|

| Operator Comfort

The crane cab provides improved livability and a more comfortable working environment.

Under-Slung Jib

A two-stage, under slung jib makes installation in narrow spaces possible

|

|

|

|

Substantial safety devices allow excellent operability.

Unobstructed view when driving

Down-slanted boom improves front and side views. A front view monitor and camera also improve driver visibility

|

| SUSPENSION |

|

Front: Semi-elliptic leaf springs with hydraulic lockout device.

Rear: Semi-elliptic leaf springs with hydraulic lockout device.

|

| STEERING |

|

Hydraulic power steering controlled by steering wheel. 4 steering modes available: 2 wheel front, 2 wheel rear, 4 wheel coordinated and 4 wheel crab

|

|

| Automatic moment limiter [AML-C] |

| Tadano's AML-C is easy to use, innovative in design, displays important information to the operator and enables the operator to preset a custom working environment. For example, the AML-C shows the boom angle, boom length, load radius, operating pressure of the elevating cylinder, the extension width of the outriggers, slewing position, rated lifting capacity and present hook load. These features allow the AML-C to move seamlessly through all lifting operations without having to change configurations or input new codes to make the lift. The AML-C safety features provide both audible and visual warnings. When an operation approaches the load limit Tadano's slow stop function engages to avoid shock loads |

| ENGINE |

|

Mitsubishi 4M50-TLC1B 4M50-TLE3A, Direct injection diesel, 4 cylinder, 4 cycle, turbo charged and after cooled

Displacement, liters: 4.90 lít

Bore x Stroke, mm: 114 mm x 120 mm

Output, Max. kW (HP): Gross 129 (172) at 2,700 min-1

Torque, Max. N•m 529 at 1,600 min-1

|

| TRANSMISSION |

|

Electronically controlled full automatic transmission. Torque converter driving full power shift with driving axle selector. 6 forward and 2 reverse speeds, constant mesh.

3 speeds - high range - 2-wheel drive; 4-wheel drive

3 speeds - low range - 4-wheel drive

|

|

|

HOOK BLOCK STORAGE

Hook block stowing system enhances work efficiency

|

|

New Headlight Design, halogen headlights is equipped

OPTIONAL EQUIPMENT

- Discharge head lamp

- Power stowing mirror

- Centralized lubricating system (Carrier portion)

|

|

|

A compact and highly maneuverable design enables operators to complete jobs more efficiently compared to other bulkier alternative models.

- Easy approach to tight or busy job sites

- Quick Setup

- Asymmetrical outriggers offer maximum work value

- Reduced transportation costs

|

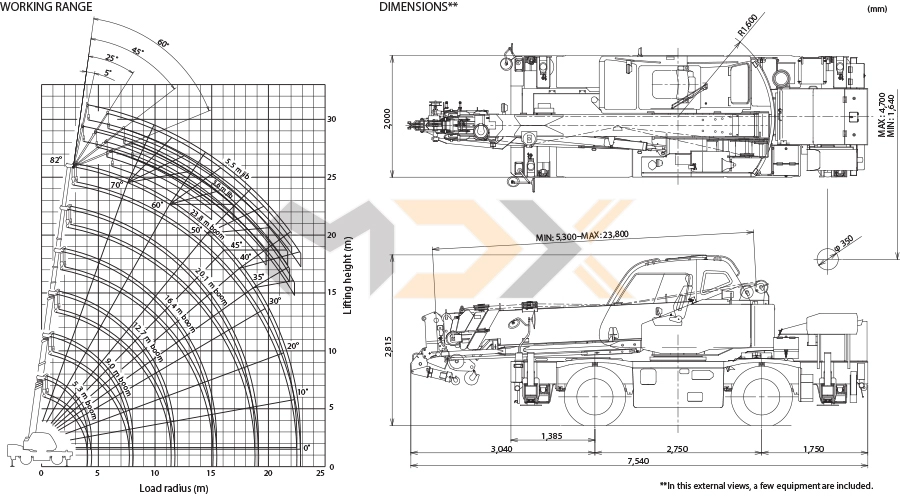

| BOOM |

| 6 section full power partially synchronized telescoping boom of rectangular box construction with 4 sheaves at boom head. The synchronization system consists of 2 telescope cylinders, extension cables and retraction cables. Hydraulic cylinder fitted with holding valve. An easily removable wire rope guard, rope dead end provided on the left side of boom head. Boom telescope sections are supported by wear pads both vertically and horizontally.

Fully retracted length....... 5.3 m

Fully extended length ...... 23.8 m

Extension speed.............. 18.5 m in 52 s

Root diameter.................. 0.225 m

|

| JIB |

|

2 stage boom under slung type with quadruple offset (tilt type). Single sheave at jib head. Box type top section telescopes from box type base section which stows under base boom section.

Length ............................. 3.6 m , 5.5 m

Offset............................... 5˚, 25˚, 45˚, 60º

Root diameter.................. 0.192 m

|

| MAIN WINCH |

| Variable speed type with grooved drum driven by hydraulic axial piston motor through speed reducer. Power load lowering and raising. Equipped with automatic brake (neutral brake) and counterbalance valve. Controlled independently of auxiliary winch. Equipped with cable follower and drum rotation indicator |

| AUXILIARY WINCH |

| Variable speed type with grooved drum driven by hydraulic axial piston motor through speed reducer. Power load lowering and raising. Equipped with automatic brake (neutral brake) and counterbalance valve. Controlled independently of main winch. Equipped with cable follower and drum rotation indicator. |

| SLEWING |

|

Hydraulic axial piston motor driven through planetary slewing speed reducer. Continuous 360˚ full circle slewing on ball bearing.

Equipped with manually locked/released slewing brake.

Slewing speed................. 2.4 min-1 {rpm}

|

| HYDRAULIC SYSTEM |

|

PUMPS: 2 variable piston pumps for crane functions. Tandem gear pump for steering, slewing and optional equipment. Powered by carrier engine. Pump disconnect for crane is engaged / disengaged by rotary switch from operator's cab.

CONTROL VALVES: Multiple valves actuated by pilot pressure with integral pressure relief valves.

RESERVOIR: 172 liters capacity. External sight level gauge.

FILTRATION: BETA10=10 return filter, full �ow with bypass protection, located inside of hydraulic reservoir. Accessible for easy replacement.

OIL COOLER - Air cooled fan type.

|

|

|

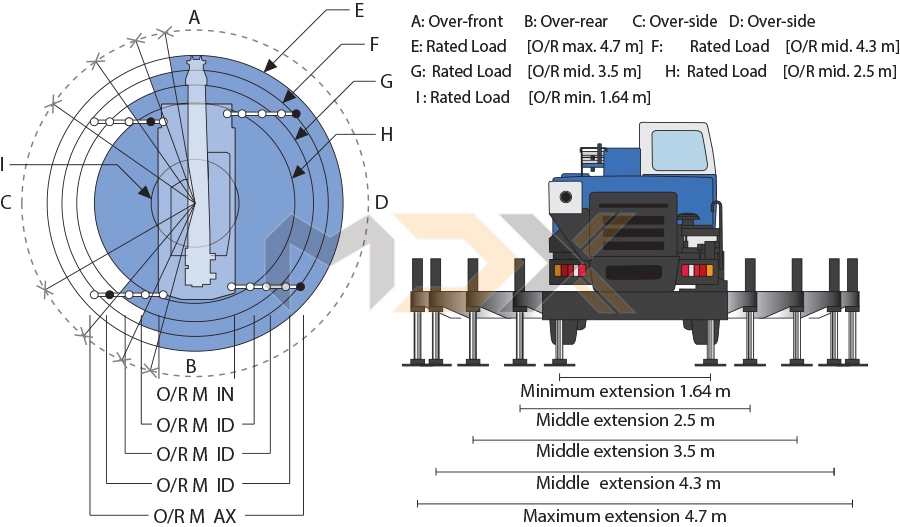

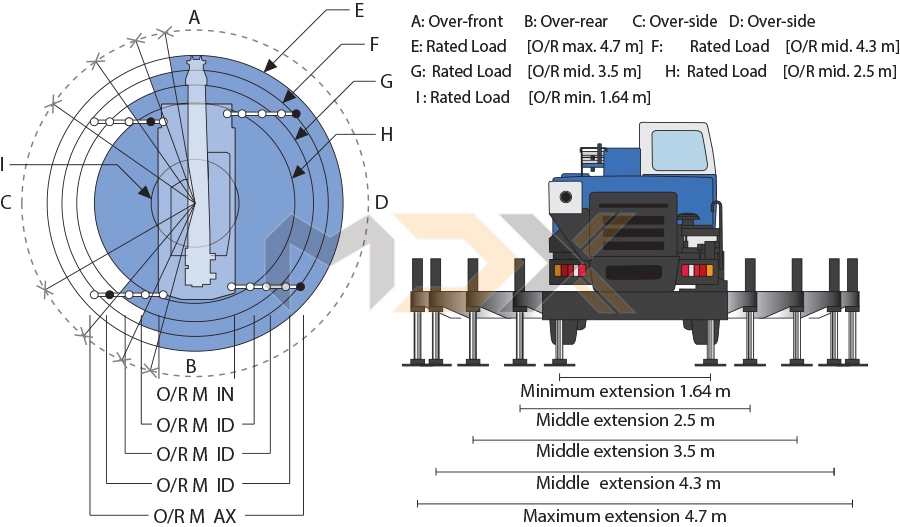

Outrigger Asymmetric Extension Width Control

When operating the crane with the asymmetric outriggers extended, the AML-C detects the extension width of all of the crane's outriggers (front, rear, left and right) to measure maximum work capacity in each area. When slewing the boom from the longer outrigger area to the shorter outrigger area, the AML-C detects the motion and displays the maximum capacity according to the extension width of each of the outriggers, and brings the motion to a slow stop before it reaches the maximum capacity. The AML-C's slow stop function will help to minimize any safety risks even in the cases of operator error.

|

| OUTRIGGERS |

|

4 hydraulic, beam and jack outriggers. Vertical jack cylinders equipped with integral holding valve. Each outrigger beam and jack is controlled independently from cab. Beams extend to 4.7 m center-line and retract to within 1.64 m overall width with floats. Outrigger jack floats are attached thus eliminating the need of manually attaching and detaching them. Controls and sight bubble located in superstructure cab. 4 outrigger extension lengths are provided with corresponding "RATED LIFTING CAPACITIES" for crane duty in confined areas.

Min. Extension 1.64 m center to center

Mid. Extension 2.5 m center to center

Mid. Extension 3.5 m center to center

Mid. Extension 4.3 m center to center

Max. Extension 4.7 m center to center

Float size (Diameter) 0.35 m

|

|

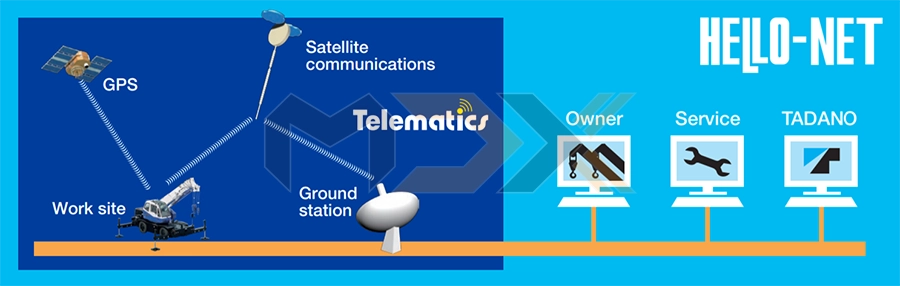

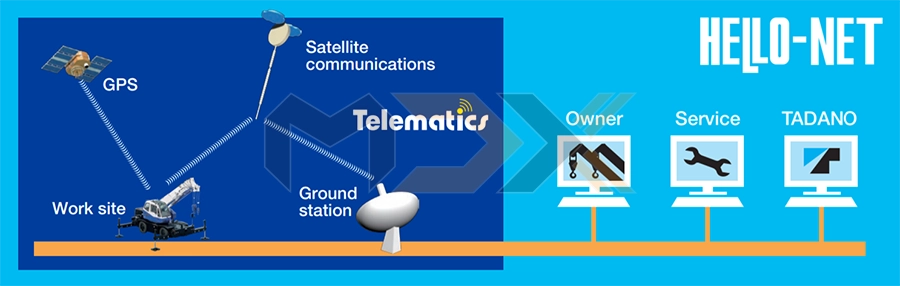

| HELLO - NET |

|

| The HELLO-NET System is used to monitor crane activity straight from your computer or mobile device. You have the ability to view work history, machine position data and maintenance information. HELLO-NET provides advanced customer support between the owners' site and TADANO Group. |

TYPE

|

| Rear engine, right-hand drive, driving axle 2-way selected type by manual switch, 4x2 front drive, 4x4 front and rear drive. |

| Capacity, liters |

| 189 L |