|

|

|

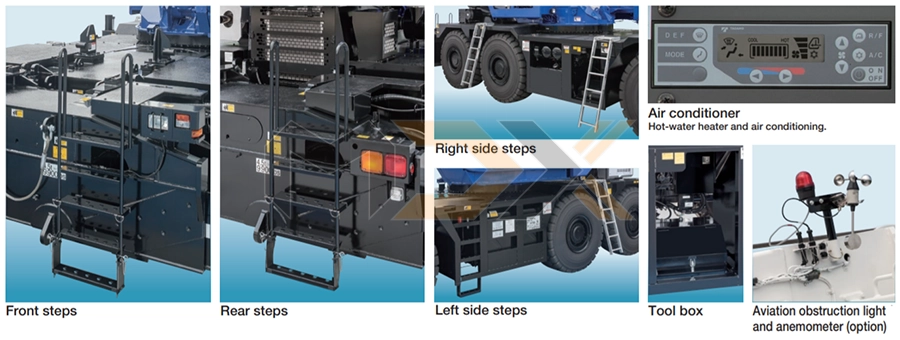

Operator Comfort

The crane cab provides improved livability and a more comfortable working environment.

The control levers are smooth and responsive to the operators touch.

|

| WIDER STEPS AND HAND RAILS |

|

| Automatic moment limiter [AML-C] |

|

| Tadano's AML-C is easy to use, innovative in design, displays important information to the operator and enables the operator to preset a custom working environment. For example, the AML-C shows the boom angle, boom length, load radius, operating pressure of the elevating cylinder, the extension width of the outriggers, slewing position, rated lifting capacity and present hook load. These features allow the AML-C to move seamlessly through all lifting operations without having to change configurations or input new codes to make the lift. The AML-C safety features provide both audible and visual warnings. When an operation approaches the load limit Tadano's slow stop function engages to avoid shock loads |

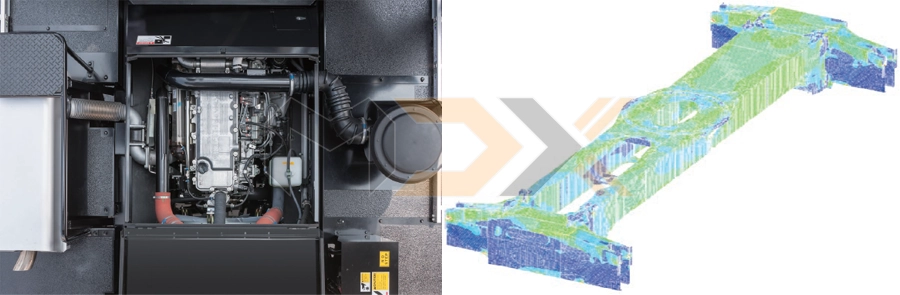

| ENGINE |

|

|

Mitsubishi 6M60-TL 4 cycle, turbo charged and after cooled, 6 cylinder in line, direct injection, water cooled diesel engine.

Max. output: 200 kW at 2,600 min-1 {rpm}

Max. torque: 785 N-m at 1,400 min-1 {rpm}

New carrier frame

The new carrier frame design was developed and built so that its lightweight is compatible with its high rigidity to achieve an advanced level of performance. As a result, the rigidity was enhanced enabling highly stabilized maneuverability.

|

| TRANSMISSION |

|

Electronically controlled, fully automatic transmission.

- Torque converter driving full power shift with driving axle selector.

- 5 forward and 2 reverse speeds, constant mesh.

2 speeds - High range - 2 wheel drive ; 4 wheel drive

3 speeds - Low range - 4 wheel drive

|

| STEERING |

|

4 Steering mode

Hydraulic power steering controlled by steering wheel.

2 wheel front: Front steering only. This steering method is the same as that of general vehicles

6 wheel coordinated: Front and rear wheels are steered in opposite directions. The turning radius is decreased. Useful for movement in a small area.

6 wheel crab: Front and rear wheels are steered in the same direction. The vehicle can move diagonally. Useful for pulling over.

4 wheel rear: Rear steering only. The rear end of the vehicle swings outward like a forklift. Useful for easy approach of a narrow area

|

| SUSPENSION |

|

1st: Rigid mounted to frame.

2nd and 3rd: "Hydro-Pneumatic suspension cylinders" with levering adjustment and oscillation

|

| WEIGHT + MIN. TURNING RADIUS |

|

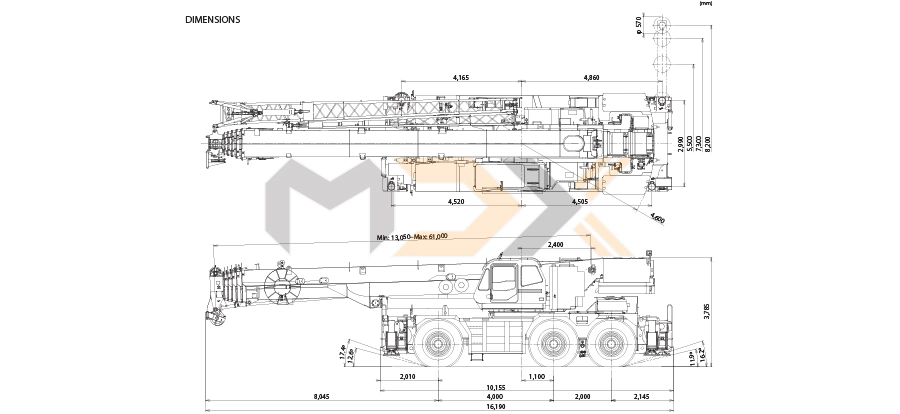

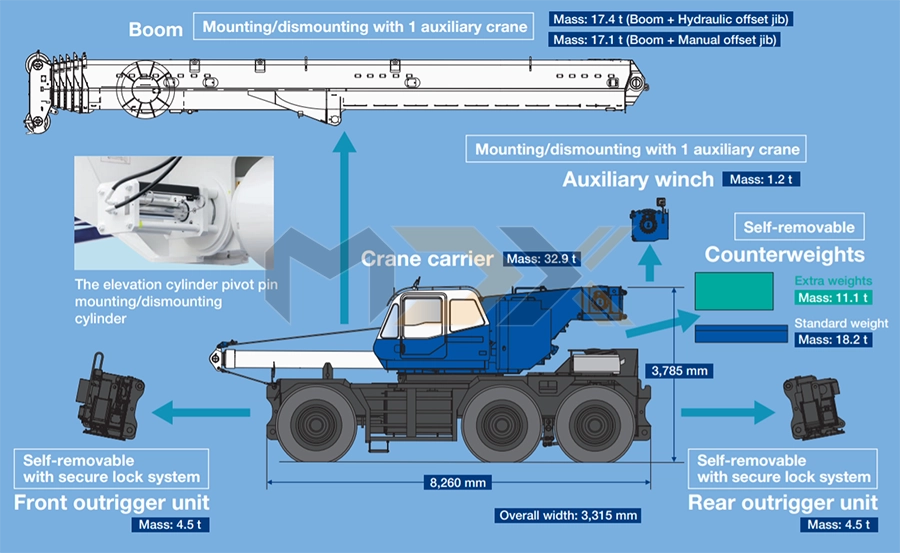

Overall length: approx. 16,190 mm

Overall width: approx. 3,315 mm approx. 3,500 mm (+ Extra weights)

Overall height: approx. 3,785 mm

Min. turning radius (at center of extreme outer tire)

- 2-wheel steering: 14.9 m

- 6-wheel steering: 9.9 m

Max. traveling speed (with counterweight): 15 km/h

Gradeability (tanθ) (with 18.2t counterweight): computed 52 % (at stall) *30 %

* Machine should be operated within the limit of engine crankcase design (17°: Mitsubishi 6M60-TL)

|

| BOOM + JIB |

|

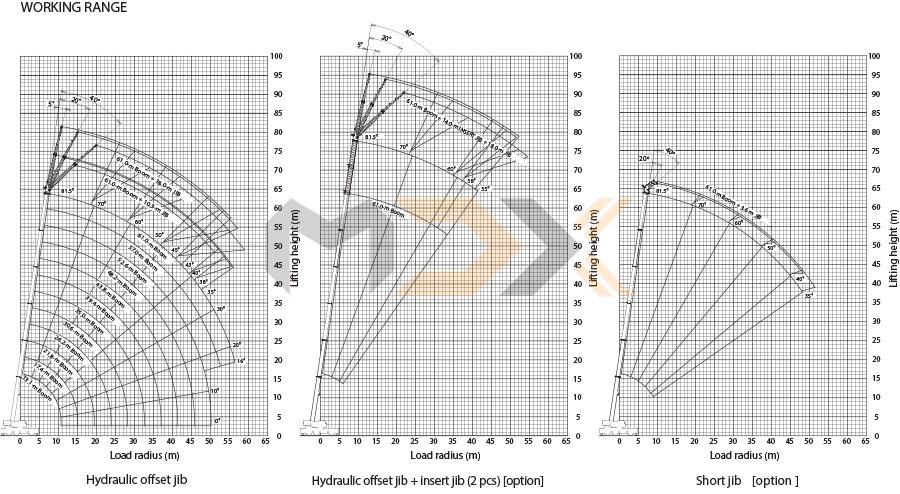

6-section long boom: 13.1 m - 61.0 m

2-staged bi-fold jib: 10.3 m / 18.0 m

Insert jib (option): 7.0 m (1 pce.) 14.0 m (2 pcs.)

Short jib (option): 3.6 m

|

| TWO WINCHES WITH CABLE FOLLOWER |

|

Both the main winch and the auxiliary winch have powerful line pull and operate at high speeds thus enhancing work efficiency.

*Maximum permissible line pull may be affected by wire rope strength.

|

| SLEWING |

|

Hydraulic axial piston motor driven through planetary slewing speed reducer. Continuous 360º full circle slewing on ball bearing turn table at 1.3min-1 {rpm}. Equipped with manually locked/released slewing brake. A 360º positive swing lock manually engaged in cab. Twin slewing system: Free slewing or lock slewing controlled by selector switch in cab.

Slewing speed................. 1.3 min-1 {rpm}

|

| HYDRAULIC SYSTEM |

|

PUMPS: 2 variable piston pumps for crane functions. Tandem gear pump for steering, slewing and optional equipment. Powered by carrier engine. Pump disconnect for crane is engaged/ disengaged by rotary switch from operator's cab.

CONTROL VALVES: Multiple valves actuated by pilot pressure with integral pressure relief valves.

RESERVOIR: 763 lit. capacity. External sight level gauge.

FILTRATION: BETA10=10 return FIlter, full �ow with bypass protection, located inside of hydraulic reservoir. Accessible for easy replacement.

OIL COOLER Air cooled fan type.

|

|

|

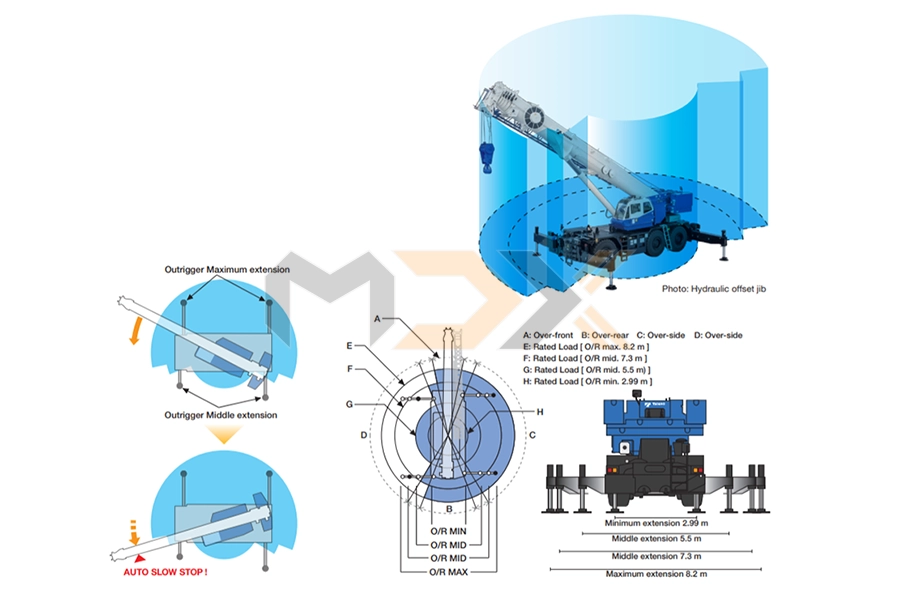

Outrigger Asymmetric Extension Width Control

When operating the crane with the asymmetric outriggers extended, the AML-C detects the extension width of all of the crane's outriggers (front, rear, left and right) to measure maximum work capacity in each area. When slewing the boom from the longer outrigger area to the shorter outrigger area, the AML-C detects the motion and displays

The maximum capacity according to the extension width of each of the outriggers,and brings the motion to a slow stop before it reaches the maximum capacity. Therefore, even in the case of operator error, the AML-C's slow stop function will help to minimize any safety risk.

|

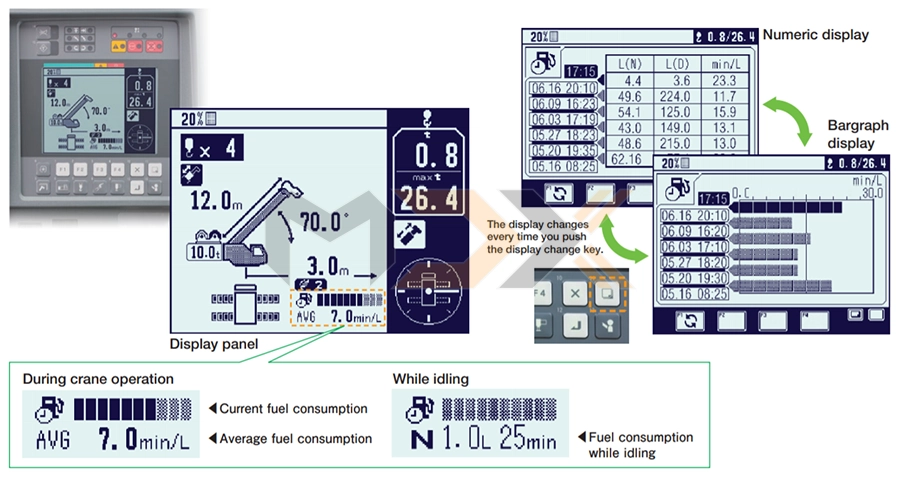

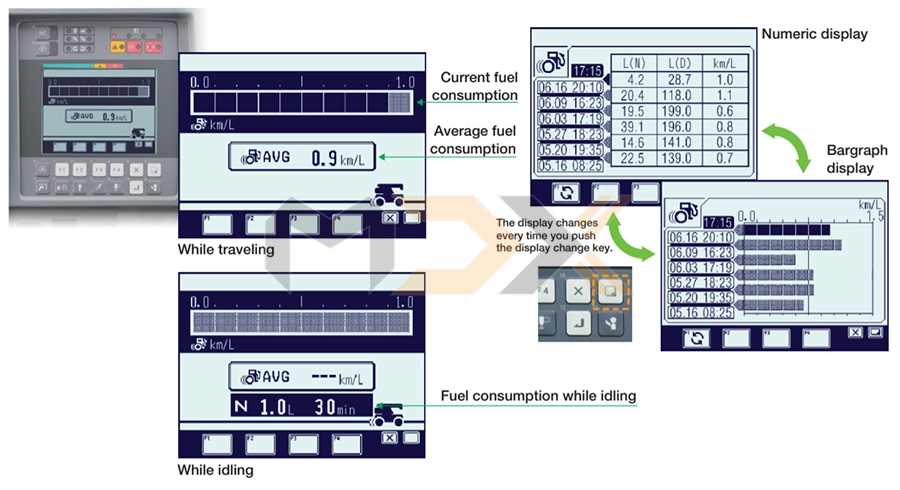

| FUEL MONITORING SYSTEM |

| The Fuel Monitoring System, displayed on the AML-C screen, monitors fuel consumption rates during crane operations, idling, and while traveling, allowing the operator to optimize fuel efficiency, reduce CO2 emissions and noise level. |

|

|

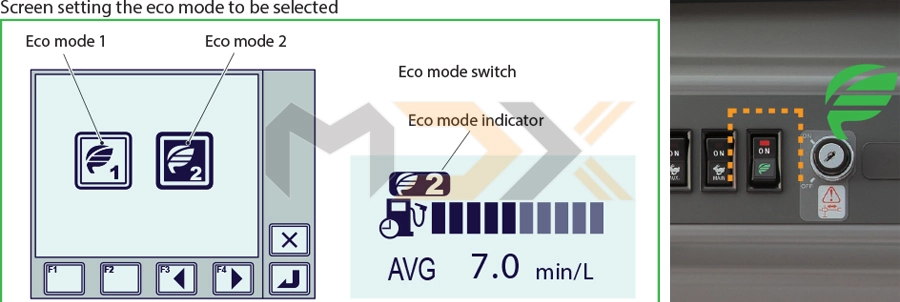

| ECO MODE SYSTEMS |

|

The Eco Mode System controls the maximum engine speed at the time of crane operation. To prevent an unnecessary rise in engine speed when there is excessive acceleration, the system enables fuel consumption and CO2 emissions to decrease by Max. 22% with Eco mode 1, and Max. 30% with Eco mode 2, and the noise level is reduced.

|

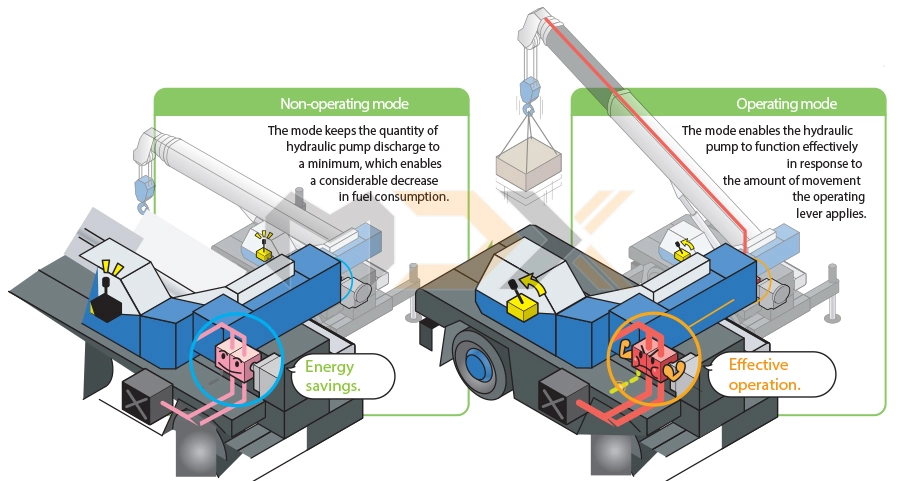

| POSITIVE CONTROL SYSTEM |

|

|

The Positive Control System effectively controls the quantity of hydraulic pump discharge during crane operation in response to the amount of movement applied by the operating control lever. When the crane is in a state of idling, the Positive Control System keeps the quantity of hydraulic pump discharge to a minimum, reducing fuel consumption and CO2 emissions by up to 20%.

Non-operating mode

The mode keeps the quantity of hydraulic pump discharge to a minimum, which enables a considerable decrease in fuel consumption.

Operating mode

The mode enables the hydraulic pump to function effectively in response to the amount of movement the operating lever applies.

|

| ULTIMATE BOOM FOR ROUGH TERRAIN CRANE |

|

|

The rounded boom is made of high tensile steel, which allows for decreased boom weight as well as increased boom strength. The high performance AML-C comes standard and helps the operator maintain safe operations

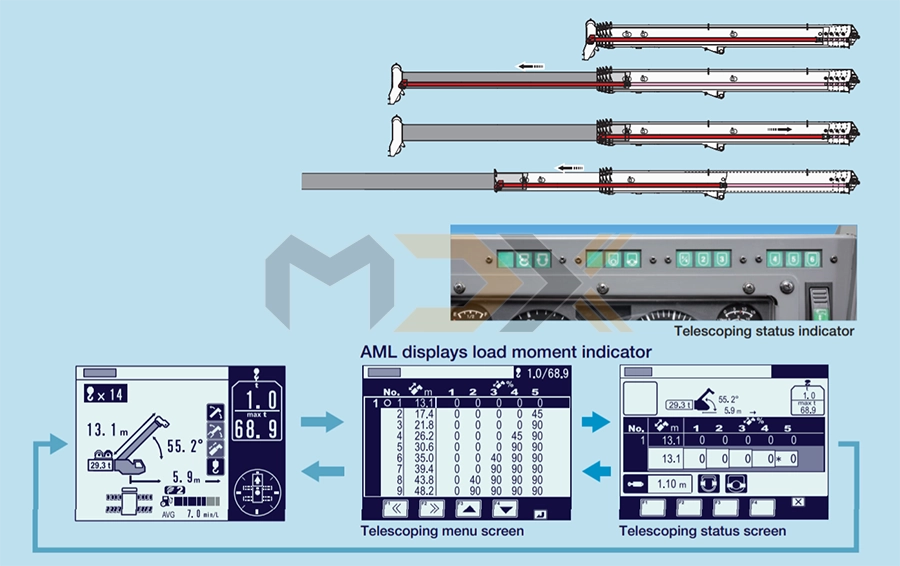

Single telescopic cylinder

For extension and retraction of sections, 6 section box type construction consist of 1 base section and 5 telescopic sections are extended by a single telescoping cylinder. All sections are fully extended/retracted automatically and locked in the selected working position

Two winches with cable follower

Both the main winch and the auxiliary winch with powerful line pull operate at high speeds, thus serving to enhance work efficiency

*Maximum permissible line pull may be affected by wire rope strength

New crane structure

During the development of the structural shape of the crane, *FEM analysis was applied to achieve a design tailored for optimal operation. The slewing frames’ structure ensures a highly rigid, compact style that is well suited for the overall planned design of the crane. Continuing the TADANO tradition of excellence and innovation

*FEM: Finite Element Method

|

|

|

Outline of telescoping mode

Boom telescoping of this crane is performed with one telescoping cylinder. Each telescopic section is extended and fixed with pins in sequence from the top with several telescoping modes based on the designated job plan

Display telescoping status

A single cylinder and each section of boom actual condition are displayed on the AML by Telescoping monitor switch.

|

|

Hydraulic offset jib (5˚-40˚)

Hydraulic offset jib can be adjusted between 5° to 40° by the jib tilt cylinder

Bi-fold jib

A two-stage, bi-fold lattice-type jib can be offset at 0°, 20°, and 40° to enable the operator to carry out jobs that require extra reaching ability

Insert jib

The new insert jib can be used for reaching higher place where the boom cannot reach.

Tiltable cab

You can operate the crane comfortably by tilting the cab during high hoisting operations such as lifting with the jib. The cab tilting angle is between 0° and 15°.

|

|

|

Short jib *Option

Two offset angle (20° and 40°), new short jib can be used for lifting heavy load in tight spaces

|

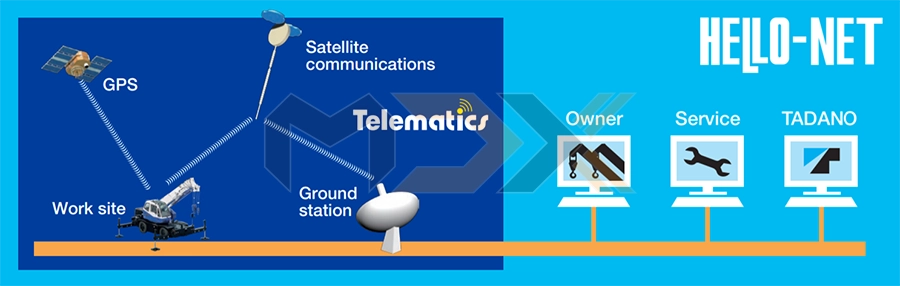

| HELLO - NET |

|

|

|

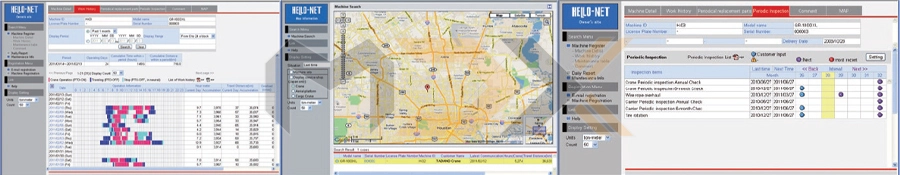

TADANO supports your crane management via the Internet, providing information about operational status, position and maintenance.

Monitoring machine information from your computer

1. Work History

HELLO-NET Owner’s Site displays the day-to-day operational status, mileage and remaining fuel for each machine equipped with a communication terminal. In addition, you can view a list displaying the number of hours of operation and the mileage of all your machines for any specified month.

2. Machine Position Data

Using HELLO-NET Owner’s Site, you can check a machine's latest position (up until the previous day) on a map. Two types of position data, listed below, are transmitted automatically from your machine once every day. Work Site: The location where the machine’s PTO has been activated (for one hour or more). Position at Day’s End: The final location from which GPS was able to receive data on a given day.

3. Maintenance Information

You can check the maintenance timetable of your machines for periodical replacement parts and inspection schedule. HELLO-NET supports the maintenance of your machine.

Telematics (machine data logging and monitoring system) with HELLO-NET via internet (*availability depends on the situation).

DETAILS: The availability of data communication systems, such as satellite or mobile communications which serve to widen the service area differs according to individual countries. Besides, there are some countries where the system itself is not in use yet. For details, please contact your distributor or our sales staff in charge.

|

|

MOUNTING AND DISMOUNTING SYSTEMS

The GR-1450EX has several mounting and dismounting systems for traveling and transportation. Only the boom mounting/dismounting system is optional.

|

|

|

|

|

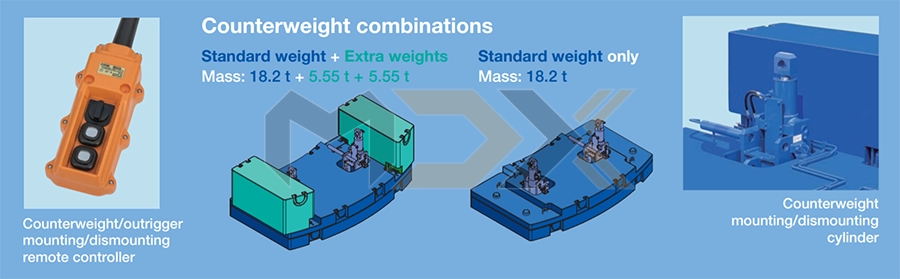

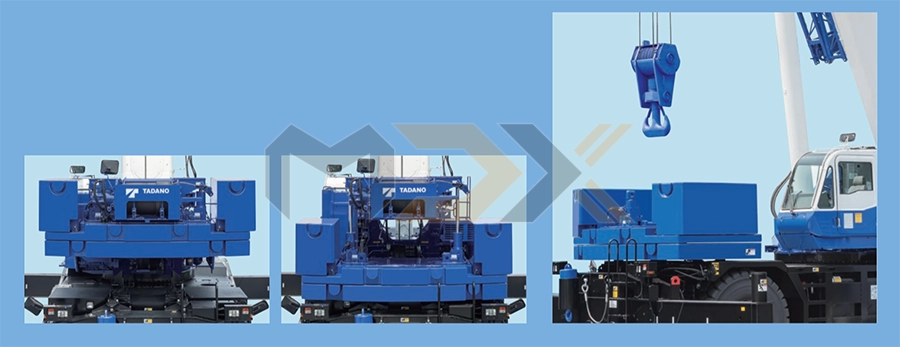

Self-removable counterweight

Counterweight along with an auxiliary winch is hydraulically mounting/dismounting; in addition, dismounted counterweights can be lifted and moved for transport without a helper crane, as well as being re-mounted at a work site for operation.

|