INTRODUCING ERGOPLUS 3 - THE NEXT GENERATION ASPHALT PAVER CONTROL SYSTEM

Even the best machine with the most advanced technology can only truly show its strengths if it can be operated as easily and intuitively as possible. At the same time, it should provide a safe and convenient working environment for the operating team. The ErgoPlus operating concept focuses on the operator. With a Vogele paver, the operator has everything under control – the entire machine and the job site.

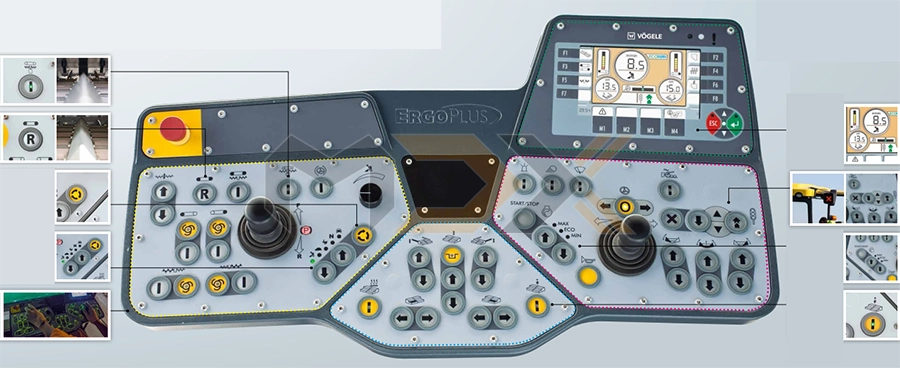

ErgoPlus 3 Operating Console

The paver operator's console is extremely clear and has been designed based on practical work habits and data. All functions are logically combined into functional groups, making it easy for the operator to always find the function they want to use easily and accurately.

On the ErgoPlus 3 console, all push-buttons can be operated by touch even when wearing gloves. When a button is pressed, a function is executed immediately, thanks to the "Touch and Work" principle. This means that a function is activated directly without any further confirmation.

Module 1: Conveyor, auger and travel drive

Module 2: Screed

Module 3: Material hopper and steering

Module 4: Display for monitoring and adjusting basic parameters

Idle Engine Speed Function

The idle engine speed function is provided for warming up the engine and hydraulic system, and for cleaning the conveyor, auger and tamper.

Reverse Conveyors

To prevent mix from falling off the conveyors when moving the paver from one job site to another, the conveyors can be reversed at the push of a button. This reverse conveyor movement takes place for a short time and then stops automatically.

AutoSet Plus - The Position Memory Function (option)

With the position memory function in the AutoSet Plus system, the paver is quickly and safely prepared for a move to the next job site at the push of a button. After the move, all paver components are reset to their previous positions simply by pressing the button again. This ensures that no settings are lost or forgotten when changing over from paving to transport and vice versa. AutoSet Plus is also highly effective in preventing damage during transport.

Selecting Paver Operating Modes

All main functions can be controlled directly by individual push-buttons on the ErgoPlus 3 console. By pressing the arrow buttons, up or down, the operator changes the modes in the following order: Neutral, Job Site mode fast/slow, Positioning mode. An LED indicates the mode selected.

Safe Operation at Night

The backlighting of the console comes on automatically when it gets dark, so the paver can also be operated safely on the job site at night.

Paver Operator's Console Display

The high-contrast color display provides excellent readability even in poor lighting conditions. Important information, such as the screed’s position or the material level in the conveyor, is shown in Level 1. Other functions such as the speed of the tampers and the vibration speed and frequency, or the speed and spreading width of the augers, can be easily set on the display. And the display also provides machine-related information such as fuel consumption or the next service interval.

PaveDock Assistant (option)

With the signal lights of the PaveDock Assistant, the paver operator can give signals to the driver of the feed vehicle without any misunderstandings, clearly indicating what needs to be done (e.g. reverse, stop, raise dump box). The lights are conveniently activated directly from the ErgoPlus 3 paver operator's console.

Selecting Engine Speed Ranges

With the diesel engine, there are three modes to choose from: MIN, ECO and MAX. To switch between modes, all the operator needs to do is press the arrow buttons, up or down. In ECO mode, the engine delivers sufficient power for 1 a large number of paving applications. Operating in ECO mode significantly reduces exhaust emissions and fuel consumption.

Selecting Paver Operating Modes

All main functions can be controlled directly by individual push-buttons on the ErgoPlus 3 console. By pressing the arrow buttons, up or down, the operator changes...

ErgoPlus 3 Operating Concept

The screed is crucial to the quality of the paved surface, so the easy and safe use of all screed functions is of paramount importance for building high-quality roads.

With ErgoPlus 3, paver operators can get to work immediately without a lengthy training period. All functions are readily understandable and all controls are clearly arranged.

Screed Console (Control Panel)

The screed console is designed to withstand the typical conditions on job sites. Push-buttons for frequently used functions are arranged directly on the screed console. These push-buttons are waterproof and surrounded by extremely durable, non-slip rubber details with a sufficiently high rim, making them identifiable even when the operator is blindfolded, simply by touch, and easy to use even when wearing work gloves. Important paver and screed data can also be adjusted from this console.

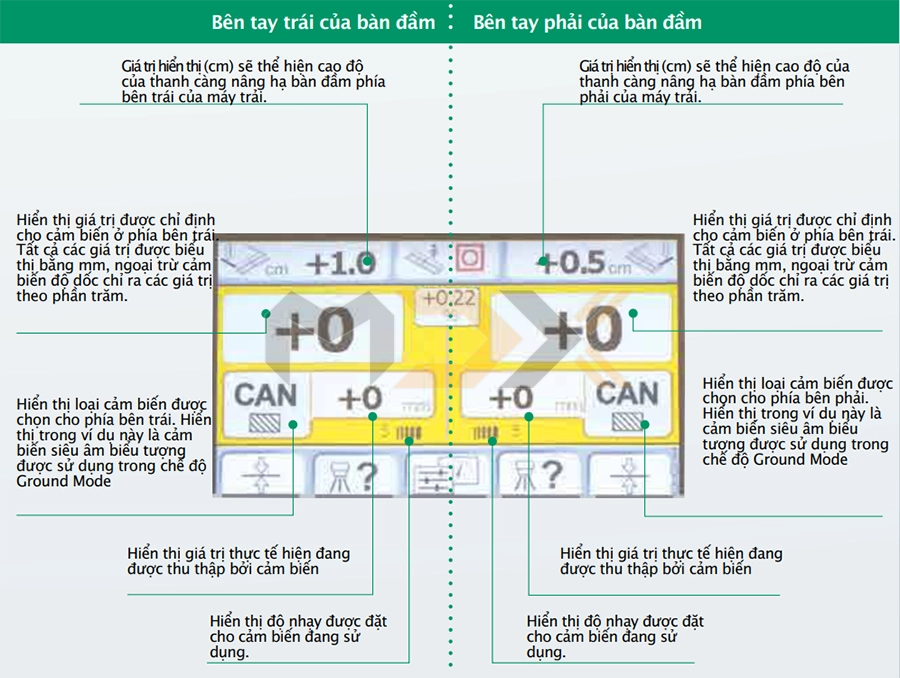

Display on the Screed Console

The display of the screed console allows the screed operator to control and monitor all paving parameters from both the left and right sides of the screed. The operator can quickly and easily adjust machine-related parameters such as tamper speed or conveyor speed. The clear menu structure, combined with self-explanatory, language-neutral symbols, makes the display panel both simple and safe to operate.

Easy Adjustment of Screed Crown and Slope

The screed crown and slope can be conveniently adjusted at the push of a button on the screed console. When pressing the keys with the plus or minus symbols, the set values are shown on the display so the operator can adjust the slope precisely.

Safe and Efficient Screed Width Adjustment

The pave width can be easily adjusted using the SmartWheel with two speed levels: slow, for precise adjustments, e.g. along the edge of a curb, or fast, for quickly retracting the extensions.

Optimized Visibility Even in the Dark

The screed console is specifically designed for night operation. To prevent operating errors, the push-buttons are illuminated as soon as dusk falls or in darkness. What's more, the high-power downlights give the operator a perfect view of all processes associated with the side plates.

VOGELE Niveltronic Plus

Niveltronic Plus, the automatic grade and slope control system, is a proprietary development by JOSEPH VÖGELE AG based on many years of experience in grade and slope control technology.

Easy operation, utmost precision and reliability are the hallmarks of this system, ensuring perfect grade and slope control for all jobs. This fully integrated system is perfectly matched to the technology of the Premium Line pavers. All wiring and connections are integrated within the tractor unit and screed, effectively eliminating all risk of damage to components.

VÖGELE offers a large number of practical sensors for every type of job site, allowing versatile use of the Niveltronic Plus system. Whether it is a parking lot, a roundabout or a highway that needs to be rehabilitated or newly constructed.

VÖGELE offers the right sensor for every situation on every job site. Sensors can be changed quickly and easily, and Niveltronic Plus automatically detects which sensor is connected, thus simplifying configuration for the operator.

ErgoPlus 3 - Sitting / Standing Platform

1. Unobstructed view: The comfortable operator's platform provides an unobstructed view of all important areas, such as the material hopper, the auger or the screed.

2. Optimal view: The seats swivel and are extendible to both sides and the cleverly designed platform with its streamlined fittings provide an optimum view of the material in the auger compartment, allowing the operator to keep an eye on the head of material in front of the screed at all times.

3. Comfortable working: The operator's seat, the paver operator's console and even the console itself can be adjusted easily to suit individual needs.

4. Centralized control: The platform, with its well-organized design, provides the paver operator with a professional workplace. The paver operator's console can be protected by a durable plastic cover, which keeps the controls safe from damage.

5. Hardtop - excellent protection: The modern hardtop made from glass fiber reinforced polymer with its inner lining effectively protects the operator from rain or sunshine.

6. Consistent service concept: On the Dash 3 pavers, the service intervals for all maintenance points have been synchronized.

7. Safe and convenient access: The convenient central walkway and steps on the screed ensure safe and convenient access to the operator’s platform.

8. User-friendly console design: The height and position of the console are easily adjusted. The high-contrast color display can be read clearly from all angles.