THE HIGHLIGHTS OF VOGELE MT 3000-2 OFFSET POWERFEEDER

The following article shares with readers the most outstanding advantages of the Vogele MT 3000-2 Offset Feeder. This powerful modern machine is specially developed by the company with many outstanding features. Both meet the needs of continuous material transfer, ensuring optimal spreading quality at the lowest cost. We hope you enjoyed this article!

VIDEO INTRODUCTION OF MATERIAL TRANSFER VOGELE MT 3000-2 OFFSET

View MT 3000-2 OFFSET at: HERE

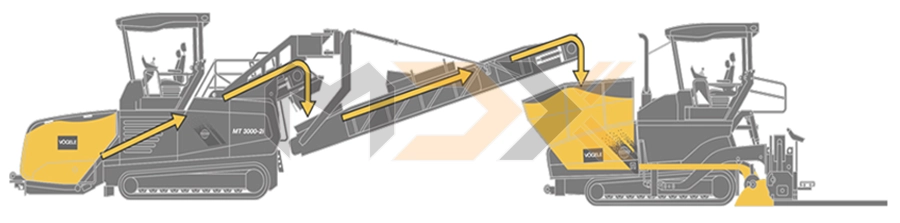

UNIFORM TRANSFER DESIGN TO ENHANCE FEED PERFORMANCE

Total material capacity up to 40 tons

Taking into account the total material storage capacity in the complete system, including the conveyor and mixing head in the auger in front of the screed, MT 3000-2 Offset system can hold up to 40 tons of material.

Large feed hopper with a capacity of 16.4 tons of material.

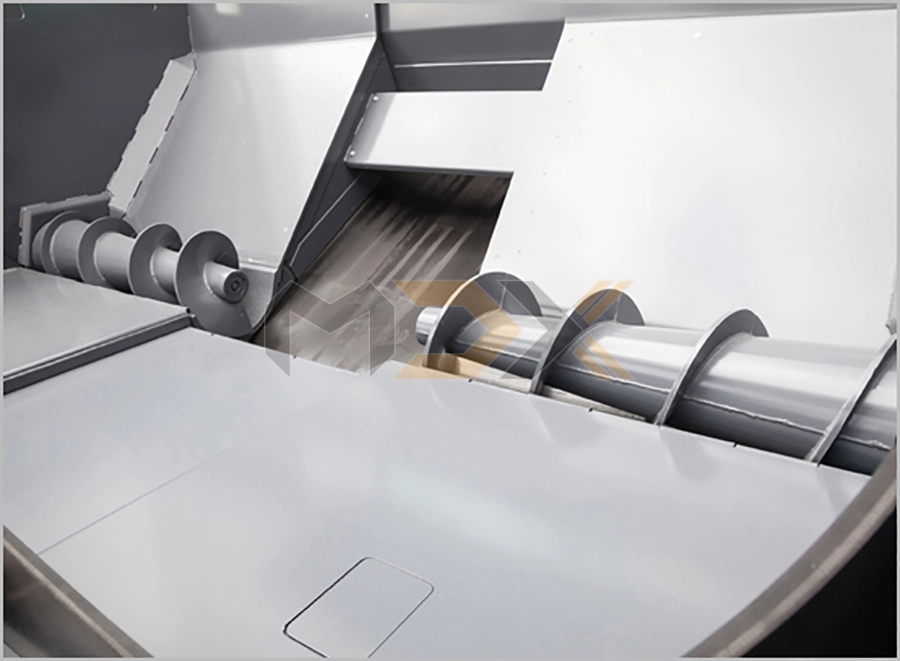

The auger are uniform and convey the mixture completely and without leaving any residue.

Trough design (30°) prevents material from separating.

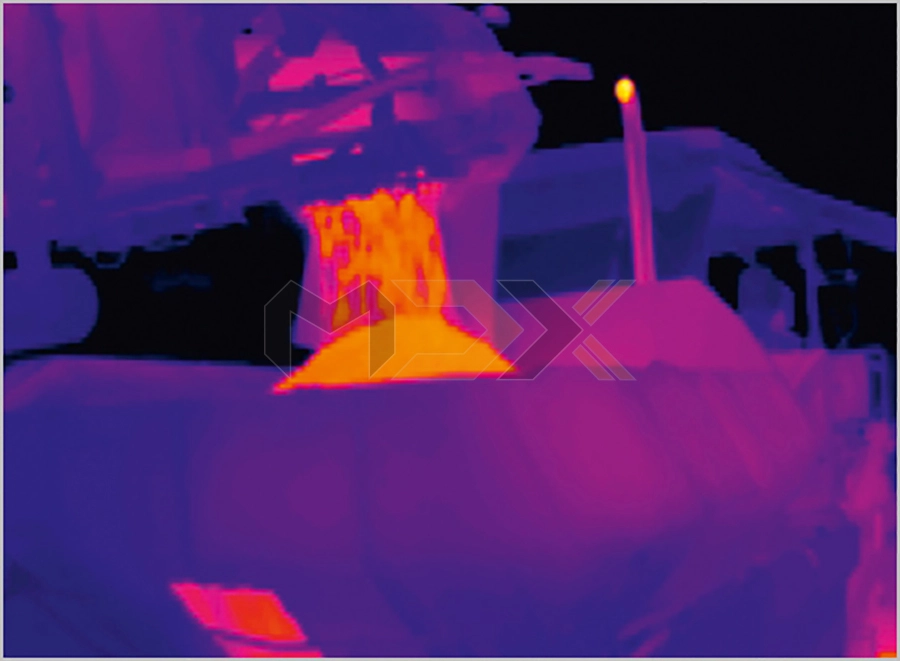

Heating diesel with non-contact infrared heating plates maintains the conveyor at the required temperature to prevent any adhesion of the material.

VIDEO DESCRIPTION OF QUALITY FEEDING SYSTEM

HIGHER PAYMENT MATERIAL

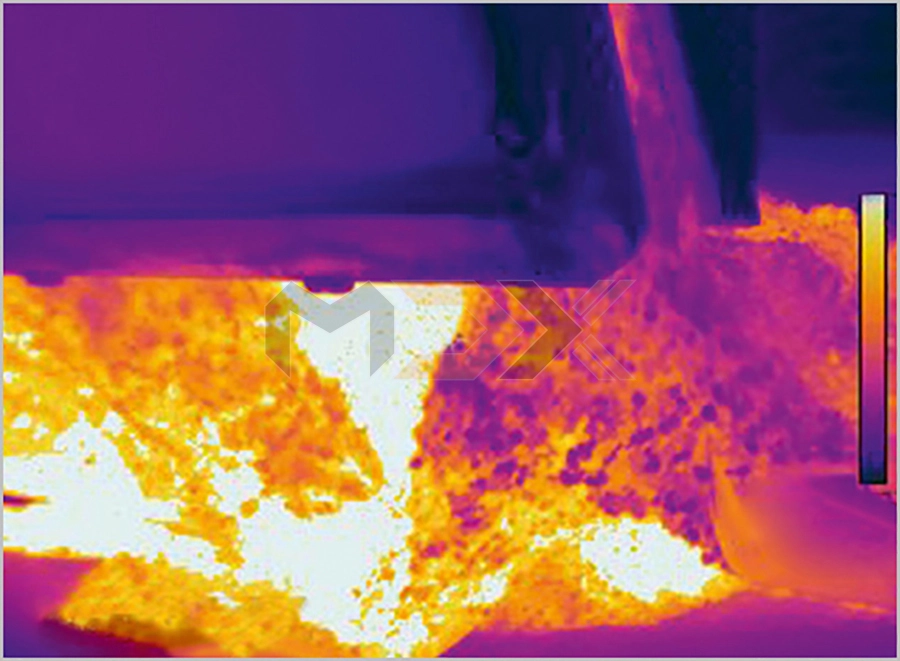

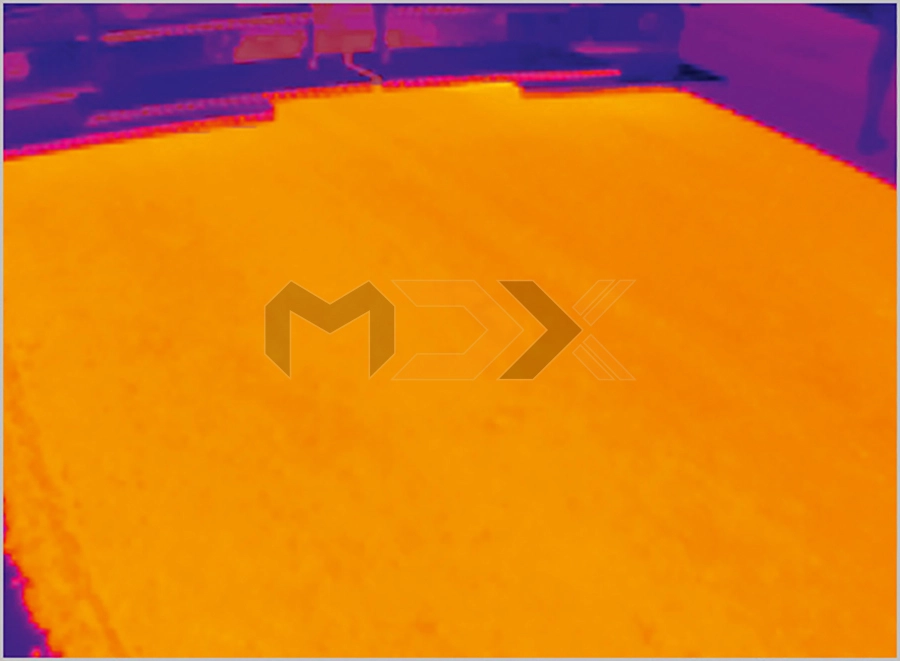

Uniform paving material is an important criterion for better pavement quality. How to prevent the separation of the mixture?

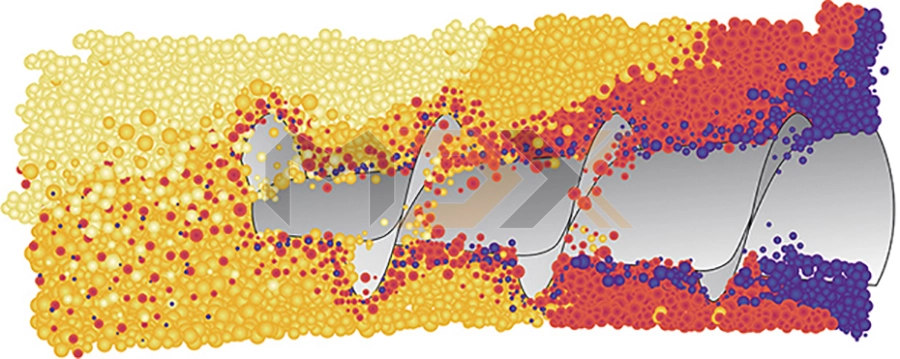

Conical auger:

- Trough-shaped conveyor with diesel heating system.

- The feed hopper optimizes the conveying flow of the mixture:

- Result: Homogeneous mixture for the asphalting process.

VIDEO: HIGHER PAYMENT MATERIALS

Conical auger for optimum material homogenization. Allows cooler materials to be uniformly mixed with warmer materials.

Vogele's new generation of material feeders have conical auger that help homogenize the material mixture: the cone (cone) of the auger prevents the formation of so-called "tunnels" in the material. In addition, the material is drawn evenly from all parts of the feed hopper.And because the hot mixture is continuously transferred from the outside, it is also thermally homogenized, resulting in better pavement quality. .

Trough conveyor with diesel heating system:

A trough conveyor ensures that the mixture is transported gently, while a modern diesel heating system with non-contact infrared plates prevents material adhesion.

Auxiliary hopper optimizes the flow of the mixture:

The auxiliary hopper contains specially designed material that effectively prevents the adhesion of the mixture. It ensures that all the asphalt is fully supplied to the asphalting process.

VIDEO: NEW ADDITIONAL MATERIALS WITHOUT ANGLES AND EDGES

Result: Homogeneous material mixture for spreading

All these technical features have been comprehensively coordinated to optimize the condition of the spreading material.

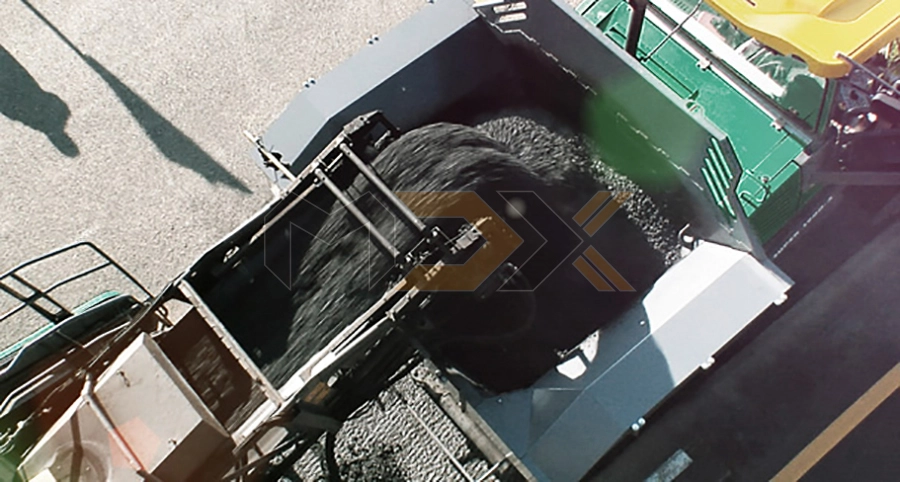

EXCELLENT TRANSFER PERFORMANCE

Innovative feeder system design enables maximum conveying efficiency to reach 1,200 tons/h. This allows a 25 ton material truck to be emptied in just 60 seconds!

Thanks to the high-performance feeder design, more than half of the 25 tons of material has been unloaded.

The material transfer process has been completed. The mixture was poured into the feed hopper and the auxiliary hopper of the spreader.

Auxiliary hopper

The Vogele crawler paver can be equipped with an additional material hopper to feed the material by means of “PowerFeeder”. The auxiliary hopper for the 2.5 m spreader has a mixing capacity of 20 tons. The auxiliary hopper of SUPER 3000-2 holds 25 tons. An insert with 60° inclines is available for the filler hopper on a 2.5 m spreader. Ensures uniform material delivery without residue.

SWIVEL CONVEYOR

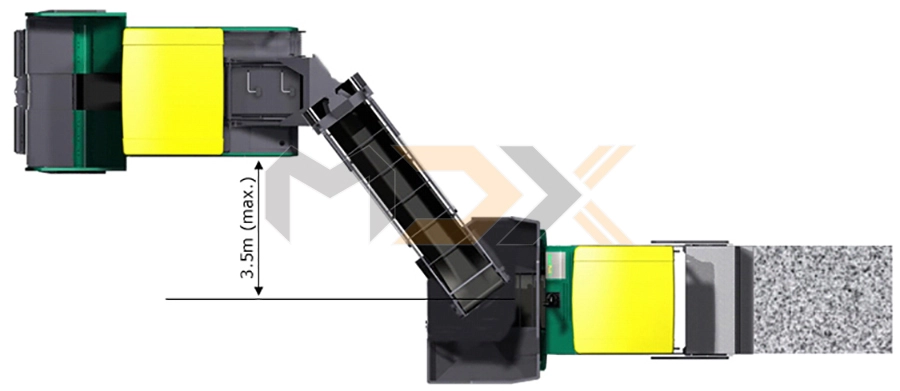

The conveyor belt can be rotated 55° to the right or left, as well as 23° upwards. Offers many possibilities such as:

Can be rotated 55° each side

VIDEO: SWIVEL CONVEYOR

Feed the spreader from the side.

For example, when placing the base material in a deeply milled strip, when the feed truck cannot reach it.

VIDEO: FEED FROM THE FEMALE PARTY

Provide materials for 2 spreading machines to spread "hot to hot"

Fill trenches, ditches, tunnels.

The maximum distance from the outer edge of the material feeder to the discharge point of the conveyor is 3.5 m.

Fill holes between safety fences on highways

Fast and economical.

Anywhere materials cannot be transported by conventional means

For example, when there is a footpath or bike path.

Various materials can be supplied with MT 3000-2 Offset

The following materials can be conveyed: Asphalt, water-bonded substrate mix, base

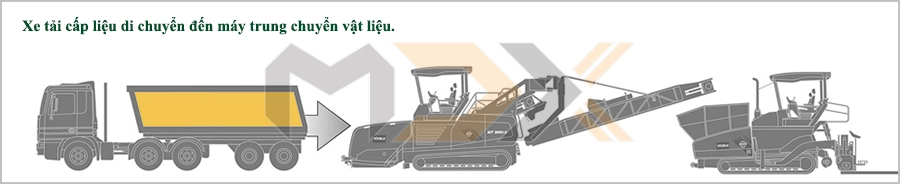

SUPPLY OF CONTINUOUS AND NO CONTACT MATERIAL

PLASTIC PLANTING PROCESS WITHOUT DISCUSSION

The quality of pavement depends on a continuous and uninterrupted paver process. This means that the spreader must be supplied with material continuously. The material feeder MT 3000-2 Offset ensures a continuous supply of materials to the pavers.

- MT 3000-2 Offset is especially suitable for large-scale road construction projects, such as construction or renovation of long roads.

- Continuous supply of raw materials.

- Non-stop construction process.

- Daily asphalt paving rate of 4,000 tons or more.

SUPPLY WITH NO CONTACT MATERIALS

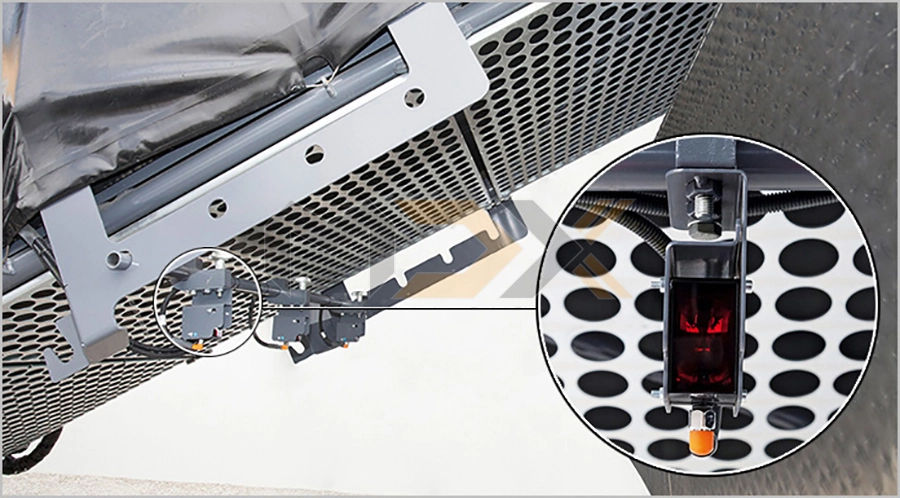

The quality of pavement also depends on the supply of non-contact materials. Sensor-controlled automatic distance control ensures a constant distance between the spreader and the material feeder, thus providing greater operator comfort.

VIDEO: PROVIDE MATERIALS WITHOUT CONTACTS

Collision protection system

- A collision protection system can be additionally fitted to the spreader in the form of a contact rod.

- Any contact with the collision protection system will cause the paver to stop immediately.

Material sensor

- The ultrasonic sensor measures the fill level in the material hopper of the spreader.

- Feed resume will stop automatically when the preset fill level is reached.

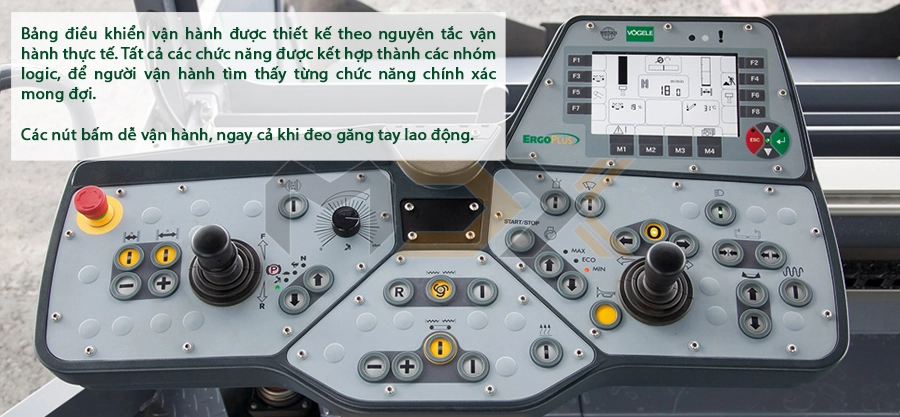

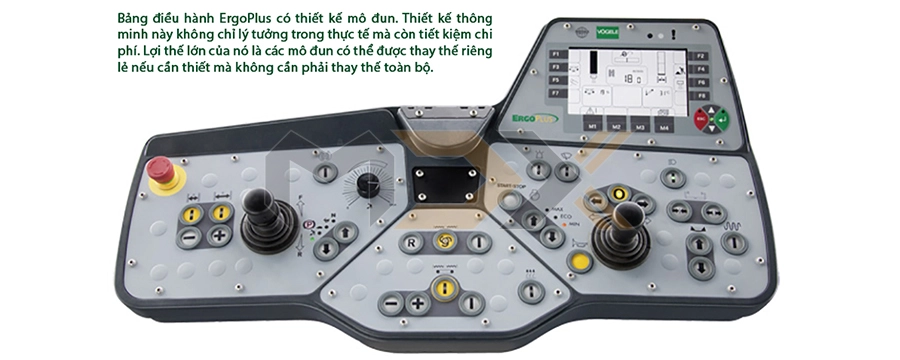

ERGOPLUS 3

|

||

| Perfect Operational Coordination | Clear, convenient and neat operating compartment | The control panel is optimally designed according to the actual working operation. |

VIDEO: ERGOPLUS 3

PLATFORM DESIGN

OPERATION PLATFORM

Comprehensive overview

Perfect visibility of all relevant parts of the conveying machine. Such as the feed hopper, direction warning and discharge point into the feed hopper of the spreader. Therefore, the machine can easily be operated by only one person.

If more complex feeding tasks are involved, a second person can also take over operating the rotating conveyor.

The seat can also be rotated to provide optimal visibility in all directions.

Everything is centralized in one place

- The operating compartment is clearly and neatly arranged.

- The paver operator's console can be protected with a shatterproof cover to prevent accidental damage.

- Sufficient storage space to keep the machine neat and tidy.

- Easy and convenient access to all major maintenance points.

SEAT AND OPERATION CONSOLE

The operator's seat and control panel can be conveniently and easily adjusted to meet the individual wishes and needs of the driver, providing maximum working comfort.

The rotating conveyor is controlled via a joystick in the operator's armrest. The lever precisely controls the horizontal movement, lifting and lowering as well as the conveying efficiency of the conveyor.

How does the joystick work?

A How does the joystick work Raise / Lower the rotary conveyor

B Faster/slower transmission

C Safety switch

D Emergency switch

E Transport in automatic mode (main transfer switch)

F Transport in manual mode (override switch)?

OPERATION CONTROL PANEL

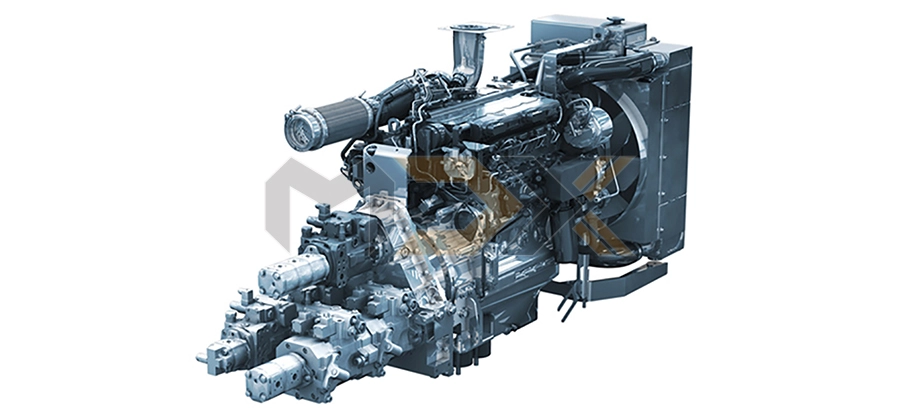

ADVANCED ENGINE TECHNOLOGY

Modern and powerful DEUTZ diesel engine with a capacity of 160 kW at 2000 rpm. The ECO mode (150 kW at 1800 rpm) saves fuel, cuts operating costs and allows for exceptionally quiet operation. The machine can be equipped with a three-phase A.C generator. It supplies 230 V to the material feeder and includes an outlet (grounded), heating rods for the conveyor scraper and a connection for two light balloons. The optimized cooling system, which includes a large cooler and separate hydraulic oil cooler for excellent cooling performance, even under full load operation. Large fuel tank with a capacity of 450 liters for a working day without refueling.

ACCURACY OF THE TRACKED UNIT

Powerful separate drives integrated directly into the sprockets of the sprocket shift the engine's output with no loss of power so any feed truck can be pushed with ease. Maximum traction is ensured by the long chainsaws with great ground contact. This ensures stable operating speed even when working on difficult terrain. Good traction in straight turns and precise cornering thanks to separate actuators, with electronic control provided on both tracks. Very small turning radius and excellent operability thanks to precise sprocket tracks. The large pads ensure a low load per unit area.

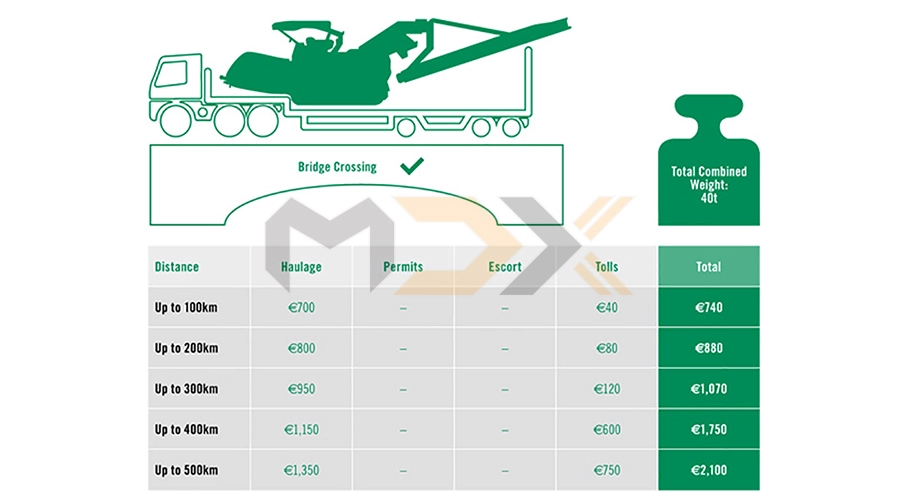

TRANSPORTATION AND TRANSFER OF MATERIALS

The Vogele material feeder is specifically designed for the normal trailer transport function. Putting the location machine into operation is very quick, saving a lot of time, effort and logistics costs. Can be transported on low bed trailers Quick preparation for shipping, thus saving time and money

Shipping size:

- Length: 14.82 m or 14.49 m (without transfer module)

- Width: 2.85 m

- Height: 3 m

- Weight: 23.8 t

EASY MAINTENANCE DESIGN

Large boards provide convenient access to all service points.

All hydraulic pumps are located on a partially driven gearbox and allow easy maintenance thanks to their clear arrangement and good accessibility.

Service indicators and easily accessible measurement ports facilitate diagnostics and maintenance.

News Related

Tags: Vogele MT 3000-2 Offset PowerFeeder, material transfer machine