THE 7 HIGHLIGHTS OF VOGELE S2100-3 PAVER

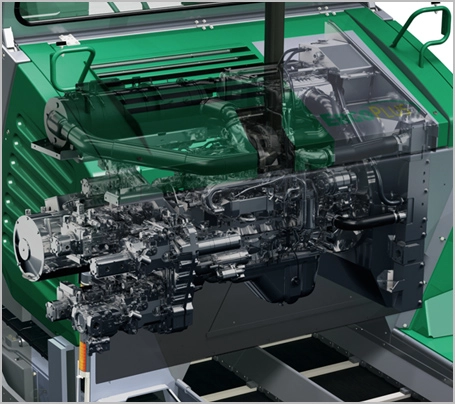

Vogele S2100-3 paver is Premium Class paver dedicated to highway construction. With a large spreading width of up to 13 m and a maximum achievable spreading capacity of 1 100 tons/hour. This is worthy of being the most outstanding and most investment-worthy spreading machine, not only Vogele but compared to other models in the world. The following article shares with readers the most outstanding advantages of the Vogele S2100-3 paver. We hope you enjoyed this article!

To see detailed specifications, please visit the link at: HERE

THE 7 HIGHLIGHTS OF VOGELE S2100-3

1. Powerful Cummins Diesel Engine

|

|

| Powerful yet economical Cummins 6-cylinders diesel engine with ECo mode allows the paver to be used worldwide | Can be used in all climatic regions thanks to perfect cooling via large cooler assembly. |

|

|

| Maintenance-free three-phase A.C. generation driven directly via the splitter gearbox. | Seperate hydraulic drivers in closed circuits |

|

|

| Low noise emission | Economical and eco-friendly thanks to low fuel consumption, soot particle filter and catalytic converter |

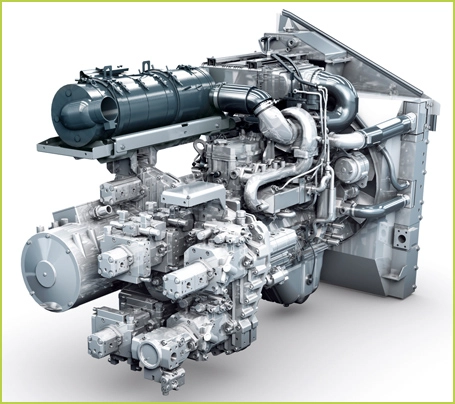

The Two Engine Versions

Exhaust emissions standards 3b and EPA Tier 4i (for Europe/USA/Canada/Japan): 186kW at 2,000 rpm, 175kW at 1,700 rpm (ECO Mode)

Exhaust emissions standards 3a and EPA Tier 3 (for all other countries): 179kW at 2,000 rpm, 168kW at 1,700 rpm (ECO Mode)

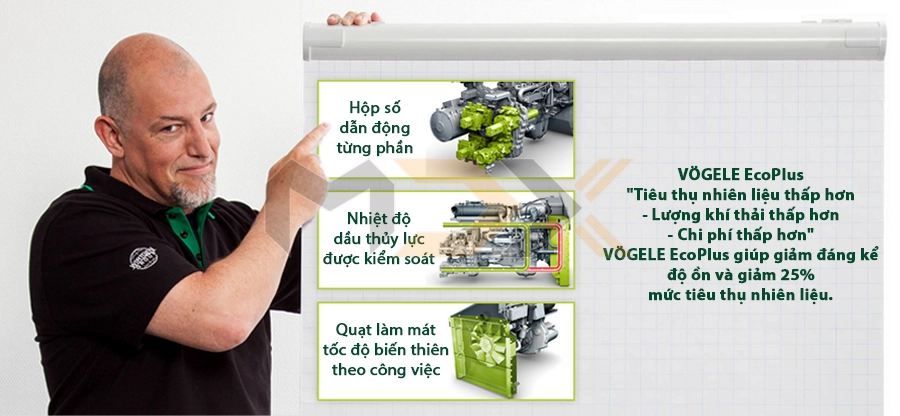

2.“VÖGELE EcoPlus” – Economical and Eco-Friendly

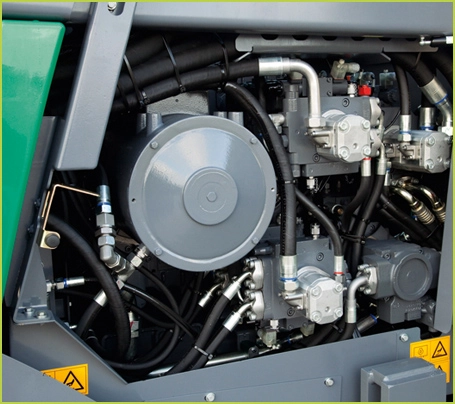

Variable- Speed Fan: Optimum load-dependent cooling is achieved by adapting the speed of the fan to the engine load and the ambient temparature.

Variable- Speed Fan

Controlled Hydraulic Oil Temparature Ciruit: A bypass circruit allows the hydraulic oil to reach its optimum operating temperature quickly. The oil is only diverted through the large cooler assembly once its temperature reaches 50 - 70 °C.

Controlled Hydraulic Oil Temparature Ciruit

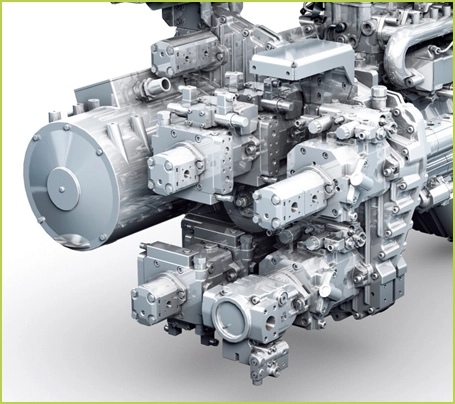

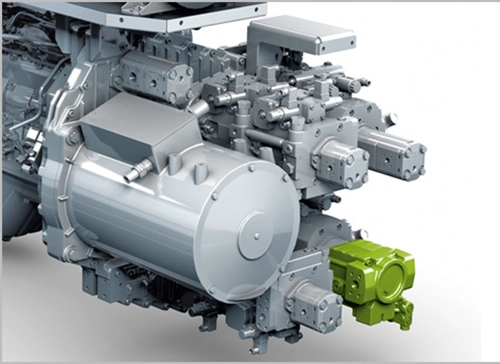

Splitter Gearbox: The hydraulic pumps for "Traction", "Conveyors and Augers" and "Compacting System" are automactically disengaged via coupling when not needed. This function reduces fuel consumption considerably.

Splitter Gearbox

Since SUPER 1600-3 has less installation space for hydraulic components, it cannot include tamper drive optimization function.

|

The tamper is driven by a variable displacement pump which always delivers exactly the amount of oil needed for the current tamper speed. |

Video - Optimizum Tamper Drive

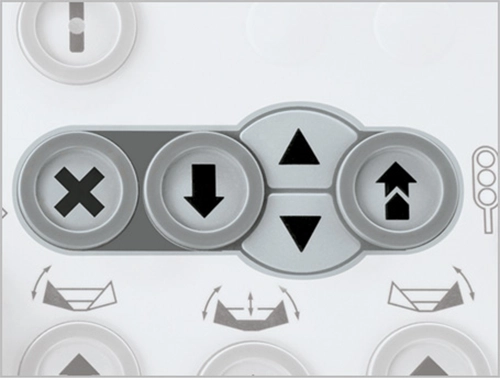

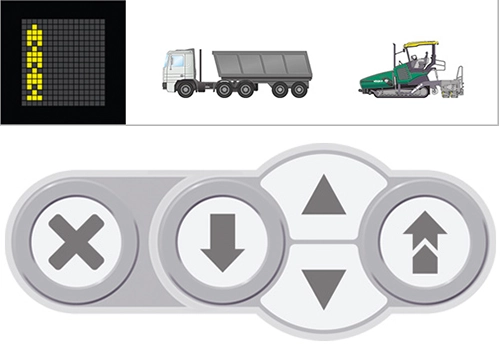

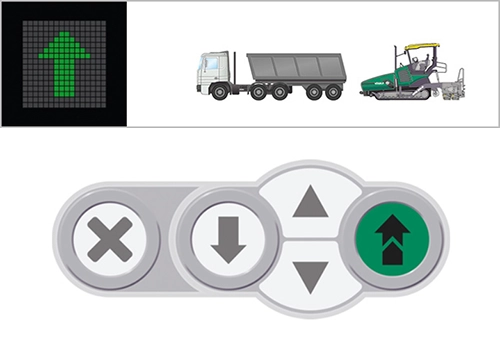

3. PAVEDOCK ASSISTANT

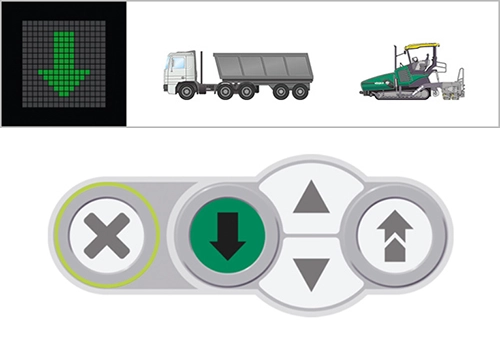

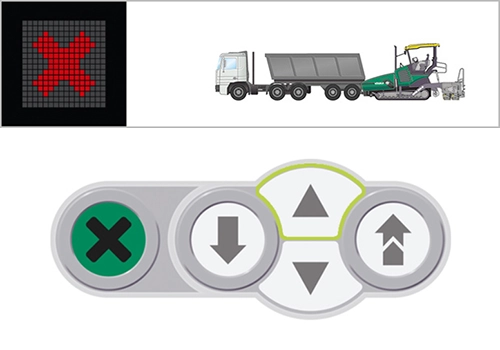

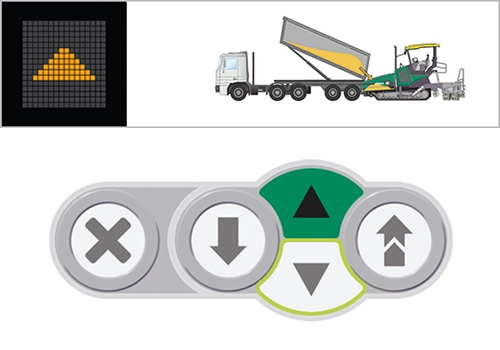

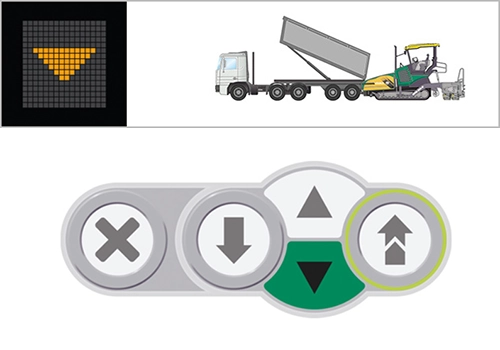

“PaveDock Assistant” is the communication unit between the paver operator and the feed vehicle driver. It allows particularly fast and reliable transfer of mix to the paver. The “PaveDock Assistant” components and process will now be explained in greater detail.

| The Components | |

|

|

| The control elements on the ErgoPlus paver operator's console. | The two signal lights mounted on the paver's hardtop indicate to the driver of the feed vehicle what needs to be done. |

| The Process

The “PaveDock Assistant” facilitates communication between the paver operator and the driver of the feed vehicle. The paver operator first presses the appropriate button and the signal light is then activated. |

|

|

|

| The yellow line on the signal light indicates that the paver is moving. This symbol may appear in combination with all displays. |

Paver moving: This symbol may appear in combination with all displays. Dock: Lorry drives up to the paver and docks. |

|

|

|

Paver moving: This symbol may appear in combination with all displays. 1. Dock: Lorry drives up to the paver and docks. 2. Stop: Lorry must halt. It has docked. |

Paver moving: This symbol may appear in combination with all displays. 1. Dock: Lorry drives up to the paver and docks. 2. Stop: Lorry must halt. It has docked. 3. Raise dump box: Lorry raises the dump box. |

|

|

| Hạ thùng: Báo tài xế hạ thùng. |

Paver moving: This symbol may appear in combination with all displays. 1. Dock: Lorry drives up to the paver and docks. 2. Stop: Lorry must halt. It has docked. 3. Raise dump box: Lorry raises the dump box. 4. Lower dump box: Lorry lowers the dump box. 5. Drive off: Lorry drives away from the paver. |

4. PAVEDOCK

“PaveDock” is a sprung push-roller. The particularly sturdy system efficiently absorbs jolts from the feed lorry while docking onto the paver so that these are not transmitted to the material being placed.

VIDEO – “PAVEDOCK ASSISTANT”

PaveDock and PaveDock Assistant form a perfect system

The sensor located in the sprung push-rollers reports to "PaveDock" when the feed vehicle has docked. The signal lights automatically show the stop signal. The feed vehicle driver can thus react immediately. The combination of both components ensures a high level of process safety when transferring mix.

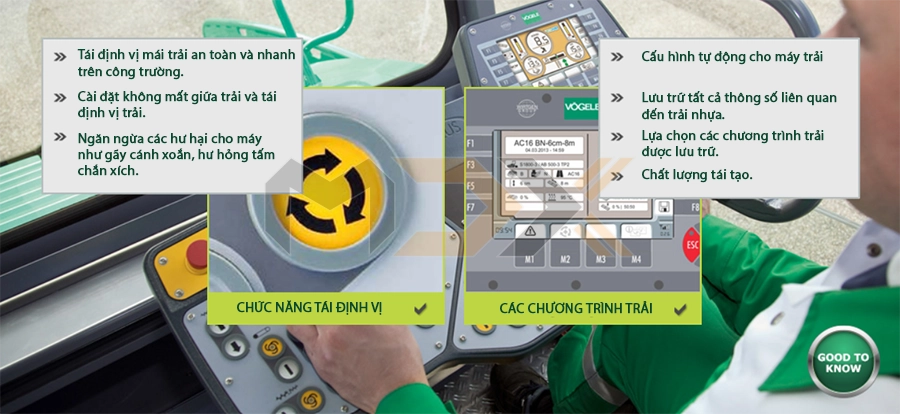

5. AUTOSET PLUS

VIDEO "AUTOSET PLUS"

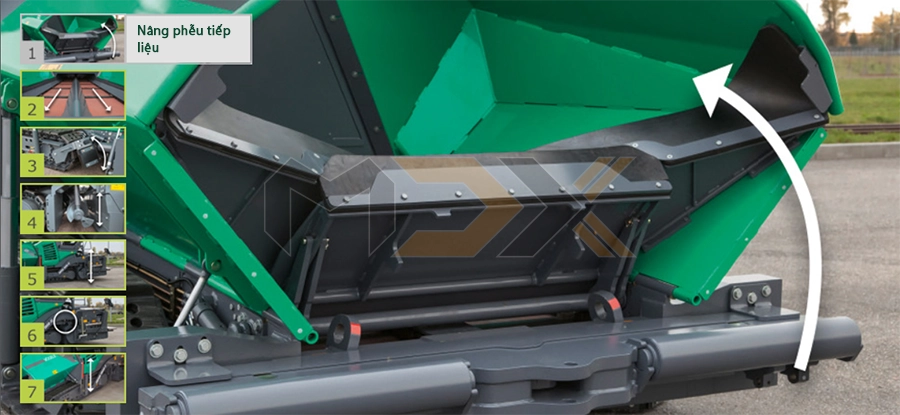

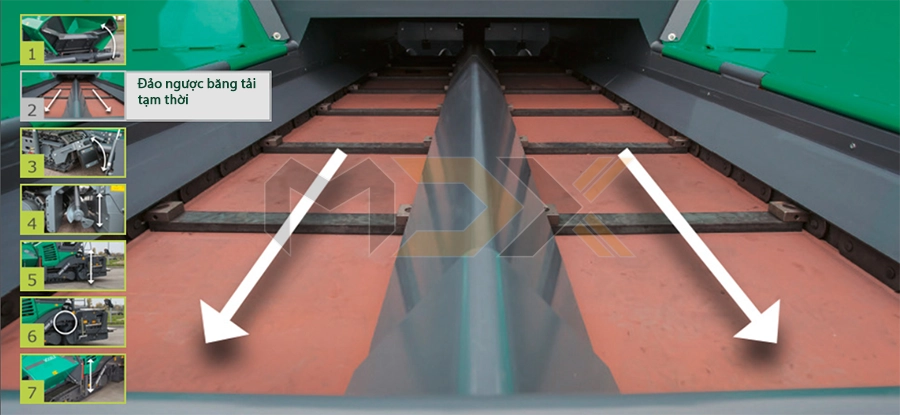

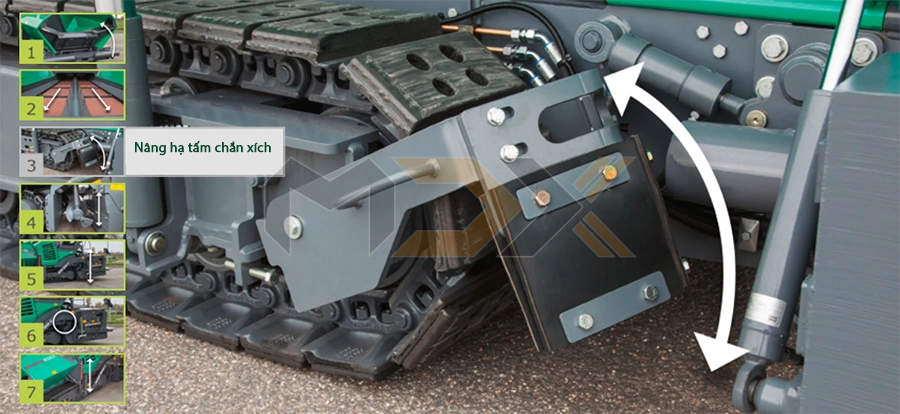

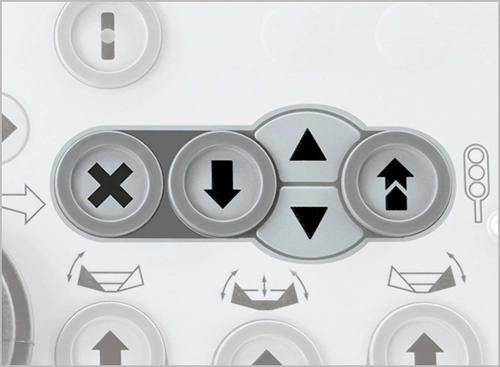

Repositioning Function

Raise front of material hopper

Temporarily reverse conveyors

Raise/lower deflectors for crawler tracks

Raise/lower auger

Raise/lower screed

Lock/unlock screed

Raise/lower tow point rams

Video - Repositioning Function

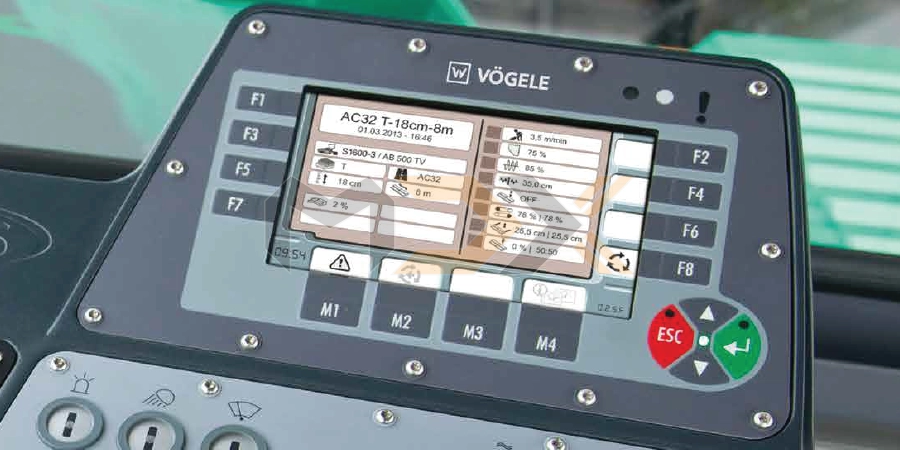

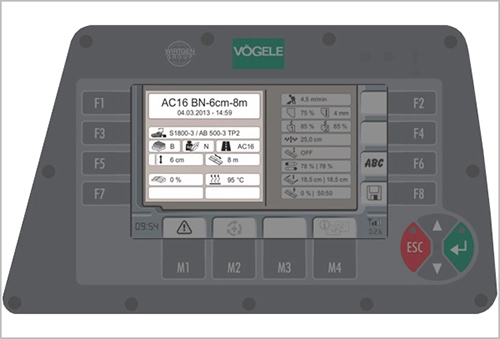

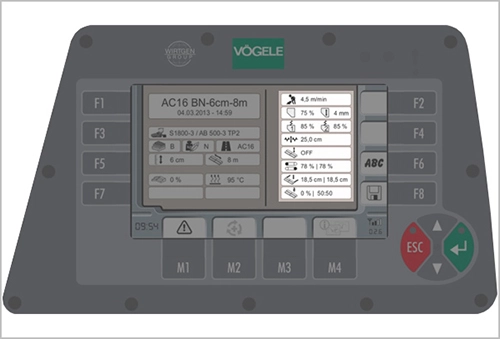

Paving Programmes

With the automatic function for paving programmes, certain paver and screed settings can be saved as programmes. Prior to saving a paving programme, various job parameters also need to be recorded. The stored paving programmes can be selected and used at any time via the “AutoSet Plus” menu. Settings can be changed as required in programmes that have been stored.

| Job parameters | Paver and screed settings |

|

|

| When saving a paving programme, the following job parameters need to be recorded: type of layer (base course, binder course or wearing course), type of mix (e.g. asphaltic concrete), grain size, layer thickness, pave width, tamper stroke | The following settings are automatically set and saved by “AutoSet Plus”: pave speed, tamper speed, pressure of the two pressure bars 1 + 2, height adjustment of the auger, screed Freeze, maximum speed of the two conveyors, height adjustment of the tow point rams, screed Assist. Press the F8 key to save the programme after entering the job parameters. |

VIDEO – AUTOSET PLUS – Paving Programmes

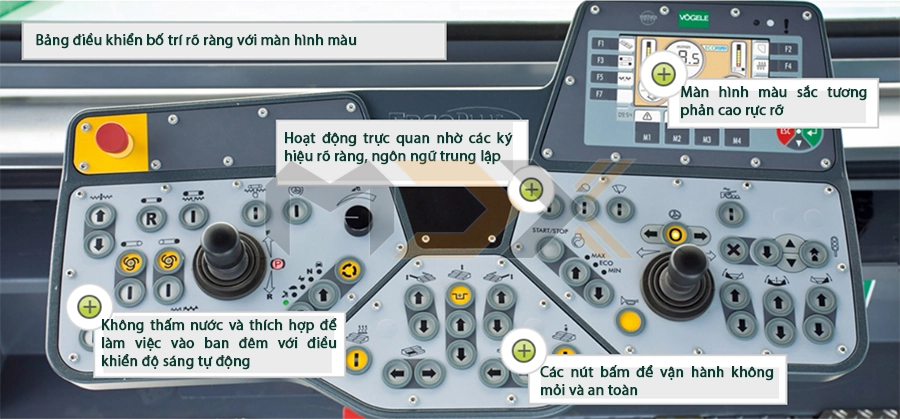

6. ERGOPLUS 3

|

|

| Colour display with a bright high-contrast display. | Backlit, language-neutral symbols on the operator's console for working in the dark and at twilight. |

|

|

| Glass side panelling protects the operator from the wind and rain. | “SmartWheel” for precise screed width control. |

|

|

| High-power LEDs on the screed console and material flow sensors for illuminating the area surrounding the screed. | Screed footstep and walkway allow operators to work safely and ergonomically. |

|

|

| “PaveDock Assistant” for perfect communication on delivery of the material. | “AutoSet Plus” relocation function for moving the paver quickly and safely at the touch of a button. |

|

|

| Crown adjustment at the press of a button for fast and direct access. |

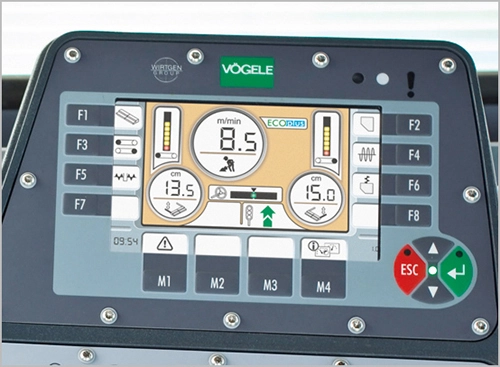

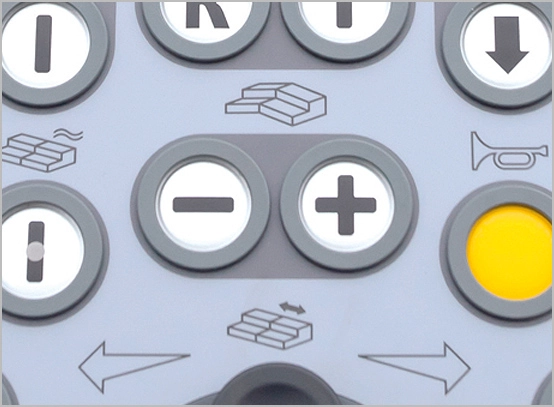

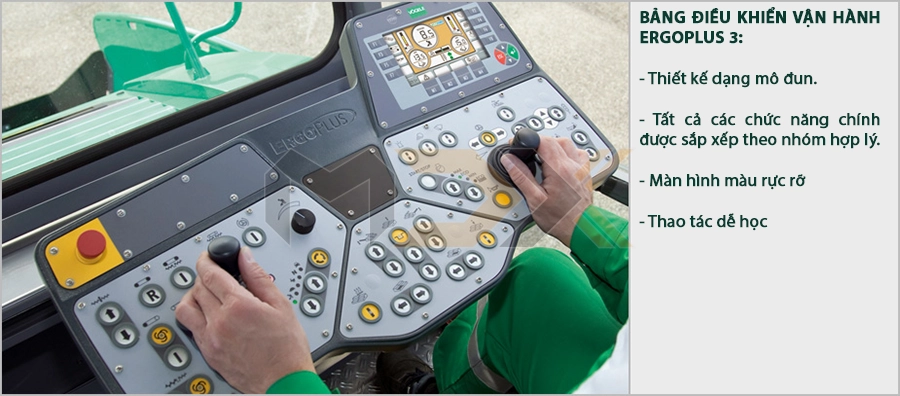

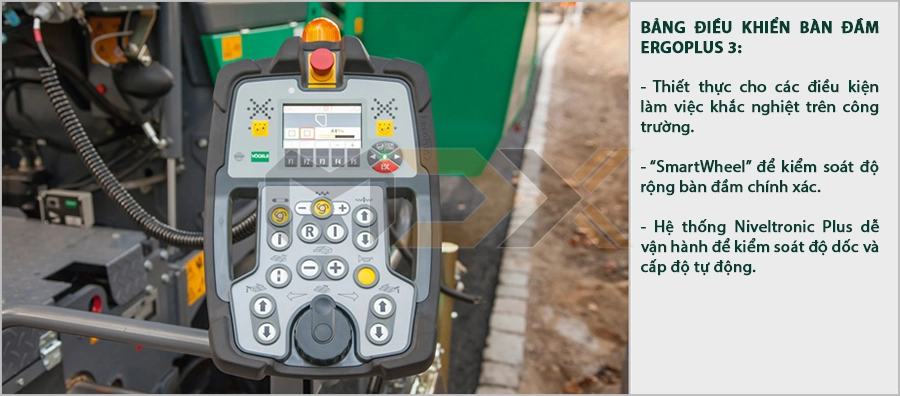

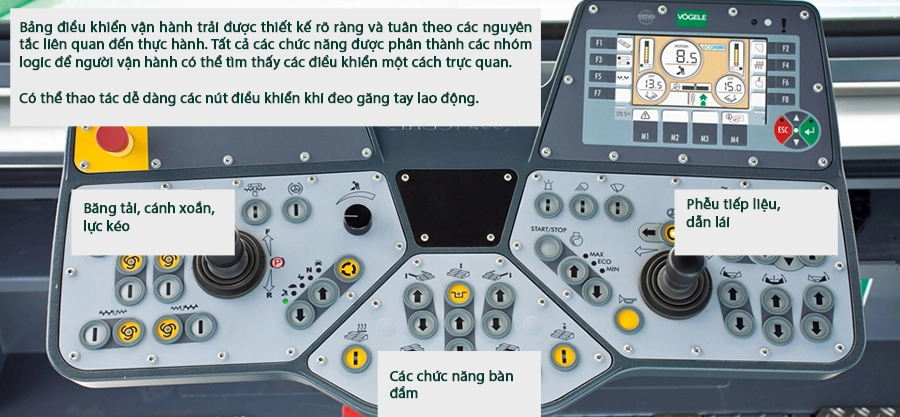

- ErgoPlus 3 paver operator's console: modular construction, all main functions arranged in logical groups, brilliant colour display, operation is easy to learn.

- ErgoPlus 3 screed console: robust for tough working conditions on site, “SmartWheel” for precise screed width control, easy-to-operate Niveltronic Plus system for automated grade and slope control

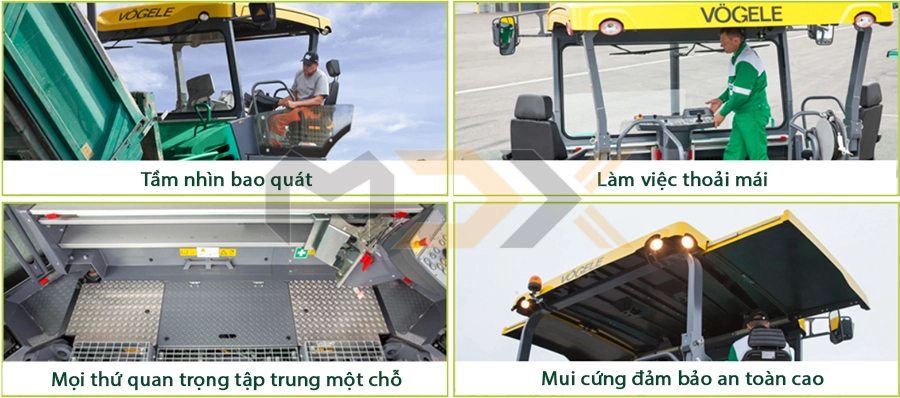

- Ergonomic workstations: clearly and neatly laid out operator's platform, glass side panelling affords protection from the wind and rain, hardtop for optimum protection against rain and sun, operator's seat and console can be adjusted separately, safe screed access with low footsteps

- Excellent all-round visibility: Unobstructed view of all crucial areas on the paver, such as the material hopper, steering guide and screed. It allows the paver operator to closely monitor the feeding process, for example. The seat arrangement and platform design provide an excellent view of the auger tunnel. As a result, the operator is able to monitor the head of mix in front of the screed at all times.

- Working comfort: The seat and console on the operator's platform are separately adjustable. The paver operator's console can be displaced across the full width of the operator's platform, swung out to the side and tilted. Side panelling affords effective protection from the wind and rain. When working with the seat swung out, the operator's console also swivels out. This ensures that an ergonomically optimum sitting position is guaranteed at all times.

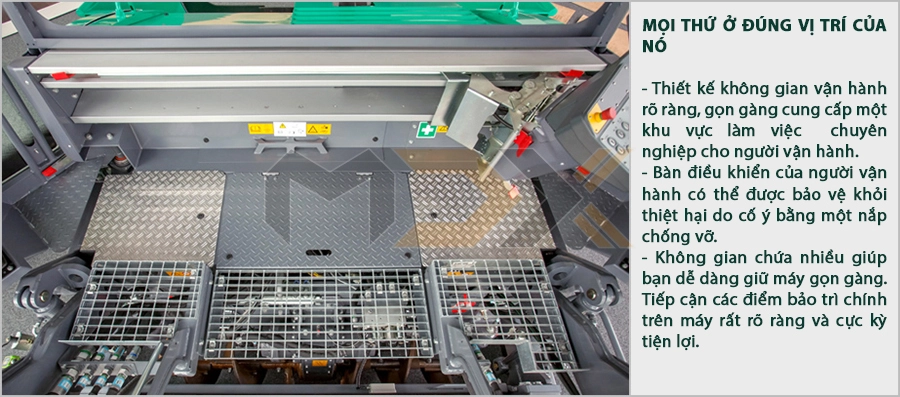

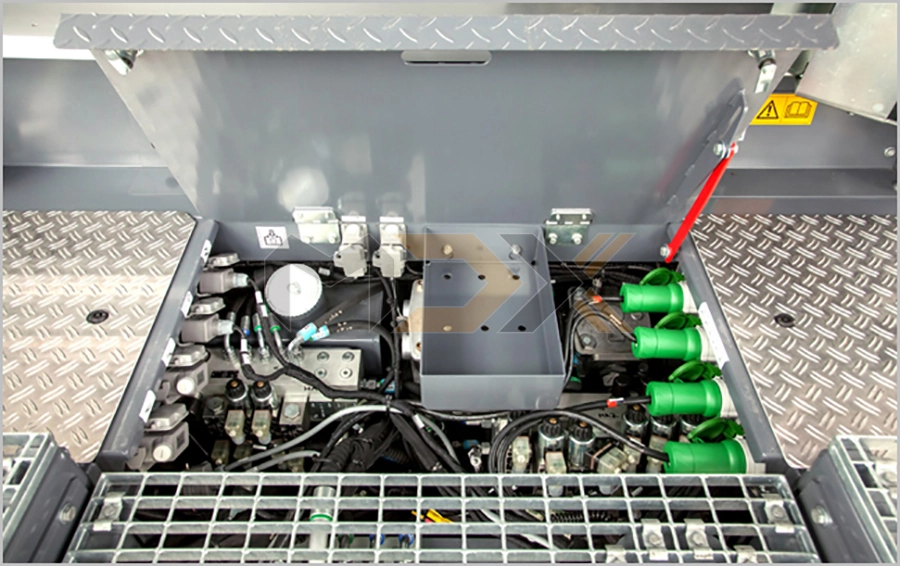

- Everything in its place: The clearly structured, neat operator's platform provides a professional workstation for the operator. The operator's console can be protected from wilful damage by a shatter-proof cover. Plenty of stowage space makes it easy to keep the machine tidy. Access to the key service points on the machine is very clear and extremely ergonomic.

- Hardtop gives excellent protection: The modern hardtop of glass fibre reinforced polymer material shelters the operator from rain and sun. The hardtop, including exhaust pipe, lifts up and lowers down quickly and effortlessly by means of a manually operated hydraulic pump. Wide sunshades which extend easily give the operator optimum protection when the seat is moved out. Six powerful working lights are built into the hardtop. As they are placed particularly high up, they provide excellent illumination for the job site.

Paver Operator's Console

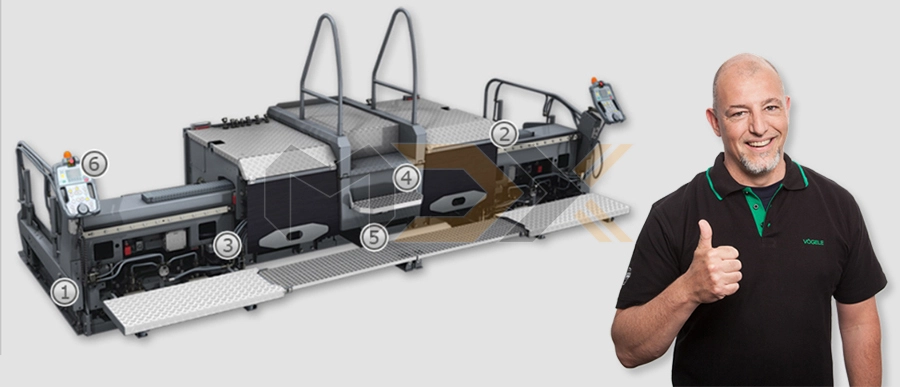

7. NEW SCREED - AB 500 VÀ AB 600

1. Newly developed side plates

All settings can be input safely and conveniently from the walkway thanks to the highly ergonomic and hydraulically adjustable side plates. The operator can easily adjust the height of the mechanical side plates.

2. Excellent floating and paving performance

The optimized geometry of the tamper bar and screed plates allows an even flatter screed planing angle, which improves the floating properties of the screed. The result is outstanding compaction with improved pavement evenness

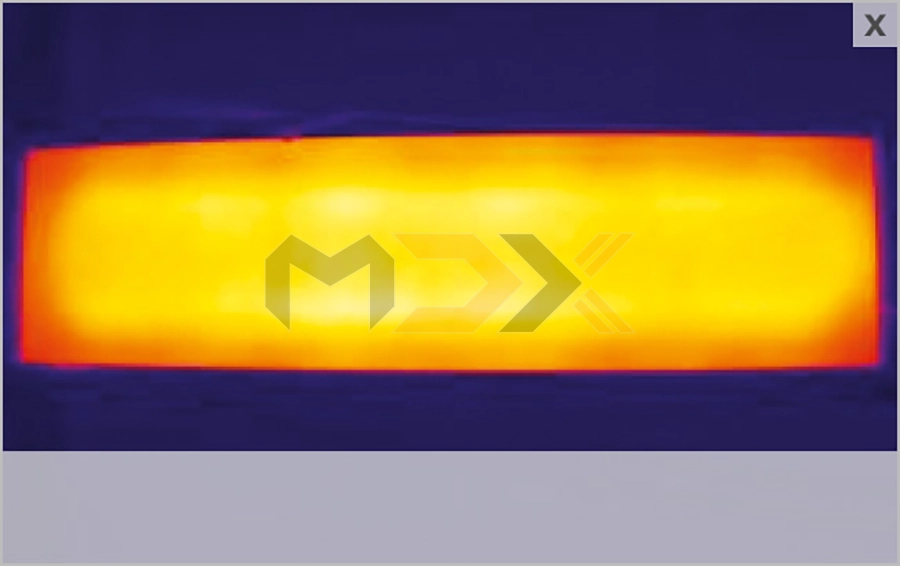

3. Highly efficient screed heating

New powerful generator provides an even better heating performance. The increased heating dynamics result in even faster and more uniform screed warm-up.

4. Safe and convenient screed footstep

The centrally positioned screed footstep provides quick and convenient access to the operator's platform. A particularly wide and vibration-damped walkway allows safe and convenient operation.

5. Hydraulic crown adjustment

The crown can be adjusted hydraulically as standard with the AB 500 and AB 600 Extending Screeds. This is realized quickly and precisely using the push buttons on the screed operator's consoles. The crown value is displayed on the console displays.

6. Ergonomic screed console

The high-contrast colour display guarantees optimum visibility from all angles and provides a brilliant display of all information. The “SmartWheel” has two speeds for precise screed width control.

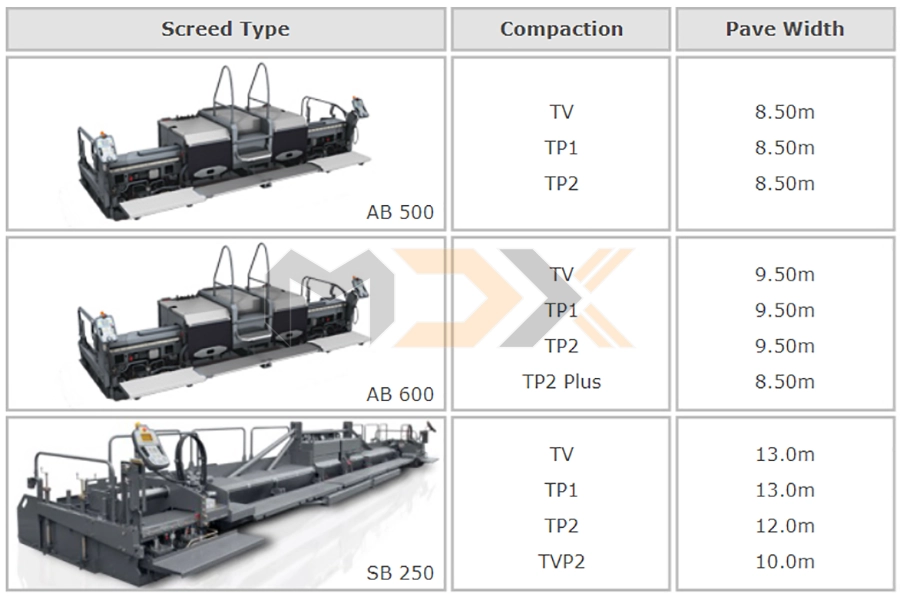

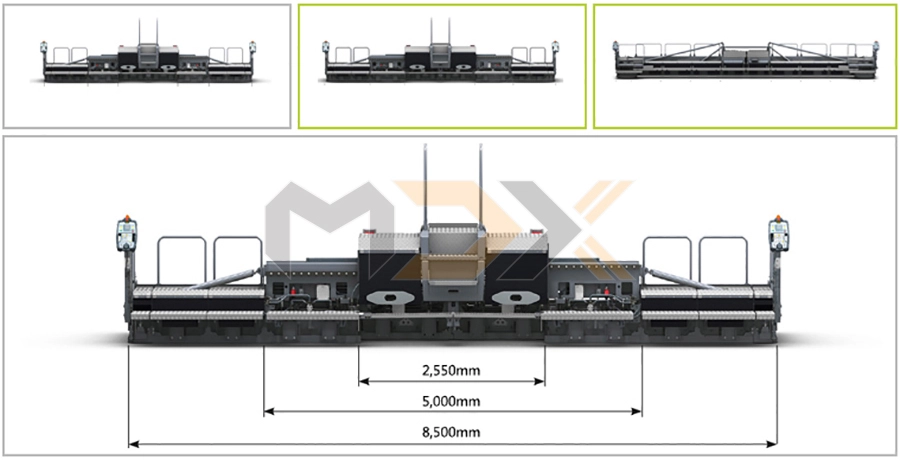

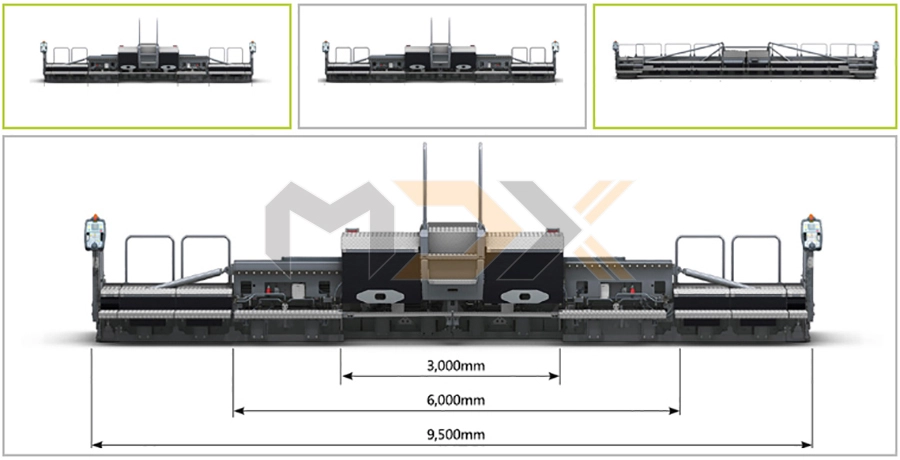

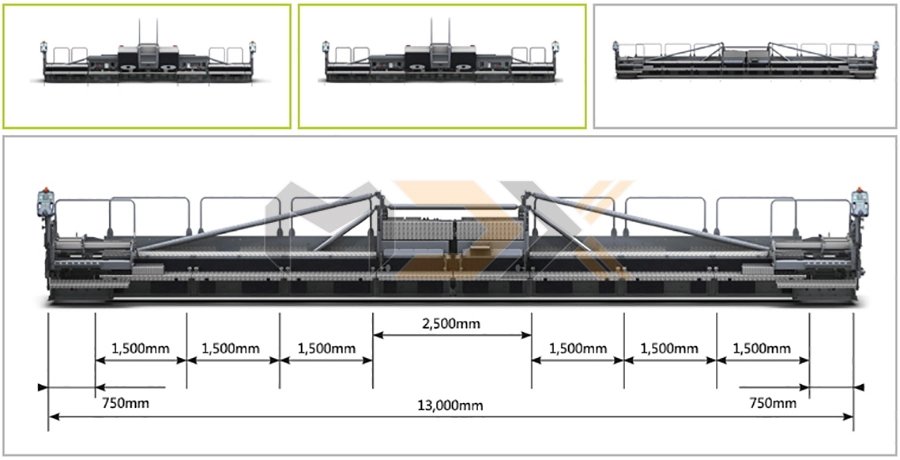

SCREED - PAVER WIDTH

Based on the huge pulling power and the ability to handle the optimal subsidence ratio, the S2100-3 can perform well when working over large spreading widths. To achieve optimum pavering results for every job, VÖGELE offers high-precision compactors in various versions integrated with compaction systems.

The SB 250 Fixed-Width Screed, as well as the AB 500 and AB 600 Extending Screeds are available

- TV = tamper + vibrator

- TP1 = tamper + 1 pressure bar.

- TP2 = tamper + 2 pressure bar.

- TVP2 = tamper +vibrator + 2 pressure bar.

AB 500 TV configured for maximum pave width 8.5m

AB 500 TV configured for maximum pave width 9.5m

B 250 TV configured for maximum pave width 13m

News Related

Tags: Vogele S2100-3, tracked paver