APPLICATION TECHNOLOGY IN EARTH WORK AND ASPHALT CONSTRUCTION

APPLICATION TECHNOLOGY IN EARTH WORK

WORK STEPS

Which compaction steps are recommended with the various compaction systems when compacting earth work?

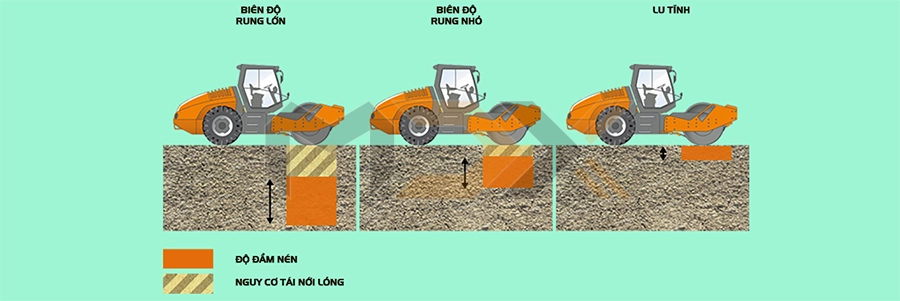

VIBRATION

During vibration: First compact with a large amplitude (1), then use a small amplitude (2), and then static (3).

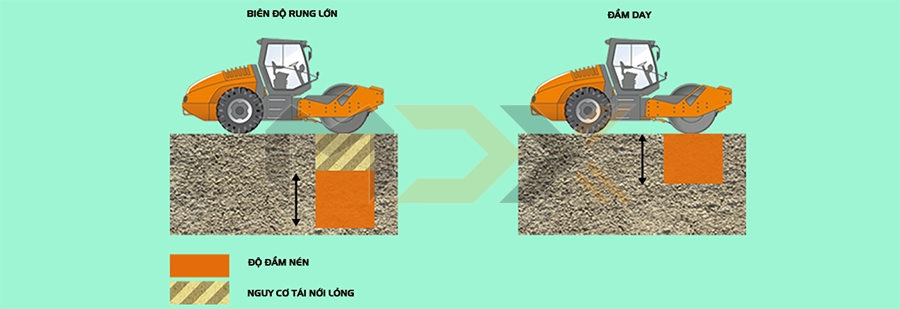

VIO

With VIO: First compact with vibration (1), then with oscillation (2).

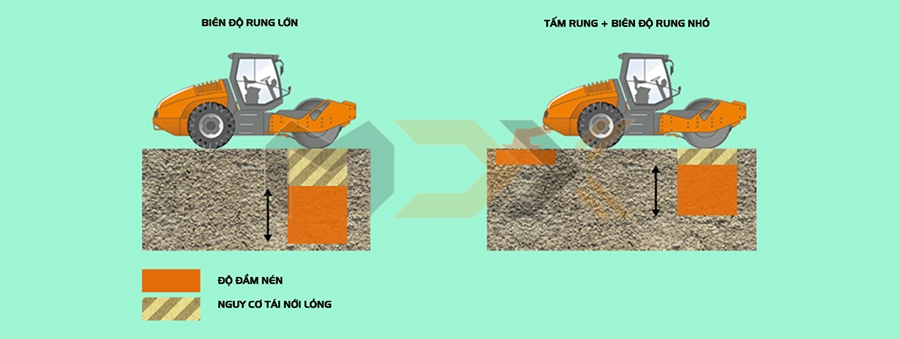

VIBRATION PLATE

With vibration plate: First compact with vibration (large amplitude) (1), then with vibration (small amplitude) (2) and simultaneous use of the vibration plate.

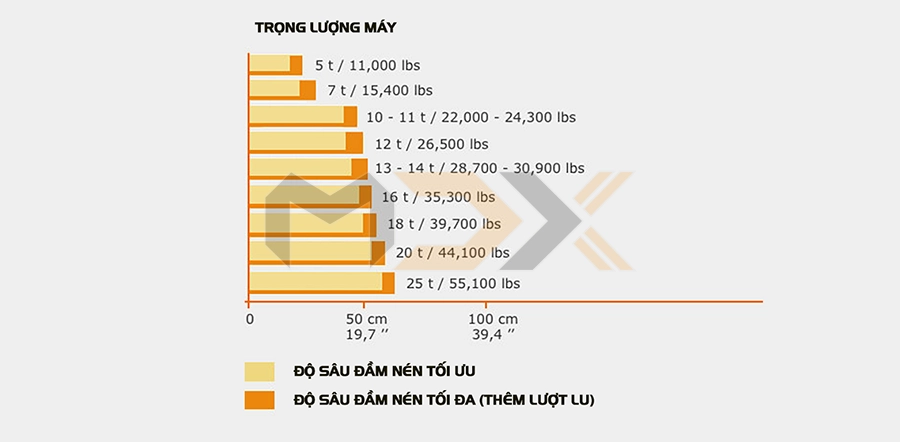

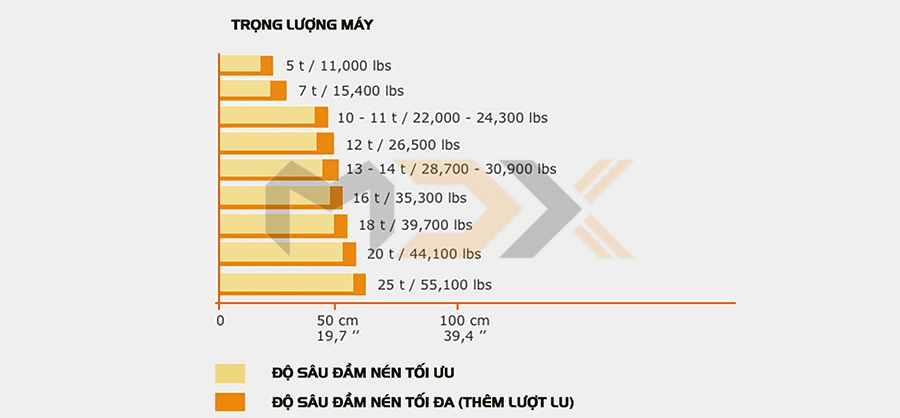

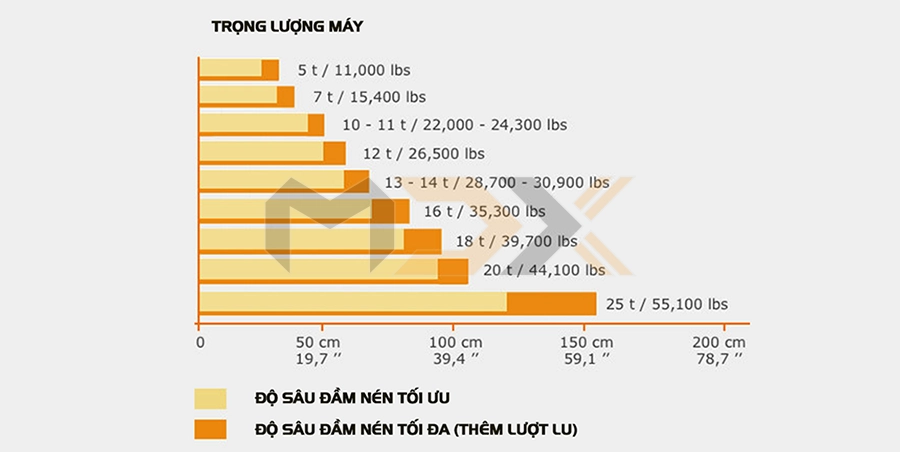

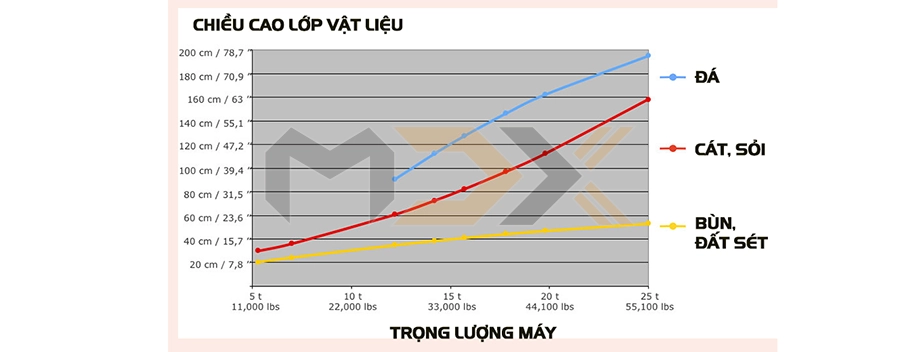

WORKING DEPTHS

The weight of the machine and the ground characteristics influence the compaction depth. The following diagrams will illustrate the respective average details, which can obviously vary quite a lot due to the different ground conditions.

Cohesive ground

Ideal:

- Step 1: Utilising a compactor with padfoot drum;

- Step 2: Utilising a compactor with smooth drum

Attention:

The water content is very important for selecting the compactor and/or the drum!

Non-cohesive ground

Ideal: Compactor with smooth drum

Rock

Ideal: Heavy compactor with smooth drum

Overview of the working depths compared to the machine weight

Ground stabilisation

Which compactor will be required after stabilisation for good compaction?

Kneading the material

Compaction in the depth

Padfoot drums and/or padfoot shells enable an expansion of the surface area and therefore a quicker drying out for the ground.

Compaction in upper areas and sealing the surface area

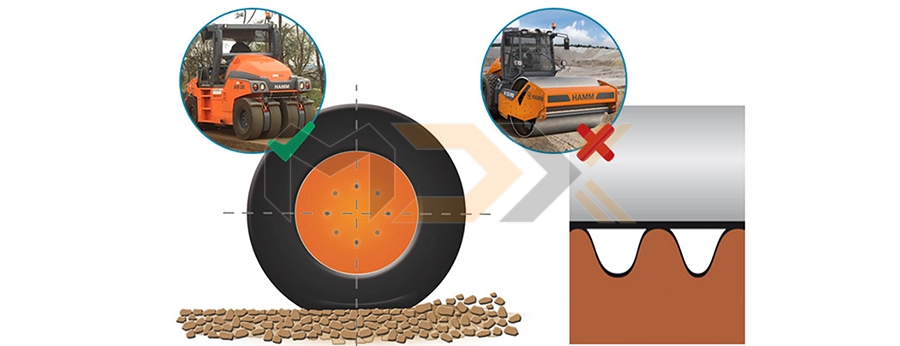

Utilising pneumatic tyre rollers

Pneumatic tyre rollers are perfectly suited for the optimum sealing for cohesive, sandy ground and for re-loosening of inclining ground. Pneumatic tyre rollers can also be utilised for sealing asphalt coverings.

Kneading effect for cohesive, sandy ground and for re-loosening inclined ground

A sealing with rubber wheels is more effective than with drums as the softer tyres are also more suited for adjusting to the surface area texture of the ground. A drum only sits on the surface area and does not adjust itself to the profile.

Frost protection

Compaction for the frost protection layer is an additional utilisation area for compactors in earth work. This is executed with a compactor with smooth drum. Normally compactors with a weight of 5 to 20 t (11,000 to 44,100 lbs) will be utilised. The frost protection layer is a non-cohesive layer formed from rough scalpings. It serves the purpose of protecting the road surface above it against damage caused by the cycle of freezing and thawing.

Vibration compactor

The compactor with vibration crusher drum offers even more additional utilisations in earth work and is mainly utilised in the following cases:

- Loosening materials

- Breaking up rocks with simultaneous compaction

- Compaction of cohesive soils (padfoot inserts)

- The possible utilisation of various chisels and with padfoot inserts make the machine into a variable utilisation device.

APPLICATION TECHNOLOGY IN ASPHALT CONSTRUCTION

WORK STEPS

Which steps are recommended when compacting asphalt construction?

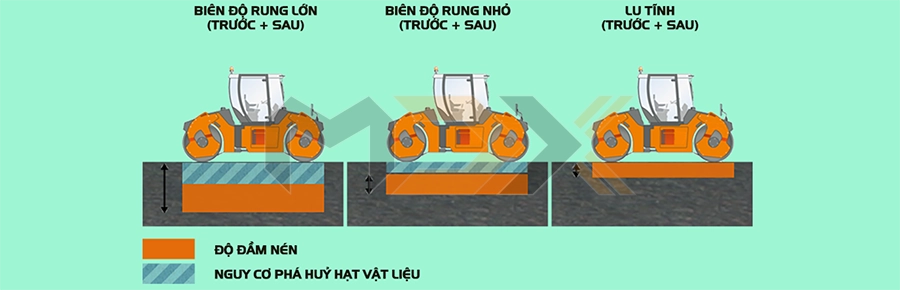

DOUBLE VIBRATION

With double vibration: When compacting thicker layers, first compact with a large amplitude (1), then use a small amplitude (2), and then static (3). When compacting thinner layers, skip step 1.

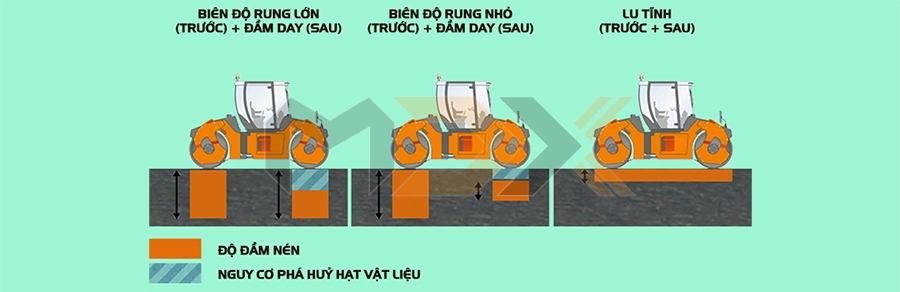

VIBRATION - OSCILLATION

During vibration + oscillation: With bigger layer thicknesses, first compact with a large amplitude and oscillation (1), then subsequently use a small amplitude and oscillation (2), and then static (3). When compacting thinner layers, skip step 1.

Installation details

Certain fundamental things need to be considered when compacting. The creation of a compact and durable structure made of numerous layers requires considerable care, attention and experience. Especially important in this case are:

Compaction

A correct, professional compaction is very important. The objective of the compaction is: Reducing the cavity content in the mixed material, Achieving the required compaction level

Flatness

A differentiation must be made between longitudinal and lateral flatness when considering flatness.

- Lateral flatness: The flatness in lateral directions (in association with lateral sloping) is important for creating sufficient drainage on the street. Interruptions and disruptions in the lateral flatness will, for example, cause rutting and the water can longer run off correctly and can then result in aquaplaning in the area of the ruts.

- Longitudinal flatness: Unevenness in longitudinal directions create vibrations in the vehicle which considerably influence driving comfort, the stresses on roadways, the noise emissions and driving safety.

Interlocking layers

Interlocking layers relate to the displacement-resistant connection between the individual layers and/or positions of the roadway to create a comprehensive package. Interlocking and adhering the individual layers prevents movement between them due to traffic and climatic effects. The importance of layer connectivity has increased considerably in recent years as a result of the consistently increasing traffic loads. A defective layer connectivity can, in conjunction with other unfavourable factors, result in damage or deformation of the asphalt attachment.

Requirements for the connection area:

- Evenness of the surface area

- Comprehensive spraying of binding agent over the whole surface area

- Roughness and porosity

- Free from dust, dirt and contamination

- Dry and free from separating agents

- No defects, imperfections or road surface markings

Joints

A joint relates to the contact surface for strip laying construction of asphalt mixed materials laid parallel to each other (longitudinal joint) and/or the joints between working sections in the construction direction (lateral joint). An optimum joint formation will be created when utilising an application as "hot on hot." Professional implementation will hereby result in a very good interlocking and reliable adhesion of the strips with each other. If the asphalt mixed material is not installed as "hot on hot" but rather as "hot on cold", then the contact surface area must be prepared similarly to the contact surface area for layer connectivity

Requirements for the joint surface area:

- Where possible as an inclined contact surface area (70 - 80° incline)

- Roughness and porosity

- Free from dust, dirt and contamination

- Dry and free from separating agents

- Coating with sufficient thick binding-agent film (where appropriate with spraying on bonding adhesive or bitumen emulsion)

Connections (joints)

If layers with non-comparable characteristics are created next to each other, then the connections should be created where possible with joints. These can be created either with poured and/or grouted joints or with fusible jointing strips. Seams, splices much be considerably wider implemented as joints as they must take up and compensate for all the temperature-related longitudinal and width alterations. The requirements for seams and splices relate essentially to those for the joints. The difference hereby is that the seams and splices must be created vertically and that they may only be smooth. In addition, they must be applied with a pre-coating.

Connections which should be implemented as a seam or splice:

- Compaction asphalt on poured asphalt or vice-versa

- Asphalt connections on channels, curb stones, concrete slabs, masonry and installations (e.g. drain covers)

- Poured asphalt on poured asphalt

- Small surface areas (excavations)

Edge formation

Edge formation relates to the creation, form-shaping, compaction and sealing of free standing and/or isolated edges for all asphalt layers. The edges must be battered by utilising an edge pressing device (normally with an incline of 2:1) and sealed with sprayed-on hot bitumen. This will therefore ensure the prevention of water, dirt, contamination or root ingression from the side into the lower layers. Contamination of the edges before sealing must be prevented at all times.

TIPS FOR MACHINE PREPARATION

Certain preparations must be made at the start of work and/or at the end of work. This check list should also be considered before meeting with the customer for machine preparation works.

Before starting work and/or starting compaction.

- Pacing up and down the area to be compacted to understand whether there are obstructions existing in the working and traffic areas

- If there is a risk of frost, ensure before starting work that there are no foreign bodies frozen on the drums and wheels

- Control the functionality of the lights, indicators and rotating beacon

- Control the engine oil and hydraulic oil fill-levels

- Inspect the functionality of the water filter and water spraying system

- Always warm up the machine in the idling mode to bring the engine and hydraulic system up to operating temperature

- Inspect the operating pressure on the air system for rubber wheeled rollers

- Inspect the functionality of the tyre heating system for rubber wheeled rollers and combination rollers

- Install the scraper on asphalt rollers

At the end of work or with longer interruptions

- Secure the roller against rolling away when parked

- Remove the battery isolation switch at the end of work

- Completely drain the water tanks and water spraying system with frost hazards and position the machine on wooden beams

- Remove the scraper from the asphalt roller at the end of work

FUNDAMENTAL RULES FOR COMPACTING ASPHALT

Certain fundamental rules must be adhered to when compacting asphalt. The preparation and execution of the roller compaction must always be considered in conjunction with the type of mixed material to be utilised, the local installation conditions and the weather conditions.

The number of required compactors will be dependent on the following factors:

Installation width and installation speed

Required number of passings

The number of required passes will be dependent on the following factors:

- Type and weight of the compactor

- Roller speed

- Installation thickness

- Mixed material temperature / weather conditions

- Compaction capability of the mixed material

- Pre-compacting by the finisher

- Resistance and durability of the sub-base

Comprehensive numerical data about the number of passes is not possible without knowledge of these parameters.

Roller speed

Typical roller speeds for all asphalts lie between 3 and 6 km/h (1,9 - 3,7 mph). Higher speeds will create a risk of wave formation when vibration is utilised ("washboard effect").

Too low speeds will create a risk of ...

- Wave formation with steering movements.

- Ridge formation when compacting with vibration.

- Grain destruction.

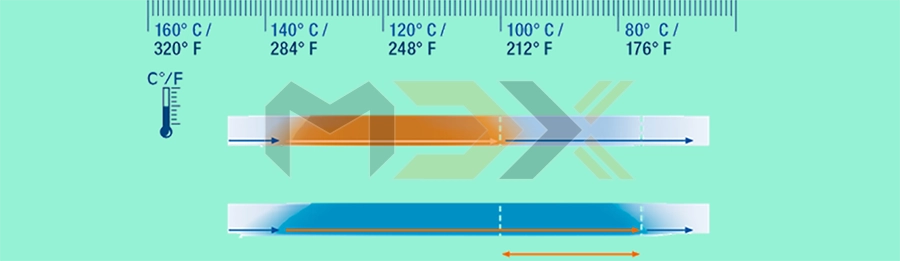

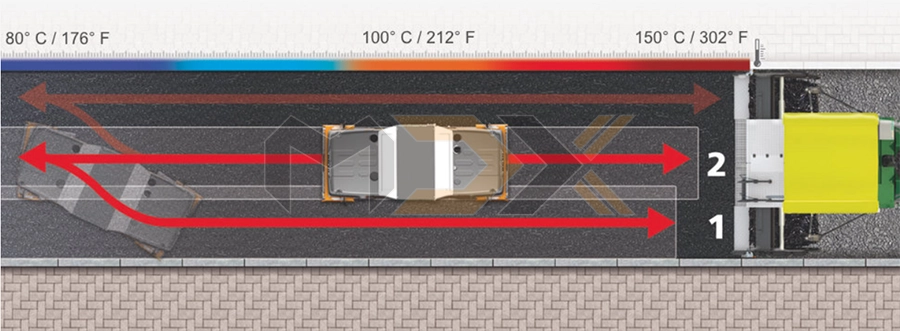

Available compaction time

Compaction temperature

The ideal temperature range for commencing compaction for hot asphalt is around 140°C (284 °F). At this temperature most asphalts can be compacted with vibration and oscillation. A dynamic compaction should only be executed with great care at higher temperatures to prevent material displacement or mixing together (e.g. drawing up the bitumen content). In certain conditions (e.g. with an asphalt with less resistance and durability), the temperature should be above 140 °C (284 °F) or even only statically compacted. With temperatures from 100 °C to around 70 °C (212 - 158 °F), the compaction should only be executed with oscillation or statically to prevent grain destructio

Compactor weight

Compactors with an application weight between 1.5 and 14 tons (3,300 - 30,900 lbs) will be utilised for asphalt construction. These compactors can be classified roughly according to their weight as:

- Light compactors 1.5 – 4.5 t (3,300 - 9,900 lbs)

- Medium compactors 7 – 11 t (15,400 - 24,300 lbs)

- Heavy compactors 11 – 14 t (24,300 - 30,900 lbs)

Peculiarities when utilising vibration compactors:

- Switch off the vibration before reversing (changing from forwards to reverse driving).

- If there is slight compaction by the finisher, then compact the first pass statically (to prevent material displacement) or utilise a pneumatic tyre roller

- Select the amplitude and frequency according to the type of asphalt and installation thickness

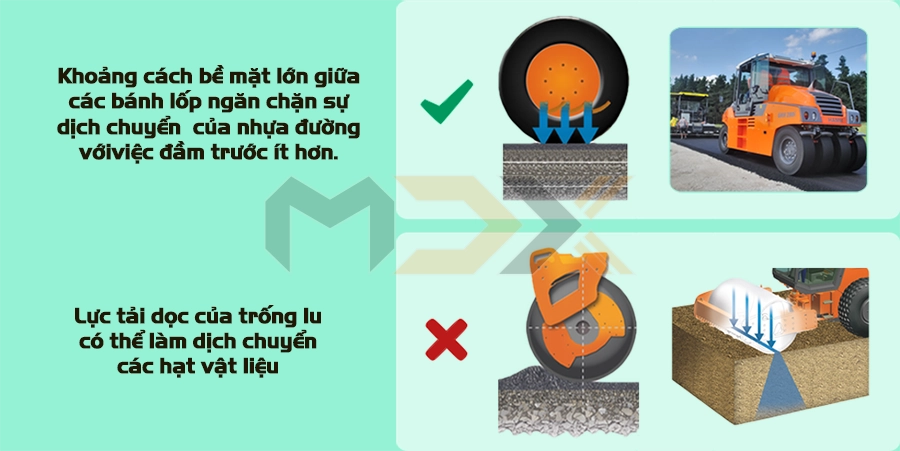

Side note for pneumatic tyre rollers:

Comparison pneumatic tyre rollers against drums

Pneumatic tyre rollers should not be utilised for compacting directly behind the finisher for top layers as the imprints from the wheels cannot be flattened out any more. This will result in a bad cosmetic surface finish for the top layers.

SUMMARY

- Compact top layers with lower amplitude and higher frequencies

- Thick layers as of 8 cm (3.1 ") should first be compacted with higher amplitude and then with lower amplitude

- Only compact inclines with vibration when climbing, statically when travelling down inclines

- Always position the wheels towards the downslope when climbing and utilising combi rollers to have the best possible traction

- Only compact statically or with oscillation with asphalt temperatures under 100 °C (212 °F) as there will be a risk of grain damage or disruption in the grain structure (tear formation) as well as a disruption in the layer connectivity

Lateral tears are created in asphalt

- When the compactor pushes a "bow wave" in front of itself. This happens with reduced compaction from the finisher and too early utilisation of heavy compactors.

- When the roller compaction is executed too long when installing thicker layers or when the asphalt surface cools down too strongly or too quickly due to the wind or too much sprinkling water. In such cases the surface has cooled down but the core zones are still hot. The roller will destroy this "cover" and tears will occur.

Results:

- Tears in the top layer will be precarious. If they are not closed, then water and contamination can ingress into the tears.

- Rubber wheels and combi rollers can close these tears very effectively for sufficiently hot asphalt with the kneading and rolling effect from the wheels.

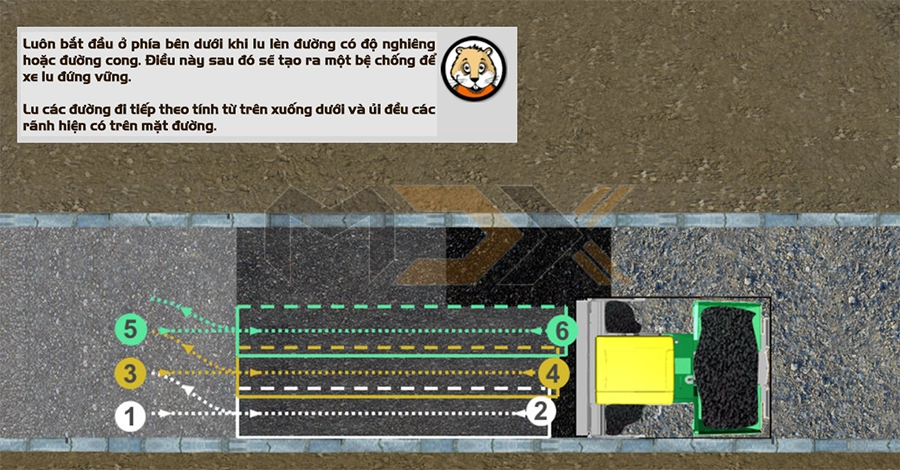

Longitudinal tears are created in asphalt

- By shearing in the mixed material when utilising heavy compactors. In such cases the surface has cooled down but the core zones are still hot. The roller will destroy this "cover" and tears will occur.

- This effect occurs especially when the compaction is commenced on the higher positioned edge for surface areas with a lateral incline. An abutment cannot be formed on which the roller can "support" itself.

- By defects in the sub-base

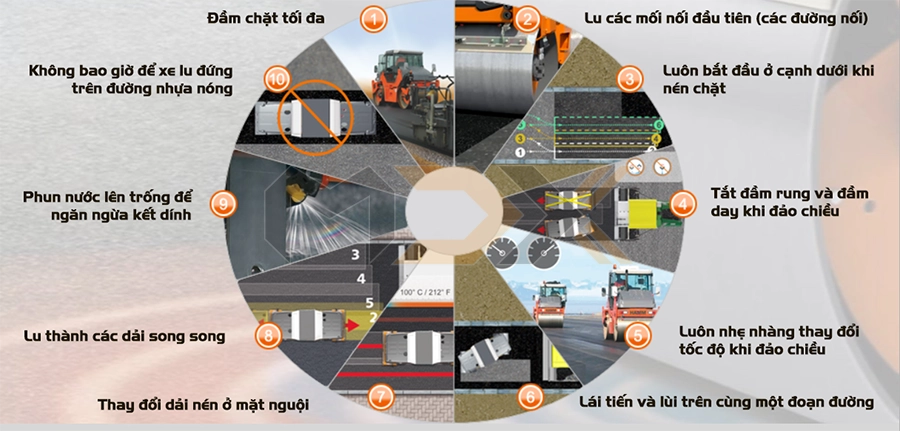

RULES FOR ROLLING WHEN COMPACTING ASPHALT

1. Compact as close as possible to the finisher

For an optimum compaction and best possible utilisation of the temperature time frame available, the compaction should be commenced as early as possible. To prevent displacement of the material, the compaction must also not be commenced too early.

- Asphalt temperatures

The distance from the finisher depends on the asphalt temperature. Typical features of too early roller utilisation:

- Bulging next to the drum

- Lateral tears behind the drum

- Adhering of the asphalt on the drum despite sprinkling

- Considerable displacement in front of the drum

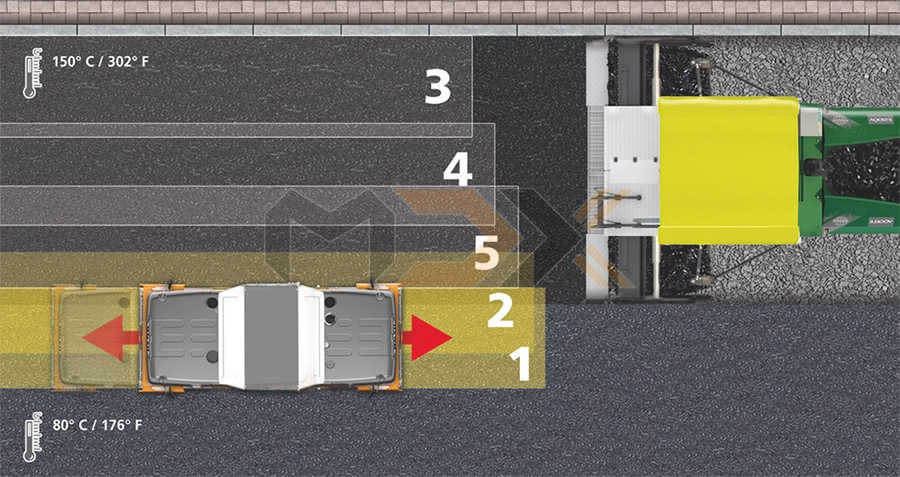

Asphalt temperatures of about 140 °C (284 °F) have proved to be the most favourable in many cases. Depending on the asphalt mixed material, the temperature for commencing rolling can still differ. The compaction should normally be finalised at temperatures between 80 °C and 100 °C (176 - 212 °F).

2. Requirement: Firstly compact the joints (connections)

Lateral joint

- Commence the compaction of the lateral joint from the cold side with around 10 - 20 cm (3.9 - 7.9 ") overlap on the hot asphalt.

- Do not drive longitudinally or at an angle over the lateral joint (only as an exception in very tight site conditions) as this will result in a wave formation which is almost impossible to flatten out again.

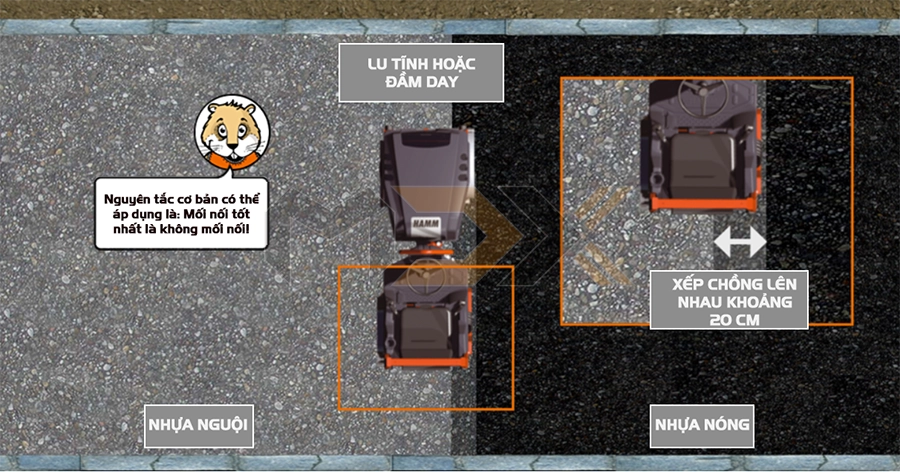

Longitudinal joint with installation "hot on cold“

- Commence the compaction of the longitudinal joint from the cold side with 10 - 20 cm (3.9 - 7.9 ") overlap on the hot asphalt. Only compact with static or oscillation to prevent damage to the cold asphalt.

- One commences the compaction for the remaining surface area on the side associated with the joint.

Longitudinal joint with installation "hot on hot“

- Leave the middle joint (approx. 15 cm / 5,9 ") and compact it at the end.

3. Requirement: Always commence at the lower edge when compacting

Always commence at the lower side when compacting roads with a lateral incline or curves. This will then create an abutment for the roller to support itself on. Compact the subsequent passes statically from the top to the bottom and iron out any possible existing tracks in the asphalt evenly.

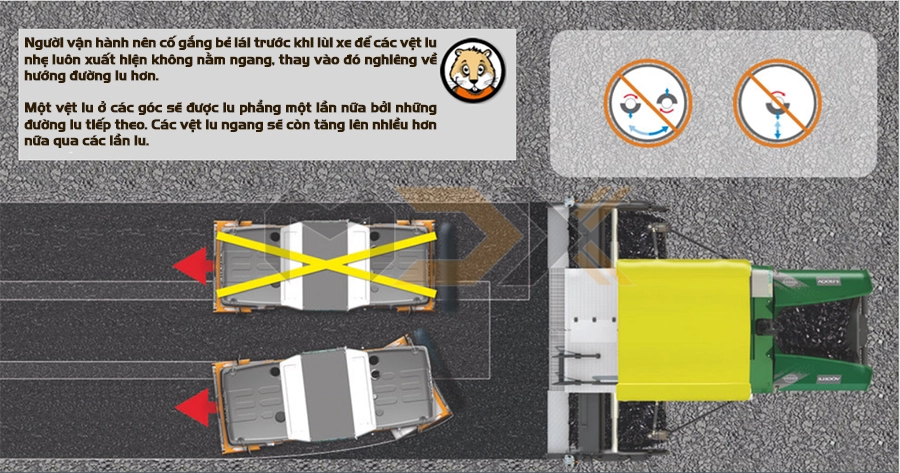

4. Requirement: Switch of the vibration / oscillation before reversing

One should try to steer before reversing so that the light imprints which always occur are not lateral, rather more so angled in the direction to the roller track. An angled imprint will be ironed out again by the subsequent passes. An imprint lateral to the roller track will be increased even more by the subsequent passes.

What still has to be considered?

Vibration / oscillation should be initially switched on after start-up, switched off respectively just before reversing and then switched on again afterwards. If vibrated / oscillated when at standstill, then waves will form in the asphalt which are also very difficult to iron out again with subsequent roller passes. The automatic mode is very comfortable for the driver here as the vibration / oscillation are automatically switched off and on again as soon as a certain speed has been not achieved or exceeded.

5. Requirement: Always alter the roller speed gently

In principal, one should always accelerate and brake gently to prevent waves in asphalt – this especially applies for reversing. These waves are also very difficult to iron out again with subsequent roller passes. Asphalt rollers with Hammtronic support the driver with gentle alterations to the speed (Soft Ramping).

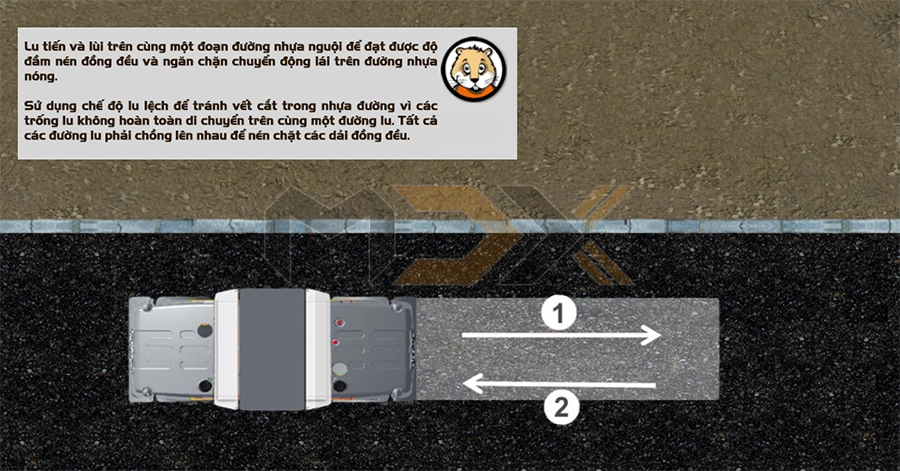

6. Requirement: Drive in the same track forwards and backwards

Drive forwards to the finisher and reverse back into the cold asphalt in the same track in order to achieve a uniform compaction and to prevent steering movements on the hot asphalt. Utilise track offset to prevent shearing in the asphalt as the drums do not then completely move in the same track. All roller tracks must overlap laterally so that no un-compacted strips remain.

Machine with driving in track offset

7. Requirement: Implement the changeover for the roller strip on the cold side

Only implement steering movements for a changeover for the roller strip where the asphalt is already cold so that pressing in is prevented.

8. Requirement: Roll off in parallel strips

Roll the asphalt surface in parallel strips to ensure the best possible, uniform compaction. Do not implement reversing of the roller in the different strips directly after another but always implement the next reversing process as offset by a couple of metres in the length. Waves will therefore be prevented by the reversing.

9. Requirement: Sprinkle the drums sufficiently to prevent adhering

The smooth rollers are sprinkled with water from fine nozzles to prevent hot asphalt from adhering on the smooth rollers. Hamm provides an applicable asphalt separating agent "Wirtgen Group Asphalt AntiStick“ for rubber wheeled and combination rollers. The advantage with this separating agent is that the wheels do not adhere so much and will not be permanently damaged.

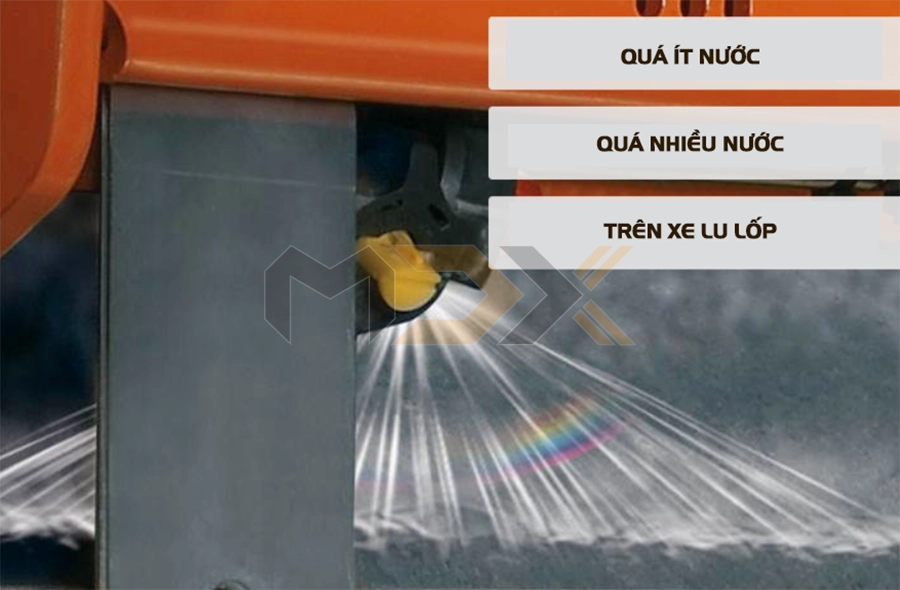

With too little water

- The asphalt stays adhered to the drum and must be scraped off. Compaction work cannot be executed during this time.

- Tracks occur on the top layer due to adhered asphalt on the drum and these cannot be repaired later on.

With too much water

- Too much water on the drum will cool out the asphalt rapidly. This will therefore reduce the time remaining for the compaction works.

- In addition, the upper surface of the asphalts can become porous in certain cases and therefore more susceptible to wear.

With rubber wheeled rollers

Only sprinkle the wheels with a special additive at the commencement of the compaction works. When they are warmed up by the asphalt, this should not normally adhere any more on the wheels

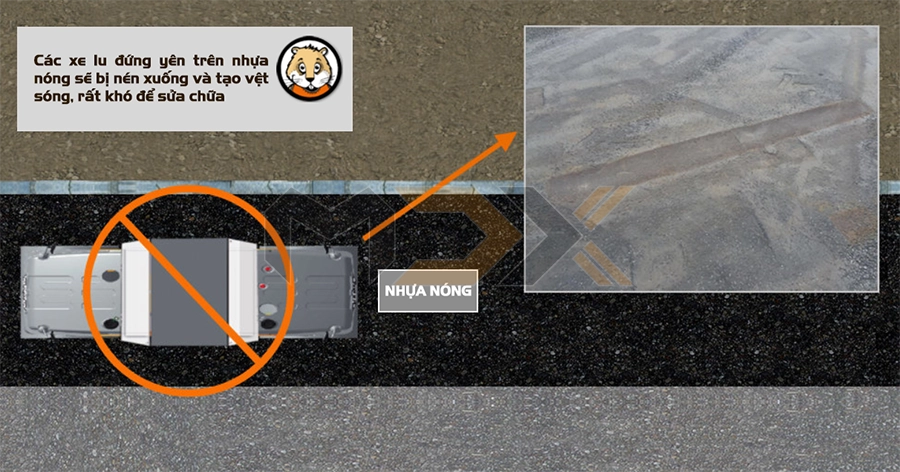

10. Requirement: Never leave the rollers standing on hot asphalt

If the rollers are left standing on hot asphalt, then this will quickly result in pressing in or waves. These cannot be normally rolled out of the asphalt any more.

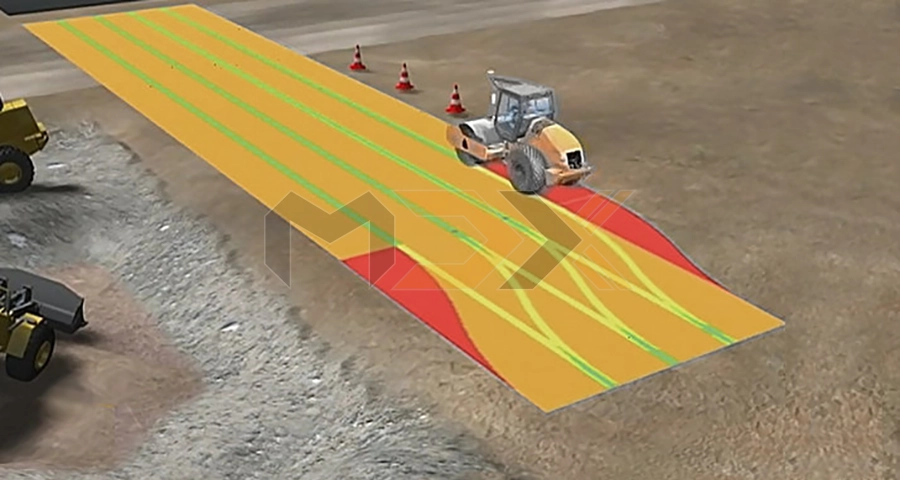

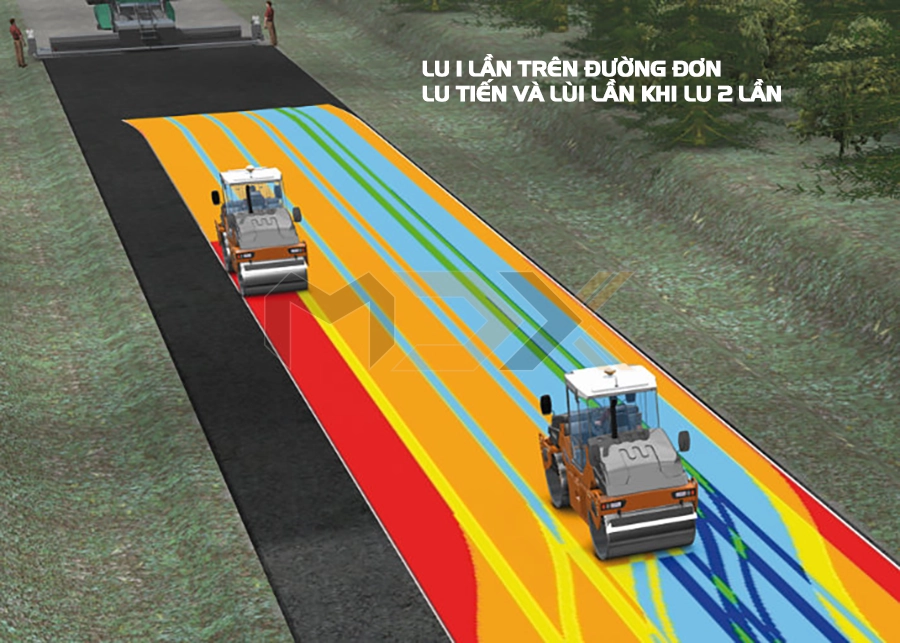

DEFINITION OF A PASS

Definition of a pass

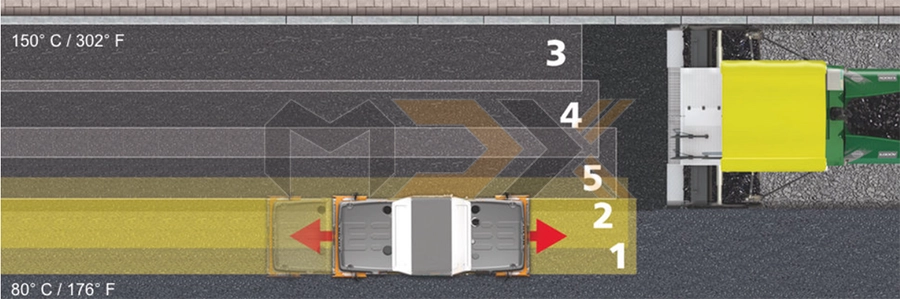

Roller schematic: Installation variants

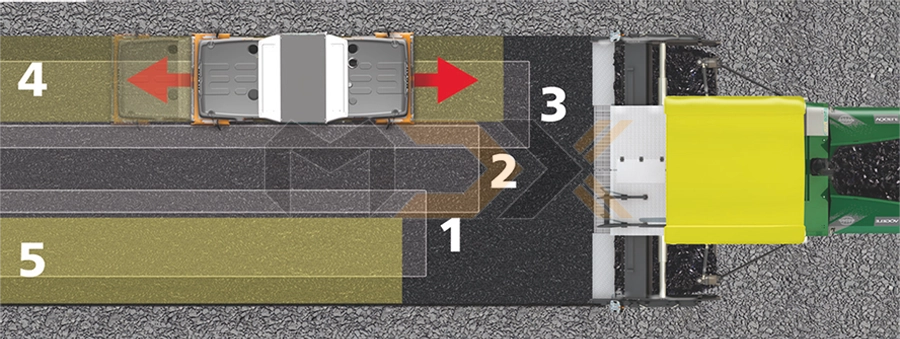

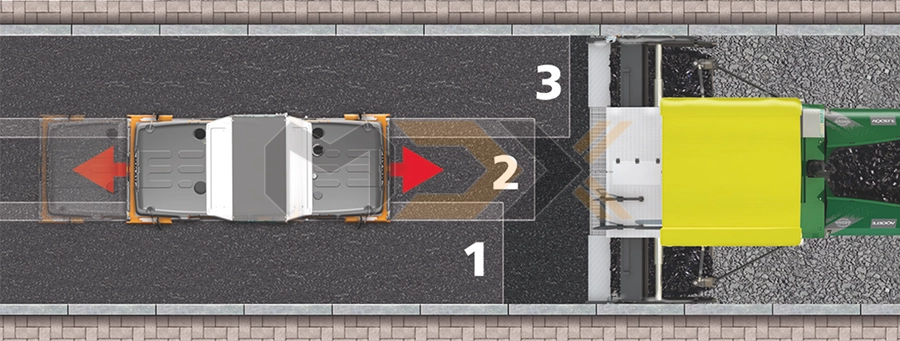

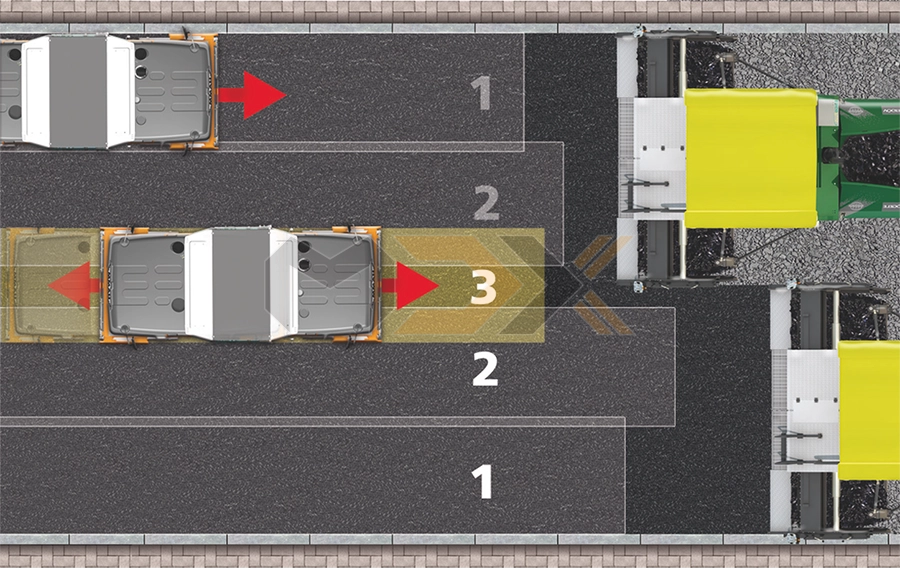

The numbering of the strips respectively indicates the chronological order in which these will be rolled.

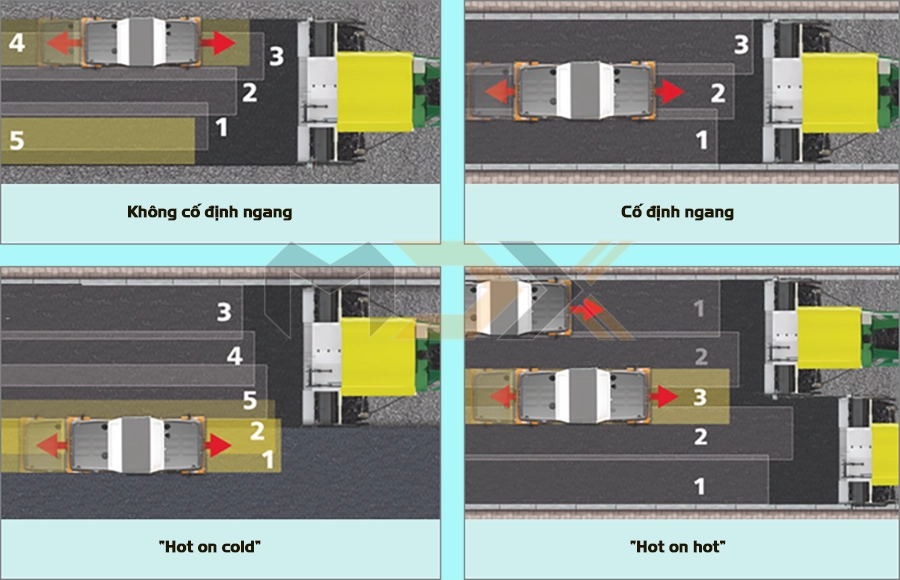

Installation without lateral fixation

The first roller track (1) will be commenced with a distance of 20 cm (7,9 ") from the side. If one commences directly on the side, it could occur that the roller will sink towards the outside and result in pressing-in in the asphalt. With the next tracks (2+3), the remaining surface will be compacted until there is only still a small strip remaining on the other side. Lastly, the two small strips on the right and left sides will be compacted (4+5).

With lateral fixation

The first roller track (1) can be directly commenced on the side as a sinking of the roller to the side is not possible in the direction of the curb. With the next tracks (2+3), the complete remaining surface will be compacted up to the opposite side.

"Hot on cold“

Assumption: Lateral fixation on the open side

With the first and second track (1+2), the joint will be compacted starting from the cold side first with an overlap of 10-20 cm (3,9 - 7,9 ") and then with an overlap of a half a drum width. Subsequently one can commence on the other side directly on the lateral fixation (3) and will work up to the joint (4+5).

"Hot on hot“

Assumption: Lateral fixation on the open side

Both rollers commence directly on the sides (1) and subsequently compact the next strip (2) so that a strip of around 15 cm (5,9 ") wide remains on the right and left of the joint free. One of the two rollers then subsequently compacts the remaining joint (3).

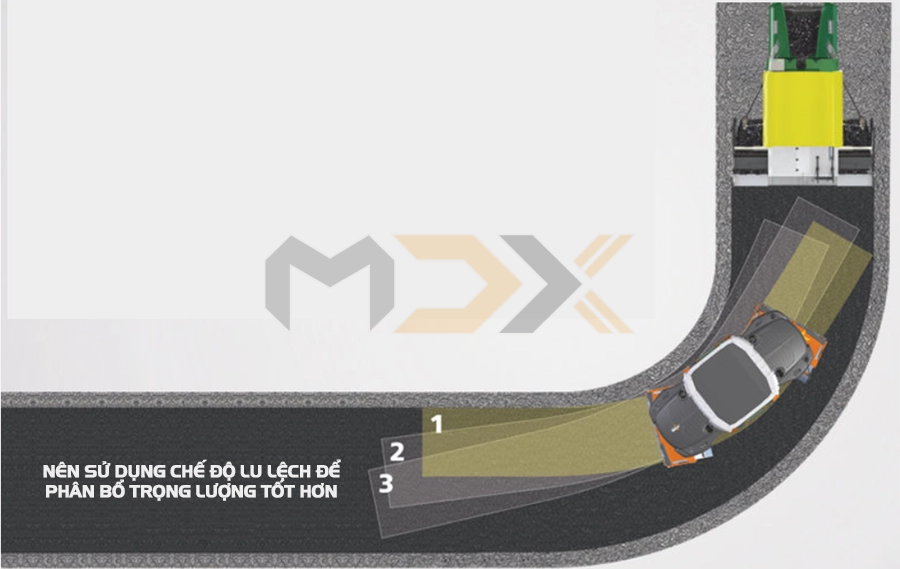

Roller schematic: Compaction in curves

Track offset - It is recommended that track offset is utilised for working to achieve a better weight distribution.

Both rollers commence on the internal side (1) and then subsequently compact towards the outside (2+3). The complete curved radius should never be compacted in one operation but rather as a sectional compaction operation. Very long curve trips will quickly result in pressing-in of the material. Shorter sections for curve trips are better which transfer into straight on trips. Care must be taken to ensure that material displacement et alia is prevented on the internal side. Moreover, edges (internal and external sides) should not be passed over.

Joints / Connections: Compact the joint laterally to the roadway

News Related

Tags: earth work, asphalt construction