OSCILLATION BY HAMM - ADVANCED

The oscillation system developed by HAMM achieves compaction results that are scientifically proven to be more homogeneous and higher quality, leading to faster, more significant compaction increases.

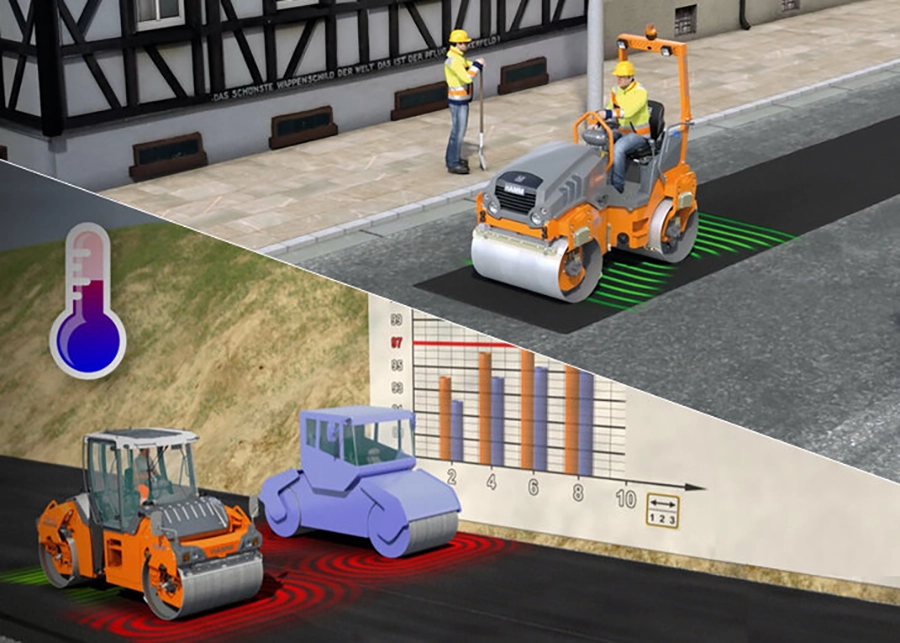

Dynamic compaction systems enable significant increases in compaction power when working with both asphalt and earth. These systems include the oscillation system developed by HAMM that achieves compaction results that are scientifically proven to be more homogeneous and higher-quality. HAMM's wide range of oscillation rollers is available worldwide for road construction (type designations VO, VO-S, OT, VS-OS) and earthworks (type designation VIO). As the sole manufacturer, HAMM offers compact tandem rollers with oscillation.

In an oscillation drum, two eccentric shafts are fitted at a 180° angle to each other. Both unbalanced masses rotate synchronously, which causes the drum to perform a rapidly alternating forwards-backwards rotational movement. This results in the compaction energy being transmitted forwards and backwards tangentially into the ground below in the form of shear forces. The drum is therefore in constant contact with the ground, which means that permanent static compaction also takes place because of the weight of the machine, as well as compaction caused by the shear forces. The result: Faster, more significant compaction increases.

DYNAMIC COMPACTION SYSTEMS

HOW THE DRUM WORKS

Compaction by utilising the weight of the machine as well as the forward-backward rotational movement of the drum plus the shearing forces directed into the ground. The drum has ground contact 100% of the time.

THE TWO MAIN ADVANTAGES OF THE OSCILLATION

1. Minimal environmental oscillation.

2. Quicker compacting V+O (vibration in simultaneous combination with oscillation)

13 FURTHER ADVANTAGES OF THE OSCILLATION

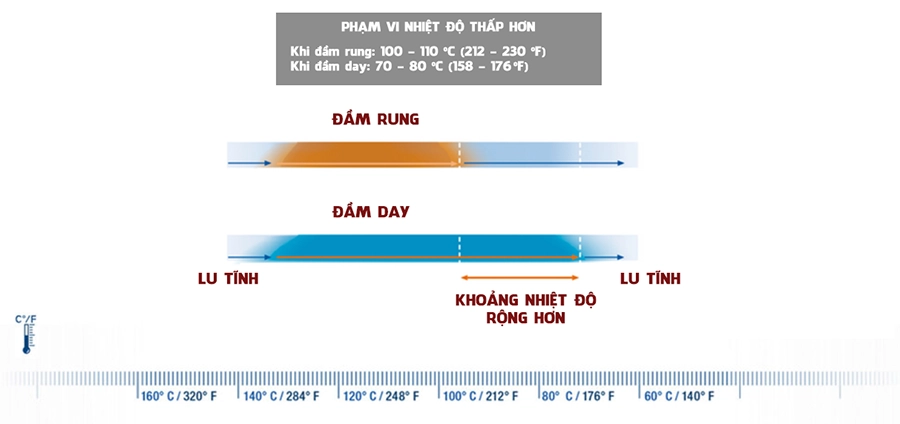

1. COMPACTION IN A WIDER TEMPERATURE WINDOW (MORE FLEXIBILITY)

If the asphalt temperature is too low, then the vibration may cause grain destruction or the destruction of the material structure. Above a certain temperature, therefore, the vibration must be turned off. On the other hand, oscillation can also efficiently and safely compact with low asphalt temperatures.

Advantage:

- Larger time window for compaction work.

- More flexibility.

- Excellent results even at low asphalt temperatures or adverse weather conditions.

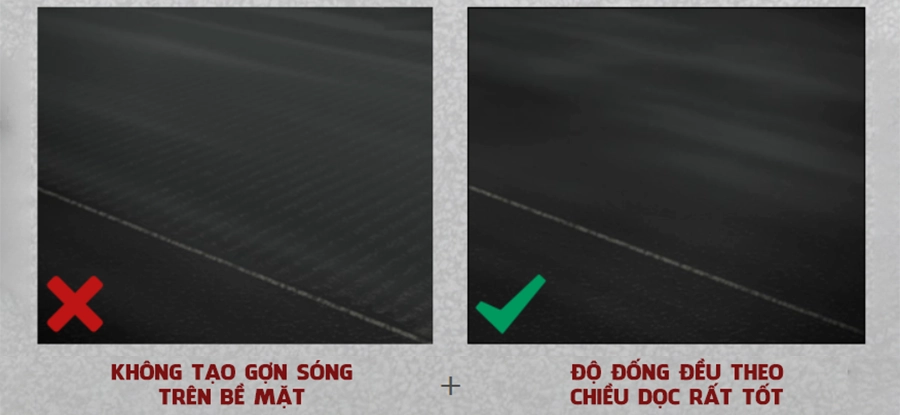

2. NO WAVE FORMATION

Compaction is not done in oscillation by vertical strokes in the sub-base but by horizontal shear forces.

3. PERFECT EVENNESS

Since no vertical shocks act on the ground, there are no waves or bumps. Oscillation means paved roadways are therefore perfectly flat.

In some countries, the longitudinal evenness is an acceptance criterion for the road.

- Germany: valued longitudinal profile (High-speed Road Monitor HRM).

- USA: Rideability

Advantage:

- Optimal driving comfort.

- High driving safety (emergency braking).

- No wave formation.

- Excellent surface cosmetics

4. NO PULLING UP OF WATER (EARTH WORK)

Oscillation can also be used on soils with increased water content. When compacting with oscillation, there is no pumping effect, which would cause the soil to lose stability.

In earth work, the layer height is limited in compaction with oscillation among other factors and the layer height must be reduced.

Advantage:

- Dynamic compaction instead of static compression is possible.

- Soil does not lose its stability.

- Higher load capacity is possible

5. NO PULLING UP OF BITUMEN (SEGREGATION) (ASPHALT)

Similar to the pumping effect of water-soil, when compacting with vibration, there can be bitumen accumulations occurring on the surface during asphalt construction works. This effect can be avoided with oscillation.

Important: The recommended temperature limits must also be adhered to with oscillation before commencing compaction.

Advantage:

- No bitumen accumulations on the asphalt surface.

- No material segregation.

- Higher initial grip due to "slip-effect" of the drum

6. PERFECT COMPACTION OF JOINTS ("HOT ON COLD")

The joint between two driving strips, e.g. for one-side renewal of a lane, will be optimally compacted by utilising oscillation without damage to the already existing roadway. A compaction of the lateral joint (connections) is easily possible.

Advantage:

- Optimal and dynamic compaction of the joints.

- No destruction of the existing coating.

- Optimal density of the joints and connections.

- Durable connection.

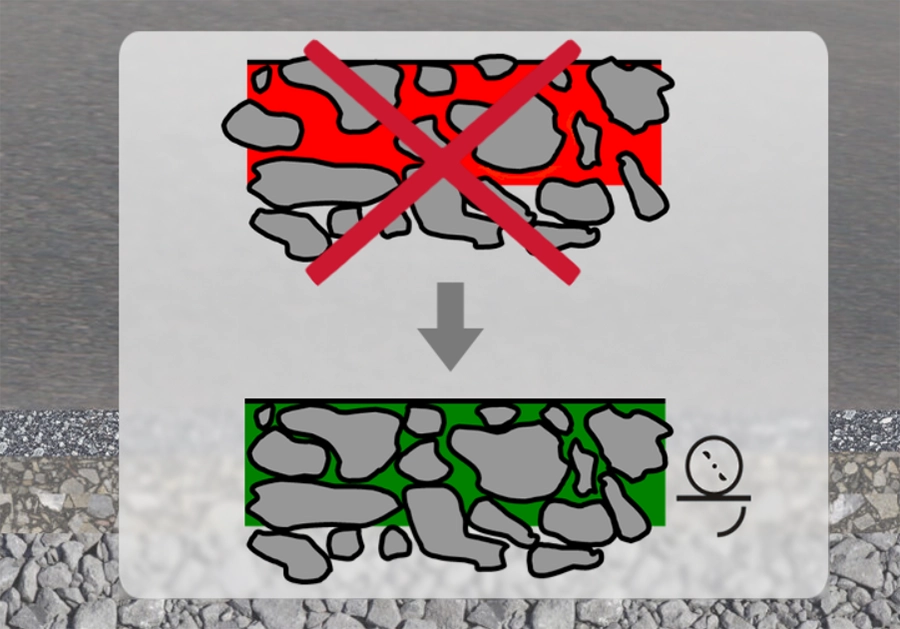

Note: In the first step, you will see the compaction by vibration with grain destroying. Subsequently, it will be gently compacted with oscillation.

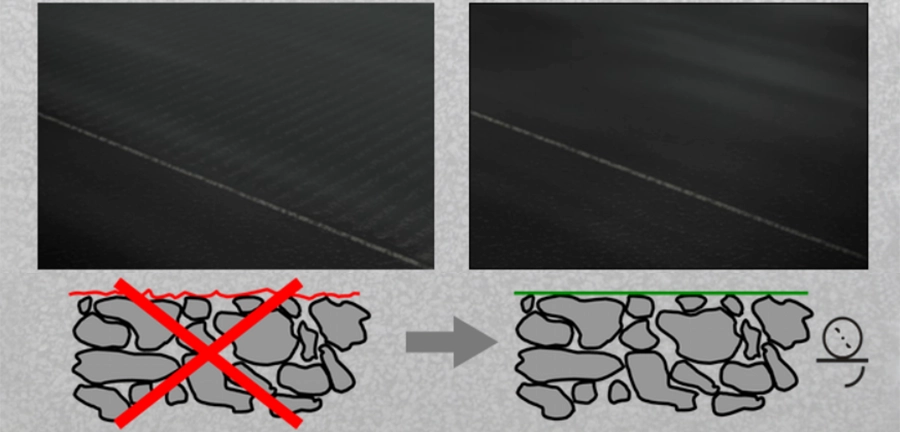

7. NO GRAIN DESTRUCTION

When compacting by vibration, one has the risk of destroying the material structure or grain destruction at lower temperatures or with excessive compaction. Not the case with oscillation. The permanent contact with the sub-base enables increased compaction with each additional crossing - without any undesirable side effects.

8. NO RE-LOOSENING

Every compaction with vibration also means a slight loosening in the near-surface region. The permanent contact with the ground during the compaction with oscillation means that this effect does not occur.

Advantage:

- Avoiding additional static crossings.

- No final compaction is necessary with a vibration plate

9. SELF-REGULATING AMPLITUDE

Self-regulating amplitude by utilising physical interaction with the material to be compacted (dead time <10 ms).

The oscillation principle intelligently utilises the laws of physics. Depending on the compaction of the material, the amplitude will amend the oscillating movement of the drum itself.

Advantage:

- Always the optimum compaction energy.

- No pre-settings -> no fine adjustments

The higher the compaction of the asphalt or subsoil, the lower the oscillation amplitude will be. Without pre-settings and without any error prone sensors for stiffness measurement, the system automatically adjusts to the compaction status and environmental conditions. The operation of the oscillation is simple because it only needs to be activated or deactivated. Additional settings are not necessary in normal cases.

10. BETTER FOR THE DRIVER, BUILDINGS AND SURROUNDINGS

Oscillation is better for buildings, for the environment, for the driver and for the machine itself.

Very low oscillations are transmitted into the subsoil in comparison with vibration.

- Structures.

- Environment.

- Driver.

- Machine

Advantages for buildings:

- Lower concussions for the surroundings.

- Dynamic compaction also for oscillation sensitive areas.

- Optimal compaction method for inner-city areas as there is no risk of destruction for older buildings or above services and pipework (e.g. gas and water pipes).

- No damage to existing structures such as e.g. houses.

- Perfect for bridges as the bridge structure will not be damaged by the very low oscillation loads.

- Hazard-free compaction in multi-storey car parks without damage to the reinforced concrete skeleton framework.

Noise levels

Advantages for the driver

- Reduced oscillations create better comfort for the driver.

- Lower noise levels create less stress for the driver

Advantages for the machine:

- Less resonance oscillation and therefore a longer life cycle for the roller

11. COMPACTION OF DIFFICULT-TO-COMPACT ASPHALTS

Oscillation is the ideal technology for compacting thinner layers and difficult-to-compact mixed materials.

Oscillation should be implemented simultaneously with vibration everywhere where the operation is feasible. This will result in a quicker increase in compaction.

Advantage:

- Gentle compaction for various asphalt coverings.

- Perfectly suitable for difficult-to-compact asphalts (e.g. chip-mastic asphalt, polymer-modified asphalt).

- Ideal compaction results for dynamic compaction of thin-layer coverings

12. GOOD INITIAL ADHESION OF THE ASPHALT SURFACE

The "abrasiveness" from the roller provides the asphalt surface with a higher initial adhesion

13. ADVANTAGES OF SPLIT OSCILLATION

The principle of HAMM's split oscillation:

Two completely mechanically independent oscillation units work in the split drum. An integrated control system quickly and precisely adjusts the position of the unbalances to the position of the drum halves. Synchronisation is effected by means of a digital hydraulic system. It ensures that both drum halves - despite their different rotational speeds in curves - oscillate synchronously at all times. This minimizes the shear stress in the asphalt to be compacted.

Comfort for the driver.

- Many years of experience: over 35 years of experience with oscillation, known compaction technology.

- Conclusion: no change in application means no relearning for the driver.

- Low noise emissions: reduction of noise emissions due to installed components.

- Conclusion: more comfort for the driver, active environmental protection, optimal steering behavior

Economic efficiency.

- Economic and efficient compaction: same to higher compaction performance than non-split drums.

- Conclusion: fewer crossings.

- Maintenance-free oscillation: roller shells made of highly wear-resistant steel, drive in oscillating bandages by temperature-resistant special belt.

- Conclusion: elimination of complex maintenance work, reduction of operating costs.

Optimum compaction results

- Reduction of shear stresses in the asphalt: low shear stresses in the asphalt due to the division of the drums.

- Conclusion: crack-free compaction even in tight curves and roundabouts.

- Perfect synchronization: fast and precise synchronisation of the two halves of the drum through innovative digital hydraulics - even at different rotational speeds

- Conclusion: surfaces with highest quality, avoidance of surface cracks.

News Related

Tags: Oscillation, oscillation drum, soil compactor, Tandem roller