Hitachi ZX70 has evolved with a number of improvements including engine torque, durability and maintainability to earn more production and profits. It is rugged and sturdy for operation under tough environment, reducing downtime. Maintenance is also simplified to increase uptime. The new ZX70 empowers your visions and dreams, shaping your future.

Key Benefits for Low Running Costs: High Quality, Low Fuel Consumption, High Durability.

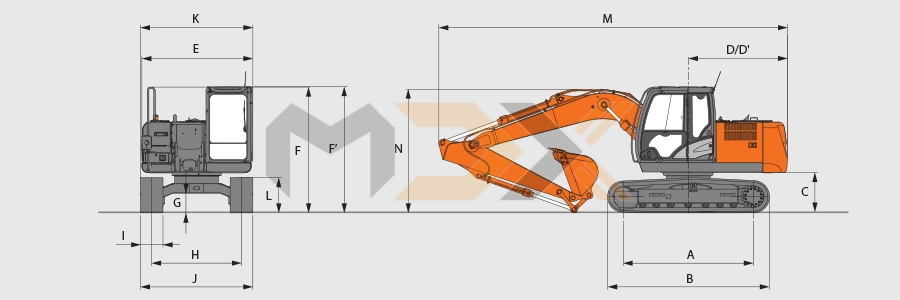

| DIMENSIONS | |||

|

|||

| Arm 1.62 m | Arm 2.12 m | ||

| A Distance between tumblers | mm | 2 140 | |

| B Undercarriage length | mm | 2 765 | |

| C Counterweight clearance (*) | mm | 760 | |

| D Rear-end swing radius | mm | 1 750 | |

| D’ Rear-end length | mm | 1 750 | |

| E Overall width of upperstructure | mm | 2 260 | |

| F Overall height of cab | mm | 2 600 | |

| G Min. ground clearance | mm | 360 | |

| H Track gauge | mm | 1 750 | |

| I Track shoe width | mm | G 450 | |

| JUndercarriage width | mm | 2 200 | |

| K Overall width | mm | 2 260 | |

| L Track height with triple grouser shoes (*) | mm | 655 | |

| M Overall length | mm | 6 080 | 6 120 |

| N Overall height of boom | mm | 2 550 | 2 880 |

| * Excluding track shoe lug - G: Triple grouser shoe | |||

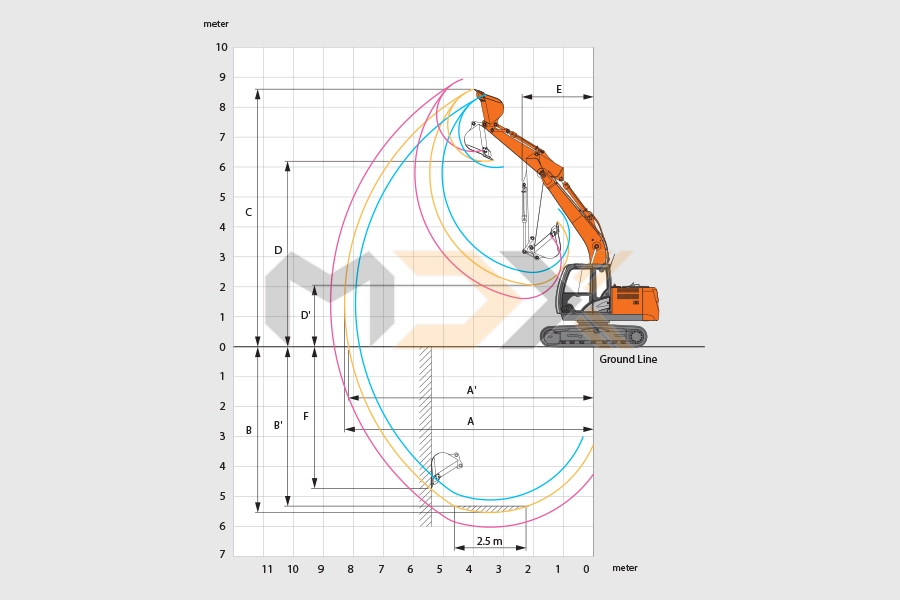

| WORKING RANGES | |||

|

|||

| Arm length | m | 1.62 m | 2.12 m |

| A Max. digging reach | mm | 6 320 | 6 810 |

| A’ Max. digging reach (on ground) | mm | 6 170 | 6 670 |

| *B Max. digging depth | mm | 4 170 | 4 670 |

| *B’ Max. digging depth for 2.5 m level | mm | 3 800 | 4 370 |

| *C Max. cutting height | mm | 7 150 | 7 550 |

| *D Max. dumping height | mm | 5 060 | 5 450 |

| *D’ Min. dumping height | mm | 2 340 | 1 920 |

| E Min. swing radius | mm | 1 720 | 2 080 |

| F Max. vertical wall digging depth | mm | 3 730 | 4 280 |

| *Excluding track shoe lug | |||

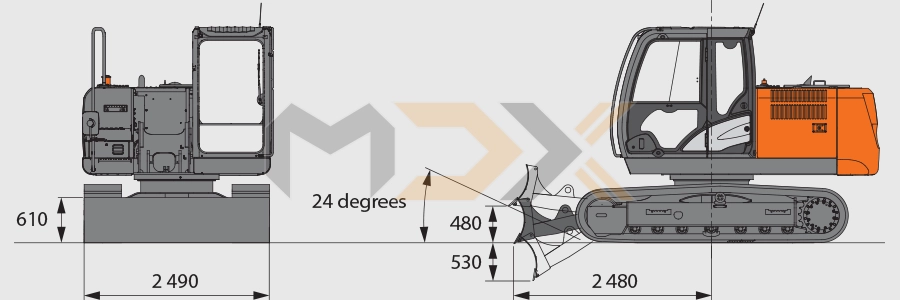

| BLADE (Optional) | ||

|

||

| A Overall width of blade | mm | 2 320 |

| B Overall height of blade | mm | 435 |

| C Blade distance | mm | 1 910 |

| *D Max. rasing height above ground | mm | 400 |

| *E Max. lowering depth from ground | mm | 280 |

| *Excluding track shoe lug | ||

| SPECIFICATIONS | ||

| ENGINE | ||

| Model | Yanmar 4TNV98-AVHBW (CHN Stage ) | |

| Type | 4-cycle water-cooled, direct injection | |

| No. of cylinders | 4 | |

| Rated power | ||

| ISO 9249, net | kW | 42.4 kW (56.9 HP) at 2 100 min-1 (rpm) |

| SAE J1349, net | kW | 42.4 kW (56.9 HP) at 2 100 min-1 (rpm) |

| Maximum torque | Nm | 236 Nm (24.1 kgfm) at 1 350 min-1 (rpm) |

| Piston displacement | L | 3.318 |

| Bore and stroke | mm | 98 x 110 |

| Batteries | 2 x 12 V / 52 Ah | |

| HYDRAULIC SYSTEM | ||

| Hydraulic Pumps | ||

| Main pumps | 3 variable displacement axial piston pumps | |

| Maximum oil flow | L/min | 2 x 63 |

| L/min | 1 x 52.5 | |

| Pilot pump | 1 gear pump | |

| Maximum oil flow | L/min | 21 |

| Hydraulic Motors | ||

| Travel | 2 variable displacement axial piston motors | |

| Swing | 1 axial piston motor | |

| Relief Valve Settings | ||

| Implement circuit | MPa (kgf/cm2) | 26.0 (265) |

| Swing circuit | MPa (kgf/cm2) | 22.6 (230) |

| Travel circuit | MPa (kgf/cm2) | 31.4 (325) |

| Pilot circuit | MPa (kgf/cm2) | 3.9 (40) |

| UNDERCARRIAGE | ||

| Tracks | Heat-treated connecting pins with dirt seals. Hydraulic (grease) track adjusters with shock-absorbing recoil springs. | |

| Numbers of Rollers and Shoes on Each Side | ||

| Upper roller | 1 | |

| Lower rollers | 5 | |

| Track shoes | 38 | |

| Travel Device | Each track driven by 2-speed axial piston motor. Parking brake is spring-set/hydraulic-released disc type | |

| Automatic transmission system | High-Low | |

| Travel speeds | km/h km/h | High : 0 to 5.0 Low : 0 to 3.4 |

| Maximum traction force | kN (kgf) | 47.8 (4 870) |

| Gradeability | % (degree) | 70 (35) |

| SERVICE REFILL CAPACITIES | ||

| Fuel tank | L | 135.0 |

| Engine coolant | L | 8.0 |

| Engine oil | L | 11.6 |

| Travel device (each side) | L | 2.5 |

| Hydraulic system | L | 100.0 |

| Hydraulic oil tank | L | 60.0 |

| UPPERSTRUCTURE | ||

| Revolving Frame | D-section frame skirt for resistance to deformation | |

| Swing Device | Axial piston motor with planetary reduction gear is bathed in oil. Swing circle is single-row. Swing parking brake is spring-set/hydraulic-released disc type | |

| Swing speed | min-1 (rpm) | 10.7 |

| Swing torque | kNm (kgfm) | 12.9 (1 320) |

| Operator's Cab | Independent spacious cab, 1 005 mm wide by 1 675 mm high, conforming to ISO* Standards. * International Organization for Standardization | |

| HYDRAULIC CYLINDERS | ||||

| Quantity | Bore | Rod diameter | ||

| Boom | mm | 1 | 115 | 65 |

| Arm | mm | 1 | 95 | 60 |

| Bucket | mm | 1 | 85 | 55 |

| Blade (Optional) | mm | 1 | 120 | 70 |

| WEIGHTS AND GROUND PRESSURE | ||||

| Shoe type | Shoe width | Arm | kg | kPa(kgf/cm 2) |

| Triple grouser | 450 mm | 1.62 m | 6 650 | 31 (0.31) |

| 2.12 m | 6 690 | 31 (0.32) | ||

| 600 mm | 1.62 m | 6 810 | 24 (0.24) | |

| 2.12 m | 6 850 | 24 (0.24) | ||

| Pad | 450 mm | 1.62 m | 6 690 | 31 (0.32) |

| 2.12 m | 6 730 | 31 (0.32) | ||

| Triangular | 500 mm | 1.62 m | 6 830 | 28 (0.28) |

| 2.12 m | 6 870 | 29 (0.29) | ||

| 700 mm | 1.62 m | 6 950 | 21 (0.21) | |

| 2.12 m | 6 990 | 21 (0.21) | ||

| Flat | 450 mm | 1.62 m | 6 810 | 31 (0.32) |

| 2.12 m | 6 850 | 32 (0.32) | ||

| *Including bucket 0.28 m3 (ISO heaped) weight (211 kg) and counterweight (800 kg). | ||||

| BUCKET AND ARM DIGGING FORCES | ||

| Arm length | 1.62 m | 2.12 m |

| Bucket digging force ISO | 55.0 kN (5 600 kgf) | 55.0 kN (5 600 kgf) |

| Bucket digging force SAE : PCSA | 47.0 kN (4 800 kgf) | 55.0 kN (5 600 kgf) |

| Arm crowd force ISO | 38.0 kN (3 900 kgf) | 32.0 kN (3 300 kgf) |

| Arm crowd force SAE : PCSA | 36.0 kN (3 700 kgf) | 31.0 kN (3 200 kgf) |

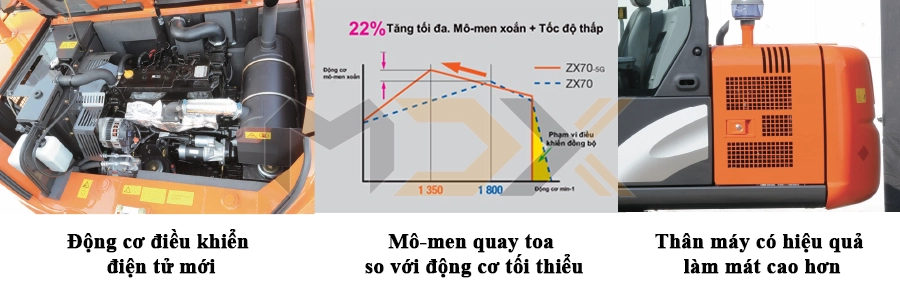

More Production with Less Fuel. Meeting Two Competing Needs |

|

|

|

|

| 7% Down Fuel Consumption*

Hitachi fuel-saving technology is more evolved than ever. The electronically controlled engine can curb fuel consumption behind the electronic governor, clutch fan, and isochronous control, which is one of fuel-saving technologies that can automatically control engine rpm through the electronic governor. This can suppress wasteful engine speed increase when big *Hitachi measurements in P mode under standard digging test conditions 22% Up Engine Torque The new engine is designed to increase its maximum torque to keep running without speed drop at high altitudes with thin air and in hot summer season. At its maximum torque, the speed is kept low to ensure stable performance even under heavy loads. Improved Heat Balance Even at high temperatures in summer or in continuous long hours operation, Hitachi ZX70 can lessen overheating, as cooling efficiency increases: heat balance is up 4% in engine coolant, and up 12% in hydraulic oil, compared to the conventional. Low-Effort Pilot Lever The new fingertip-control pilot lever reduces operator fatigue in long hours operation. This pilot lever resembles the one proven on the ZX200 in the larger class. |

Enhanced Operator Comfort with Refined Controls and Cab Interior |

|

| Comfortable Operating Environment

The cab is improved to enhance operator comfort and controllability. The monitor panel is positioned for easy reading from the operator. Twin analog meters are easy to read operating status. The simple-to-control switch panel is within easy reach. The comfortable vinyl-made operator seat is provided with a headrest and armrests, and is precisely adjustable to operator's build. It can be reclined and slid for pleasant positioning. Monitor panel indicators are shown lit for demonstration. Auto Idle and indicators disable. |

|

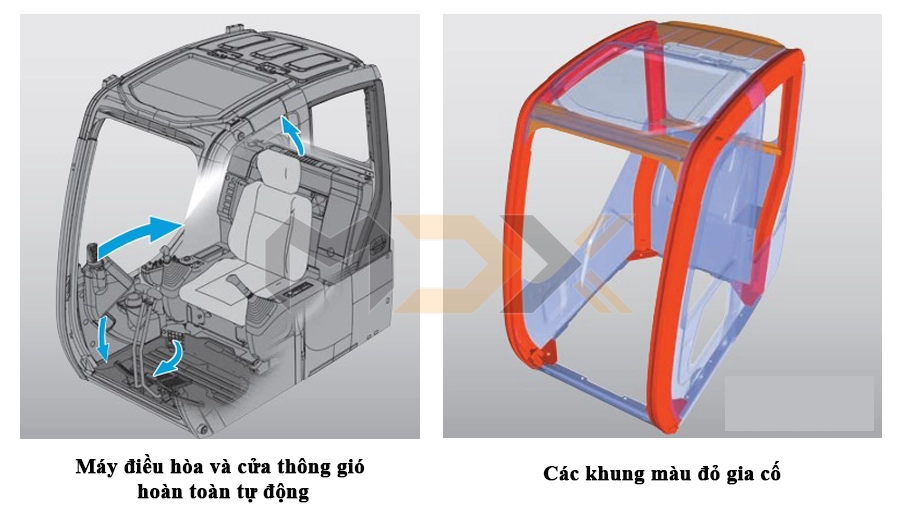

| Full-Auto Air Conditioner (Standard)

The full-auto air conditioner can keep preset in-cab temperatures by blowing fresh air. Air flow and outlets are adjusted automatically. Bi-level air flow makes it possible to warm leg space and cool head space simultaneously. Neutral engine start systemThe pilot control shut-off lever is provided with a neutral engine start system that permits engine starting only when the pilot control shut-off lever is in Lock position. CRES* Cab The CRES cab is reinforced with high-rigidity steel tubes at corners to significantly increase strength and rigidity for higher safety. *CRES: Corner Reinforced Structure |

|

Hitachi Support ChainHitachi Support Chain is a full customer support system offered after buying a Hitachi machine |

|

Parts and ServiceHitachi full customer support is available every area on the globe for full customer satisfaction through Hitachi local dealers. |

|||

|

|||

| Parts

Hitachi Global Online Network, a parts supply system, is linked with Japan Parts Center, overseas depots and over 150 dealers abroad to deliver on-line parts information, including in-stock parts, order receptions, shipments and delivery period of over one million parts and components. Genuine Hitachi Parts Genuine Hitachi parts, meeting Hitachi stringent quality standards, are guaranteed according to Hitachi warranty standards. The use of genuine Hitachi parts, including engine, fuel, hydraulic oil and filters, may slash running costs, and extend machine life. Ground Engaging Tools (GETs) Hitachi provides an array of Hitachi Ground Engaging Tools developed and built for a variety of applications. Using high-quality, well-maintained GETs will help you get customers' trust. Note: Some dealers do not handle Hitachi GETs. Remanufactured Components Hitachi components are remanufactured according to the stringent remanufacturing standards at four factories around the world. They have high quality equivalent to new ones, and backed up by Hitachi warranty system. Note: Some dealers do not handle Hitachi Remanufactured Components. |

|||

| Service

Extended Warranty - HELP Hitachi Standard Warranty System is available on all new Hitachi machines. In addition, Hitachi offers Hitachi Extended Life Programs (HELPs) to suit customer expectations - protecting machines under tough operating conditions, avoiding unexpected downtime, and reducing repair costs. Note: Warranty conditions vary by equipment. Diagnostic Tools - Maintenance Pro Electronic control system needs quick on-site solutions, apart from mechanical repairs. Hitachi’s Maintenance Pro can diagnose machine failures in a short time by plugging a PC into a failed machine. Technical Training On-site servicing matters despite locations to keep the machine at peak performance and reduce downtime. Technical Training Center (TTC), located in Japan, educates and trains service technicians and service support personnel coming from Hitachi dealers and factories on the globe according to the international training programs |

Tags: excavator for sale, excavator hire, excavator Komatsu, excavator hitachi, sany excavator, wheel excavator for sale, bucket wheel excavator, power wheel excavator, largest bucket wheel excavator, bucket wheel excavator price, volvo wheel excavator, bucket wheel excavator for sale, wheeled excavator, wheeled excavator for sale, wheel bucket excavator, wheel type excavator, wheeled excavator volvo, wheeled excavator hitachi