HAMM- 100 YEARS OF INNOVATION & EXPERIENCE

It was in 1911 when Hamm developed the first road compaction equipment with a diesel engine – since then our innovative team has been designing trend-setting machinery. Today, HAMM is the world‘s major producer of asphalt rollers and soil compactors.

HAMM is famous worldwide for powerful and user-friendly compaction machines for a wide variety of jobs associated with road construction and earth works. Moreover, Hamm rollers are convincing because of their ergonomic and innovative design. HAMM has been awarded a total of 20 design prizes for all its innovations.

Hamm HD+ 120 VV is one of the typical products in Hamm Series HD+, perfect combination of features such as: strong operation, user-friendliness, fast, optimal compacting ability but extremely reasonable price. And most of all, besides bringing many economic benefits to the business, Tandem roller HD+ 120 VV with two vibrating roller drumshas many other values such as fuel saving, construction and environmental protection.

We offer a broad range of services in all areas of road construction and refurbishment. With passion and dedication our highly motivated team ensures your success at the construction site.

Market-leading products and top service with tried and tested quality standards give you the confidence you need in your fiercely competitive environment. The Wirtgen Group’s successful brands of long standing will safely keep you on the road to success.

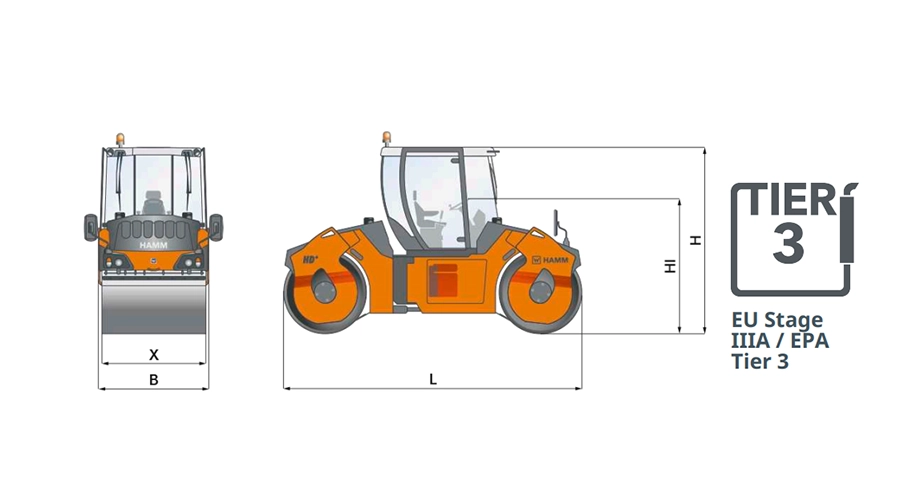

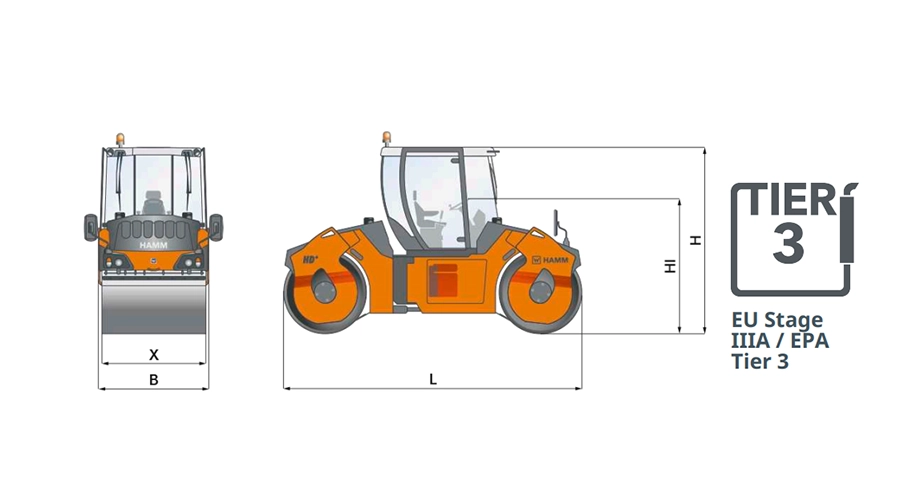

TECHNICAL DATA

|

| |

Unit |

HD+ 120 VV |

| WEIGHTS |

| Operating weight with cab |

kg |

12 570 |

| Operating weight with ROPS |

kg |

12 330 |

| Operating weight, max. |

kg |

13 320 |

| Static linear load, front |

kg/cm |

32 / 31.4 |

| French classific., data/class |

|

31,0/VT2 |

|

| MACHINE DIMENSIONS |

| Total length (L) |

mm |

4600 |

| Total height with cab (H) |

mm |

3050 |

| Height, loading, min. (HI) |

mm |

2185 |

| Wheelbase |

mm |

3 600 |

| Total width with cab (B) |

mm |

2 145 |

| Max. working width |

mm |

2 150 |

| Kerb clearance, left/right |

mm |

880 / 880 |

| Turning radius, inside |

mm |

5 285 |

| DRUM DIMENSIONS |

| Drum width, front/rear |

mm |

1 980 / 1 980 |

| Drum diameter, front/rear |

mm |

1 400 / 1 400 |

| Drum thickness, front/rear |

mm |

19 / 19 |

| Drum type, front |

|

Smooth / non-split |

| Drum type, rear |

|

Smooth / non-split |

| Track offset, left/right |

mm |

170 |

| DIESEL ENGINE |

| Manufacturer |

|

DEUTZ |

| Type |

|

TCD 2012 L04 2V |

| Number of cylinders |

|

4 |

| Power rat. ISO 14396 |

kW/PS/rpm |

100,0 / 136,0 / 2 300 |

| Power rating SAE J1349 |

kW/PS/rpm |

100,0 / 134,0 / 2 300 |

| Emission standard |

|

EU Stage IIIA / EPA Tier 3 |

| DRIVE |

| Speed, working gear |

km/h |

0 - 6.0 |

| Speed, transportation gear |

km/h |

0 - 12,0 |

| Regulation, infinitely variable |

|

Hammtronic |

| Climbing ability, vibration on/off |

% |

30 / 35 |

| VIBRATION |

| Vibration frequency, front, I/II |

Hz |

40 / 50 |

| Vibration frequency, rear, I/II |

Hz |

40 / 50 |

| Amplitude, front, I/II |

mm |

0.88 / 0.35 |

| Amplitude, rear, I/II |

mm |

0.88 / 0.35 |

| Centrifugal force, front, I/II |

kN |

159 / 95 |

| Centrifugal force, rear, I/II |

kN |

159 / 95 |

| STEERING |

| Oscillation angle +/- |

° |

10 |

| Steering, type |

|

Articulated steering |

| SPINKLER SYSTEM |

| Water sprinkler, type |

|

Pressure |

| TANK CAPACITY / FILL CAPACITY |

| Fuel tank, capacity |

L |

180 |

| Water tank, capacity |

L |

1 160 |

| SOUND LEVEL |

| Acoustic power LW(A), sticker |

db(A) |

108 |

| Acoustic power LW(A), measured |

db(A) |

107 |

EQUIPMENTS

Note: standard or optional equipment depends on the standard of each country. Please contact us for the answer.

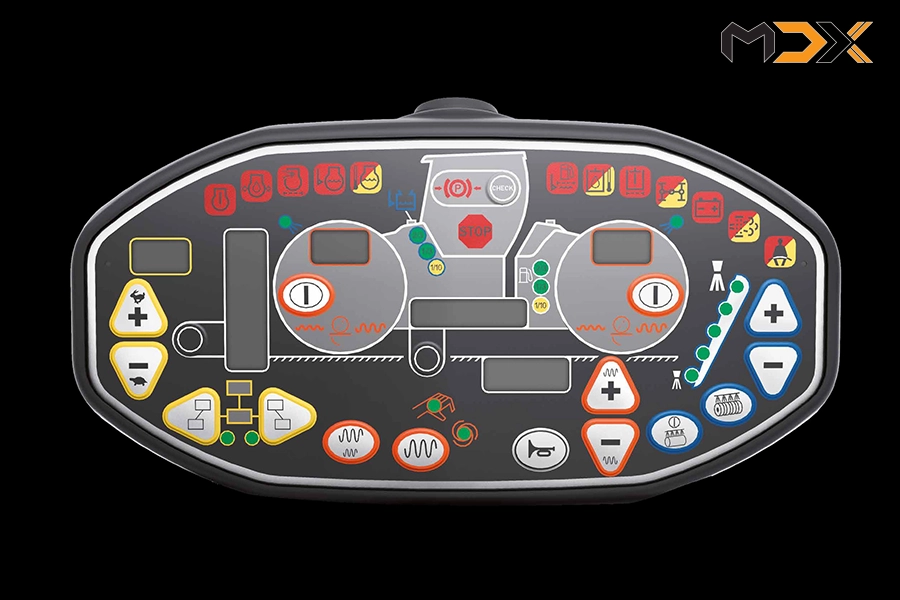

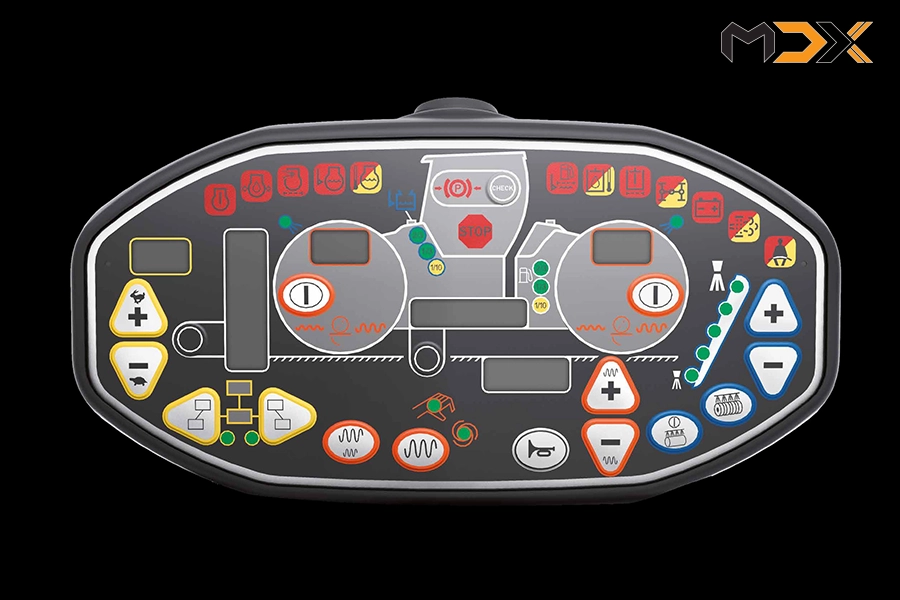

EQUIPMENT: 2 water pumps, Foldable scraper, Dashboard with displays, indicator lights and switches, Tiltable dashboard, Spring-mounted driver's seat with armrests and safety belt, Hammtronic - electronic machine management, Seat-operating unit, can be moved and rotated laterally, Track offset, Vibration parameters, adjustable individually, Spray system with spray bars front and rear, Water filtering (triple), Water tank front and rear, can be filled from both sides, Central water drain

OPTIONAL EQUIPMENT: ROPS cabin with split doors, ROPS, rigid, Air conditioning, Steering column with comfort exit and tiltable dashboard, Safety belt monitoring device, Additional drive lever, left, Radio, HCQ Navigator, Protective roof, Edge pressing and cutting equipment, Version with additional fuel prefilter, HAMM Compaction Meter (HCM), HAMM Temperature Meter (HTM), Track offset display, Camera system, Rotating beacon, Drum edge lighting

HIGHLIGHTS

|

| Available in different versions: with handrails (with or without protective roof), with ROPS or ROPS cabin |

XXL panoramic cabin with all-round view and ROPS. Generous headroom. Two drinks holders and storage compartments as standard. Two sockets (12 V) for cold box, etc. Optional split door. |

| Steps to cabin on both sides, additional service steps in the drum area. |

Air outlets for agreeable climate control and supply of fresh air as standard. Ventilation slots for fast deicing. Heating as standard in machines with cabin. Air conditioning (option). |

| Bright working spotlights on the cabin or roof. Halogen lights as standard; long-lasting, very bright LED technology is also available as an option. Optional LED drum edge lighting. |

Ergonomically optimised operator’s platform with mechanical seat movement and rotation; wide rangeof adjustment possibilities. Continuously adjustable steering column. Language-neutral design |

|

| 3-point articulation. Large track offset. |

Safe drive control with joystick and steering wheel. Pre-selection of maximum speed as standard. Automatic system for gentle braking and acceleration |

| Electronic machine management system fitted as standard for monitoring of all engine and vehicle functions. Automatic adjustment of drive, vibration or oscillation drive and engine speed to the prevailing operating conditions. Significant reduction in fuel consumption, exhaust and noise emissions. |

Future-proof, water-cooled engines with advanced exhaust post-treatment in line with the applicable regulations (EU Stage IIIA / EPA Tier 3). Low-noise, environment-friendly operation. Optional fuel pre-filter available |

|

| Available with two vibrating drums (VV), with vibrating and oscillation drums (VO) or as a combi roller (VT). |

Option. Enables precise edge finishing. Clearly visible position. Pressing rolls and cutting wheels available in many diameters and angles. Track indicator and separate water sprinkling system included |

| Two large tanks. Even filling and weight distribution thanks to interconnecting pipework. |

One spray bar per drum. Arranged in such a way that the spray bar and drum can be seen by the driver. Simple mounting and removal of spray nozzles and spray bars. Triple water filtration. Five sprinkling stages with speed control |

| Option. HAMM Compaction Meter (HCM) for the evaluation of rigidity when compacting asphalt. HAMM Temperature Meter (HTM) for the measurement and display of asphalt surface temperature |

Option. HCQ Navigator for comprehensive compaction control and documentation as well as exceptionally uniform compaction. |

| Option. Acoustic and visual alert on the display if the safety belt is not being worn or is not locked. |

|

Excellent visibility - The basis for top-class work

A large operator’s platform provides an unobstructed view of the working area directly around the roller as well as the surrounding site. Neither the exhaust pipe nor side rails interfere with the view. This visibility ensures high-quality compaction and a high level of safety.

- Fully glazed panoramic cabin with large, wide-opening doors

- The open frame and the shape of the tanks make for a clear view of the area directly in front of the drums.

XXL workspace

The comfortable workspace in the large panoramic cabin of Hamm HD+ 120 VV provides the perfect conditions for concentrated working.

Comfort and ergonomics

Drivers get to their daily workspace, the XXL operator’s platform of Hamm HD+ 120 VV, via a wide stepway with broad footplates. The convenience features continue with an optional rearward-tilting steering column that makes getting on very easy. The comfortable seat can be supplied with a backrest extension and fabric covers. The driver’s seat can be rotated and moved sideways to the edge as standard, the height and springing are adjustable.

The seat always includes two armrests and can be optionally equipped with a control lever on the left. In addition, there are a wealth of agreeable details that characterise working in HD+ 120 VV: for example, 12 V sockets for charging a mobile phone or for a cold box, ample storage space, several drinks holders and various fresh air nozzles. On request, a lunchbox holder can also be provided in all ROPS machines.

- The tilt of the dashboard with steering wheel is adjustable to suit every operator.

- The XXL cabin of Hamm HD+ 120 VV offers generous space and plenty of headroom.

- The driver’s seat can be moved sideways and rotated by 90° to either side.

A little extra quality

The perfect interplay between articulated joint, vibration drives and the powerful water sprinkling system makes for high-quality compaction.

Quality factor: articulated joint

The 3-point articulation developed by HAMM is the key to exceptionally even weight distribution, first-rate directional stability and high stability when turning together with great resistance to tipping. This benefit is particularly apparent when compacting on curved sections. Surfaces with impeccable evenness and no deformations are produced rapidly.

Quality factor: compaction parameters

In addition to the usual adjustment of vibration frequency, some HD+ models offer yet another special extra: the frequency and amplitude of each drum can be set independently as standard, allowing extremely easy variation of the compaction parameters for each construction site and type of asphalt.

The turning circle of Hamm HD+ 120 VV is remarkably small. This means that even the large models can manoeuvre well in tight spaces, too.

Quality factor: water sprinkling system

The position and mounting of the spray bar also ensure high quality: it is positioned in front of the cross member so that the driver has the sprinkling system in view at all times and can quickly adjust the water volume. In addition, the spray bar is secured in such an ingenious way that it can be mounted and removed in a matter of moments

With their large water tanks, Hamm HD+ series rollers are equipped for long working days without stopping to top up. Here, the desired water delivery is automatically adjusted in line with speed. Two water pumps, an optional antifreeze filling system and a triple water filtration system ensure maximum availability.

- The panoramic cabin and the frame, which is open at the top, provide a clear view of the spray bar and spray nozzles.

Ready for big jobs - Large drums for large area coverage capability

Everything about Hamm HD+ series rollers is geared to performance: the generously sized tanks and the large drum diameters, as well as the powerful traction and vibration (or oscillation) drives. Thanks to Hammtronic and many other intelligent solutions, Hamm HD+ 120 VV is very economical in use. That is the reason why these rollers are the right choice for efficient compaction of large areas

Hamm HD+ 120 VV has won more design awards than any other construction machine in the world: it received the “iF design award“ in gold, the “red dot design award“, the American “Good Design Award” and the French “Observeur du design”.

- Driver safety is provided through a protective roof with ROPS.

Simple, intuitive operation

Operation of HD+ 120 VV is clear and easy to follow, and thus very easy to learn.

Simple, logical and language-neutral

Straightforward operation is one of the hallmarks of the HAMM rollers. In Hamm HD+ 120 VV as well, drivers will find to all the important display and control elements on the dashboard. Less important or less frequently-used operating elements are positioned at the front of the cabin or at ceiling height. Moreover, all displays are languageneutral. Clear symbols and logical layout are a major contribution to intuitive operation.

Hamm HD+ 120 VV are also impressive in terms of ergonomics and comfort. For example, the seat in Hamm HD+ series rollers is permanently attached to the steering column including the dashboard. As a result, all of the displays remain within the driver’s field of vision in any sitting position.

Ready to go – by day or night

See and be seen – important criteria for quality and safety when working at night. That is the reason why Hamm HD+ 120 VV comes fitted with numerous halogen lights as part of the standard specification (LED lighting optional). They illuminate an extensive area around the roller, thus enabling work to be carried out as accurately and safely after dark and in tunnels as it is in daylight. On request, additional LED drum edge lighting provides optimal illumination of critical areas.

Service & maintenance: simply easy. - Easily accessible, few operations

HD+ 120 VV enables fast and easy maintenance – the best recipe for ensuring that it is done regularly!

- Wide-opening door.

- Easily accessible filters and dipsticks

- Fold-up steps on the drums for easy filling.

- Easily replaceable scrapers.

Efficient service

To ensure fast and thorough servicing, HAMM uses the WIRTGEN GROUP’s service diagnostic tool WIDIAG. For customers who also want to exploit the benefits of remote diagnostics and an efficient fleet management system, Hamm HD+ 120 VV can be equipped with the WITOS FleetView telematics system.

Maintenance quickly completed

With long maintenance intervals and few maintenance items, HAMM makes life easier for workshop technicians. For example, all items requiring routine maintenance are grouped together on the same side of the machine. Here, a large, wide-opening door to the engine compartment provides optimum access to the filters and dipsticks.

Modern engine technology

Hamm HD+ series rollers come equipped with dependable and robust engine technology. In all models, the environment-friendly engines comply with the requirements of the applicable exhaust emission standard (EPA Tier 3 or EU Stage IIIA)

A supplementary fuel filter can also be installed. It eliminates excess water from the diesel fuel, ensuring reliable operation.

More information about WITOS system of Wirtgen Group at: HERE

No compromises - Maximum compaction quality at all times – even where space is tight

HAMM offers numerous models in Hamm HD+ series. They differ in drum width, operating weight, compaction type (vibration or oscillation drum or rubber wheels) and engine output. In addition, there are many options with which each machine can be precisely tailored to meet local or technical requirements. But they all have one thing in common: thanks to their outstanding driving and handling characteristics, they deliver top-class compaction even on cramped sites in urban areas because their small turning circle makes compacting child’s play even in tight curves.

- Elevated drum suspension for maximum side clearance.

- An unaccustomed feature on articulated rollers: large track offset for precise edge finishing.

TECHNOLOGIES

3-POINT ARTICULATTION

3-point articulation is different to conventional joints due to its geometric arrangement and connection of the three individual joints and one additional connecting link between the two conventional upper joints. This allows optimum steering, excellent driving safety and maximum driving comfort.

See more at: HERE

HCQ – HAMM COMPACTION QUALITY

See more at: HERE

The HCQ modules create transparency, increase compaction quality and make for a high level of efficiency.

HCQ: smart system for maximum compaction quality

High-quality compaction means compacting the ground to the required load-bearing capacity – over the entire area and to the required depth. HAMM has developed various measurement systems to check the compaction and bundled them under the name HCQ. These products aid the measurement, documentation and analysis of the compaction processes and offer the maximum possible flexibility, because they are modular in design and perfectly matched to one another.

HAMM Compaction Meter: measuring subsoil rigidity in real time

The HAMM Compaction Meter (HCM) serves to measure and display the subsoil rigidity. To do so, an acceleration sensor on the drum measures the ground rigidity during dynamic compaction. The measurement result, the HMV value, shows the driver whether or not the subsoil is sufficiently compacted. In many cases, this information helps to reduce the number of passes and avoid over-compaction.

HCQ Navigator: area-wide, homogenous compaction

The HCQ Navigator is a satellite-based documentation system for the collection and display of all important parameters during compaction. It creates a real-time compaction map via the HCQ satellite receiver. It shows the areas that have already been adequately compacted and those that require further compaction on a panel PC in the roller. The data from a number of rollers may also be linked via a WLAN. This enables the roller drivers to compact even more efficiently.

The HCQ Navigator’s mobile panel PC for the display and storage of all measurement data.

HAMMTRONIC

Everything about Hamm HD+ series rollers is geared to performance: the generously sized tanks and the large drum diameters, as well as the powerful traction and vibration (or oscillation) drives. Thanks to Hammtronic and many other intelligent solutions, Hamm HD+ 120 VV is very economical in use. That is the reason why these rollers are the right choice for efficient compaction of large areas.

See more at: HERE