CALCULATING MAXIMUM FUEL CONSUMPTION

Optimizing operational costs and maximizing machinery productivity are paramount concerns for any enterprise. Accurately determining fuel consumption rates for internal combustion engines is crucial for effective cost management and operational efficiency. Experienced machine operators understand the significant impact of fuel consumption on long-term operational costs. This article provides a theoretical framework for calculating maximum fuel consumption, illustrated with a case study of the Deutz TCD 2012 L4 engine.

Download the Deutz TCD 2012 L4 engine documentation: HERE

It's important to note that real-world operating conditions expose machinery to various external factors and operator habits that can influence fuel consumption. These factors contribute to variations in fuel consumption rates, making measured values relative rather than absolute.

ABOUT THE DEUTZ TCD 2012 ENGINE

The Deutz TCD 2012, developed by Deutz (Germany), is a robust and reliable diesel engine commonly employed in construction, agricultural, and power generation applications. Renowned for its exceptional performance, durability, and fuel efficiency, the TCD 2012 complies with EU Stage IIIA / US EPA Tier 3 emission standards and offers numerous practical benefits to users.

Key Features:

- Power output: 66 - 155 kW (91 - 210 hp) at 2400 - 2600 rpm

- Emission standard: EU Stage IIIA / US EPA Tier 3

- Compact design: Facilitates easy installation on various machinery, saving space and weight.

- PTO drive: Three PTO drive options allow for flexible connection to a wide range of auxiliary equipment, enhancing operational efficiency.

- DEUTZ Common-Rail (DCR®) high-pressure fuel injection system: Optimizes combustion efficiency, increasing engine performance and reducing emissions.

- Electronic engine management (EMR 3): Provides precise engine control and optimization, ensuring high performance and fuel efficiency.

- Reliable cold starting capabilities: Enables easy starting at low temperatures and ensures stable operation in harsh weather conditions.

- Optional counter-rotating balancer shaft: Minimizes noise and vibration, providing smooth and comfortable operation.

- Long oil change intervals: Up to ... hours (information to be added), reducing maintenance costs.

- Compatibility with high-sulfur fuels: Adapts to various fuel qualities, ensuring consistent performance.

Applications:

The Deutz TCD 2012 engine finds extensive applications in:

- Construction machinery: Excavators, bulldozers, rollers, etc.

- Agricultural machinery: Tractors, harvesters, etc.

- Power generators

The Deutz TCD 2012 is an ideal solution for applications demanding high performance, durability, and fuel efficiency. With its advanced design, the engine offers powerful, smooth, and environmentally friendly operation.

The maximum fuel consumption rate of an engine can be calculated based on its maximum power output and brake specific fuel consumption (BSFC), using the following formula:

Fuel Consumption Rate (liters/hour) = [BSFC (g/kW.h) x Power (kW)] / ρ (kg/liter)

Application to the Deutz TCD 2012 L4 Engine:

1. Key Parameters

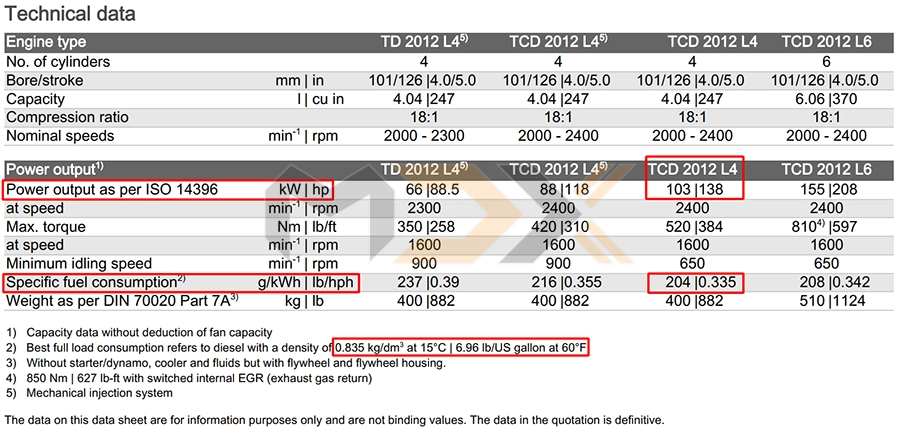

The density of diesel fuel is 0.835 kg/liter.

2. Calculating Fuel Consumption

The following calculation demonstrates the maximum fuel consumption for the TCD 2012 L4 engine operating at peak power output:

- Fuel Consumption (liters/hour) = [BSFC (g/kW.h) x Power (kW)] / ρ (kg/liter)

- Assuming a BSFC of 204 g/kW.h and a maximum power output of 103 kW:

+ Fuel Consumption = [204 g/kW.h x 103 kW] / 0.835 kg/liter

+ = 21,012 g/ 0.835 kg/liter

+ = 25.164 liters/hour

Therefore, the Deutz TCD 2012 L4 engine consumes approximately 25 liters of diesel fuel per hour when operating at maximum power output (based on manufacturer specifications).

3. Estimating Operating Time

Considering a 290-liter diesel fuel tank and a 7-hour workday:

- Operating Time (hours) = Tank Capacity (liters) / Fuel Consumption Rate (liters/hour)

- Operating Time = 290 liters / 25 liters/hour = 11.6 hours

Theoretically, the engine can operate at maximum power for 11.6 hours on a full tank, which is equivalent to 1.65 work shifts. Refueling would be necessary after approximately 1.5 shifts.

4. Real-World Fuel Consumption

In practice, engines rarely operate at maximum power continuously. Actual fuel consumption varies depending on factors such as operating conditions, load, and operator behavior. On-site measurements are crucial for determining accurate fuel consumption for specific applications and work sites. Field data indicates that the Deutz TCD 2012 L4 engine consumes approximately 35-42 liters per shift, which is equivalent to 5-6 liters per hour.

5. Conclusion

Understanding fuel consumption is crucial for optimizing operational costs and improving the efficiency of construction machinery. By monitoring and managing fuel consumption, businesses can reduce expenses and improve their financial planning.

Watch our video for a detailed explanation of how to calculate maximum fuel consumption: