-

Your shopping cart is empty!

|

|||

|

|||

|

| ENGINE | ||

| Model | Komatsu SAA6D170E-5 | |

| Type | Water-cooled, 4-cycle | |

| Aspiration | Turbocharged, aftercooled | |

| Number of cylinders | 6 | |

| Bore x stroke | 170 mm x 170 mm | |

| Horsepower | ||

| SAE J1995, gross | kW (HP) | 396 (530) at 1 800 rpm |

| SAE J1349/ISO 9249, net | kW (HP) | 393 (527) at 1 800 rpm |

| Governor | All-speed, electronic | |

| Fan drive method for radiator cooling | Hydraulic | |

| Lubrication system: | ||

| Method | Gear pump, force-lubrication | |

| Filter | Full-flow type | |

| Piston displacement | L | 23.15 |

| Air cleaner | Dry type with double elements and dust evacuator, plus dust indicator | |

| AXLE AND FINAL DRIVE | ||

| Drive system | Four-wheel drive | |

| Front | Fixed, semi-floating | |

| Rear | Center-pin support, semi-floating, 26˚ total oscillation | |

| Reduction gear | Spiral bevel gear | |

| Differential gear | Conventional type | |

| Final reduction gear | Planetary gear, single reduction | |

| BRAKES | ||

| Service brakes | Hydraulically actuated, wet multiple-disc brakes actuate on four wheels | |

| Parking brake | Wet disc brake | |

| Secondary brake | Parking brake is commonly used | |

| STEERING SYSTEM | ||

| Type | Articulated type, full-hydraulic power steering | |

| Steering angle | 43˚ each direction | |

| Minimum turning radius at the center of outside tire | 7 075 mm | |

| HYDRAULIC SYSTEM | ||

| Control positions: Boom - Raise, hold, lower, and float | ||

| Control positions: Bucket - Tilt-back, hold, and dump | ||

| Hydraulic pump (Steering system) | Gear type pump | |

| Capacity | L/min | 163 |

| Relief valve setting | MPa | 34.3 |

| Hydraulic cylinders | ||

| Type | Double-acting, piston type | |

| Bore x stroke | 115 mm x 510 mm | |

| Hydraulic pump (Loader control) | Piston pump | |

| Capacity | L/min | 239 + 239 |

| Relief valve setting | MPa | 34.3 |

| Hydraulic cylinders | ||

| Type | Double-acting, piston type | |

| Number of cylinders-bore x stroke |

Lift cylinder: 2 - 200 mm x 1067 mm Lift cylinder: 1 - 225 mm x 776 mm |

|

| Control valve | 2-spool type | |

| Hydraulic cycle time (Rated load in bucket) | ||

| Raise | s | 9.3 |

| Dump | s | 2.3 |

| Lower (Empty) | s | 4.1 |

| SERVICE REFILL CAPACITIES | ||

| Fuel tank | L | 718 |

| Cooling system | L | 147 |

| Engine | L | 86 |

| Torque converter and transmission | L | 83 |

| Axle front | L | 155 |

| Axle rear | L | 155 |

| Hydraulic system | L | 443 |

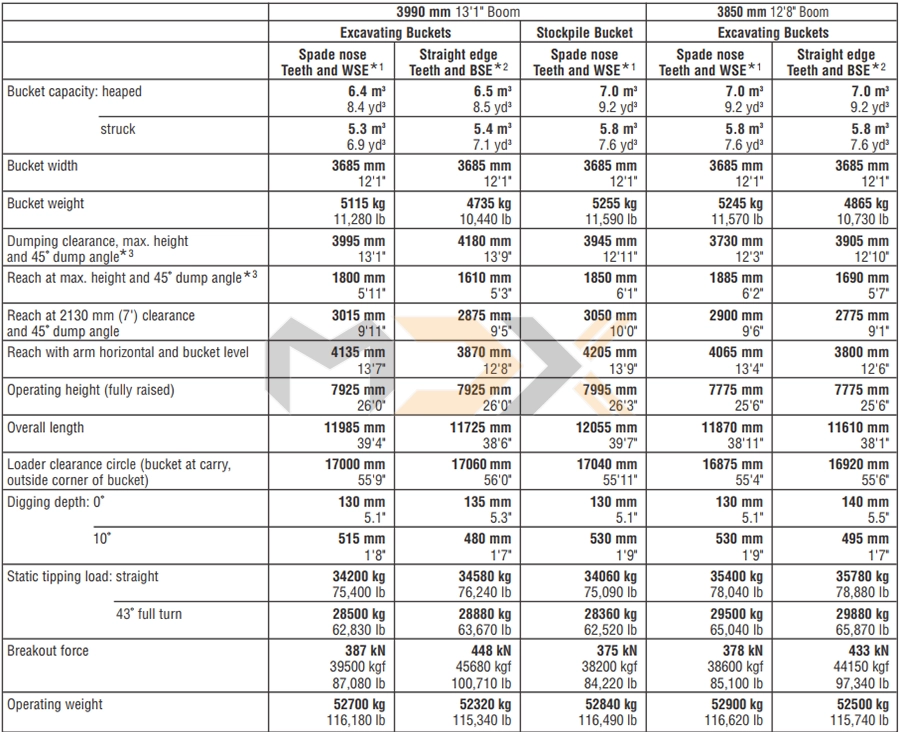

High Performance SAA6D170E-5 Engine

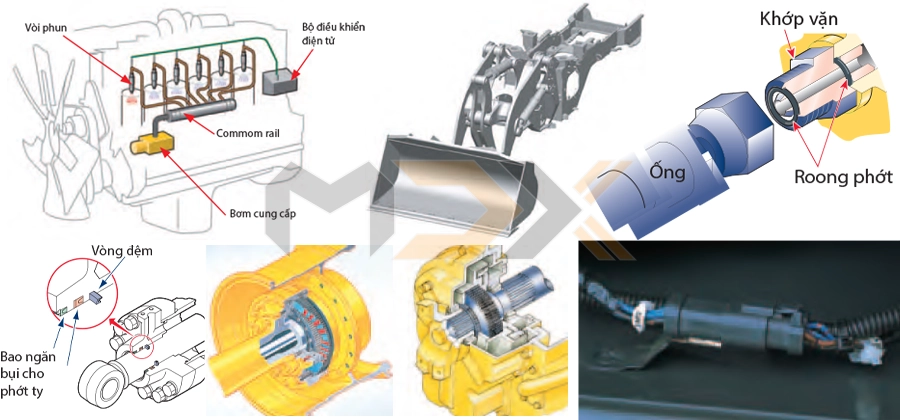

Electronic Heavy Duty Common Rail fuel injection system provides optimum combustion of fuel. This system also provides fast throttle response to match the machine’s powerful tractive effort and fast hydraulic response. This engine is EPA Tier 2 and EU Stage 2 emissions equivalent. Net: 393 kW 527 HP

Low Fuel Consumption

The fuel consumption is reduced greatly because of the low-noise, high-torque engine and the large-capacity torque converter with maximum efficiency in the low-speed range.

Dual-mode Engine Power Select System

This wheel loader offers two selectable operating modes E and P. The operator can adjust the machine’s performance with the selection switch.

- E Mode: This mode provides maximum fuel efficiency for general loading.

- P Mode: This mode provides maximum power output for hard digging operation or hill climb.

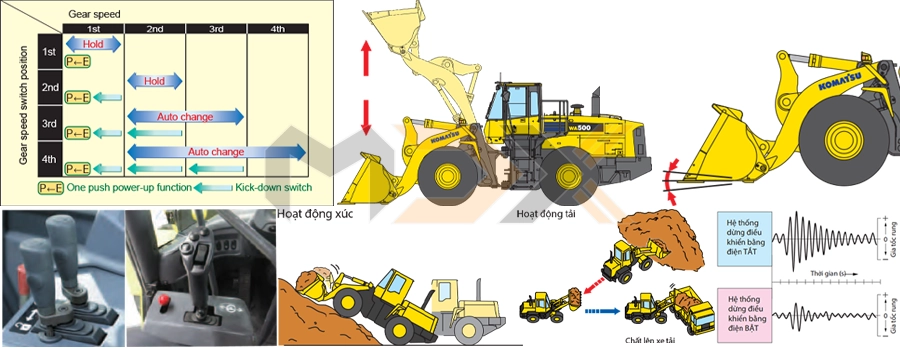

Automatic Transmission with Mode Select System

This operator controlled system allows the operator to select manual shifting or two levels of automatic shifting (low, and high). Auto L mode is for fuel saving operation with the gear shift timing set at lower speeds than Auto H mode. Therefore Auto L mode keeps the engine in a relatively low rpm range for fuel conservation while yielding adequate tractive force by depressing the accelerator pedal.

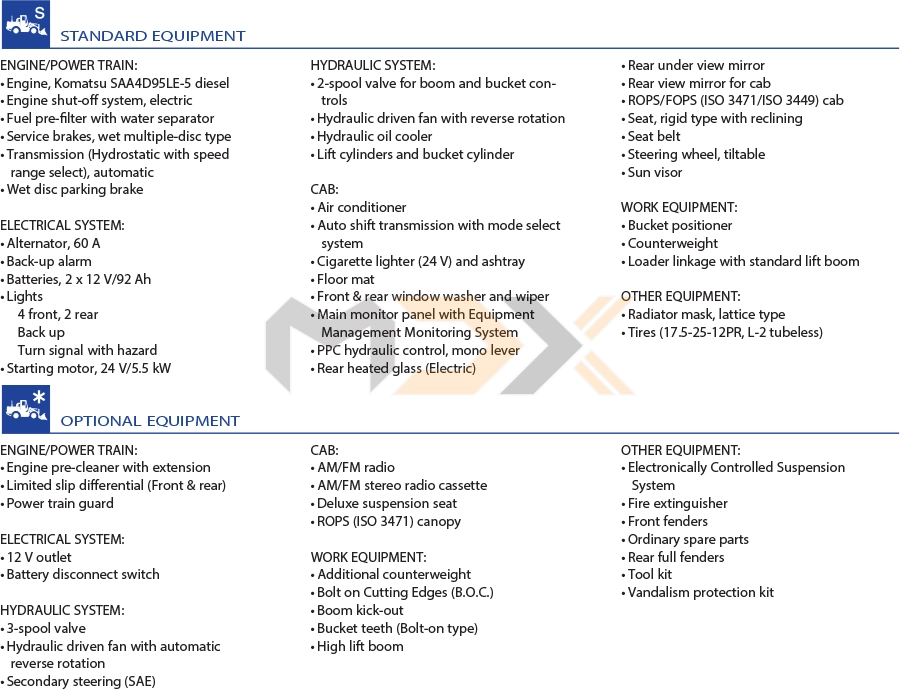

Lock-up Torque Converter

The Komatsu designed lock-up torque converter provides increased production efficiency, reduced cycle times and optimum fuel savings in load & carry or hill-climb operations. This optional feature allows the operator to activate the system on/off with a switch located on the right-side control panel.

Variable Displacement Piston Pump & CLSS

New design variable displacement piston pump combined with the Closed-center Load Sensing System delivers hydraulic flow just as the job requires preventing wasted hydraulic pressure. Minimized waste loss contributes to better fuel economy.

- New Variable Displacement Piston Pump: The pump delivers only necessary amounts minimizing waste loss.

- Fixed Displacement Piston Pump: The pump delivers the maximum amount at any time and the unused flow is disposed.

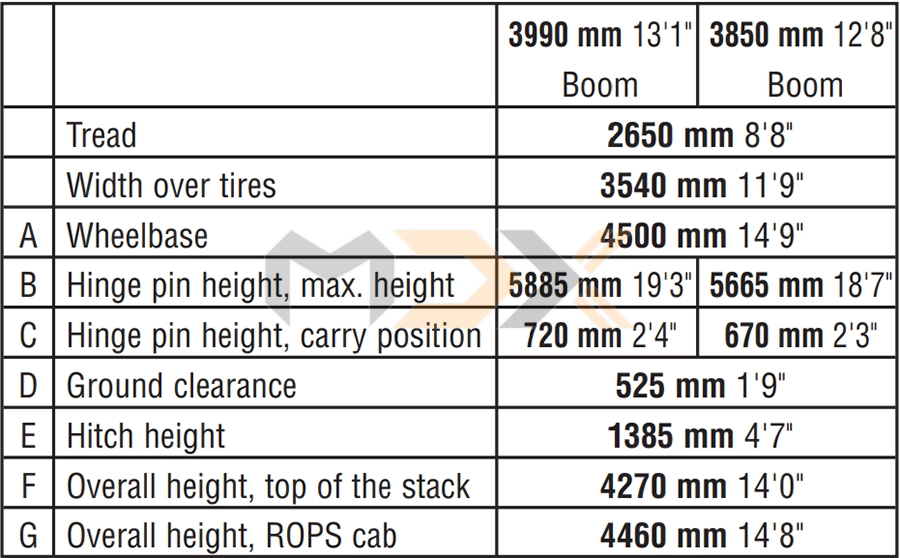

Increased Bucket Capacity Matches with One Class Higher Dump Truck

Komatsu WA600 can load 60t (70 Short ton) trucks with standard boom. The WA600-3 required an optional high lift boom and 6.4m3 bucket. WA600-6 wheel loader maintains good visibility for loading because of increased operator cab height.

- Dumping Clearance: 3995 mm.

- Dumping Reach: 1800 mm (6.4 m3 8.4 yd3 spade nose bucket with tooth)

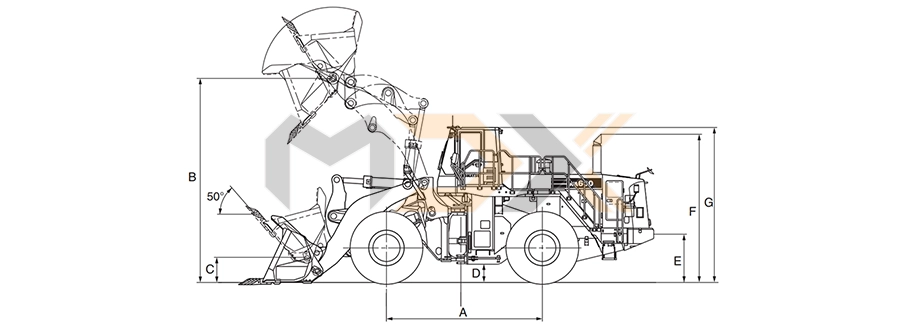

Long Wheelbase/Articulation Angle of 43˚

The widest tread in class and the long wheelbase provide improved machine stability in both longitudinal and lateral directions. Since the articulation angle is 43˚, the operator can work efficiently even in the tightest job sites.

- Tread 2650 mm.

- Wheelbase 4500 mm.

- Minimum turning radius 7075 mm (center of outside tire)

Komatsu Components

Komatsu manufactures the engine, torque converter, transmission, hydraulic units, electric parts, on Komatsu WA600-6R wheel loader. Komatsu loaders are manufactured with an integrated production system under a strict quality control system.

Wet Multi-disc Brakes and Fully Hydraulic Braking

System mean lower maintenance costs and higher reliability. Wet disc brakes are fully sealed. Contaminants are kept out, reducing wear and maintenance. Brakes require no adjustments for wear, meaning even lower maintenance. The new parking brake is also an adjustment-free, wet multi-disc for high reliability and long life. Added reliability is designed into the braking system by the use of two independent hydraulic circuits. Provides hydraulic backup should one of the circuits fail. Fully hydraulic brakes mean no air system to bleed, or the condensation of water in the system that can lead to contamination, corrosion, and freezing.

High-rigidity Frames and Loader Linkage

The front and rear frames and the loader linkage have more torsional rigidity to secure resistance against increased stress due to the use of a larger bucket. Frame and loader linkage are designed to accommodate actual working loads, and simulated computer testing proves its strength.

Flat Face-to-face O-ring Seals

Flat face-to-face O-ring seals are used to securely seal hydraulic hose connections and to prevent oil leakage. In addition, buffer rings are installed to the head side of the all-hydraulic cylinders to lower the load on the rod seals and maximize the reliability

Cation Electrodeposition Primer Paint/ Powder Coating Final Paint

Cation electrodeposition paint is applied as a primer paint and powder coating is applied as topcoat to the exterior sheet metal parts. This process results in a beautiful rust-free machine, even in the most severe

environments. Some external parts are made of plastic providing long life and high impact resistance.

Sealed DT Connectors

Main harnesses and controller connectors are equipped with sealed DT connectors providing high reliability, water resistance and dust resistance.

Sweeper Wing (Large Size Tire Guard)

To prevent tire damage, Komatsu WA600 provides a Sweeper Wing (Large size Tire Guard) on both sides of bucket.

Wet Multi-disc Brakes and Fully Hydraulic Braking

System mean lower maintenance costs and higher reliability. Wet disc brakes are fully sealed. Contaminants are kept out, reducing wear and maintenance. Brakes require no adjustments for wear, meaning even lower maintenance. The new parking brake is also an adjustment-free, wet multi-disc for high reliability and long life. Added reliability is designed into the braking system by the use of two independent hydraulic circuits. Provides hydraulic backup should one of the circuits fail.

Fully hydraulic brakes mean no air system to bleed, or the condensation of water in the system that can lead to contamination, corrosion, and freezing.

Sweeper Wing (Large Size Tire Guard)

To prevent tire damage, Komatsu WA600 provides a Sweeper Wing (Large size Tire Guard) on both sides of bucket.

With long service intervals and best-in-class accessibility, Komatsu WA600-6R reduces the time and money you need to suspend on maintenance. A gas spring helps the operator open and close each gull-wing side door for easy daily servicing.

Easy Radiator Cleaning

Reversible hydraulic fan

A push-button switch in the cab allows the operator to run the radiator fan in reverse for working in dusty environments.

Swing out fan

The hinged, bolt-on fan can be swung out for easier cleaning. The coolers feature wider spacing of the cooling fins to reduce clogging.

Simple fluid level checks

All important fl uid levels can be easily checked from ground level. Sight gauges for coolant, oil and air cleaner let you check the level at a glance.

Modular radiator core system

The modular radiator core is easy to replace without removing the entire radiator assembly.

Equipment Management Monitoring System

Monitor is mounted in front of the operator for easy viewing, allowing the operator to easily check gauges and warning lights. A specially designed two-spoke steering wheel allows the operator to easily see the instrument panel. Maintenance Control and Troubleshooting Functions

Action code display function

If abnormality occurs, the monitor displays action details on the character display at the bottom center of the monitor.

Monitor function

Controller monitors engine oil level, pressure, coolant temperature, air cleaner clogging, etc. If controller finds abnormalities, the error is displayed on Liquid Crystal Display (LCD).

Replacement time notice function

Monitor informs replacement time of oil and fi lters on LCD when replacement intervals are reached.

Trouble data memory function

Monitor stores abnormalities for effective troubleshooting.

Maintenance Accessibility

Gull-wing type engine side doors open wide

The operator can open and close each gull-wing type engine side door easily with the assistance of a gas spring to perform daily service checks from the ground.

Engine compartment

With all fi lters collected into a centralised arrangement, the down time for servicing is reduced to a minimum. The engine air fi lter can be easily accessed from the platform while the transmission oil fi lters are externally mounted.

Easy engine access

For engine inspections, the bolt-on top cover can be removed in minutes providing the easy access to the engine compartment.

External fluid drains

All fl uids can be drained through externally mounted valves for easy maintenance and reduced spillage.

ROPS/FOPS Cab

The ROPS/FOPS Cab is standard for operator’s safety. A wide pillar-less fl at glass provides excellent front visibility, and a heated rear window provides excellent rear visibility in cold and freezing weather conditions.

- ROPS (ISO 3471) : Roll-over Protective Structure

- FOPS (ISO 3449) : Falling Objects Protective Structure

Left or Right Side Cab Entry

The operator can get on and off the machine from either side of the vehicle. This design is convenient when getting on and off in a narrow jobsite or on uneven ground.

Rear-hinged Full Open Cab Door

The cab door hinges are installed to the rear side of the cab providing a large opening angle for the operator to enter and exit. The steps are designed like a staircase, so that the operator can get on and off the cab easily.

Safety Features

Secondary steering

If the steering pump is disabled, a secondary steering pump provides hydraulic flow.

Two independent lines brake system

Added reliability is designed into the braking system by the use of two independent hydraulic circuits, providing hydraulic backup should one of the circuits fail.

Battery disconnect switch

The battery disconnect switch is located in the right side battery box. This can be used to disconnect power when performing service work on the machine.

Komatsu Total Support

To keep your machine available and minimize operation cost when you need it, Komatsu Distributor is ready to provide a variety of supports before and after procuring the machine.

Fleet recommendation

Komatsu Distributor can study the customer’s job site and provide the most optimum fleet recommendation with detailed information to meet all of your application needs when you are considering to buy new machines or replace the existing ones from Komatsu

Product support

Komatsu Distributor gives the proactive support and secures the quality of the machinery that will be delivered.

Parts availability

Komatsu Distributor is available for emergency inquiry by the customers for genuine, quality guaranteed Komatsu parts.

Technical support

Komatsu product support service (Technical support) is designed to help customer. Komatsu Distributor offers a variety of effective services to show how much Komatsu is dedicated to the maintenance and support of Komatsu machine.

- Preventive Maintenance (PM) clinic

- Oil & Wear analysis program

Repair & maintenance service

Komatsu Distributor offers quality repair and maintenance service to the customer, utilizing and promoting Komatsu developed programs.

Komatsu Reman (Remanufactured) components

Komatsu Reman products are the result of the implementation of the Komatsu global policy which establishes and agrees to reduce the owning, operating and total Life Cycle Costs (LCC) to Komatsu’s customer through high quality, prompt delivery and competitively priced in own remanufactured products (QDC)

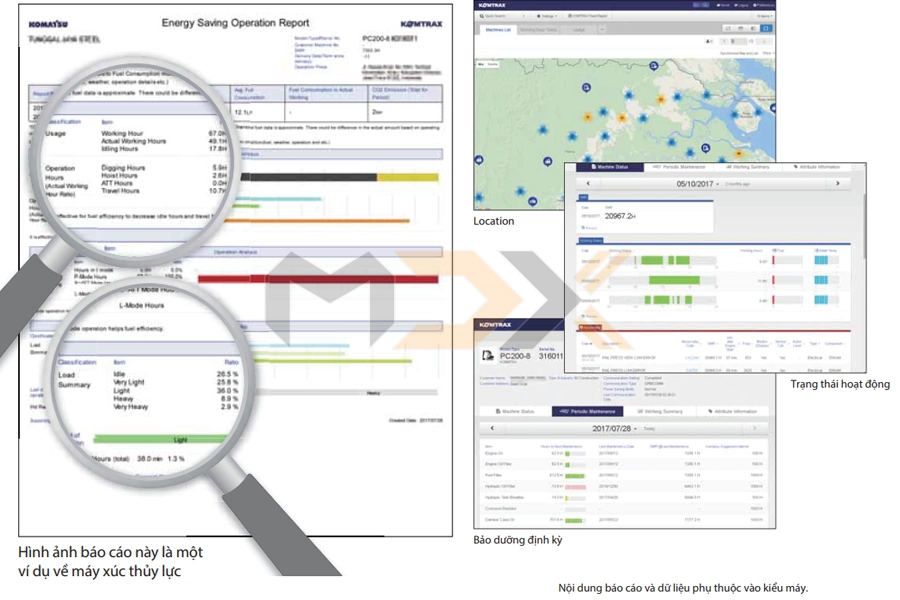

The Komatsu remote monitoring and management technology provides insightful data about your equipment and fleet in user-friendly format.

Energy Saving Operation Report

KOMTRAX delivers the energy-saving operation report based on the operating information such as fuel consumption, load summary and idling time, which helps you efficiently run a business.

Equipment Management Support

Through the web application, a variety of search parameters are available to quickly find information about specific machines based on key factors. Moreover, KOMTRAX finds out machines with problems from your fleet and shows you through an optimal interface

Optimal Strategy for Efficient Work

The detailed information that KOMTRAX puts at your fingertips helps you manage your fleet conveniently on the web anytime, anywhere. It gives you the power to make better daily and long-term strategic decisions.

Tags: Komatsu WA600 6R, wa150 6, Komatsu WA150 6 wheel loader, WA250 6, wheel loader, caterpillar wheel loader, hitachi wheel loader, Komatsu wheel loader, Doosan caterpillar wheel loader, wheel loader specifications, wheel loader Komatsu, wheel loader for sale, wheel loader capacity, wheel loader vs excavator, wheel loader caterpillar, wheel loader liugong, kubota wheel loader, volvo wheel loader, compact wheel loader, bobcat wheel loader, wheel loader volvo, wheel loader jcb, hitachi wheel loader dealers, hitachi wheel loader models, hitachi wheel loader specifications, hitachi wheel loader zw80, hitachi wheel loader parts, hitachi wheel loader zw180, used hitachi wheel loader, hitachi wheel loaders usa, hitachi 310 wheel loader, hitachi 220 wheel loader, hitachi 140 wheel loader, hitachi 370 wheel loader, hitachi 310 wheel loader specs, hitachi zw140 6 wheel loader specs