THE 6 HIGHLIGHTS OF VOGELE SUPER 1400 AND SUPER 1403

Super 1400 and Super 1403 are two popular models of Vogele which are 100% directly manufactured in India. They possess many outstanding features as well as meet diverse needs in work. The following article shares with readers the 6 most outstanding advantages of them. We hope you enjoyed this article!

You can refer to the product information of pavers: HERE

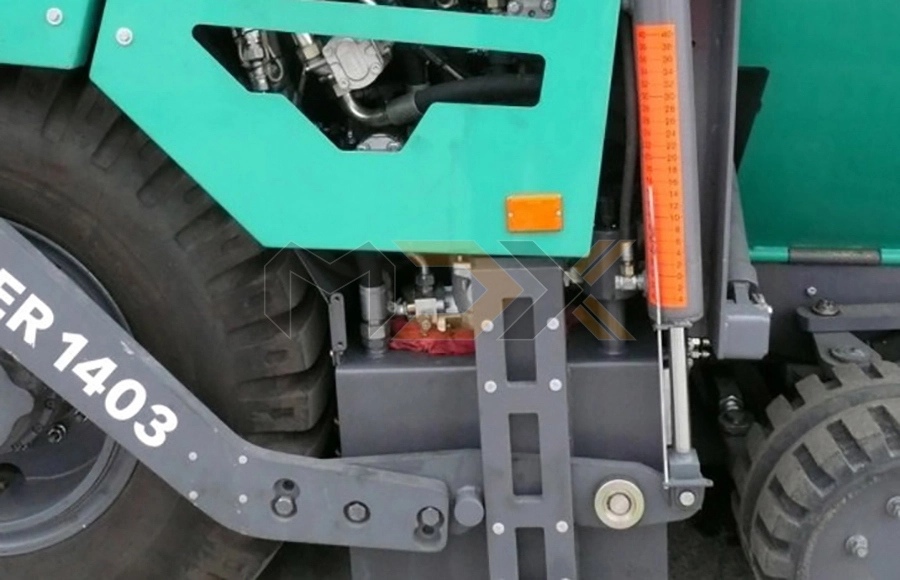

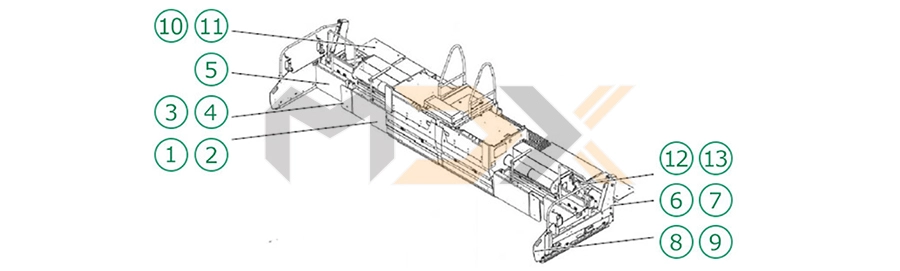

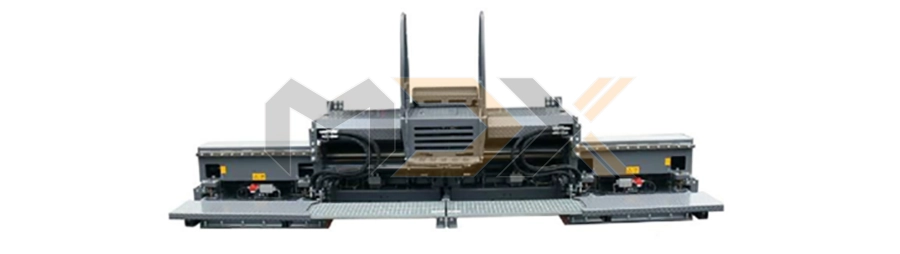

1. PAVER

The VÖGELE SUPER 1400 is a cutting-edge 2.5m-class paver suitable for a wide variety of applications. The paver is able to lay WMM, DBM, BC and DLC. Typical jobs are: the construction of secondary roads, the construction of highways, commercial paving jobs, municipal paving jobs, laying WMM, DBM, BC and DLC.

The VÖGELE SUPER 1403 is a cutting-edge 2.5m-class paver suitable for a wide variety of applications. The paver is able to lay WMM, DBM, BC and DLC. Typical jobs are: the construction of secondary roads, the construction of highways, commercial paving jobs, municipal paving jobs, laying WMM, DBM, BC and DLC.

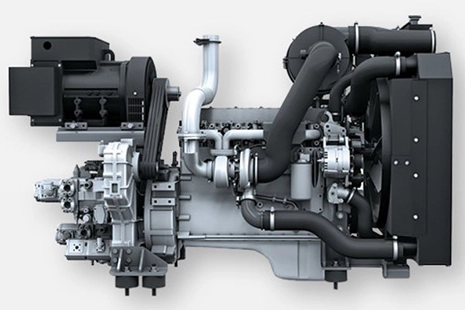

2. POWERFUL DIESEL ENGINE

|

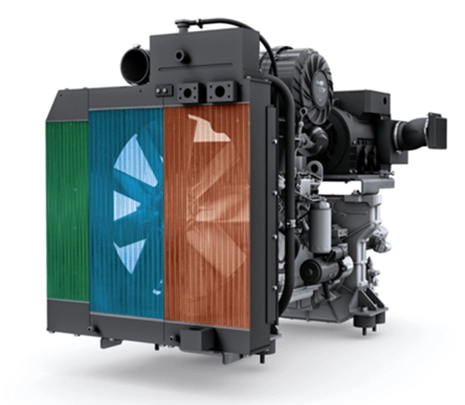

Three main components are the key to its power: its modern, liquid-cooled diesel engine, a splitter gearbox flanged directly to the engine, a large cooler assembly The driving force in this power pack from VÖGELE is its diesel engine. Yet the fuel-saving ECO mode is sufficient for many applications. The cooling assembly prevents any problems due to high ambient temperatures. |

|

|

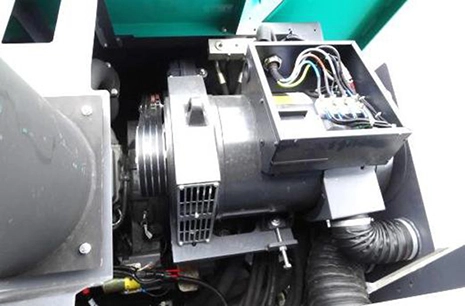

Self-diagnostics and sensors for almost all engine vitals simplify daily checks. The fuel tank holds enough for a day's work. A powerful belt-driven generator ensures rapid, uniform heating of the screed |

| The generator is for screed heating only. Use of a maintenance-free, brushless three-phase generator with an output of 18kW. To increase the safety of the system, an insulation monitoring device is supplied as standard. Screed heating is used to prevent material from sticking to the screed plates or tampers |  |

3. PRECISION PAVING WITH MATERIAL MANAGEMENT

A continuous flow of mix is key to ensuring uninterrupted and high-quality paving. That is why we attach such importance to professional material management when designing our pavers. Thanks to their large material hopper with a special shape, the SUPER 1400 und the SUPER 1403 can be supplied with material easily and quickly.

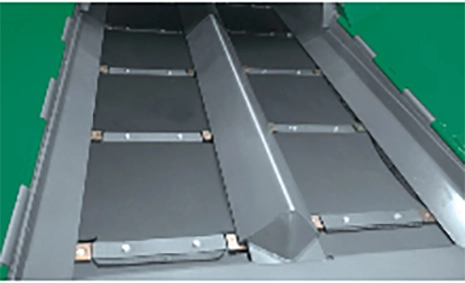

4. EXTRA-LARGE MATERIAL HOPPER AND EASY MATERIAL FEED

| The large material hopper holds 12t and is dimensioned so that an ample supply of mix is stored at all times. Sloped inner design of the hopper for an optimal flow of material to prevent segregation. Easy feeding with mix thanks to dump height of just 560mm, wide hopper sides and sturdy rubber baffles fitted to the hopper front. Independently operated hopper sides. Applies to SUPER 1400 and SUPER 1403 |  |

|

|

| Large oscillating push-rollers can be set to three different positions for convenient and shock-free docking of feed vehicles even in curves. Push-roller position Standard position +75mm +150mm | |

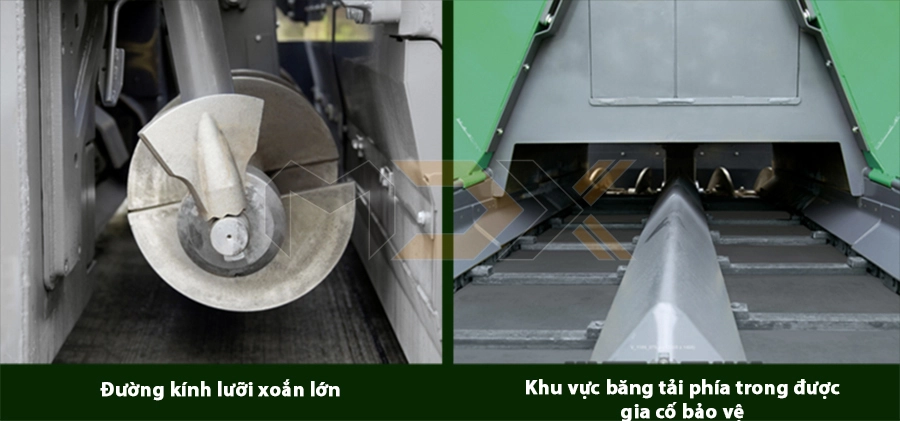

5. PRECISION MATERIAL DELIVERY PREVENTS SEGREGATION

| Thanks to effective spreading of the material, the SUPER 1400 and the SUPER 1403 always have an optimal head of mix in front of the screed to meet the demands of every paving situation. The wide conveyor tunnel and powerful, separate hydraulic drives on the conveyors and augers support high laydown rates of up to 600t/h. |  |

| WMM KIT AVAILABLE | |

| WMM stands for: "Wet Mix Macadam", which is a very common type of mix used in India. Due to the higher wear to certain parts – such as conveyor tunnels, conveyor chains and augers – modifications are added to the paver to prevent those parts from excessive wear. The WMM Kit includes for example rubber covers for the conveyor chains. |  |

|

Proportional control and continuous monitoring of conveyors and augers guarantee a constant head of mix in front of the screed. Large-diameter auger blades with precision pitch ensure excellent spreading of the material when paving across large widths or at lower engine rpm. VÖGELE’s unique auger blade design makes for a prolonged service life compart to standard blade designs. Narrow conveyor guard in the material hopper guarantees uniform material flow. |

|

|

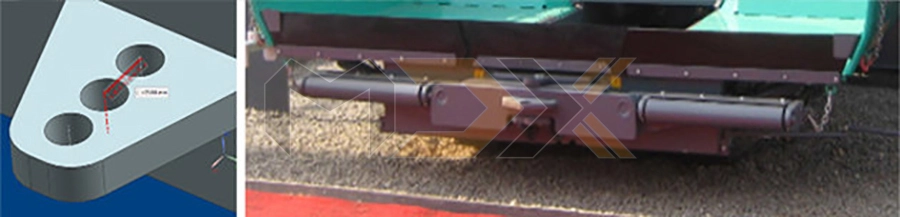

6. THE DRIVE CONCEPTS - TRACKS AND WHEELS

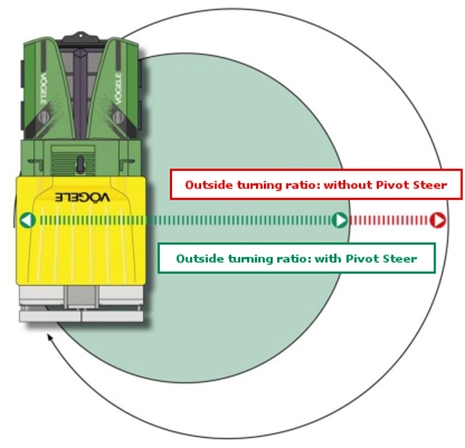

Mobility on wheels

| Whenever maximum manœuvrability is required, the paver operator can activate Pivot Steer. The rear inside wheel is then automatically slowed down hydraulically. This minimizes the outside turning radius to no more than 11 ft. 6 in. (3.5m) for positioning manœuvres. |  |

PivotSteer_Schnitt_Neutral_eTraining

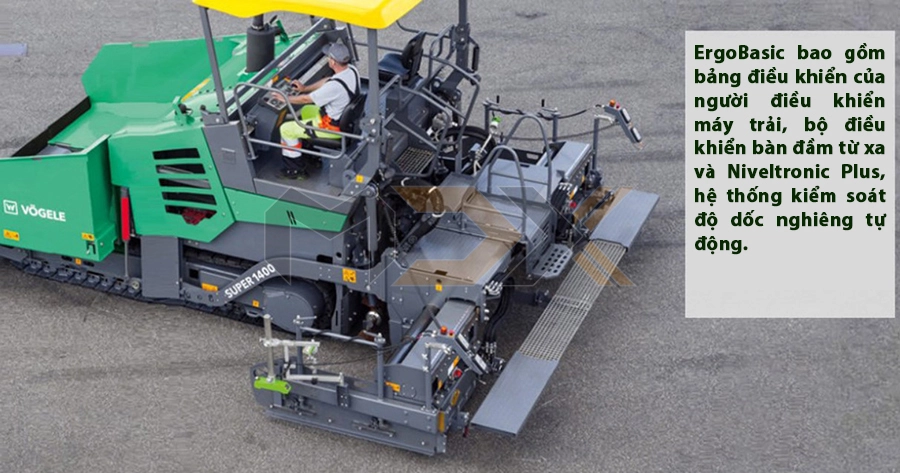

7. THE ERGOBASIC OPERATING SYSTEM

ErgoBasic encompasses the paver operator’s platform, the paver operator’s console, the remote control units for the screed and Niveltronic Plus, the System for Automatic Grade and Slope Control.

All the main paving functions can be controlled via the two ErgoBasic remote control units. Simple, language-neutral symbols allow the machine to be operated intuitively.

The remote control units for Niveltronic Basic come with all the functions required for high-precision grade and slope control. Clear symbols allow the machine to be operated intuitively.

On the paver operator's ErgoBasic console the functions are arranged in a clear, logical and practical layout that has clearly been inspired by the ErgoPlus operating console.

|

|

|

|

THE PAVER OPERATOR'S ERGOBASIC PLATFORM

|

The comfortable paver operator's platform gives an unobstructed view of all crucial areas on the paver such as material hopper, steering guide or screed. It allows the paver operator to closely monitor the paver’s feed with mix and the paving process. Working comfort: the pavers are equipped with luxury operator’s seats and an easy-to-adjust operator's console. A place for everything and everything in its place: the paver operator's platform, with its streamlined design, is well organized, offering the paver operator a professional workplace. The paver operator's console can be protected by a shatter-proof cover to prevent willful damage. |

|

SERVICE AND MAINTENANCE ACCESS POINTS

Even on the wheeled pavers, the access for service and maintenance is perfect..

Consistent service concept: All VÖGELE pavers have a consistent maintenance concept with identical service intervals.

THE PAVER OPERATOR'S ERGOBASIC CONSOLE

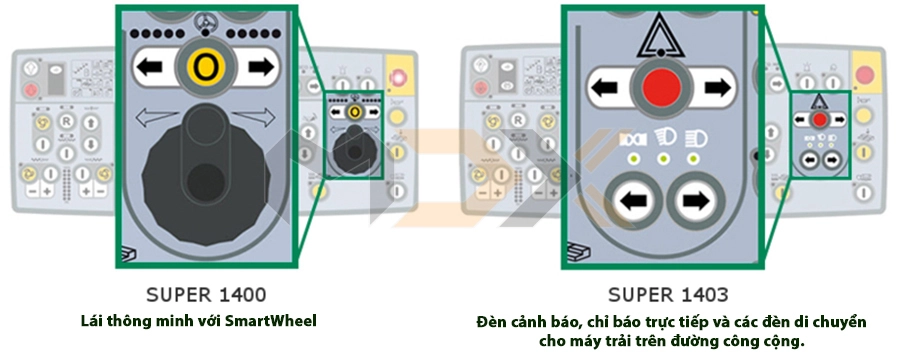

Differences in the paver operator's consoles (tracked and wheeled pavers)

The design of both paver operator's consoles (i.e. on wheeled and on tracked pavers) is identical, apart from the components for steering.

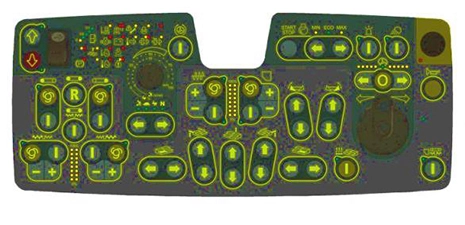

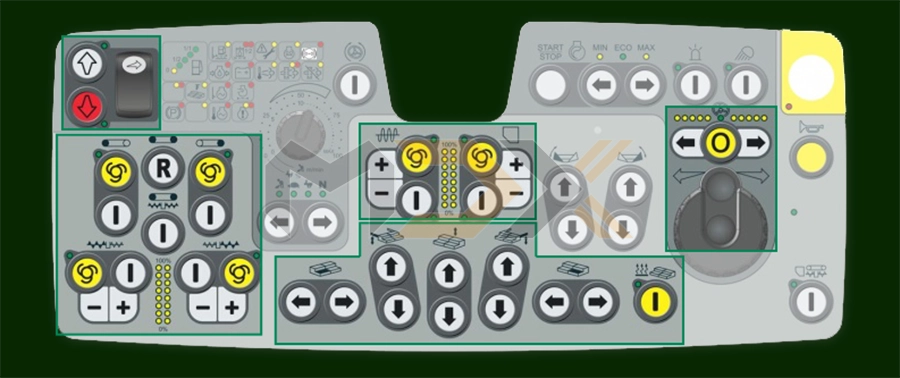

THE ERGOBASIC CONSOLES AND REMOTE CONTROL UNITS

Clearly laid out paver operator's console:

- Functions arranged in logical groups

- "Touch and Work" principle

- Self-explanatory symbols

- Dust-tight and waterproof (IP 67)

- Backlit console for night-time work

| Backlit console for night-time work |  |

Function groups on the paver operator's console

THE ERGOBASIC REMOTE CONTROL UNIT FOR THE SCREED

|

|

|

Robust remote control unit for the screed:Simple, logical and functional operation. Controls for all relevant paving functions. Controls for direct set-up of conveyor and auger. Direct access to sonic sensor for auger. With ErgoBasic, the screed operator has the process of paving at his fingertips. All important functions are easily comprehensible and all controls are clearly arranged. |

1. LED warning light "override conveyor“ -2. Horn -3. Conveyor automatic/override - 4. Specified value: filling level - 5. Screed floating - 6. Auger: automatic/specified value +/- - 7. Reverse auger - 8. Override auger - 9. Adjustment of screed tow point ram, raise/lower - 10. Screed width control |

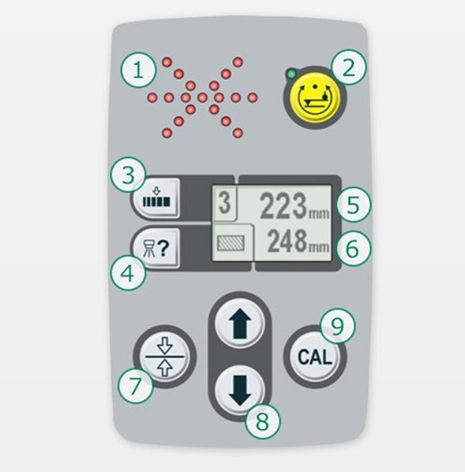

THE NIVELTRONIC BASIC REMOTE CONTROL UNIT

|

|

| Easy-to-operate Niveltronic Basic:Small, compact, easy to understand. Easy operation of advanced "Dash 3" sensor system. Automatic sensor detection. Change of sensors at the push of a button. Display of actual values set | 1. LED cross (deviation from specified values) - 2. Niveltronic Basic on/off - 3. Sensor sensitivity - 4. Tow point sensor selection - 5. Display set value - 6. Display actual value - 7. Quick set-up - 8. Setting: specified values - 9. Sensor calibration |

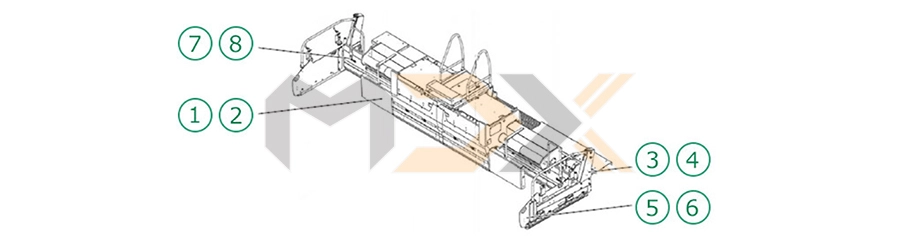

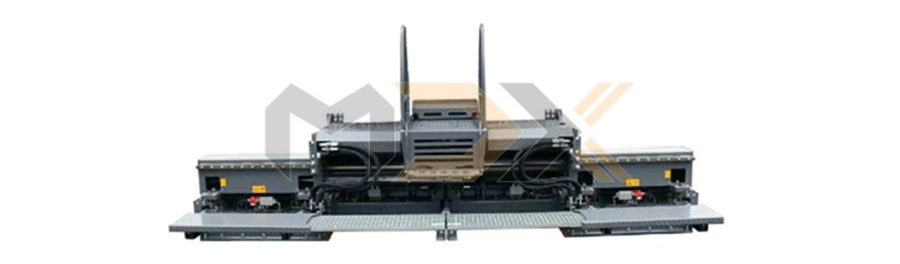

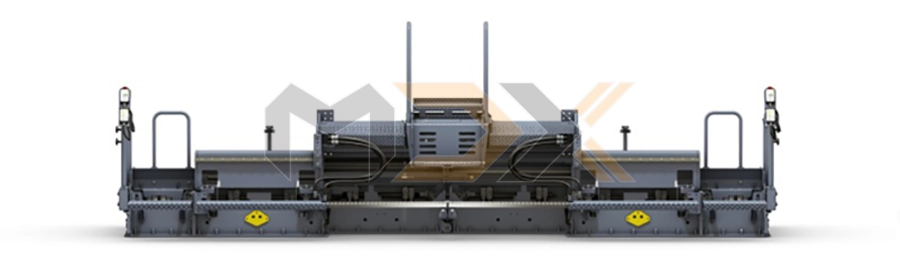

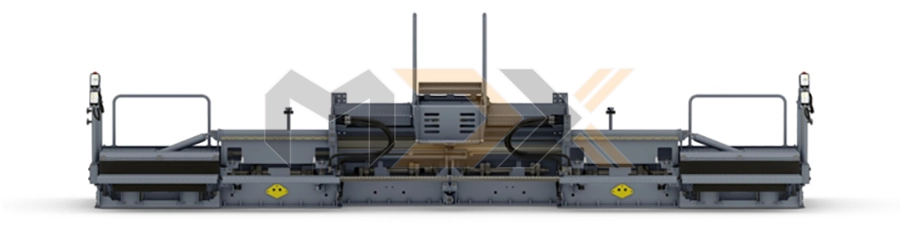

8. AB 480 TV EXTENDING SCREED

|

Stability and variability are not mutually exclusive, as the front-mounted AB 480 TV Extending Screed from VÖGELE proves. With a basic width ranging from 2.55 to 4.8m and a maximum pave width of 6m for the SUPER 1403 and 7.3m for the SUPER 1400 with bolt-on extensions, it is the ideal tool for multivariable width applications and mainline paving. The unique VÖGELE telescoping system supports screed width control which is accurate to the millimetre. The compacting systems ensure excellent material texture and compaction. So for the SUPER 1400 and SUPER 1403, the AB 480 TV Extending Screed is the perfect match. |

|

|

Pave widths: Infinitely variable range from 2.55 to 4.8m. Maximum pave width with bolt-on extensions: SUPER 1400: 7.3m (2 x 125cm), SUPER 1403: 6m (2 x 60cm) Compacting systems: AB 480 TV with tamper and vibrators |

BOLT-ON EXTENSIONS: EXTENSION SCHEME 6M

1. Left strike-off plate - 2. Right strike-off plate - 3. Left end plate carrier - 4. Right end plate carrier - 5. Left end plate - 6. Right end plate - 7. Extension 0.6m left - 8. Extension 0.6m right.

AB 480 TV, fully extended (4.8m) with bolt-on extensions (2 x 0.6m for 6m maximum pave width)

BOLT-ON EXTENSIONS: EXTENSION SCHEME 7.3M

1. Left strike-off plate - 2. Right strike-off plate - 3. Left guide angle - 4. Right guide angle - 5. Strike-off plate 0.75m - 6. Left end plate carrier - 7. Right end plate carrier - 8. Left end plate - 9. Right end plate - 10.Extension 0.75m left - 11. Extension 0.75m right - 12. Support 1, extension 0.75m, left (729mm) - 13. Support 1, extension 0.75m, right (729mm)

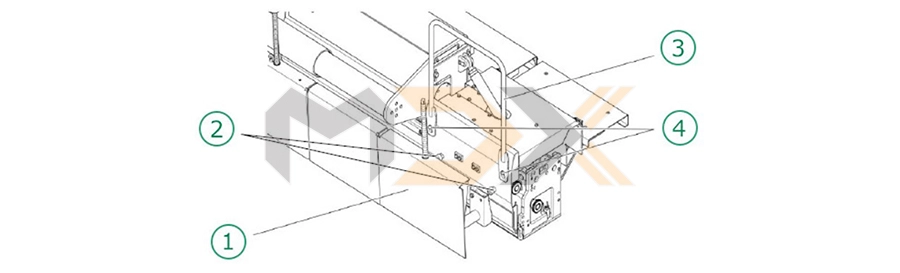

9. FITTING STRIKE-OFF PLATE AND PROTECTION BAR

1. Strike-off plate - 2. Mounting points for strike-off plate - 3. Protection bar - 4. Protection bar mounting point

INDIAN PAVERS IN OPERATIONAL USE

News Related

Tags: vogele super 1400, vogele super 1403