Hitachi Excavator ZX330LC-5G

A ZAXIS hallmark – industry-leading hydraulic technologies, and performance no other can beat. New ZAXIS provides reliable solutions: impressive fuel economy, swift front movements, and easy operation. You'll also find Hitachi technological prowess and expertise, such as the optimized hydraulic system and engine.

New ZAXIS features the key benefits of high quality, low fuel consumption, and high durability, all of which serve to ensure low running costs. New ZAXIS, which is empowered by comprehensive evolution, will realize customers’ visions and dreams, and pioneer your colorful future.

Key Benefits for Low Running Costs: High Quality, Low Fuel Consumption, High Durability.

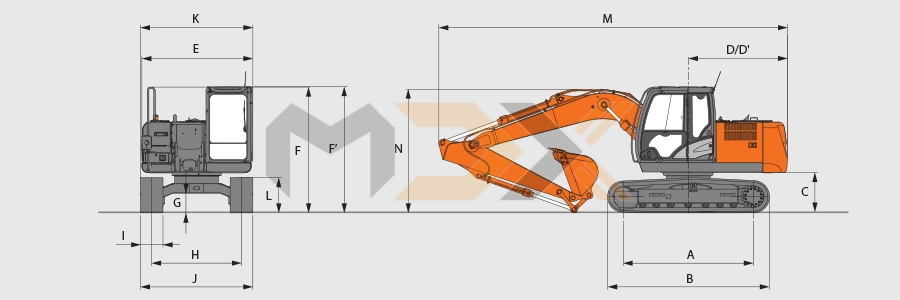

| DIMENSIONS | ||

|

||

| ZX330LC-5G | ||

| A Distance between tumblers | mm | 4 050 |

| B Undercarriage length | mm | 4 940 |

| C Counterweight clearance (*) | mm | 1 160 |

| D Rear-end swing radius | mm | 3 590 |

| D’ Rear-end length | mm | 3 590 |

| E Overall width of upperstructure | mm | 2 990 |

| F Overall height of cab | mm | 3 160 |

| F’ Overall height of upperstructure | mm | 3 270 |

| G Min. ground clearance | mm | 500 |

| H Track gauge | mm | 2 590 |

| I Track shoe width | mm | G 600 |

| JUndercarriage width | mm | 3 190 |

| K Overall width | mm | 3 190 |

| L Track height with triple grouser shoes | mm | 1 060 |

| M Overall length | ||

| With 2.67 m arm | mm | 11 350 |

| With 3.20 m arm | mm | 11 220 |

| With 4.00 m arm | mm | 11 310 |

| N Overall height of boom With 2.91 m arm | ||

| With 2.67 m arm | mm | 3 470 |

| With 3.20 m arm | mm | 3 270 |

| With 4.00 m arm | mm | 3 270 |

| * Excluding track shoe lug G: Triple grouser shoe | ||

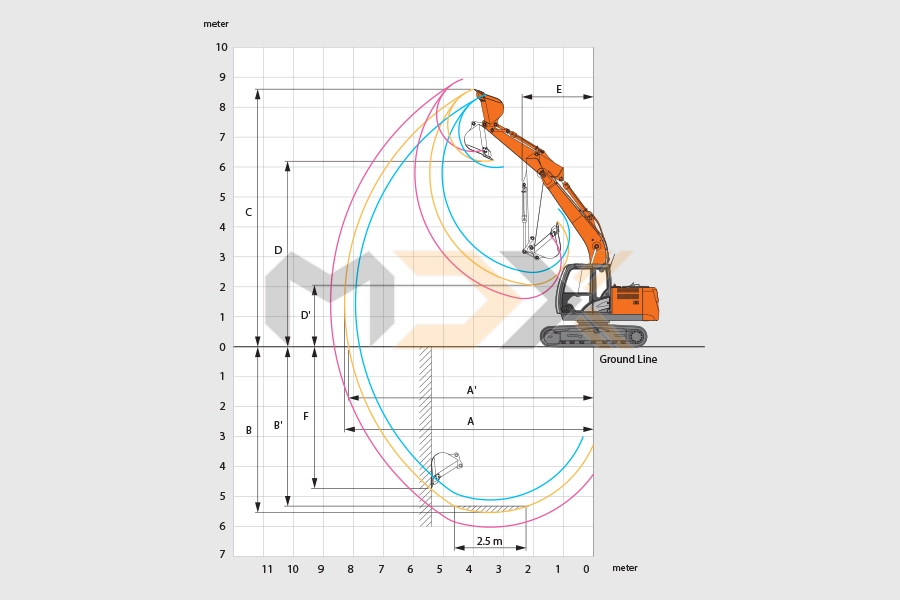

| WORKING RANGES | ||||

|

||||

| Arm length | m | 2.67 m | 3.20 m | 4.00 m |

| A Max. digging reach | mm | 10 570 | 11 100 | 11 860 |

| A’ Max. digging reach (on ground) | mm | 10 360 | 10 890 | 11 670 |

| B Max. digging depth | mm | 6 840 | 7 380 | 8 180 |

| B’ Max. digging depth for 2.5 m level | mm | 6 640 | 7 210 | 8 040 |

| C Max. cutting height | mm | 9 990 | 10 360 | 10 750 |

| D Max. dumping height | mm | 6 940 | 7 240 | 7 630 |

| D’ Min. dumping height | mm | 3 210 | 2 680 | 1 880 |

| E Min. swing radius | mm | 4 610 | 4 460 | 4 470 |

| F Max. vertical wall digging depth | mm | 5 510 | 6 420 | 7 270 |

| Excluding track shoe lug | ||||

| SPECIFICATIONS | ||

| ENGINE | ||

| Model | Isuzu AH-6HK1X | |

| Type | 4-cycle water-cooled, direct injection | |

| Aspiration | Turbocharged, intercooled | |

| No. of cylinders | 6 | |

| Rated power | ||

| ISO 9249, net | kW | 184 kW (246 HP) at 2 000 min-1 (rpm) |

| SAE J1349, net | kW | 184 kW (246 HP) at 2 000 min-1 (rpm) |

| Maximum torque | Nm | 873 Nm (89.0 kgfm) at 1 700 min-1 (rpm) |

| Piston displacement | L | 7.790 |

| Bore and stroke | mm | 115 mm x 125 mm |

| Batteries | 2 x 12 V / 128 Ah | |

| HYDRAULIC SYSTEM | ||

| Hydraulic Pumps | ||

| Main pumps | 2 variable displacement axial piston pumps | |

| Maximum oil flow | L/min | 2 x 279 |

| Pilot pump | 1 gear pump | |

| Maximum oil flow | L/min | 32.8 |

| Hydraulic Motors | ||

| Travel | 2 variable displacement axial piston motors | |

| Swing | 1 axial piston motor | |

| Relief Valve Settings | ||

| Implement circuit | MPa (kgf/cm2) | 34.3 (350) |

| Swing circuit | MPa (kgf/cm2) | 32.4 (330) |

| Travel circuit | MPa (kgf/cm2) | 34.3 (356) |

| Pilot circuit | MPa (kgf/cm2) | 3.9 (40) |

| Power boost | MPa (kgf/cm2) | 38.0 (388) |

| UNDERCARRIAGE | ||

| Tracks | Heat-treated connecting pins with dirt seals. Hydraulic (grease) track adjusters with shock-absorbing recoil springs | |

| Numbers of Rollers and Shoes on Each Side | ||

| Upper roller | 2 | |

|

Lower rollers |

7 : ZX330-5G/ZX350H-5G/ZX350K-5G 8 : ZX330LC-5G/ZX350LCH-5G/ZX350LCK-5G |

|

|

Track shoes |

45 : ZX330-5G/ZX350H-5G/ZX350K-5G 48 : ZX330LC-5G/ZX350LCH-5G/ZX350LCK-5G |

|

| Track guard |

3 : ZX330-5G/ZX330LC-5G/ZX350K-5G/ ZX350LCK-5G Full track guard : ZX350H-5G/ZX350LCH-5G |

|

| Travel Device | Each track driven by 2-speed axial piston motor. Parking brake is spring-set/hydraulic-released disc type. | |

| Automatic transmission system | High-Low | |

|

Travel speeds |

km/h km/h |

High : 0 to 4.9 km/h Low : 0 to 3.1 km/h |

| Maximum traction force | kN (kgf) | 298 kN (30 400 kgf) |

| Gradeability | % (degree) | 70 (35) |

| SERVICE REFILL CAPACITIES | ||

| Fuel tank | L | 630.0 |

| Engine coolant | L | 35 |

| Engine oil | L | 36 |

| Swing device | L | 15.7 |

| Travel device (each side) | L | 9.2 |

| Hydraulic system | L | 340 |

| Hydraulic oil tank | L | 180 |

| UPPERSTRUCTURE | ||

| Revolving Frame | D-section frame skirt for resistance to deformation | |

| Swing Device | Swash plate piston motor with planetary reduction gear is bathed in oil. Swing circle is single-row. Swing parking brake is spring-set/hydraulicreleased disc type. | |

| Swing speed | min-1 | 10.7 |

| Swing torque | kNm (kgfm) | 120 kNm (12 200 kgfm) |

| Operator's Cab | Independent spacious cab, 1 005 mm wide by 1 675 mm high, conforming to ISO* Standards. * International Organization for Standardization | |

| HYDRAULIC CYLINDERS | ||||

| Quantity | Bore | Rod diameter | ||

| Boom | mm | 2 | 145 | 100 |

| Arm | mm | 1 | 170 | 115 |

| Bucket | mm | 1 | 140 | 95 |

| WEIGHTS AND GROUND PRESSURE | ||||

| Shoe type | Shoe width | Arm length | kg | kPa(kgf/cm 2) |

| Triple grouser | 600 mm | 2.67 m | 31 900 | 61 (0.62) |

| 3.20 m | 32 100 | 60 (0.61) | ||

| 4.00 m | 32 200 | 62 (0.63) | ||

| 700 mm | 2.67 m | 32 500 | 53 (0.54) | |

| 3.20 m | 32 700 | 53 (0.54) | ||

| 4.00 m | 32 800 | 54 (0.55) | ||

| 800 mm | 2.67 m | 32 900 | 47 (0.48) | |

| 3.20 m | 33 100 | 46 (0.47) | ||

| 4.00 m | 33 200 | 48 (0.49) | ||

| Trianglar | 600 mm | 2.67 m | 32 100 | 62 (0.63) |

| 3.20 m | 32 300 | 61 (0.62) | ||

| 4.00 m | 32 400 | 62 (0.63) | ||

| Flat | 600 mm | 2.67 m | 32 800 | 63 (0.64) |

| 3.20 m | 33 000 | 64 (0.65) | ||

| 4.00 m | 33 100 | 64 (0.65) | ||

|

*1 :Including 1.40 m3 (ISO heaped) bucket weight (1 170 kg) and counterweight (6 350kg). *2 :Including 1.38 m3 (ISO heaped) H-bucket weight (1 340 kg) and counterweight (6 900kg). *3 :Including 1.40 m3 (ISO heaped) reinforced bucket weight (1 380 kg) and counterweight (7 600kg). |

||||

| WEIGHT: BASIC MACHINE and COMPONENTS | ||

| Shoe width | Weight | Overall width |

| 600 mm | 24 500 kg | 3 190 mm |

| 700 mm | 25 100 kg | 3 290 mm |

| 800 mm | 25 500 kg | 3 390 mm |

| COMPONENT WEIGHTS | |

| Counterweight | 6 350 kg |

| Boom (with boom and arm cylinder) | 3 630 kg |

| 3.2 m arm (with bucket cylinder) | 1 800 kg |

| 2.67 m arm (with bucket cylinder) | 1 640 kg |

| 4.0 m arm (with bucket cylinder) | 1 900 kg |

| 1.4 m3 bucket | 1 170 kg |

| BUCKET AND ARM DIGGING FORCES | |||

| Arm length | 2.50 m | 2.96 m | 3.61 m |

| Bucket digging force* ISO | 246 kN (25 100 kgf) | 246 kN (25 100 kgf) | 246 kN (25 100 kgf) |

| Bucket digging force* SAE : PCSA | 214 kN (21 800 kgf) | 214 kN (21 800 kgf) | 214 kN (21 800 kgf) |

| Arm crowd force* ISO | 222 kN (22 600 kgf) | 185 kN (18 900 kgf) | 158 kN (16 200 kgf) |

| Arm crowd force* SAE : PCSA | 213 kN (21 700 kgf) | 177 kN (18 100 kgf) | 154 kN (15 700 kgf) |

| * At power boost | |||

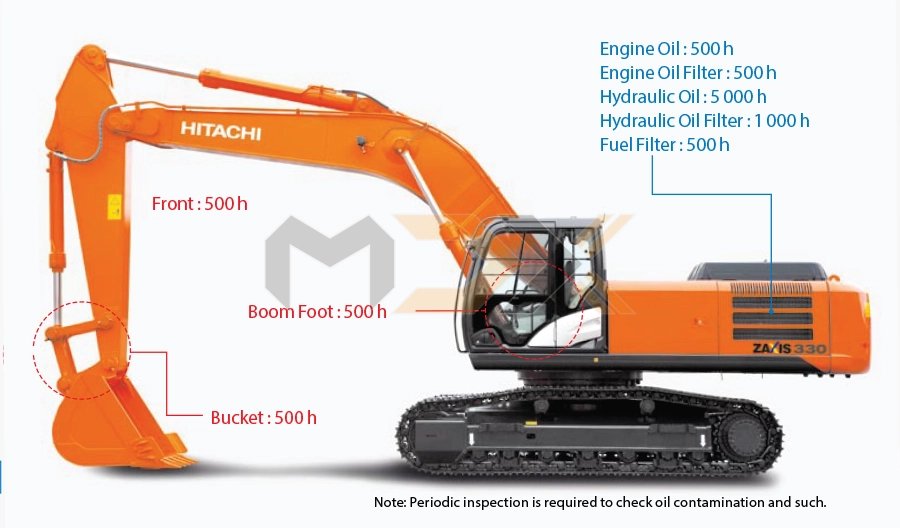

Simplified Maintenance |

|

| Dust-Proof Net

A dust-proof net, provided at the front of radiator, can be easily removed and cleaned with compressed air. Grouped Remote Inspection PointsService points are concentrated inside left and right covers that are readily accessible from ground level for convenient servicing and inspection, including water draining from the fuel tank, replenishment of coolant, and replacement of filters. The fuel tank is anti-corrosion coated on its inside, and has a large cleaning port at the bottom. These wise designs effectively keep fuel clean, and ease servicing. Handrails are provided at convenient locations for easy riding on the upperstructure. Plenty slip-resistant plates are located for safe maintenance. |

| Attractive, Robust Body

Side frame tops of the undercarriage are sloped to let muck slide away. Track adjuster greasing ports are repositioned for easier lubrication, and well protected from muck packing |

|

| Low Life Cycle Costs

Service intervals are long enough to slash maintenance costs |

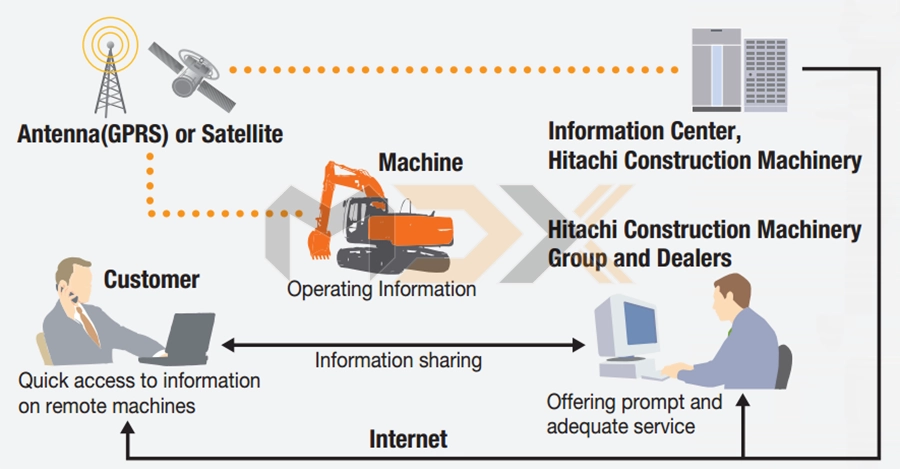

Hitachi Support ChainHitachi Support Chain is a full customer support system offered after buying a Hitachi machine |

| Remote Fleet Management with Global e-Service |

|

Easy Access to On-Site Machines through the Internet This on-line fleet management system allows you to access each on-site machine from a PC in your office. You can get its operating information and location to increase productivity of the fleet and reduce downtime. Operating data and log are sent to a Hitachi server for processing, and then to customer and dealers around the world. This system is available 24 hours a day, all the year around. Note: In Some Regions, Global e-Service Is Not Available by Local Regulations |

|

|

Main Features of Global e-Service Functions Global e-Service provides easy access to a machine on site, conveying operating information and log, including daily operating hours, fuel level, temperatures, pressures, and likes. Maintenance Maintenance data and log are displayed on a easy-to-read monitor screen, suggesting recommended maintenance for efficient fleet management. |

Parts and ServiceHitachi full customer support is available every area on the globe for full customer satisfaction through Hitachi local dealers. |

|||

| Parts

Hitachi Global Online Network, a parts supply system, is linked with Japan Parts Center, overseas depots and over 150 dealers abroad to deliver on-line parts information, including in-stock parts, order receptions, shipments and delivery period of over one million parts and components. Genuine Hitachi Parts Genuine Hitachi parts, meeting Hitachi stringent quality standards, are guaranteed according to Hitachi warranty standards. The use of genuine Hitachi parts, including engine, fuel, hydraulic oil and filters, may slash running costs, and extend machine life. Ground Engaging Tools (GETs) Hitachi provides an array of Hitachi Ground Engaging Tools developed and built for a variety of applications. Using high-quality, well-maintained GETs will help you get customers' trust. Note: Some dealers do not handle Hitachi GETs. Remanufactured Components Hitachi components are remanufactured according to the stringent remanufacturing standards at four factories around the world. They have high quality equivalent to new ones, and backed up by Hitachi warranty system. Note: Some dealers do not handle Hitachi Remanufactured Components. |

|||

| Service

Extended Warranty - HELP Hitachi Standard Warranty System is available on all new Hitachi machines. In addition, Hitachi offers Hitachi Extended Life Programs (HELPs) to suit customer expectations - protecting machines under tough operating conditions, avoiding unexpected downtime, and reducing repair costs. Note: Warranty conditions vary by equipment. Diagnostic Tools - Maintenance Pro Electronic control system needs quick on-site solutions, apart from mechanical repairs. Hitachi’s Maintenance Pro can diagnose machine failures in a short time by plugging a PC into a failed machine. Technical Training On-site servicing matters despite locations to keep the machine at peak performance and reduce downtime. Technical Training Center (TTC), located in Japan, educates and trains service technicians and service support personnel coming from Hitachi dealers and factories on the globe according to the international training programs |

Tags: excavator for sale, excavator hire, excavator Komatsu, excavator hitachi, sany excavator, wheel excavator for sale, bucket wheel excavator, power wheel excavator, largest bucket wheel excavator, bucket wheel excavator price, volvo wheel excavator, bucket wheel excavator for sale, wheeled excavator, wheeled excavator for sale, wheel bucket excavator, wheel type excavator, wheeled excavator volvo, wheeled excavator hitachi