HOW DO I CREATE A COMPETITOR COMPARISON

The first sub-area which we wish to examine in detail is the technical data comparison. The technical values can be divided into categories. The following technical values play a role in this respect: weight, machine dimensions, drum dimensions, engine, drive unit, compaction, steering, tank capacity/fill capacities.

TECHNICAL DATA - DIVIDING TECHNICAL VALUES INTO CATEGORIES

| Weight | Machine dimensions | Drum dimensions | Engine |

|

|

|

|

| Operating weight with cabin/ROPS. Operating weight, max. Weight distribution (axle load). Static linear load. Wheel load | Height, length, width. Max. working width (track offset, tyre overlap). Ground clearance. Curb clearance. Slope angle. Turning radius | Drum type – split/non-split. Drum type – smooth drum/padfoot drum/vibration crusher drum. Drum width. Drum diameter. Drum thickness. Track offset | Manufacturer. Output. Exhaust gas after-treatment. Exhaust emissions category |

| Drive unit | Compaction | Steering | DUNG TÍCH THÙNG NHIÊN LIỆU |

|

|

|

|

| Climbing ability. Speed. Regulation: infinitely variable | Amplitude. Frequency. Centrifugal force | Steering type | Diesel. Water. AdBlueA. Additive |

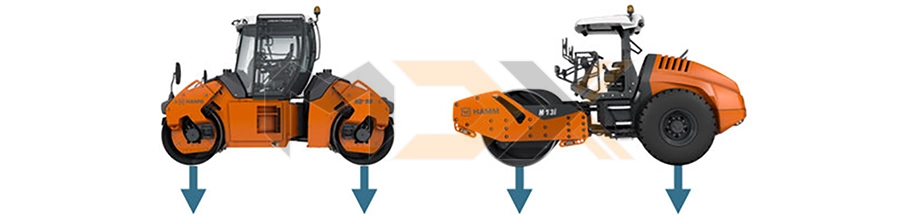

IMPORTANCE OF TECHNICAL DATA FOR ROLLER TYPES IN EARTH WORK AND ASPHALT CONSTRUCTION

Important in earth work and asphalt construction:

- Operating weight with cabin/ROPS/max.

- Weight distribution (axle load)

- Static linear load

- Machine dimensions (height, length, width)

- Turning radius

- Drum thickness

- Engine (manufacturer, power, exhaust gas after-treatment)

- Speed

- Regulation: infinitely variable

- Amplitude

- Frequency

- Steering type

- Fill capacities (diesel, water, AdBlue)

Extremely important for earth work

- Climbing ability

- Centrifugal force

- Ground clearance

- Slope angle

- Wheel loa

Extremely important for asphalt construction

- Drum width

- Drum diameter

- Max. working width (track offset, tyre overlap)

- Track offset

- Curb clearance

TECHNICAL DATA - MACHINE COMPARISON

The manufacturer-specific abbreviations in model names often hint at some technical data

WEIGHT

Operating weight with cabin/ROPS/max. There may be differences in a machine's operating weight due to selected options, equipment variants or similar.

Effects of differences:

- Exceeding the permitted transport weight

- Machine cannot be used to make a comparison

- The compaction result may be distorted with options such as a chip spreader (increased linear load)

- Options which may change the machine weight considerably may have negative effects on the surface quality

Other aspects and effects of machine weight

- Weight distribution (axle load)

- Static linear load

- Wheel load (for pneumatic-tyre rollers)

Weight distribution (axle load)

Asphalt construction – surface quality: The aim is to achieve a uniform compaction result. That is why we seek to achieve a balanced linear or wheel load. 50:50 would be optimal.

Earth work – compaction performance and traction: The aim is to find the balance between the greatest possible linear load and sufficiently effective traction. This means as much weight as possible should be on the front axle and as little as possible on the rear axle. About 2/3 of the overall weight is on the drum, depending on the machine size.

Static linear load

The influence of the static linear load on dynamic compaction is low.

Influencing factors on the static linear load: Drum width, Operating weight, Machine weight distribution

Result of a higher linear load: Better static compaction performance, Displacement of material with small drum diameter (asphalt)

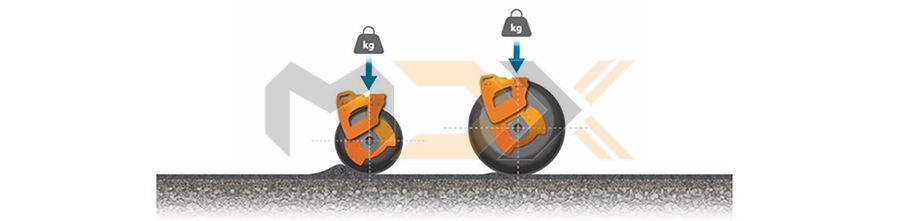

Wheel load (for pneumatic-tyre rollers)

Influencing factors on the wheel load:

- Number of wheels (eight or nine wheels)

- Operating weight of the machine

- Weight distribution front/rear

The wheel load is different between the front and rear axle in machines with an uneven number of wheels, e.g. four at front and five at the rear. This can produce an inhomogeneous compaction result.

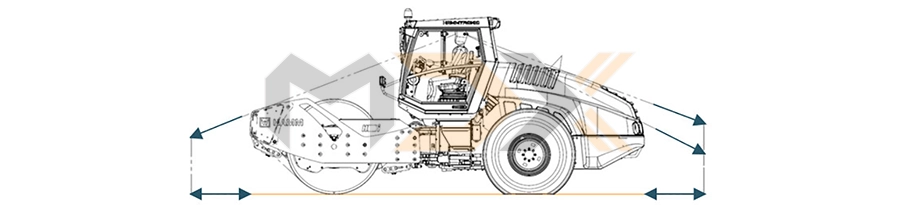

MACHINE DIMENSIONS

Width: The machine width also plays a role in loading. The machine needs to be carried as an abnormal load if it is more than 2.55 m wide. The width of the container door is relevant if the machine is loaded onto a container. The width is less than 2.55 m and depends on the container type.

Length: The machine's length has an effect on its manoeuvrability. It obviously also plays a role in loading (e.g. the number of machines which can be loaded onto a transport vehicle). The machine overhangs are decisive for off-road mobility (on driving slopes in earth works). Machines with a short installation length generally offer a better view to the front and rear.

Height: The machine can no longer be loaded onto a truck or into a container without dismounting machine parts if it is 3 m high or more. It must be transported on a low loader or ro-ro/flat ships (sea transport). The machine height is also important when the machine is in use, e.g. when driving under bridges or in tunnels or when used in civil engineering.

Machine dimensions – other measurements

Max. working width – track offset

- The track offset can extend the working width.

- The track offset is particularly important for the surface quality since it can be used to smooth out edges in the asphalt surface.

- The track offset is also crucial to be able to compact curb edges in a non-destructive way.

- The machine is not manoeuvrable along obstacles without a track offset

Max. track offset – tyre overlap

- The tyre overlap can smooth out lanes.

- If the tyres overlap, no ruts will appear in the surface. These would have a considerable adverse effect on compaction quality.

- Moreover, overlapping also favours a smooth compaction result on bends.

Ground clearance

- Machines with low ground clearance are in danger of becoming stuck or coming to rest on rugged terrain.

- Ground clearance can also be crucial when loading.

Curb clearance

- Machines with low curb clearance are often unable to compact to the edge (e.g. along walls).

- Additional devices such as vibrating plates need to be used in such cases.

Slope angle

- A shallow driving angle allows work to be performed in earth works since the machine does not collide with slopes.

- Slope angles also affect machine manoeuvrability, e.g. when driving in and out of trenches.

Turning radius

- The turning radius has an effect on the machine's manoeuvrability.

- The smaller the turning radius, the faster the machine can be placed in its work position.

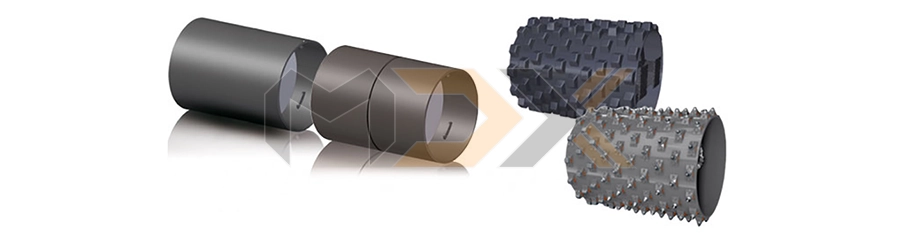

DRUM

Drum type

A distinction is made between split and non-split smooth drums or between smooth, padfoot or vibration crusher drums. The type of drum used depends on the application concerned.

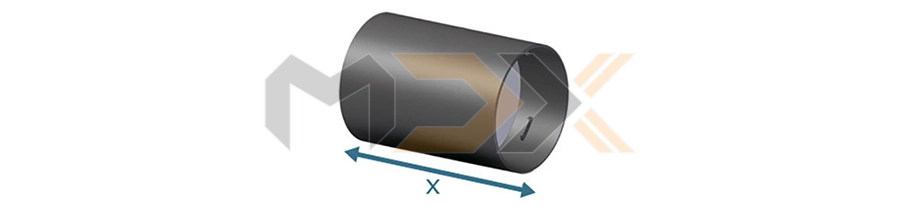

Drum width

The drum width is always adjusted to the weight class on the asphalt. The drum width is crucial for the machine's surface coverage performance and therefore an important efficiency factor. It is of secondary importance in earth work. The compaction performance or penetration is more important. Depending on the drum width size.... the working width increases/decreases... the static linear load increases/decreases.

Drum diameter

Large drum diameters decrease the spreading of material. This has a direct impact on the surface quality. The relationship between weight, drum width and drum diameter is crucial.

Drum thickness

The roller shell service life depends very much on the material being compacted. The stronger the roller shell, the longer the drum service life. Highly wear-resistant steel is used for drums subject to high stress such as oscillation drums.

Track offset

The track offset can be used to increase the working width by 50 mm - 1,370 mm, depending on the machine type. This is particularly beneficial during the final work steps, such as ironing, rolling in chippings or finishing edges. Important: Not all tandem rollers feature a track offset. But: All Hamm machines for asphalting are available with a track offset.

ENGINE

Manufacturer – important for clients: Reliability, Service support, Availability of spare parts

Power – important for clients: Engine power (hp or kW), Engine speed, Output per ton. It is also crucial for the engine power and hydraulic system to be optimally matched to one another.

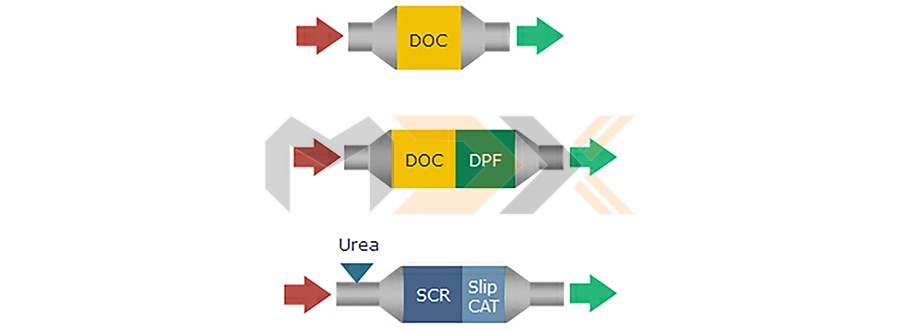

Exhaust gas after-treatment: Different systems are used for exhaust gas after-treatment. The type depends on exhaust gas legislation and the engine power.

Important: Not all manufacturers offer all models in all exhaust emissions categories. This must be taken into account for the country concerned when selecting a machine.

The costs for maintenance and component replacement are very different at times, so they have an impact on machine operating costs.

DRIVE UNIT

Three points are important for the drive:

Climbing ability

Climbing ability refers to the theoretical gradient which a machine can handle under optimum conditions. The greater the climbing ability, the better the fields of use are for the machine, especially in earth work and landfill construction.

Speed

A constant speed is important for uniform compaction and compaction control. Helpful in this respect are: Speed display, Cruise control, Infinitely variable speed adjustment

Control – infinitely variable

Benefit: The speed can be optimally adapted to all important conditions on the construction site without needing to select a specific gear.

- Material (earth work or asphalt)

- Amplitude

- Frequency

- Paver speed

Infinitely variable control vs. drive modes: Hamm distinguishes between infinitely variable control (= Hammtronic with speed preselect) and the drive modes (hare, tortoise, loading mode).

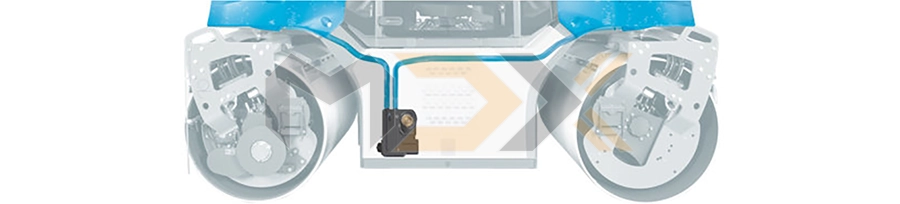

COMPACTION PARAMETERS

Amplitude

The amplitude defines the route that the drum has covered during dynamic compaction. However, the amplitude is not the only parameter for compaction performance. The following are also important:

- Machine weight

- Frequency

- Operating speed

- The amplitudes in earth work tend to be greater than in asphalt construction.

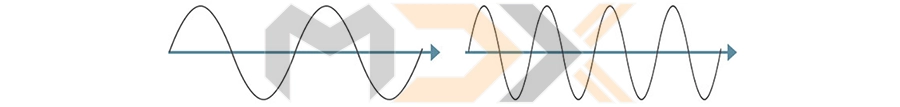

Frequency

The frequency determines the number of compaction impulses per second. It is measured in Hertz (Hz). Uniform compaction is not achieved if the frequency does not match the speed. Frequencies tend to be lower in earth work than asphalt construction.

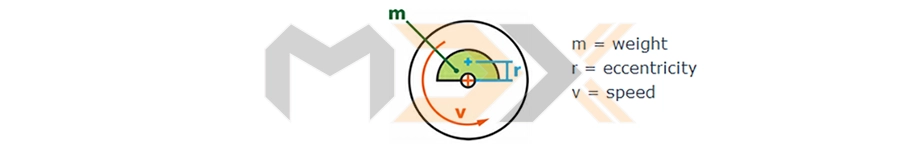

Centrifugal force

Centrifugal force describes the compaction energy generated by imbalance. It is measured in kN. Key factors are: weight of the imbalance, imbalance centre of gravity, frequency

Important: The indicated compaction power is only meaningful to a certain extent since manufacturers calculate it.

STEERING TYPE

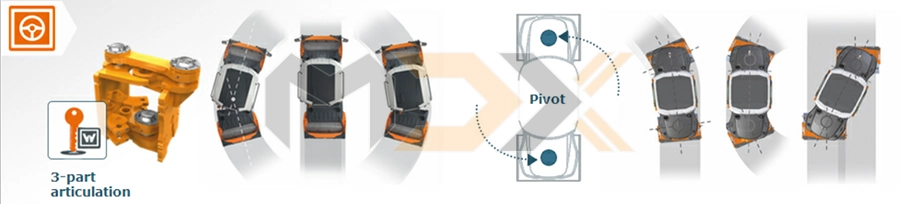

Articulated steering - There is a distinction between:

- Conventional articulated joint

- 3-point articulation

The 3-point articulation was developed by Hamm and offers a variety of advantages over a conventional articulated joint. It is fitted in all articulated Hamm rollers as standard.

Pivot steering - Key influencing factors:

- Gap between drums

- Steering angle

- Adjustment options (steering types)

FILLING CAPACITIES

Diesel/water: It is crucial for filling capacities to be sufficient to work the machine all day without needing to refill.

Diesel: The lower diesel consumption is, the lower operating costs are. Diesel consumption varies, depending on the area of use.

AdBlue: On average, a machine requires 5% AdBlue in its diesel consumption. A sufficiently large AdBlue tank is thus important.

Additive: It is crucial to know whether the additive needs to be pre-mixed or if there is an additive mix system.

Comparison of technical data as demonstrated by SideBySide

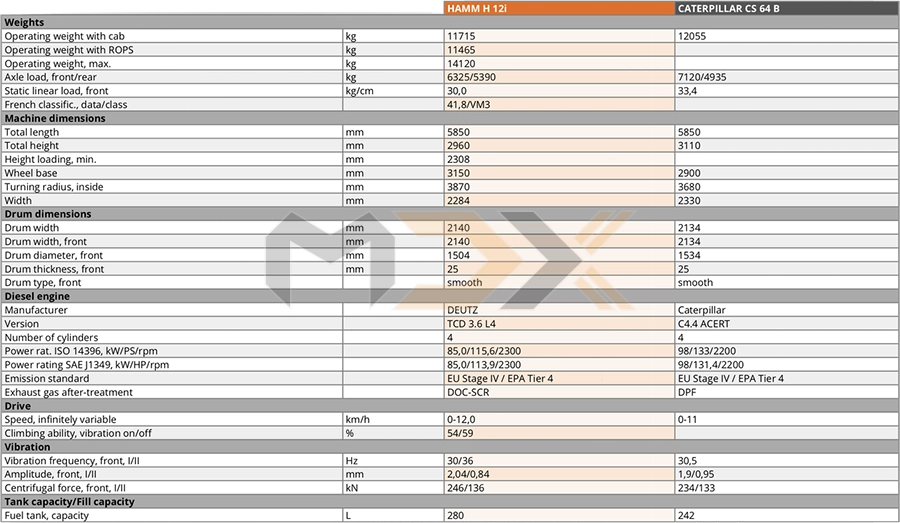

Earth work - Example H 12i vs. CS 64B

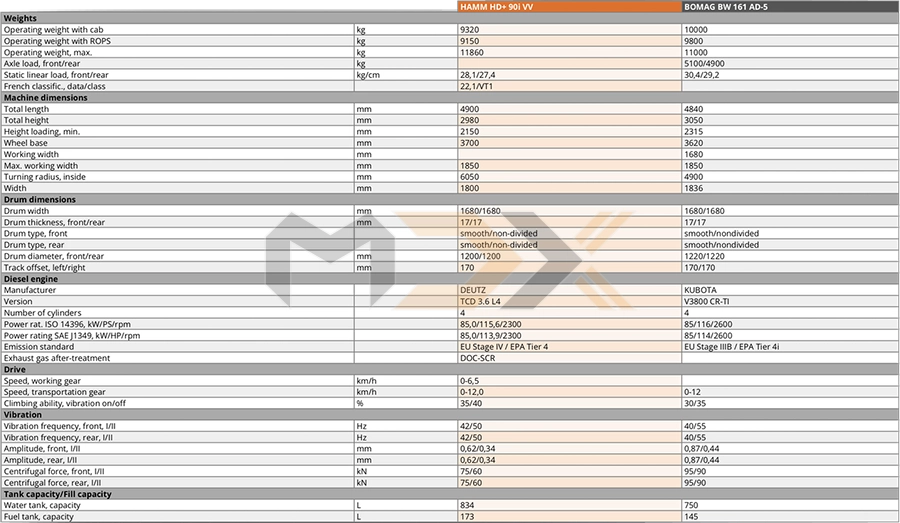

Asphalt construction - Example HD+ 90i VV vs. BW 161 AD-5

Comparison of features

Machine features also need to be examined in addition to the purely technical comparison. You should always ask yourself the following questions for this comparison:

- What is important about...?

- What does this depend on...?

- What must you pay attention to...?

We will then take a closer look at the machine features and client needs which are relevant for a direct comparison. This evaluation always includes responding to the aforementioned questions.

Client needs

The competitive comparison should take into account the needs of the client group concerned. Every client has different reasons for their purchase decision. The details thus make the difference! There are different basic needs for clients: easy & comfortable, time savings, safety, health, image & prestige, environment & ecology, fun, profit maximisation & productivity, aesthetics & design.

The first impression

Design and image are often a selling point for clients. The design awards which HAMM has received provide a good argument in such cases.

Appearance: Contouring/design, Colouring, Proportions, High quality, Powerful

Image: Premium manufacturer, "Everything from a single supplier" (synergy within the Wirtgen Group), Sales and service network (branches + dealers), Machine's resell value

Operator's platform

Variants

Variants: ROPS cabin, ROPS, Handrails

Access – what needs attention?

- Steps: Number of steps, Width of steps, Gap between steps, Step arrangement (stairs or ladder), View of steps when climbing in and out

- Surface on steps: Closed (slip hazard), Holes (dirt can drop below), Ribbing

- Anti-slip edges (affixed or integrated)

- Ergonomics

- Handrails (number, position, surface feel)

- Comfort for drivers (access, getting into seat)

- Non-slip operator's platform floor

If the client slips or feels unsafe when climbing into the machine, they will probably not buy the machine.

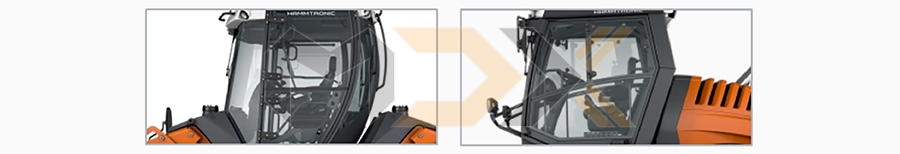

Door (to ROPS cabin) – what is important?

- Number of doors

- Door opener (lever, push button, lock)

- Split or non-split door

- Opening direction and angle

- Door hold-open device

- Window: Quantity, Position, Setting options, Locking mechanism

Emergency exit – how is it designed?

- Emergency set (if one door)

- Emergency set and emergency exit identification

- Accessibility

- Exit through second door (if two doors)

A quick escape from the cabin saves lives in dangerous situations.

Comfort/ergonomics

What should you take into account regarding the seat? -Manufacturer, material (imitation leather, fabric), robustness, seat console, safety features (safety belt, seat contact switch, safety belt monitoring device).

Seat adjustment: height adjustment, weight adjustment, back rest inclination, longitudinal adjustment, rotating seat, seat sliding right/left.

Good to know: The seat position is important to ensure an optimum view of the drum edge and the use of options, such as edge pressing and cutting equipment.

| Oscillation loads | Heating/air conditioning | Operating controls (general) | Seating comfort |

|

Arms, Legs, Insulation on the seat console, Operator's platform damping (rubber buffer). Important: Fatigue-free work is not possible if exposed to excessive vibration. |

Availability, Position of operating elements, Position of outlet nozzles, Settings for temperature, Settings for fan, Automatic climate control Important: A poor interior climate is created if the nozzles are positioned incorrectly (cold feet, hot head). |

Ergonomic layout, Overview (easy & convenient), Accessibility, Emergency-off position |

High backrest, Backrest extension (headrest), Armrest(s), Shock absorption |

| Seat operation | Trays | Sense of space | Armrests |

|

Steering column/display, moving, Seat and operating unit separate |

Quantity, Type: Cup holder, Secured tray (netting, box), Document compartment, Tool compartmentClothes hook, Tray for small items, Storage space for cool box, Space for smartphone, Lockable trays/compartments Good to know: A 12 V socket is useful for connecting electronic devices on the operator's platform. |

Available space, Legroom, Headroom, Glass surfaces |

Quantity, Adjustment options (foldable, swivelling) Good to know: Armrest adjustment options are crucial to ensure drivers can climb in and out easily. |

Operation

A rotary knob makes sense for certain functions, such as radio volume. A button is a better choice for functions such as working lights.

Operating controls: Dashboard/display, Drive lever/joystick, Steering wheel, Armrest, Buttons and/or rotary knobs, Number of operating panels

| Drive lever | Steering wheel | Steering column | Dashboard |

|

Ergonomics, Functionality, Number of functions (too many), Feel (free movement), Functional description in field of vision Easy and comfortable, safety |

Type/size (steering wheel, mini-drive lever), Position (centre, off-centre), Response, Sensitivity/steering behaviour Easy and comfortable |

Setting options, Comfort access Easy and comfortable |

Tiltable or installed in a permanent position, Vandalism protection, Lighting, Overview/legibility. Easy and comfortable, safety, profit maximisation and productivity |

| Armrest | Additional control panels | Buttons and/or rotary knobs | Control logic |

| Function assignment, Number of functions | Standard functions, Options | Quantity, Function |

Layout, Clear, language-neutral symbols, Graphic support, Colour coding, Functional groups, Visibility (sunlight, night). Safety, profit maximisation and productivity |

|

Operating concept Easy Drive A key unique selling point! |

Cross-product (e.g. HD+ series, DV+, H, GRW 280i), Self-explanatory (Easy Drive), Minimum learning time Easy and comfortable, safety, profit maximisation and productivity |

||

Visibility conditions

Legislation

Required standard: 1x1.5 m

Future standard: 1x1.2 m (over 10 t) and 1x1 m (under 10 t)

All-round visibility

- Working environment/construction site

- Drum edges

- Tyres

- Water sprinkling system/drum surface

- Options (edge pressing and cutting equipment)

- Exhaust pipe position

- No intrusive components or trims (A or B column)

- Rear view camera

- Camera phía sau.

Easy and comfortable, safety, profit maximisation and productivity

Lighting fixtures

- Working lights

- Lighting package as per road traffic regulations

- Additional lighting: Drum lighting, Drum edge lighting, Tyre lighting, Options (e.g. chip spreader)

Easy and comfortable, safety, profit maximisation and productivity

Mirror

- Quantity

- Position

- Size

- Adjustment options (manual or electric, from outside or from operator's platform)

- Heated

Easy and comfortable, safety, profit maximisation and productivity

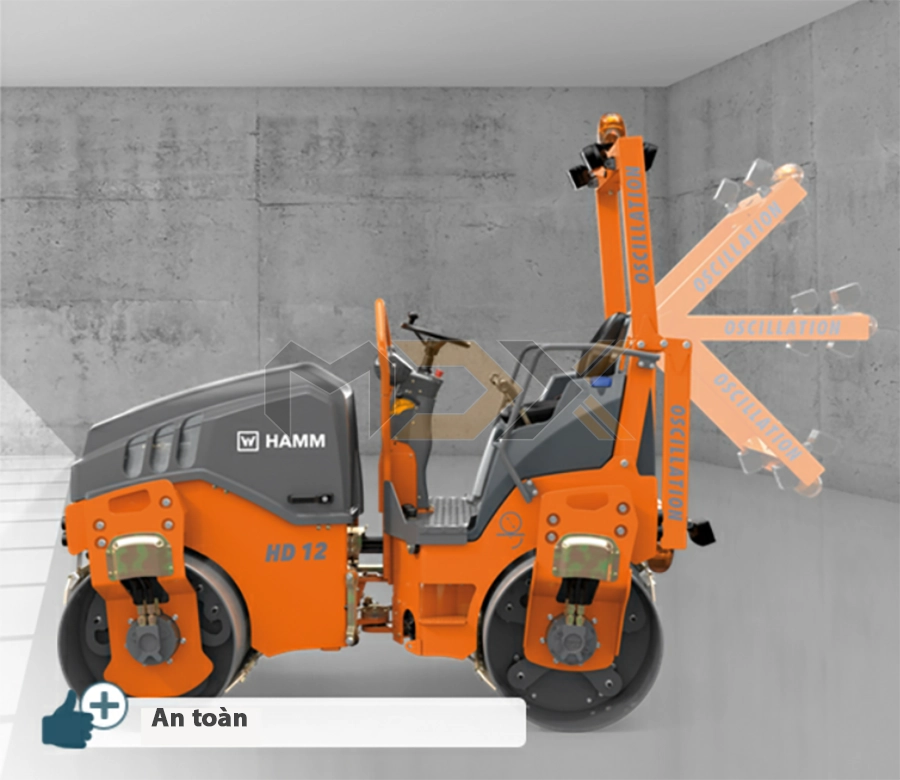

Safety

Operator's platform: ROPS, FOPS, Protective roof

Operational safety: Emergency stop, Seat contact switch (audio signal), Safety belt, Safety belt monitoring device, Armrest safety system, Emergency stop (drive lever), Foot brake (GRW)

Accesses: Handrails and access steps, Non-slip.

Warning systems: Warning indicator, Back-up alarm (reversing), Rotating beacon

Compaction

Important for compaction performance comparison

- During use on construction site

- Same conditions (material, temperature/weather, water content)

- Same weight class

- Same compaction parameters

- Documented proof through official test method (e.g. load plate, core drill hole)

Note: The comparison must take place under the same general conditions to determine the true, actual compaction performance. Best if at the same time on the same construction site.

| Compaction types | Drum types | Tyre pressure | Compaction parameters |

|

Dynamic: Vibration, Oscillation, VIO, Directed vibrator Static: Pneumatic tyres |

Smooth drum (split/non-split), Padfoot drum, Vibration crusher drum, Polygon drum |

Display Tyre pressure: Optimal, Too high, Too low Filling: Manual, Tyre inflation system |

Amplitude: Large – small (vibration), Steps (e.g. 5-amplitude system), Infinitely variable Frequencies: Frequency range: min. & max., Infinitely variable control, Frequency display Speed: Display, Pre-selection, Steps |

| Setting of parameters | Compaction mode | Working width | |

| Setting options for drum front/rear: Amplitude and frequency can be adjusted separately from one other. | Automatic (automatic vibration system), Manual | Track offset (adjustable), Track offset |

Drive

View Hammtronic at: HERE

| Engine | Hydraulic | Cooling system | Axle |

|

Installation position, Noise level, Diesel consumption (during use on construction sites). Note: Higher engine power does not automatically mean greater compaction performance. Coordination between diesel engine and hydraulics is key for performance. |

Hydraulically: Hydrodynamic (mechanical gear change, e.g. GRW 10-24), Hydrostatic (e.g. GRW 280) Hybrid hydraulic drive |

Does the machine heat up under extreme conditions? Extreme conditions may include: High outside temperature, Steep uphill or downhill drive, Full load over a longish period Note: Cooling capacity can only be tested under real operating conditions. Theoretical values are meaningful to a limited extent only. |

Axle: yes/no (e.g. twin lock system) Axle with self-locking differential Axle: split/non-split (pneumatic-tyre roller) |

| Machine management system | Tyres | ||

| ECO mode, Start/stop automation, Speed control, Anti-slip control, ABS, Speed control (cruise control function), Hammtronic |

Tyre manufacturer, Profile type (tractor profile, diamond profile, earth-moving profile), Tyre size, Tyre pressure Note: When performing comparative drives, it is extremely important to ensure that the machines are equipped with the same tyres under the same tyre pressure. Tyres play a major role in the machine's climbing ability and traction. |

||

Water sprinkling system

Water tanks

- Quantity

- Position

- Filling – from above/below

- Number of filler necks per water tank

- Water tank connection

- Pressure refuelling

- Outlet: Position, Central outlet, Water tap (practical on construction site)

Water tank access

- Access structures

- Steps

-Handles

Water pumps and water filters

- Water pumps: Quantity, Reserve pump

- Water filter: Quantity, Position, Capacity

Spraying bar and spray nozzles

- Quantity and position of spraying bar(s)

- Maintenance requirements (uncomplicated and without tools)

- Air deflector

- Number of spraying nozzles

- Spray pattern

- Combination nozzle comprising spray nozzles and membrane (to seal and shorten the response time)

- Sprinkling settings adjustable

- View of the spraying bar

- Speed adjustment (spray interval is adjusted depending on the speed)

Scraper

- Position

- Material

- Adjustment: rigid – foldable

- Ergonomics (handles, screw, foot pedal...)

Steering

- Types of steering: Articulated steering (conventional or 3-point articulation), Pivot steering, Axle steering

- Steering properties: Directional stability, Steering behaviour (smooth or stiff), Precision, Steering angle (turning radius), Track offset adjustable, Swing (oscillation angle)

OPTIONS

There are other options available in addition to the standard equipment.

- Built-in options, such as: Compaction meter, Asphalt temperature meter, Documentation systems (HCQ), Chip spreader, Edge pressing and cutting equipment, Padfoot shells, Dozer blade, Vibration plate

Options not only have a great impact on the price, but also the machine's operating weight.

View Hamm's Options 2020 at: HERE

Transport

- Loading and lashing eyes: Quantity, Identification/marking, Integrated or attached, Dimensions, Position, Central lifting point, Towing eyes, Version (rounded, sharp-edged)

- Loading: Buckling blocking, Loading mode, Ground clearance, Traction during loading, Loading equipment

Service and maintenance

| Service point | Layout of components | Documentation | Tools |

| Accessibility to service and maintenance points, Markings (stickers), Opening engine hood or cover, Miniature measuring points | Engine block, Exhaust system, Air flow direction (cooling air and exhaust gas), Cooler (easy to clean?), Filter, Hydraulic hosing (wear-proof?) | Operating and maintenance instructions, Engine manual, Maintenance stickers, Servicing intervals | Workshop manuals, Diagnostics interface (WIDIAG), Special tool, Service kits, Maintenance contracts |

| Supporting systems | |||

| WIDOS, WITOS...Systems for remote diagnosis (WITOS Fleet View) | |||

Environment

- Noise emissions, Oscillation loads, Biological operating fluids, Alternative drive (hybrid, electrical motor)

View Exhaust emissions legislation and engine technology (2019) at: HERE

IMPORTANT INFORMATION ON COMPETITIVE COMPARISON

- Machines must be directly comparable (weight class, options, emission class).

- Comparison must be based on target groups (end customer, hirer, service employees, drivers, branch colleagues/dealers).

- Machine can also be selected based on construction site parameters.

+ Asphalt construction, earth work (layer thickness, mixed material).

+ Size of the construction site (bicycle lane, airport, inner city...)

+ Location of the construction site (LRC, HRC)

Client needs

The competitive comparison should take into account the needs of the client group concerned. Every client has different reasons for their purchase decision. The details thus make the difference! There are different basic needs for clients: Easy & comfortable, Time savings, Safety, Health, Image & prestige, Environment & ecology, Fun, Profit maximisation & productivity, Aesthetics & design

Conclusion

A neutral competitive comparison creates trust and demonstrates our expertise. It is important to be aware of our own strengths and weaknesses. This is the only way to present convincing arguments and appear confident to the client.