INTRODUCTION TO THE ERGOBASIC OPERATING SYSTEM

Since the end of 2018, Vogele has launched two main lines of asphalt pavers: the Classic Line and the Premium Line. The Classic Line is equipped with ErgoBasic, a simple and intuitive operating system, along with Niveltronic Basic, which is particularly suitable for compact machines.

Niveltronic Basic, the automatic grade and slope control system from Vogele, is designed with a focus on the operator and seamlessly integrated with the ErgoBasic system. This system features a user-friendly interface that allows for all settings to be adjusted directly on the screed console. You can find more information about Niveltronic HERE.

ERGOBASIC: OVERVIEW AND KEY BENEFITS

Classic Line Models and their corresponding screed consoles:

| Mini Class | Compact Line | Universal Line |

| S700(i) | S1000(i) | S1400 |

| S800(i) | S1300(i) | S1403 |

| S1600 | ||

| S1603 | ||

| S1600 L | ||

| S1880 L |

Classic Line Screed Console:

Premium Line Models and their corresponding screed consoles:

| Compact Line | Universal Line | Universal Line | Special Line |

| S1300-3(i) | S1600-3(i) | S1900-3(i) | S1800-3(i) SprayJet |

| S1303-3(i) | S1600-3 L | S1900-3 L | S1900-3(i) Ballast Paver |

| S1603-3(i) | S2100-3 L(i) | S2100-3(i) IP | |

| S1700-3(i) | S2000-3(i) | MT 3000(i) Standard | |

| S1703-3(i) | S2003-3(i) | MT 3000(i) Offset | |

| S1800-3(i) | S2100-3(i) | ||

| S1803-3(i) | S3000-3(i) | ||

| S1880-3 L |

Premium Line Screed Console:

|

|

|

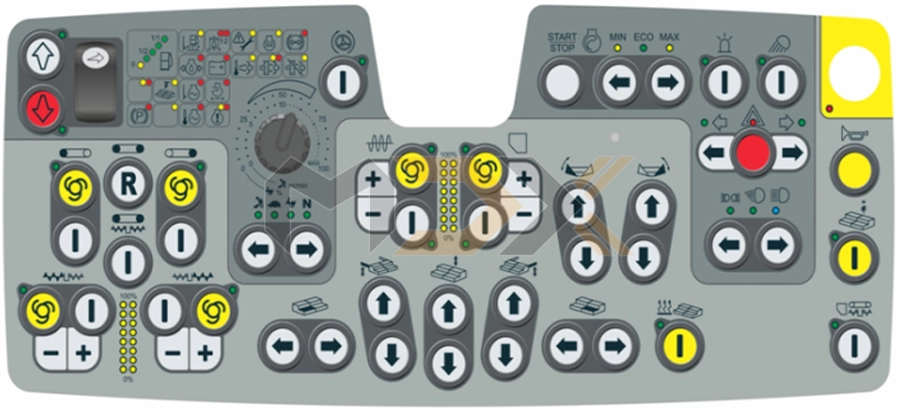

Developed from the ErgoPlus platform of the Premium Line, ErgoBasic brings an optimized operating experience to the Classic Line. This system fulfills all essential operating requirements, ensuring high paving quality. ErgoBasic provides the operator with all necessary functions while maintaining simplicity and intuitiveness. All control buttons are logically arranged by work area and marked with easy-to-understand symbols. The display clearly shows function and status messages. Machine control is also easier than ever with the rotary controller (for tracked pavers) or steering wheel (for wheeled pavers). Non-glare backlighting provides maximum support for the operator when working at night. |

|

Keys and symbols

| Arrow keys | LED keys | On/off keys |

|

|

|

| This is a momentary contact control; when the key is released, the system remains in its current position or the current setting is retained. | The key's LED lights up when the function is active or when automatic mode is switched on. | This is a momentary contact control; when the key is released, the system remains in its current position or stops. |

Differences between screed consoles

|

|

| The screed console only has one material conveyor control for Mini Class pavers such as the S700 (i) and S800 (i). | The screed console does not have a SmartWheel for wheeled pavers, such as the S1003(i), S1403, or S1603. |

|

|

| The screed console does not have a "Screed Assist" key for pavers that do not have this function or where it is only available as an option, depending on the market. | All Vogele pavers, except for the Mini Class, have two separate material conveyors. |

Paving Function Groups

|

|

|

- All functions are grouped into logical groups. - The function keys are waterproof and can even be operated when wearing gloves. - Backlit symbols are easy to see at dusk or at night. - LEDs indicate functions and statuses. |

Preselect the direction of travel for the paver (left side) - White key = Forward - Red key = Reverse |

| Traction main switch (right): confirm the desired direction of travel with the switch position. Do not operate the switch until the direction of travel has been selected. | |

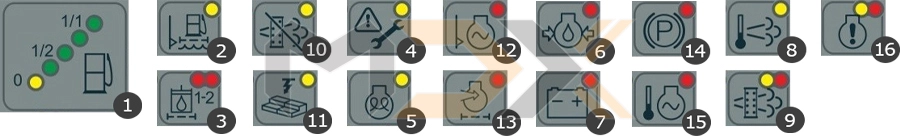

|

|

| 1. Fuel level | 2. Complete water separation | 3. Return filter (hydraulic system) | 4. Error | 5. "Pre-heat diesel engine" indicator |

| 6. Engine oil pressure | 7. Generator faulty or "D+ signal" interference | 8. Temperature of the reclaimer (i-machine) | 9. Error in the reclaimer (i-machine) | 10. Reclaimer deactivated (i-machine) |

| 11. Insulation monitoring | 12. Coolant level too low | 13. Air filter clogged | 14. Parking brake engaged | 15. Coolant temperature too high |

| 16. Engine fault (Level 2) |

| When a fault is active, the LED on the corresponding symbol lights up or flashes. The red LED on the brake symbol indicates that the parking brake is engaged. | |

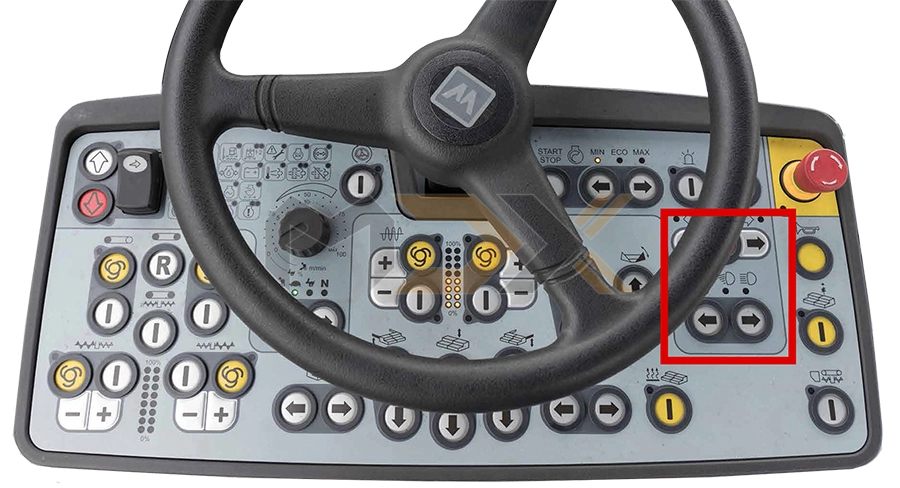

|

|

1. Moving a tracked paver in reverse (spot turning - positioning the paver). - Step 1: Activate the traction main switch. - Step 2: Hold the reverse key. - Step 3: Turn the SmartWheel to the left or right. |

2. Paving/travel speed control dial | 3. Operating mode selector switch: Paving, Positioning, Job Site, Neutral. |

|

||

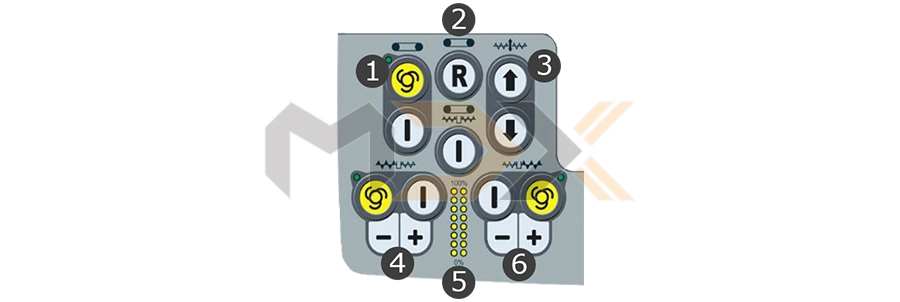

| 1. Automatic / Deactivated conveyor mode. | 2. Conveyor reverse. | 3. Auger height adjustment (optional). |

| 4. Left auger: Automatic / Deactivated / Speed control. | 5. Display of left and right auger speed. | 6. Right auger: Automatic / Deactivated / Speed control with + and - keys. |

|

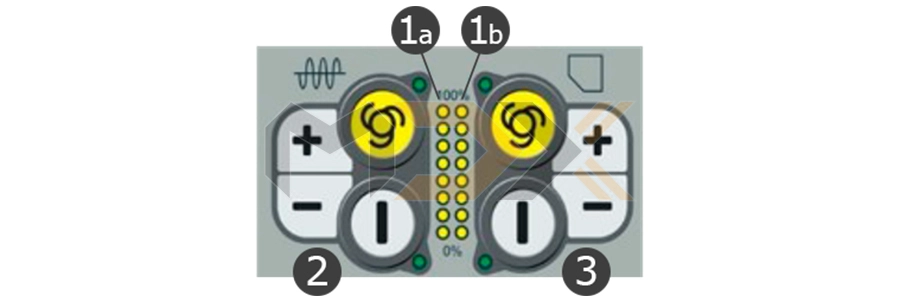

||

| 1. LED indicator for rotational speed. | 2. Vibrators. | 3. Tamper bar. |

| 4. Vibrator speed: Automatic / Deactivated / Speed adjustment. | 5. Tamper bar: Automatic / Deactivated / Speed adjustment. | |

|

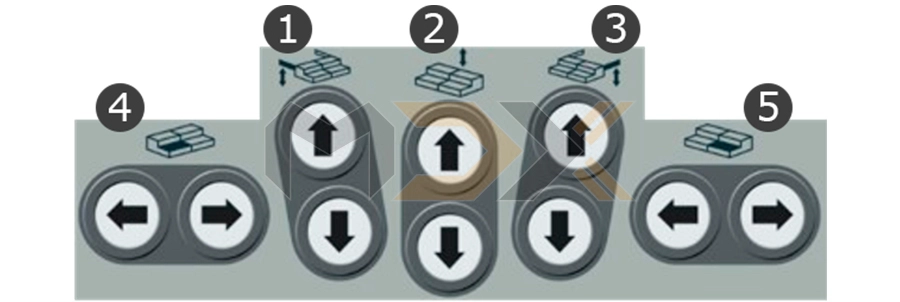

||

| 1. Screed raising/lowering cylinder, left. | 2. Screed raise / lower. | 3. Screed raising/lowering cylinder, right. |

| 4. Left screed width control. | 5. Right screed width control. | |

|

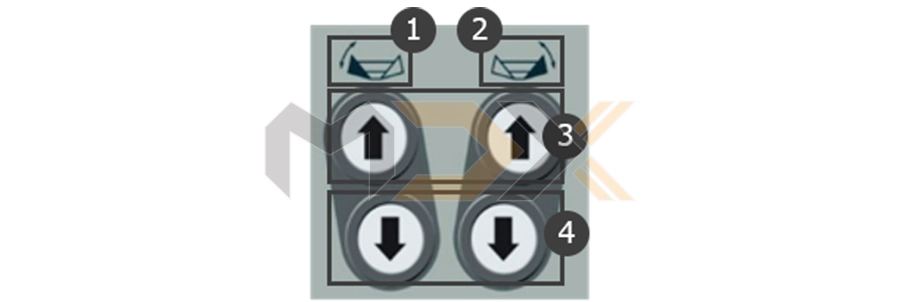

||

| 1. Left material hopper side. | 2. Right material hopper side. | 3. Raise. |

| 4. Lower. | ||

|

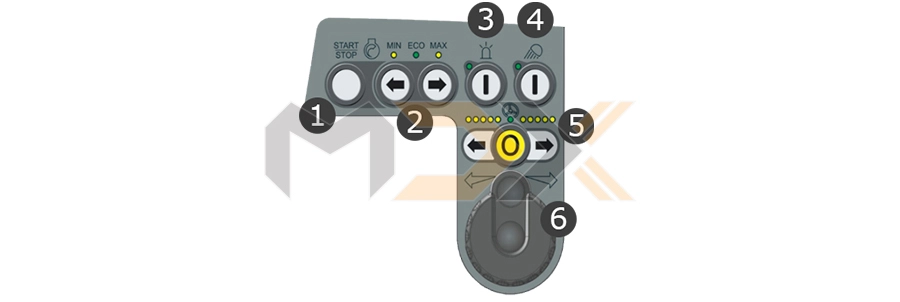

||

| 1. Start/stop diesel engine | 2. Diesel engine speed adjustment | 3. Hazard warning lights |

| 4. Working lights | 5. Steering trim, preselect radius | 6. Steering with SmartWheel |

|

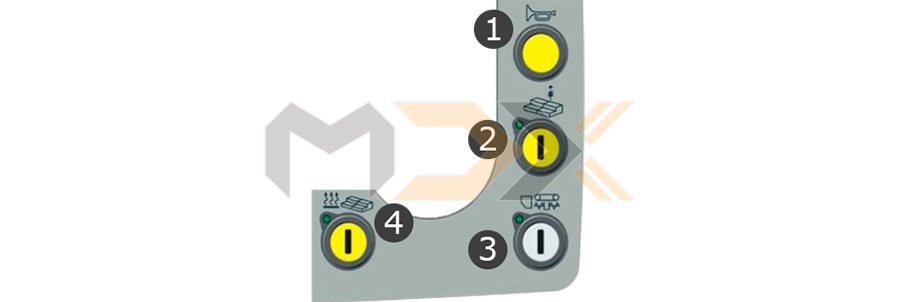

||

| 1. Horn | 2. Screed Assist | 3. Screed heating / cleaning |

| 4. Screed heating on/off | ||

Remote Control Unit for Screed

|

Remote Control Unit for Screed, specially developed for the ErgoBasic operating system: - Robust, practical design. - Direct access to the material conveyors. |

|

| 1. "Conveyor off" LED indicator | 2. Horn | 3. Automatic / Deactivated conveyor mode | 4. Preset value: fill level | 5. Float position |

| 6. Auger: Automatic / Preset value +/- | 7. Auger reverse | 8. Deactivate auger | 9. Screed raising/lowering cylinders | 10. Screed width control |

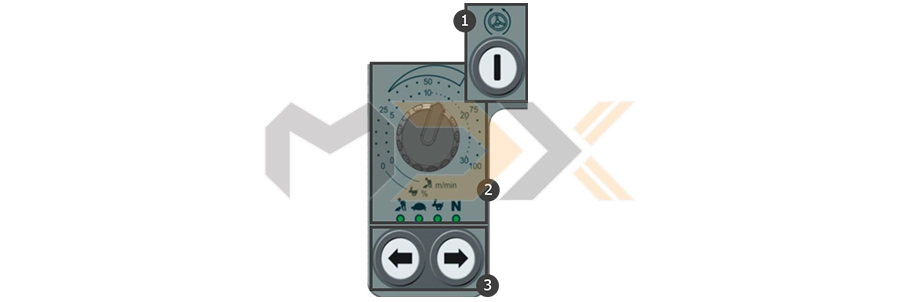

Grade and Slope Control Unit

|

Niveltronic Basic, integrated into the ErgoBasic operating system, provides automatic grade and slope control. It can be connected to two grade sensors and one slope sensor simultaneously. The system is fully integrated into the machine controller. Magnetic holders allow for easy attachment and removal of the remote control units, providing greater freedom of movement. Further advantages: - Precise control of grade and slope. - All necessary grade and slope control functions can be set with automatic sensor recognition. - Checking of set and actual values. - Sensor changeover at the touch of a button. - Large display. |

|

| 1. Display of the different controls. | 2. Niveltronic Basic on / off. | 3. Sensor sensitivity setting. | 4. Select reference mode (ground / string line / slope). | 5. Display of the set value. |

| 6. Display of the actual value = value measured by the sensor. | 7. Quick set (set value = actual value). | 8. Increase or decrease the set value. | 9. Calibration of the display value. |