CLOSED-CIRCUIT HYDRAULIC PUMPS: POWERING SUPERIOR CONCRETE PUMP PERFORMANCE

- How crucial are closed-circuit hydraulic pumps to the operational efficiency of machinery? - What are the common failures associated with hydraulic pumps? - Are you unsure which hydraulic system is best for your concrete pump? Let's explore the answers to these questions in the following article!

Hydraulic pumps are often referred to as the heart of machinery. They enable the automatic and accurate reception and transmission of operational status information from various components to the control center. This system is widely used in various types of machinery, such as Everdigm concrete pumps, which are equipped with FFH closed-circuit hydraulic pumps.

In addition, hydraulic pumps are utilized in many specialized fields, including maritime, mining, and aviation. Within a hydraulic system, pressurized fluid acts as a medium for transmitting force and generating motion. There are two main types of hydraulic circuits: closed-circuit and open-circuit.

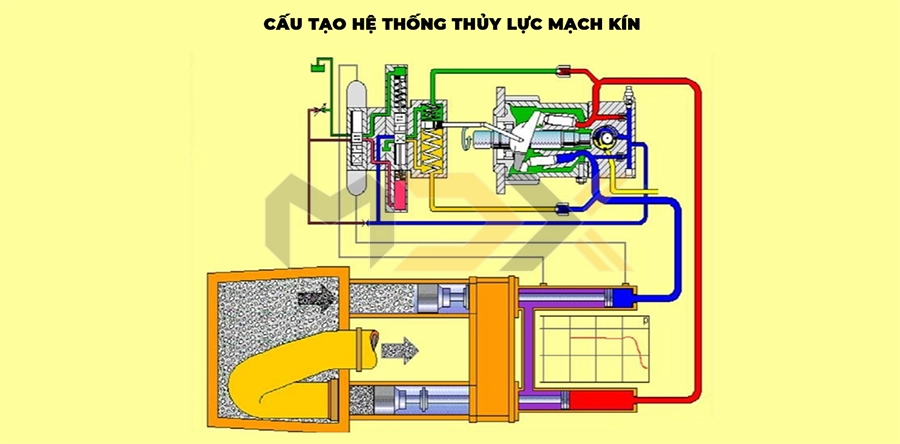

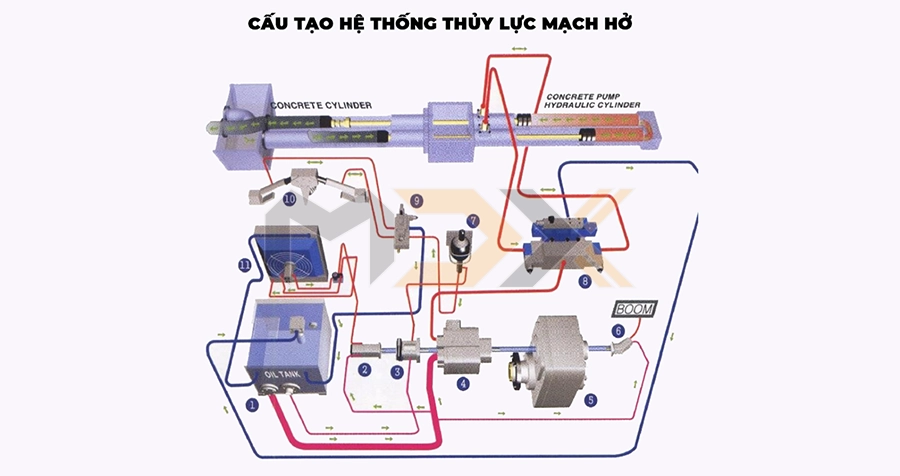

BASIC HYDRAULIC CIRCUIT STRUCTURE OF A TYPICAL CONCRETE PUMP TRUCK

A basic hydraulic circuit inside a concrete pump truck consists of the following components:

1. Hydraulic oil tank

2. Hydraulic pump for control system, outriggers, cooling fan, and water pump

3. Swing pump

4. Main pump

5. Pump switching gearbox

6. Hydraulic pump for boom system

7. Accumulator

8. Pump cylinder control valve

9. Swing control valve

10. Swing drive system

11. Hydraulic oil cooling fan

Currently, many concrete pump truck manufacturers often utilize two types of hydraulic pumps in their equipment: closed-circuit and open-circuit.

BRIEF INTRODUCTION TO OPEN-CIRCUIT AND CLOSED-CIRCUIT HYDRAULIC PUMPS

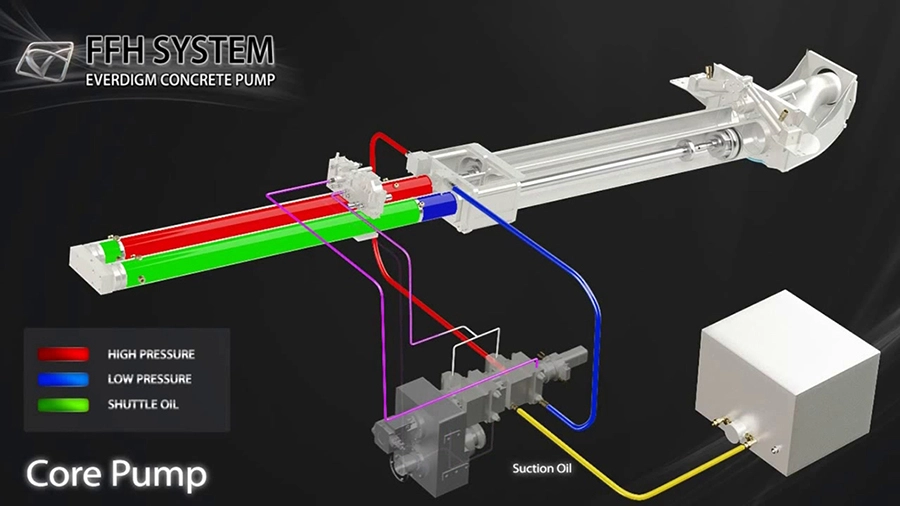

FFH (FREE FLOW HYDRAULIC) CLOSED-CIRCUIT HYDRAULIC SYSTEM

HYDRAULIC OIL TANK => MAIN PUMP => CYLINDER => MAIN PUMP

This is the hydraulic cycle used in the boom system of Everdigm concrete pump trucks. In this system, hydraulic oil from the rotating cylinder is returned directly to the main pump. Only a small amount of hydraulic oil is diverted back to the tank for cooling purposes.

This design generates higher efficiency compared to systems where all hydraulic oil is returned to the tank. By minimizing pressure losses, it enhances the concrete pump's performance and improves fuel economy.

OPEN HYDRAULIC SYSTEM

HYDRAULIC OIL TANK => MAIN PUMP => CYLINDER => HYDRAULIC OIL TANK

This is the open-circuit hydraulic cycle used in some other concrete pump truck brands.

In an open-circuit system, the hydraulic oil is returned to the tank after being pumped to the cylinder. This significantly reduces the pressure of the hydraulic flow, potentially eliminating it completely. As a result, the main pump has to operate at a higher capacity to maintain the necessary pressure for the system, leading to increased fuel consumption and unstable pumping performance.

COMPARING

Comparing the Advantages of Closed-Circuit Hydraulic Systems in Hyundai Everdigm Concrete Pumps with Open-Circuit Systems from Other Brands

All Hyundai Everdigm concrete pump trucks in Vietnam utilize the advanced FFH closed-circuit hydraulic system. Everdigm's pumps deliver exceptional performance and long service life. The following comparison table highlights the advantages of Everdigm's hydraulic system compared to other brands:

| FEATURE | Everdigm FFH Closed-Circuit Hydraulic System | Open-Circuit Hydraulic Systems (Other Brands) | Notes |

|

HYDRAULIC SYSTEM |

- No need for a controller between the pump and cylinder. - Compact structure, minimizing noise and heat generation during high-pressure opening and closing of hydraulic oil. This also limits excessive pressure fluctuations and reduces wear on components. |

- Complex structure due to the additional controller between the pump and cylinder. - High noise and impact levels result in reduced wear resistance. |

Unrestricted oil flow |

| - Minimizes pressure loss and increases efficiency. | - The controller between the pump and valve acts as an obstacle in the oil flow path, resulting in lower system efficiency. | Performance | |

| - Smaller oil tank capacity, resulting in lower hydraulic oil costs. | - Requires a larger oil tank capacity, leading to higher hydraulic oil costs. | Hydraulic oil tank capacity | |

|

- Two sequential pump lines minimize pressure fluctuations and shocks in the system. - The cyclical process ensures a smooth and consistent concrete flow. |

- A single pump line subjects the sequential valve to continuous maximum pressure, reducing its lifespan. - Long cycle time results in a sputtering concrete flow. |

Main pump |

|

| - Low impact when pressure is reduced on the pump control valve, extending pump lifespan. | - The high load on the concrete output control system increases the risk of unexpected failures. | Durability | |

| - Most control components in the FFH system are enclosed and easily accessible for maintenance. | - Continuous high-pressure operation reduces the lifespan of the hydraulic oil, leading to higher oil costs. The complex structure makes repairs more difficult. | Maintenance and repair | |

| - Very short concrete discharge time. | - Longer concrete discharge time due to the complex structure. | Concrete outlet | |

|

PUMP COMPONENTS |

- Low-noise gearbox with a long lifespan. | - Standard gearbox with high noise levels. | Transmission |

| - Low impact generated during concrete pumping. | - Pump operation is characterized by high impact and noise. | Main pump | |

| - More convenient with a separate priming pump for the control system. | - The pump handles both hydraulic oil control and pressure maintenance for the cylinder, resulting in high impact and noise levels. | Hydraulic control |

In addition, Hyundai Everdigm concrete pumps offer the following outstanding features:

- Hawe control valve block (Germany): Ensures precise and reliable operation.

- Integrated water pump for cleaning: Provides convenient cleaning after use.

- Durable hard chrome-plated cylinders: Increases durability and wear resistance.

- Pipe support rack on the rear outrigger beam: Smart design optimizes space utilization.

- Automatic and manual lubrication system for the hopper: Facilitates easy maintenance and hopper operation.

- Anti-retraction valve for outriggers: Enhances safety during operation.

- HBC wireless remote control (Germany): Offers convenient and safe operation.

- Non-slip aluminum alloy platform: Ensures operator safety.

- Work lights mounted on the turntable: Provides illumination in low-light conditions.

COMMON FAILURES IN HYDRAULIC SYSTEMS AND TROUBLESHOOTING

Hydraulic systems offer significant performance enhancements for machinery, especially closed-circuit hydraulics. However, without proper maintenance, these systems are prone to damage, potentially harming the machine and reducing its operational lifespan. Here are some common failures in hydraulic systems and how to address them.

| Reason |

- Contamination of the suction filter. - Loose connection between the suction pipe and filter. - Pump operating beyond the permissible speed. - Pump wear due to prolonged operation. - Excessive hydraulic oil temperature. |

- Air ingress: Air can enter the pump through leaks in the connections or hoses. - Incorrect pump selection: The pump may not be the correct speed or size for the system requirements. - Faulty coupling: The coupling between the motor and pump may be worn or loosely fitted. |

- Malfunctioning directional control valve. - Insufficient supply pressure. - Damaged hydraulic cylinder. |

- Excessive hydraulic oil temperature due to a malfunctioning oil cooler. |

| Harmful effects | - The pump is too noisy or vibrates too much. | - The pump output pressure is significantly lower than expected. | - Hydraulic cylinder malfunctions: slow, erratic, or no movement, and vibrations. |

- Insufficient reservoir capacity: The hydraulic reservoir is too small to hold the required volume of hydraulic fluid. - Low oil level: The oil level in the reservoir is insufficient for proper lubrication and cooling. - Use of incorrect oil type: The hydraulic fluid used does not meet the system's specifications. - Malfunctioning oil cooler: The oil cooler is not functioning correctly, leading to inadequate cooling of the hydraulic fluid. - Continuous operation of the relief valve: When the system is idle, hydraulic fluid continuously flows from the pump through the relief valve back to the reservoir, wasting energy and generating heat. |

| How to fix |

- Perform a hydraulic system flush. - Verify the pump's technical data and operating parameters. - Inspect and tighten all valves and connections. - Top up the hydraulic fluid reservoir if the level is low. |

- Replace all worn seals and damaged seals to prevent leaks and maintain system pressure. - Thoroughly inspect all hydraulic lines and fittings for leaks, damage, or wear. Repair or replace components as required. - Select a pump and motor with compatible speed and power ratings to ensure efficient and reliable operation. |

- Inspect the electrical system, including wiring, fuses, switches, and related components. Ensure all connections are secure and free of corrosion. - Thoroughly examine the hydraulic cylinder, including the piston rod and cylinder barrel. Look for any signs of bending, scratches, or damage on the surfaces. Such damage can wear down the piston seals and lead to oil leakage. |

- Verify that the hydraulic reservoir size is appropriate for the pump flow rate. Ideally, the reservoir capacity should be three times the pump flow rate. - Inspect and clean the hydraulic oil filter. Replace the filter with a new one if it is clogged or damaged. |

News Related

Tags: concrete pump