PISTON ROD POSITION SENSOR FOR CONCRETE PUMP TRUCKS

Concrete pump truck piston rod position sensors are readily available. However, careful consideration must be given to sensor selection due to their high cost and direct impact on hydraulic system operating frequency and stability, both of which are critical for efficient concrete pumping operations.

Therefore, customers need to pay attention to important features and characteristics to avoid choosing a high-priced product but the quality is not commensurate. Through the following article, we will help you solve the following problems:

- How many types of sensors are there and what are the common types of sensors today?

- What issues should be considered when buying a piston stroke sensor?

- And where can you buy quality and genuine sensors?

CLASSIFICATION OF POPULAR SENSORS TODAY

In fact, when referring to a type of sensor, people often associate it with the name of the sensor, which is PNP or NPN, this refers to the structure and output signal of that sensor. NPN sensor (also known as Normally-Open). PNP sensor (also known as Normally-Closed). Being able to recognize these 2 types of signals is very important for selecting equipment and connecting wires between the sensor and the controllers.

Based on the technical properties to apply to each type of activity, each type of sensor is used for different types of equipment such as:

- PNP line: Normally open sensor - Used for concrete pump trucks in general and motor vehicles in particular because of the high frequency of operation, requires high accuracy and operates in harsh environments. The piston stroke sensor mounted on the Hyundai Everdigm concrete pump truck is also classified as a PNP sensor.

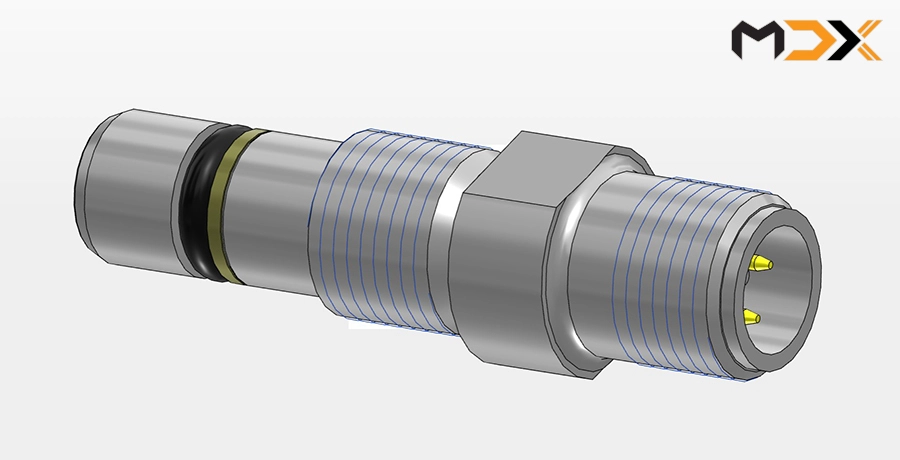

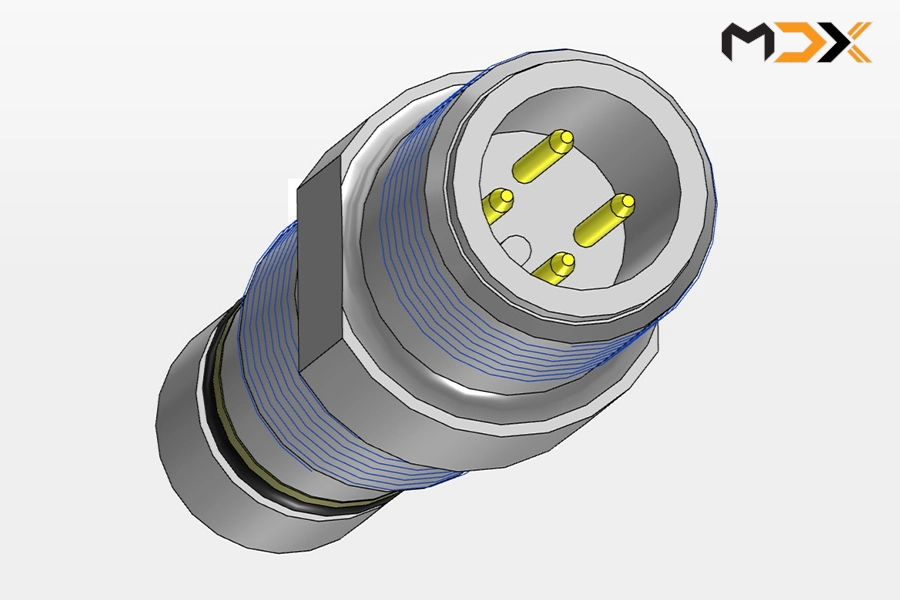

Illustration of a piston stroke sensor

To better understand these types of stroke sensors, you can watch the detailed comparison video below:

+ NPN type: Normally closed sensor - Used for light duty applications such as components in closed production processes in factories....

IMPORTANT CONSIDERATIONS WHEN BUYING A PISTON STROKE SENSOR

The piston stroke sensor is installed on the hydraulic cylinder of the concrete pump truck. Its function is to read the position of the piston and send a signal to the controller. This information allows the system to control the piston movement accurately, easily, and automatically.

Hydraulic concrete pumping cylinder

Figure 1: Piston stroke sensor BHS00032

Each piston stroke sensor has unique characteristics and will only function effectively when used with compatible equipment. Here are some important factors to consider when choosing a sensor:

1. Sensor Code

Before purchasing a sensor, you should carefully check the product code to ensure compatibility with your vehicle's hydraulic system. The sensor code is usually printed or embossed on the sensor body, near the brand name. Currently, there are two common types of sensors on the market:

- Standard sensors: These sensors require the user to manually adjust the distance between the piston top and the sensor end. If not adjusted correctly, the piston may hit the sensor end causing damage (if over-adjusted), or the sensor may not receive a signal (if under-adjusted).

- Balluff sensors (Germany): These come in two codes:

+ BHS00032: Designed for Everdigm and Putzmeister vehicles. This sensor is manufactured and imported directly from Germany.

*BHS00064: Used on other Korean and Chinese vehicles with similar designs. This code is mainly manufactured and imported from China, Taiwan, India, etc.

However, different sensor types can be used interchangeably if they have the same dimensions, design, and thread pitch.

2. Brand

In addition to the sensor code, we should also pay attention to the brand. Currently, the most popular brand is Balluff (Germany), which is being used on all Hyundai Everdigm and original German Putzmeister concrete pump equipment.

The Putzmeister piston stroke sensor is longer than the sensor mounted on the Everdigm vehicle at the sensor wire connector. However, Putzmeister and Everdigm sensors can be used interchangeably because they are compatible in terms of frequency and current (sensor voltage).

3. Product Specifications

To determine the specifications of your sensor, you can visit the website Balluff.com. This brand has over 100 years of experience in the research and manufacture of sensors and related components.

The BHS00064 sensor has a current rating of 10dcc and a frequency of 200MHz, while the BHS00034 currently used on Everdigm pump trucks has a current rating of 10-30dcc and a frequency of up to 2000MHz.

If the sensor is not compatible with the equipment being used, it will cause instability or the hydraulic flow will not meet standards, leading to easy damage.

When checking the specifications, we should pay attention to the product code, voltage (MHz), and frequency: These are three important parameters that determine the suitability and stable working performance for the pump truck.

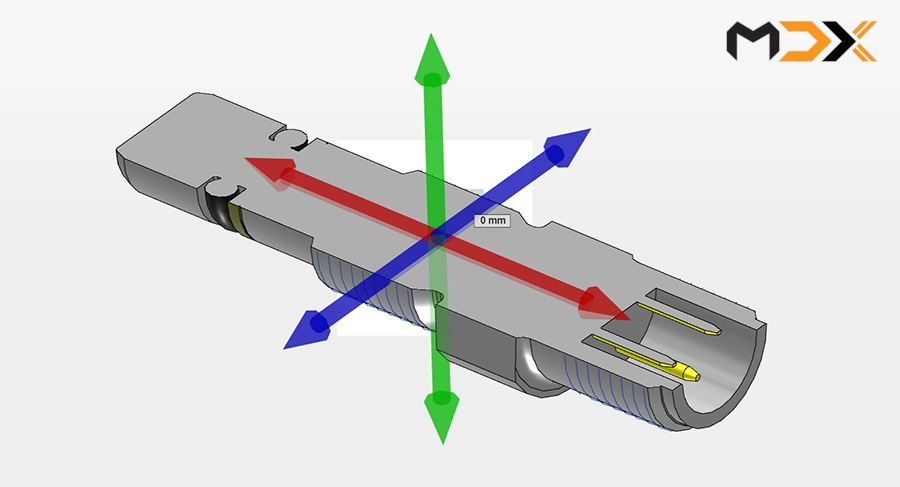

Figure: Cross-section of BHS00032 Balluff sensor

Despite its compact size, the sensor's internal structure reveals a sophisticated circuit board encased in high-grade resin. This resin provides protection against melting, fire, and water ingress, ensuring the sensor's control and power circuits remain unaffected by external factors.

TAM HOÀNG MINH - YOUR TRUSTED SOURCE FOR GENUINE, HIGH-QUALITY PISTON STROKE SENSORS

To maximize profits, some suppliers exploit the lack of information and understanding among buyers by altering sensor codes, engraving new specifications, and changing brand names on the sensors. This is particularly common with sensors that have been modified and labeled with "Everdigm" on the casing.

Figure: BHS00032 (right - shorter) and BHS00064 (left) sensors

However, a closer look reveals differences in finishing quality and evidence of tampering. To ensure you are purchasing genuine sensors, it is recommended to source them from authorized distributors or reputable suppliers.