THE 6 HIGHLIGHTS OF HAMM 3410/3411 (TIRE 2)

The 6 highlights of the series 3410/3411 (Tire 2): drive unit, compaction, ergonomic, 3-point articulated joint, service, competitiveness.

MODEL OVERVIEW

Both soil compactors can be respectively differentiated according to their models and their technical data.

| MODELS AND THEIR TECHNICAL DATA | ||

| Variants | 3410, 3410 P, 3410 X | 3411, 3411 P, 3411 X |

| Engine performace | 98 kW / 131.3 HP | 98 kW / 131.3 HP |

| Detail for drum width | 214 cm | 214 cm |

| Operating weight (with ROPS) | 3410: 10.7 t - 3410 P: 10.9 t - 3410x: 10.7 t | 3411: 11.5 t - 3411 P: 11.7 t - 3411x: 11.4 t |

| P = Model with padfoot drum, X = Model without padfoot drum | ||

- See more about 3410 at: HERE

- See more about 3411 at: HERE

THE 6 HIGHLIGHTS OF HAMM 3410 – 3411 (TIER 2)

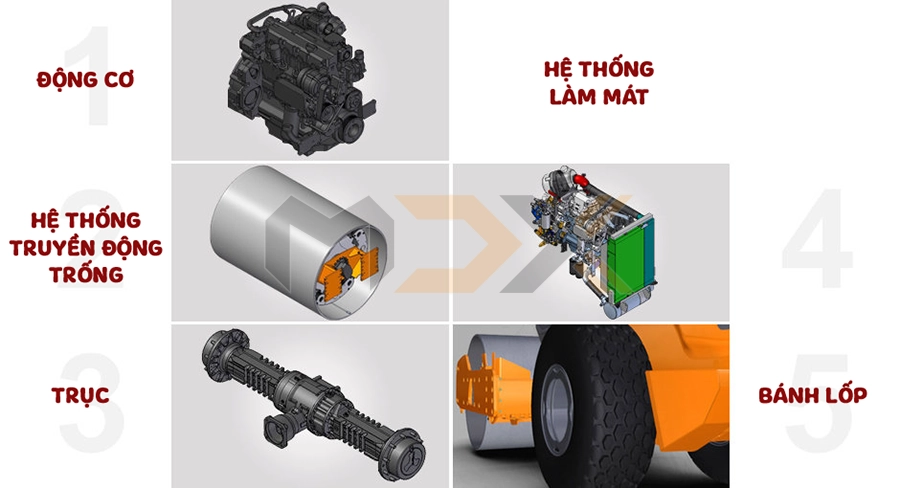

1. DRIVE UNIT

ENGINE

The soil compactors 3410 and 3411 are driven with a DEUTZ engine.

Advantages:

- Less electronic (no drive computer/ engine control device)

- Reduced maintenance

OPTIONS

- Additional fuel prefilter: This is recommended for countries with very poor diesel quality (higher water proportion in the fuel).

- Engine rpm counter

- Battery isolation switch

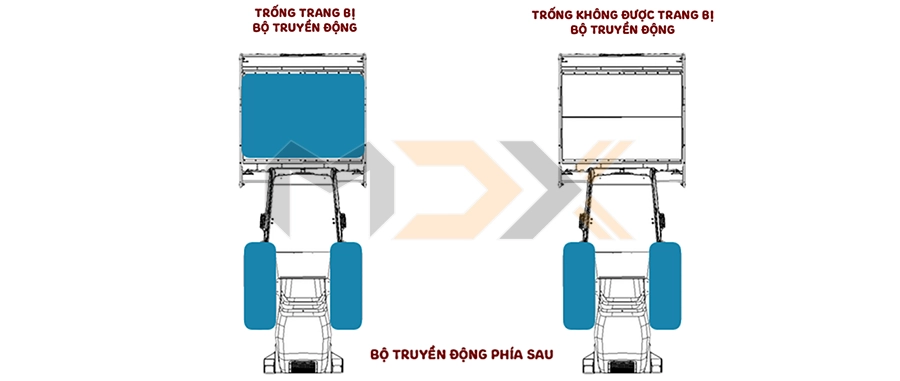

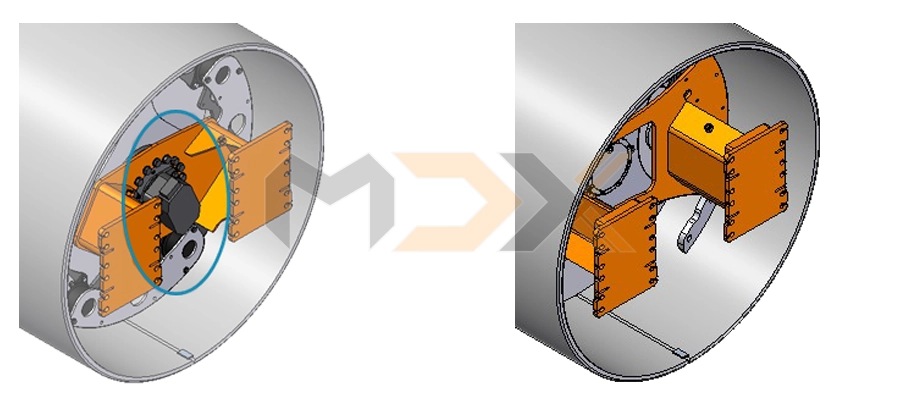

DRUM DRIVE

These models are available with and without drum drive compared to other soil compactors.

The P-Version always has a drum drive.

| WITH DRUM DRIVE | WITHOUT DRUM DRIVE |

|

|

| Machines without drum drive belong to the soil compactors of the x-Version. | |

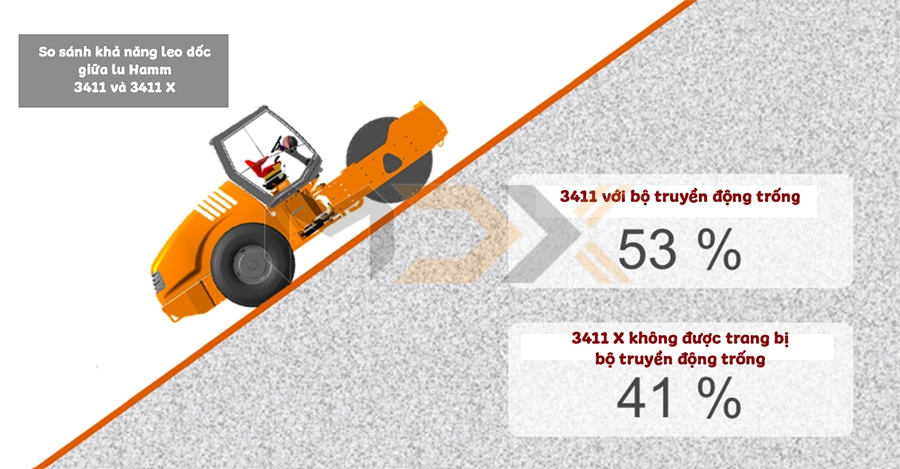

CLIMBING ABILITY

Means less traction and less climbing ability. This is however sufficient for many applications.

AXLE

The rear wheel pair are connected and driven via one axle. The axle with differential lock prevents the wheels from spinning and/or improve the driving torque of the machine and therefore has advantages in certain situations.

- Starting up in difficult conditions, off-road driving: The differential guides the driving torque from one slipping wheel to the wheel with better ground contact and therefore improves the traction.

- Directional stability: A locked axle runs better in a straight line than an unlocked axle.

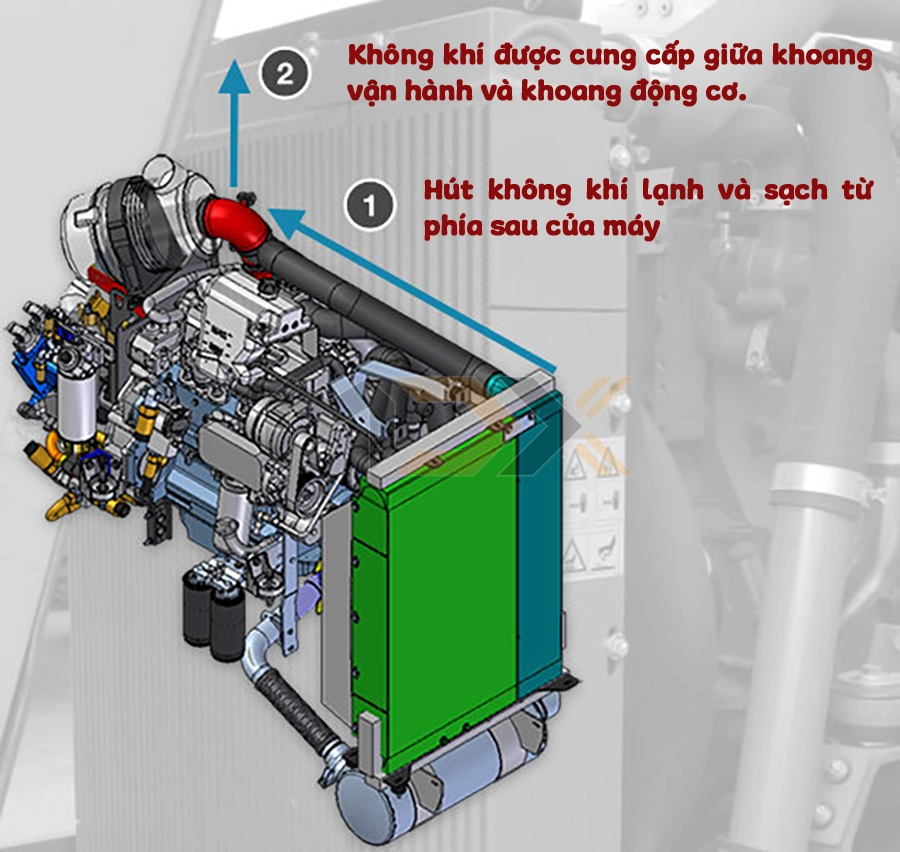

COOLING SYSTEM

The high-performance cooling system enables the machine to also be operated with high ambient temperatures. The one-part cooler is simple to clean and enables an optimal cooling performance in just two steps.

- Increasing the utilisation temperature from 40 °C to 50 °C. The utilisation is therefore possible even under extreme climatic conditions.

- Utilisation temperature: - 15 °C up to + 50 °C

All other machines in the Series 3000 have the air introduction in the contrary direction.

COOLING - ASSEMBLY DESIGN

Installing a longitudinal compensator...will increase the resistance against vibrations.

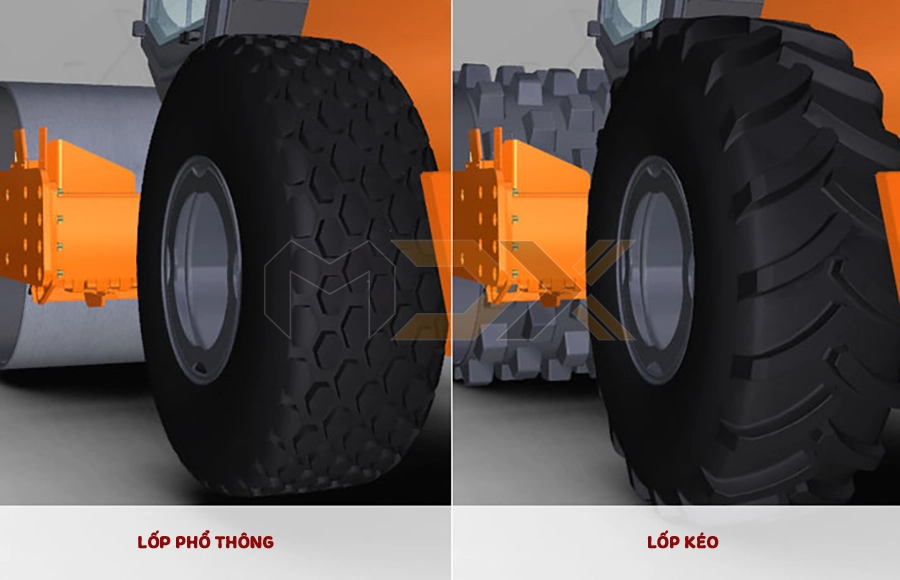

TYRES

Two different wheel variants are offered for the soil compactors 3410 and 3411.

- Universal tread for smooth drums: For less damage, imprints and marks on the surface area.

+ Advantages: Reduced tyre marks, Less damage on the surface area

+ Disadvantage: Worse traction on the material as the tread degrades quickly (with binding materials et alia.)

- Tractor tyres for padfoot drums: For better self-cleaning and higher traction on binding ground.

+ Advantages: Good traction, among others with binding material, Better self-cleaning

+ Disadvantage: Lots of tyre marks

2. COMPACTION

DRUM MODELS

VIBRATION

Both soil compactors compact with vibration. Vibration is compaction induced by the circular up-and-down movement of the drum and the therefore high compaction energy directed vertically into the ground.

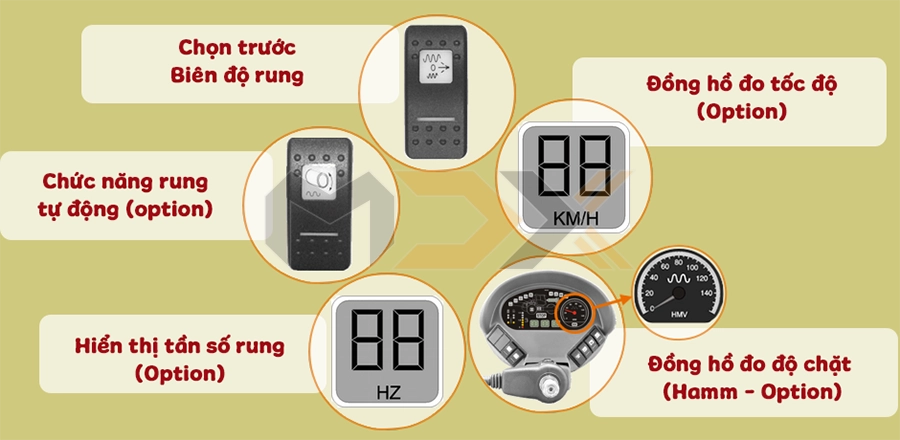

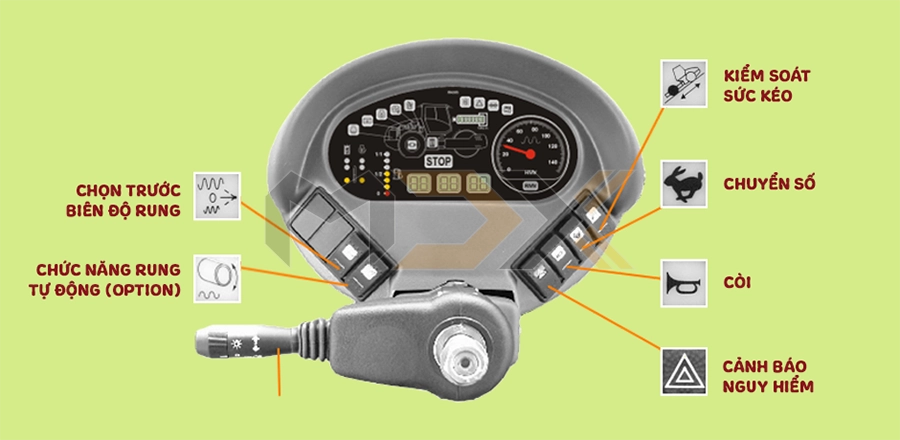

PARAMETER

- Amplitude pre-selection: Large amplitude, Zero position, Small amplitude

- HAMM Compaction Meter (optional): Measurement and display of the rigidity of the subsoil by utilising acceleration sensors on the vibrating drum.

- Speedometer (optional): Display for the current speed.

Automatic vibration system (optional) - Vibration mode: Manual, Automatic. If the pre-set speed is exceeded and/or not achieved, then the vibration will be automatically activated.

- Frequency display(optional): Variable adjustment of the frequency via the engine rpm.

Pre-selection for engine rpm

3. ERGONOMIC

OVERVIEW

The ergonomics also play an important part with these machines. Here is an overview of the most important features.

ACCESS

OPERATOR'S PLATFORM

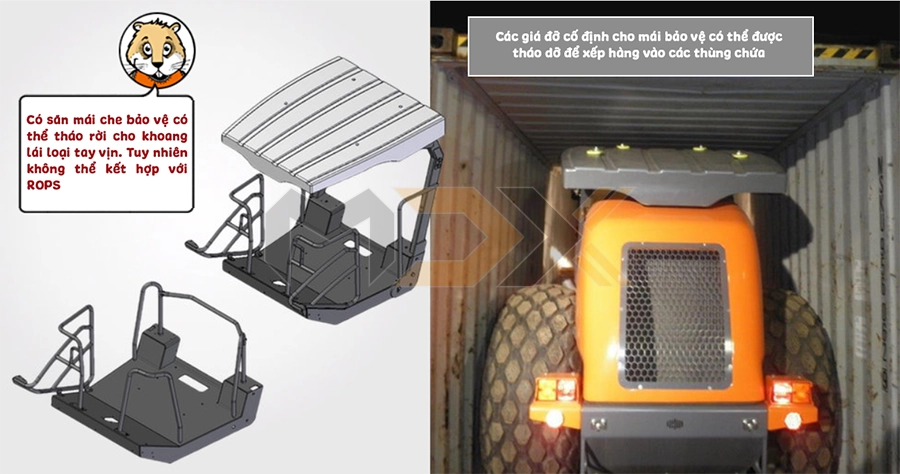

The machines are equipped with a modular installed operator´s platform.

Example: Operator´s platform with ROPS and protective roof

The conversion from ROPS to ROPS cabin (and reversed) is possible at all times. The conversion of an operator´s platform which is not suitable for ROPS to a ROPS variant is not possible as the complete operator´s platform would have to be exchanged in such a case.

| VARIANTS WITH ROPS | NOT SUITABLE FOR ROPS VARIANTS |

| ROPS, ROPS with protective roof, plastic, ROPS with protective roof, plastic, and with integrated FOPS, ROPS cabin | Handrail, Handrails + plastic roof |

Operator´s platform with ROPS

ROPS with a protective roof, plastic, (left), ROPS with a protective roof with integrated FOPS (right)

ROPS cabin

Cabin ROPS Variants: Without heating, With heating, With heating and air conditioning

Rapid coupling for connection of the air conditioning. For safe and simple shipping and/or commissioning (no leaking refrigerants when assembling and dismantling the cabin)

Handrail (left), handrail + protective roof (right)

ERGONOMIC - OPERATION

The machines 3410 and 3411 impress with their simple and safe operational controls.

- Steering columm

Steering column is tiltable with the foot button

- Drive lever

- Dashboard: Less, clearly represented operating and control elements with increased functionality. Compact dashboard with international, easily understood symbols and displays. Roller symbols for easy-to-read representation of the selected functions

There is no loading mode.

|

|

|

| Amplitude pre-selection: Large amplitude, Zero position, Small amplitude | Automatic vibration system (option): Manual, Automatic (automatic vibration system) | Signal horn |

|

|

|

| Warning indicator | Gear shift: Transport gear, Working gear | Traction control (for versions with drum drive) |

SEATS

The range of comfort on offer will also impress the driver.

|

|||||

| SEAT VARIANTS | |||||

| Driver´s seat, black imitation leather | Driver´s seat, black imitation leather - with back- extension | Driver´s seat, black imitation leather - with higher back- extension | Driver´s seat, anthracite cloth - with back- extension | Driver´s seat, anthracite cloth - with higher back- extension | |

| ROPS | Yes | Yes | |||

| ROPS Cabin | Yes | Yes | Yes | Yes | |

| Handrail (with/without protective roof) | Yes | ||||

| Seat for the operator´s platform with ROPS | Seat for the operator´s platform which are not suitable for ROPS |

| Mechanical spring-suspension (large spring package). Safety belt with roll-up mechanism. Configurable armrest (2x). Rotating seat. Longitudinal adjustment (forward-backward). Weight adjustment. Seat back adjustment. Height adjustment | Mechanical spring-suspension (small spring package). Without safety belt. No armrest. Longitudinal adjustment (forward-backward). Weight adjustment. Seat back adjustment |

STORAGE AREAS IN THE ROPS CABIN

|

|

|

| Storage areas in both side doors | Storage area behind the seat (operating and maintenance instructions - BWA, first aid kit) | Beverages holder |

STORAGE AREAS WITH HANDRAIL

|

|

|

| Storage area behind the seat (BWA, first aid kit) | Beverages holder | Lunch box holder (optional) |

|

||

| Operator´s platforms with handrails have a large storage area under the seat (BWA, first aid kit). |

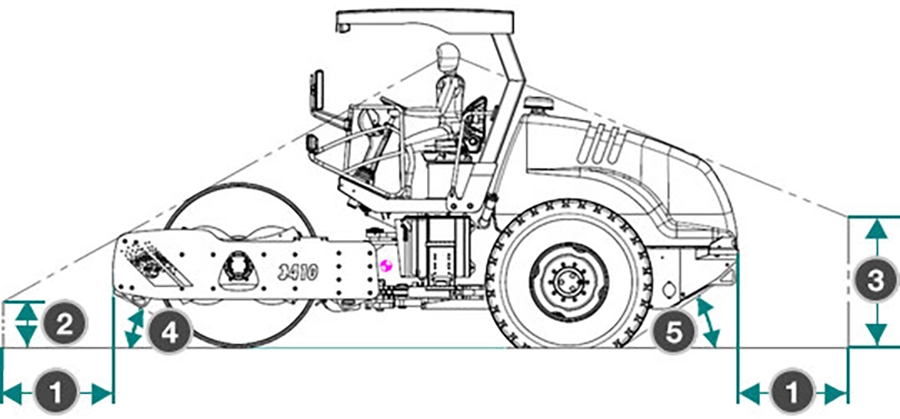

ERGONOMIC - VISIBILITY

1 x 1.5 m visibility for the driver

1. 100 cm, 2. 42 cm, 3. 119 cm, 4. 28°, 5.34°

|

|

|

| Forward visibility | Rear visibility | Rear visibility over the tyres |

|

|

|

| No exhaust visible when looking backwards | Working mirror, 2 units: Standard with a cabin, optional for all other versions | Working spotlight, 4-fold |

4. 3-POINT ARTICULATED

See more at: HERE

Hamm does not utilise a conventional articulated joint, rather a special construction design: The 3-point pendulum articulated joint

- Uniform weight distribution on the rear axle when turning for excellent traction on rough terrain

- Damping for impacts

- Excellent on-centre-feel

- Increased anti-tipping safety when cornering

5. SERVICES

The machine features also impress when it comes to considering servicing.

- The engine compartment is easily accessible from both sides.

- The service points on the engine can be viewed in more detail on the next page.

|

|

|

|

| The bonnet can be easily opened hydraulically with a manual pump. | The electronics are easily accessible. | The battery can also be easily accessed. | The engine compartment can be illuminated at night by utilising the working spotlight (standard with the ROPS cabin, optional for all other variants). |

DIAGNOSTICS AND DOCUMENTATION

- Simple and quick repairs as there are not many electrical components installed (no drive computer, no engine control device)

- WITOS ("Wirtgen Road Technologies Telematics and on-site Solutions"): intelligent telematic system for efficient fleet and service management worldwide

- WIDOS (Wirtgen Group Documentation system): includes, among other things, the entire catalogue of spare parts; all instructions; hydraulic, electrical, and hosing diagrams; machine data and documentation; safety notices; images of components; and service documentation

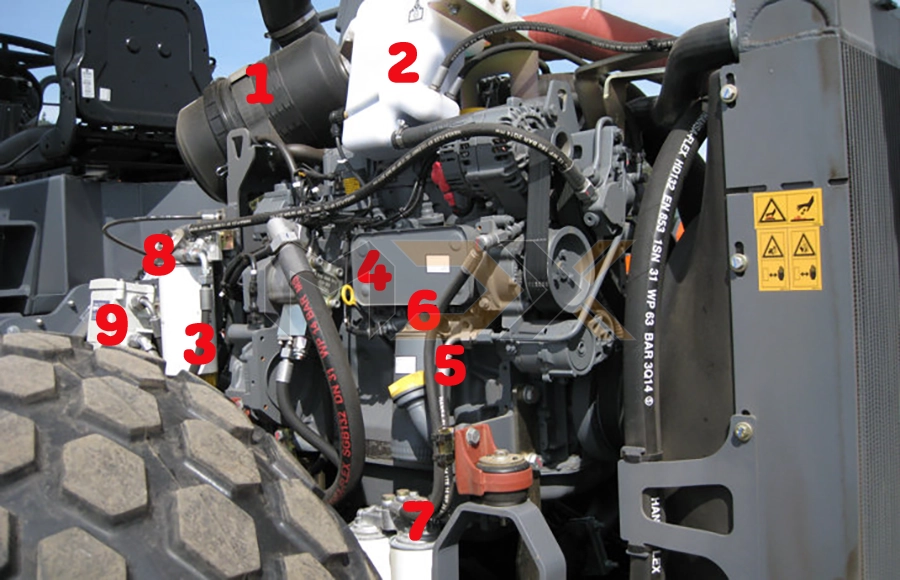

SERVICE POINTS

The service points are located on one side of the engine compartment and are easy to access.

1. Air filter, 2. Compensation tank with cooling water display, 3. Fuel prefilter, 4. Oil dipstick, 5. Oil filling lud, 6. Oil filter, 7. Fuel double filter, 8. Hydraulic oil filter, 9. Additional fuel prefilter (option)

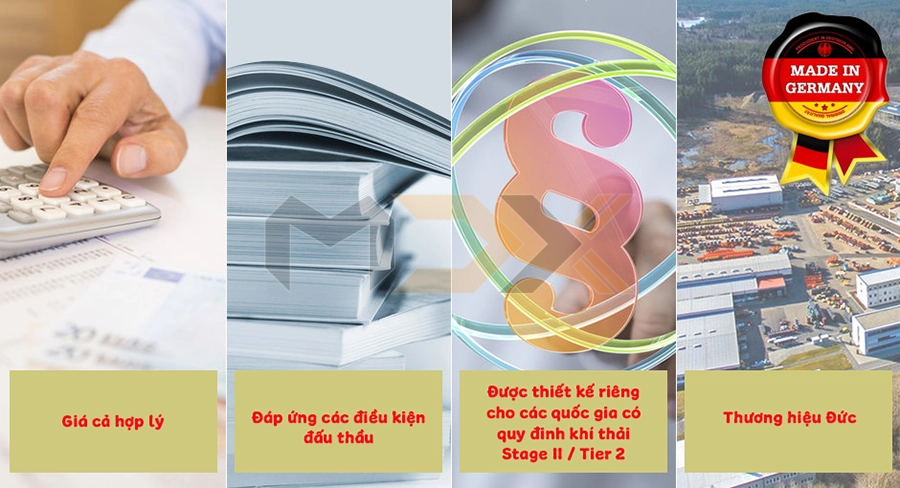

6. COMPETITIVENESS

The x-Version is the perfect machine for tender documents and provides possibilities for cost differentiations compared to the competition. If the competition offers a machine without band drive, then the x-Version is the comparative model.

News Related

Tags: hamm compactor, hamm 3410, 3411, soil compactor