|

| Non-contact optical sensors can be installed. Three independent laser sensors continuously measure the distance between the material feeder cooler and the paver. It accurately calculates the average parameter. | Rigid conveyor and hopper insert with reflector plate for optical distance control. The reliability of the optical distance control depends on how clean the reflector is. |

| TRANSFER PERFORMANCE | |

|

|

| Feeder efficiency reaches 1,200 tons/h. Total capacity to hold up to 40 tons of material (combined with a 20-ton auxiliary hopper in the spreader). The high-performance material feeder design allows the feed truck to be emptied in just 60 seconds. Precise transfer of a variety of materials other than asphalt, e.g. topsoil, recycled materials. | According to the Dynapac datasheet, which transfers 27 tons of gravel, sand or asphalt in 35 seconds (equivalent to about 2,800 tons/h), no paver can cover this amount. Gravel, sand or asphalt are transported. |

| VẬN CHUYỂN | |

|

|

|

Travel width: 3 m Machine height: 3.09 m Machine length: 14 m Travel weight: 24 t Transport cost from Ludwigshafen to Seesen, Germany (about 500 km): €1,200 |

Travel width: 2.55 m Machine height: 3.1 m Machine length: 13.35 m Travel weight: 23.5 t Standard shipping by truck. |

| 5 KEY DISADVANTAGES OF DYNAPAC 2500CS + SWINGAPP | |

|

1. Lack of conveyor heating 2. No spiral blades in the receiving hopper (causes separation) 3. Low material capacity 4. The control panel is not user-friendly. 5. Limit the ability to comprehensively observe. |

|

News Related

Tags: Vogele MT 3000-2 Offset, Roadtec SB-2500e, Dynapac 2500CS, Swingapp