AUTOMATING THE PAVING PROCESS WITH AUTOSET BASIC AND AUTOSET PLUS

With AutoSet Basic and AutoSet Plus, Vogele has increased the efficiency, convenience and quality of key job site processes. AutoSet Basic and AutoSet Plus have two convenient automatic functions.

INTRODUCING AUTOSET BASIC

At the touch of the "Execute" button, hydraulically raise the augers, the front of the hopper and the deflectors in front of the crawler tracks to their uppermost positions. The screed is also brought into its transport position. The conveyors are temporarily reversed, preventing mix from falling to the ground when the paver travels to the next work section on the job site.

Once the paver has been repositioned, pressing the "Execute" button again returns all systems to their previously stored working positions. This ensures that no settings are lost when changing from paving to repositioning or transport. It also effectively prevents any damage to the machine.

INTRODUCING AUTOSET PLUS

The repositioning and transport function significantly improves the continuation of work when moving the paver on the job site from one area to another, or after the paver is hooked up to be moved to another job site.

Simply pressing the Execute button quickly and reliably prepares the machine for travel on the job site or for transport. Press the button again to return it to its previously stored working position.

The Paving programs function allows the operating personnel to save configured machine parameters and store them as “paving modes” in the menu. This program can then be recalled for use whenever needed.

The two convenient functions of AutoSet Plus automate routine tasks, allowing work processes to be performed more quickly and with greater control. This means that construction projects can be completed faster and more reliably.

AutoSet Plus is available for the Universal and Highway Class machines of the Premium Line. In addition to the repositioning and transport function, paving programs can also be saved here.

1. AutoSet Plus - Repositioning Function

Quick and safe repositioning of the paver on the job site. No settings are lost between paving and repositioning and it also prevents any damage to the augers and deflectors in front of the crawler tracks.

2. AutoSet Plus - Paving Programs Function

Automatic configuration of the paver.

Storage of all paving-related parameters.

Selection of stored paving programs.

AutoSet Plus - Position Memory Function

AutoSet Plus is particularly useful when the paver has to be moved frequently on large job sites.

Simply pressing the "Execute" button activates the following actions: The augers are raised, the hopper sides are folded in to the transport position, the deflectors in front of the crawler tracks are raised to their uppermost position. Screed and screed tow point rams are brought into the transport position. In addition, the screed is automatically hydraulically locked to prevent any movement when travelling over long distances.

The conveyors are also temporarily and automatically reversed, which counteracts the unintentional spilling of mix when the paver travels from one point to another on the same job site for the next section to be paved.

Once the paver has been repositioned, pressing the "Execute" button again returns all systems to their previously stored working positions.

This ensures that no settings are lost or forgotten when changing over from paving to repositioning or transport. It is also highly effective in preventing any damage to the machine.

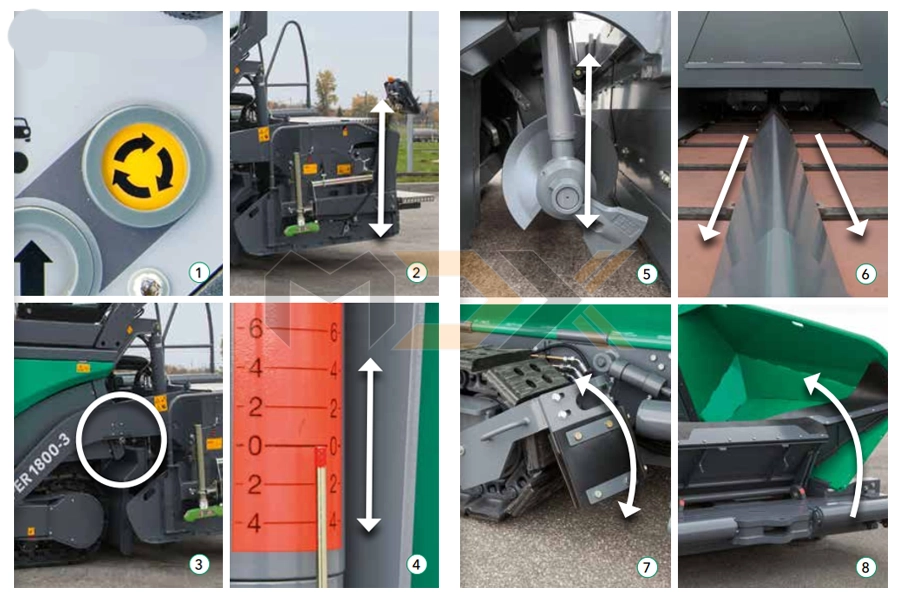

1. AutoSet Plus position memory function easily activated by pressing the “Execute” button

2. Screed raised/lowered

3. Screed locked/unlocked

4. Screed tow point rams in transport position/last set value

5. Augers raised/lowered

6. Conveyors briefly reversed

7. Deflectors in front of the crawler tracks raised/lowered

8. Hopper sides raised and folded in

AutoSet Plus - Paving Programs

The paving programs function allows the operating personnel to save paving-related parameters for future use. All the main paving parameters, for instance a layer thickness of 18 cm, can be stored in the system.

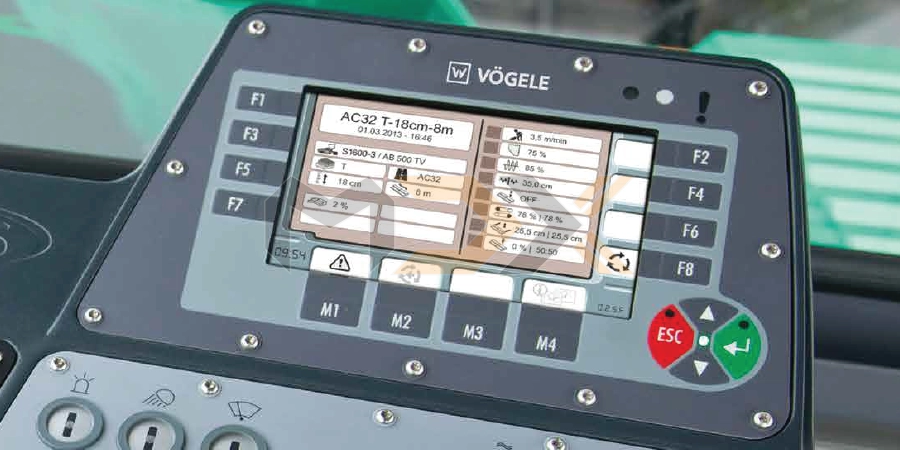

On the display, the paver operator enters the values to be set for paving and precompaction, such as tamper speed, screed vibration frequency, pressure bar pressure, auger height, screed tow point ram position, screed supports and paving speed.

The operator can also enter the screed crown and the screed temperature. The paving program is completed with additional information on the type of mix, layer thickness and pave width.

The stored paving programs can then be selected and used at any time via the menu. In the event of recurring jobs, the work is guaranteed to be carried out with precisely the same settings, which helps to maintain a consistent quality.

Retrieving Programs, Adopting and Optimizing Settings

Step 1: Adopting a program

When selecting and activating a program, the stored paver and screed settings can be adopted without changes if the new paving situation is identical to the saved one.

Step 2: Changing individual program settings

If required by the demands on the new job site, the stored values (such as paving speed, tamper speed, pressure bar pressure, etc.) can be changed individually as applicable and adapted to the prevailing conditions.

Result

Maximum paving quality with a much faster and easier set-up process. With AutoSet Plus, that is no longer a contradiction in terms! For users, it means process safety, time savings and significantly greater convenience in operation.