HYDRAULIC CYLINDERS FOR VOGELE ASPHALT PAVERS

To "pave" a smooth, flat asphalt road requires the harmonious coordination of many components within a Vogele asphalt paver. Among them, the hydraulic cylinders for height adjustment play a crucial role, determining the accuracy and efficiency of the entire process. Today's article will provide a detailed "dissection" of this important component, helping you better understand its operating mechanism and its role in paver operation.

Today, asphalt pavers are widely used in road and bridge construction projects in Vietnam. These paving devices meet all stringent quality requirements of the projects with extremely high accuracy. Among the leading reputable brands, it is impossible not to mention Vogele asphalt pavers. This is the line of machines that many contractors prioritize using to meet the most demanding needs of the market because they have many outstanding advantages such as:

- High-quality manufacturing: The equipment is manufactured to the highest standards.

- Continuous innovation: They are constantly updated and equipped with modern features.

- Expert engineering: Created by highly qualified engineers, meeting international standards.

- User-friendly operation: Easy to operate and user-friendly.

In road construction, it is common to use a paver in conjunction with a roller to spread and compact the asphalt mix. The thickness of the paved layer depends on many factors such as the type of material, road grade, construction process, road slope, and the flatness of the road base. Therefore, during operation, the screed of the paver must be constantly adjusted to control the thickness of the paved material. The road surface after paving must be flat, have uniform compaction, and ensure the correct slope and gradient of the road.

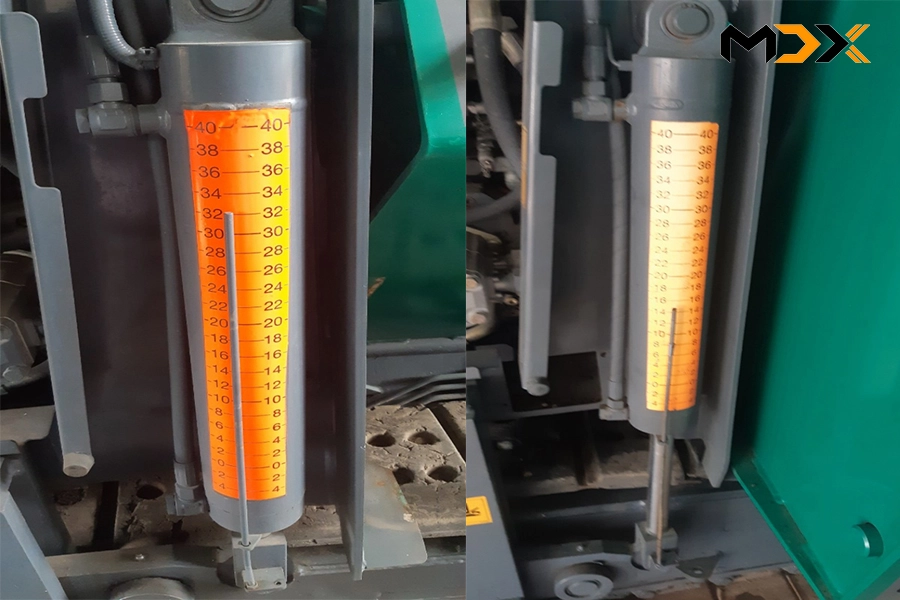

Hydraulic cylinders for height adjustment on a Vogele paver

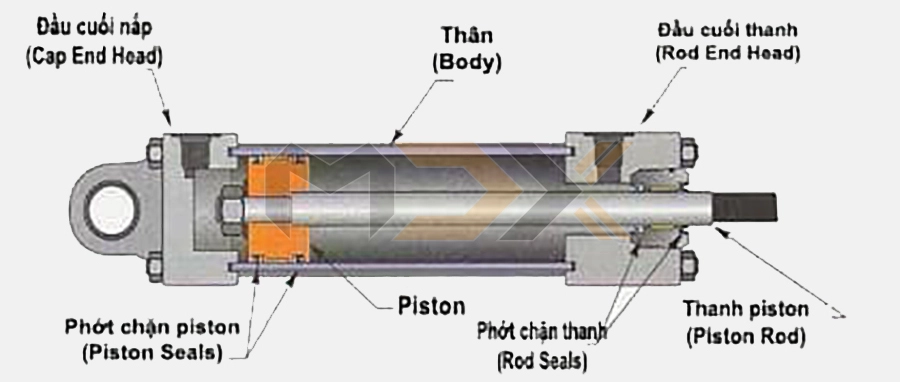

HYDRAULIC CYLINDER STRUCTURE

Simply put, this is a linear actuator used to generate mechanical force along a straight line through pushing or pulling force. The basic structure of a hydraulic cylinder includes a cylinder barrel, a piston rod, two end caps, and seals. The height adjustment cylinders on pavers are also equipped with sensors at the end of the cylinders, which help adjust the paving angle as desired by the user.

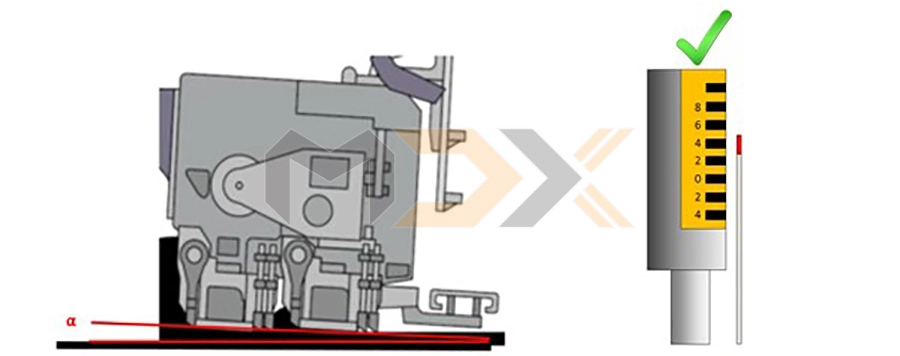

PAVING ANGLE SETUP WHEN OPERATING A VOGELE ASPHALT PAVER

- Paving angle allows more material under the screed: This increases the paving depth in balance with the screed weight and achieves preliminary compaction.

- Raising the hydraulic cylinders increases the paving angle (⍺): This, in turn, increases the thickness of the paved layer.

- Practical paving angle: The screed angle should be set from 0% to 50% greater when using the "dash 3" generation of pavers (and 50-100% on "dash 2" machines).

+ The value shown on the scale summarizes the thickness and screed angle.

+ This ensures optimal effectiveness of the compaction effort with the asphalt.

+ Wear on the tamper bar, vibrators, and pressure bar is reduced.

- Optimal paving angle equals optimal tamper bar position: The optimal paving angle corresponds to the optimal position of the tamper bar.

- Screed weight positively impacts compaction: The weight of the screed has a positive effect on material compaction.

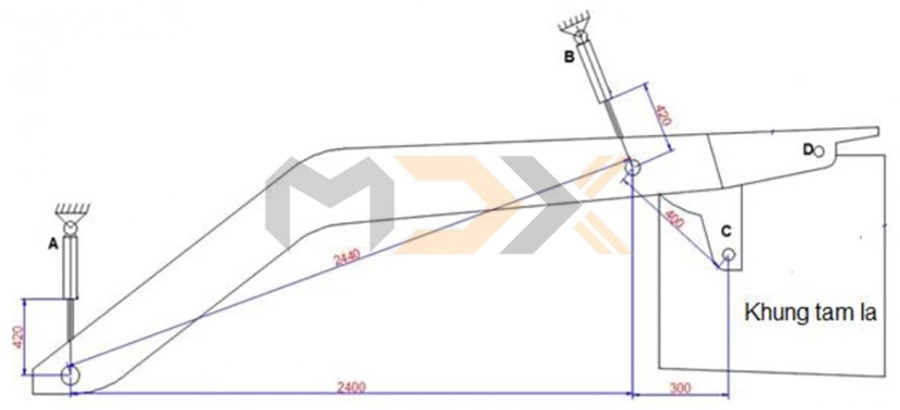

Diagram of the screed suspension system