-

Your shopping cart is empty!

The Doosan Group - founded in 1896 and headquartered in Seoul, South Korea - is one of the fastest-growing companies in the world:

- With more than 37,500 employees in 38 countries, we are a major player in a variety of industries worldwide.

- A global leader in the Infrastructure Support Business (ISB), with 56 subsidiaries and 3,700 distributors worldwide.

- Dramatic growth over the past two decades, with an annual Doosan Group revenue rising from €2.4 billion in 1998 to €12.8 billion in 2016

- Doosan Infracore: Among the world's Top 5 manufacturers of construction equipment

- Doosan Bobcat: A leading company in the design, manufacture, marketing, distribution and service of small equipment and attachments for construction, agriculture, and landscaping. Leading position in the global compact equipment market. N° 1 in North America for SSL, CTL and MEX.

- Doosan Heavy Industries & Construction: World N° 1 in desalination plant construction, World N° 1 in heat recovery steam generator market, World N° 1 in mould & tool steel, World N° 3 in crankshafts

- Doosan Engineering & Construction: A pioneering leader in construction of residential and public buildings, civil works and industrial facilities. World N° 1 chemical process equipment products

Creating construction equipment for over 40 years. For over 40 years, we've been building a global production and business network to become one of the world’s foremost construction equipment manufacturers.

A solid partner, close to you. A truly global player in every respect, we have large-scale factories, sales subsidiaries and dealers all over the world.

To ensure the highest trade-in and residual values, our parts and service support professionals maintain the performance, productivity and reliability that you expect of our products throughout their lifetime.

As your local specialist, your dealer ensures that you receive the maximum benefit from our integrated package. Plan ahead to ensure the success of your equipment!

- Articulated Dump Trucks

- Doosan Wheel Loaders

- Doosan Wheeled Excavators

- Doosan Mini Excavators

- Doosan Crawler Excavators.

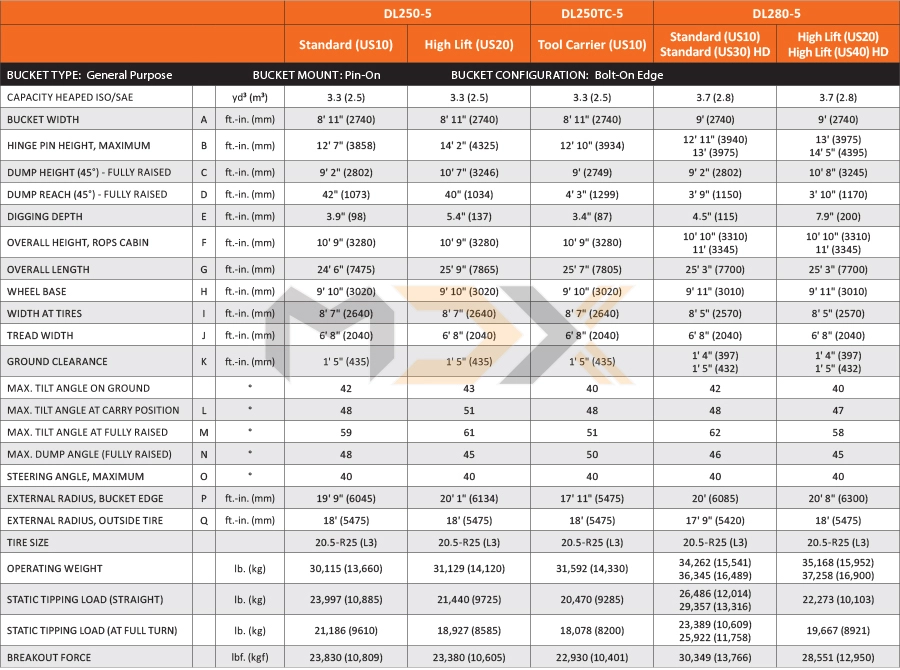

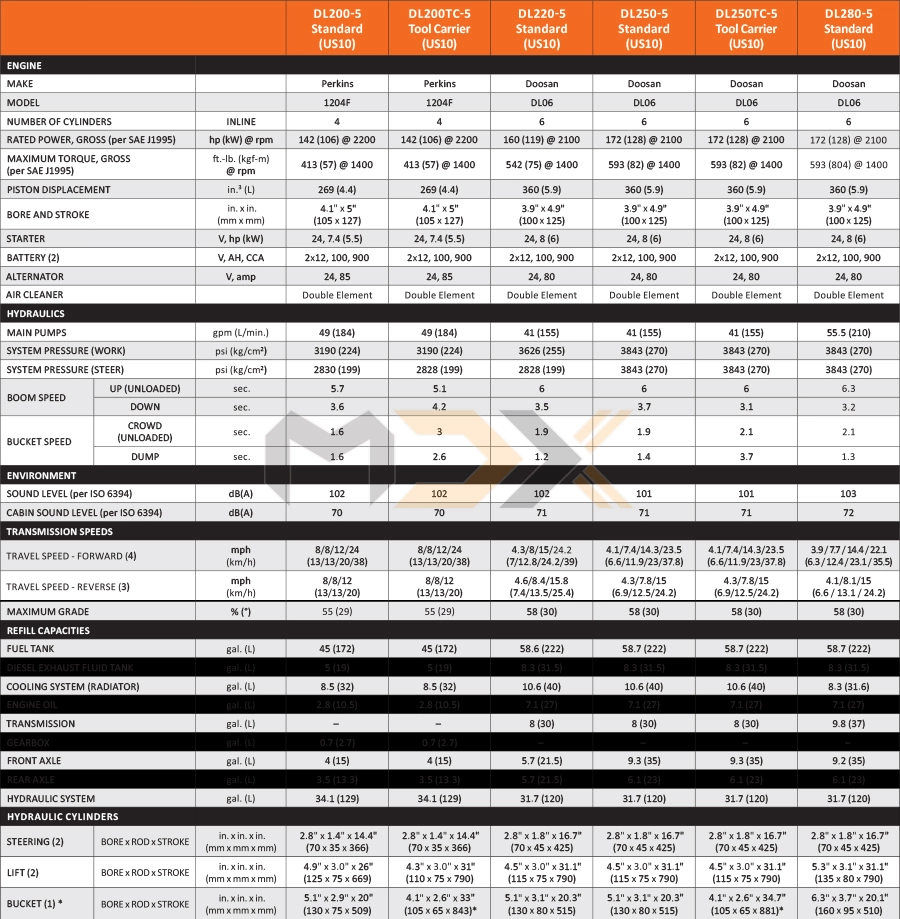

DIMENSION AND WORKING RANGE

GENERAL SPECS

Even the most brutal workday looks better from the seat of your Doosan wheel loader. Here you command tremendous lift height and capacity, plus enough torque to bite into the toughest materials. Scoop, carry material, load trucks and even run attachments. Cut long days and tough jobs down to size in a hurry and do it profitably in a Doosan wheel loader.

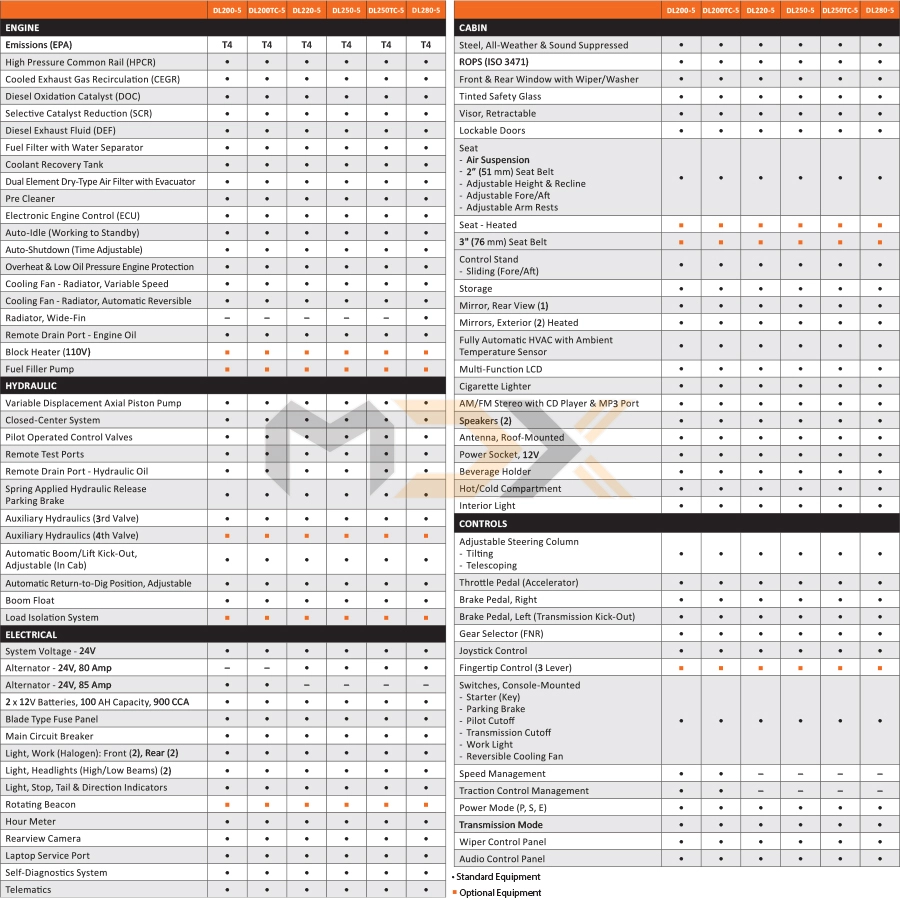

Optimized Engine Horsepower

A finely tuned horsepower curve and higher torque ensure you can move mountains of material fast. A high pressure common rail fuel injection system and cooled exhaust gas recirculation (CEGR) valve reduce emissions.

Outstanding Traction and Pushing Power

Doosan axles are carefully designed to maximize traction, provide easy maneuverability and generate excellent pushing power, making short work of even the biggest pile.

Limited Slip Differential allows the wheel with the most traction to receive the proper torque, providing superior tractive effort and maneuverability in tough terrain.

Lift Capacity

There’s no secret to doing more work in less time. You have to quickly and efficiently handle the biggest, heaviest load that you can. With its load-sensing, closed center hydraulics, Doosan wheel loaders deliver superior lift capacities for every model size.

Self-Adjusting Brakes increase performance and minimize maintenance. If needed, a technician can easily check the brakes and adjust externally. The brake piping is safely integrated with the axle housing and protected from jobsite debris.

Optional Front-Locking Differential locks the front left and right wheels together, providing superior traction for driving over loose, slippery terrain or pushing into big, heavy piles (DL220-5, DL250-5, DL250TC-5 and DL280-5 only).

Power Modes

Choose from three different power modes to change machine performance for job conditions or reduce fuel consumption.

- Power Mode delivers the highest level of performance for quick loading and fast travel. Finish more heavy-duty work in less time.

- Normal Mode is ideal for general work conditions and optimal fuel consumption.

- Economy Mode minimizes fuel consumption and reduces engine sound levels, providing for comfortable, economical light-duty work.

Planetary Final Drives

The planetary final drives transfer torque to the wheels through the transmission and differential. They enable higher travel speeds and greater torque. The outboard, hub-mounted design makes maintenance easy.

Productivity is what it’s all about and Doosan delivers. Whether you’re loading a small truckload or moving a mountain of material, your DL280-5 wheel loader will have you feeling good about the results at day’s end.

Fast Cycle Times

Speed and control are the keys to optimal production. Doosan DL280-5 wheel loader is engineered to perfectly balance both. Durable, low-maintenance vane pumps deliver the power you need to complete every job quickly.

Tier 4 (T4) Compliant

Optimized to provide more power output with reduced fuel consumption, Doosan wheel loaders are designed with T4 compliant engines to reduce air pollution.

Cooled Exhaust Gas Recirculation (CEGR)

CEGR recycles a portion of the engine exhausts to reduce oxygen (O) and lower the temperature in the combustion chamber. This reduces nitrogen oxide (NOx) emissions.

Diesel Oxidation Catalyst (DOC)

In the DOC, carbon monoxide (CO) and particulate matter (PM) emissions are transformed into harmless water (H2O) and carbon dioxide (CO2)

Evaporative Module

In the evaporative module, or mixing pipe, diesel exhaust fluid (DEF) solution is injected in small doses and mixed with hot exhaust gases, decomposing it into urea (CO(NH2)2) and water vapor, which then catalyzes into carbon dioxide and ammonia (NH3).

Selective Catalytic Reduction (SCR)

In the SCR canister, nitrogen oxide mixes with ammonia, and a chemical reaction takes place, resulting in nitrogen (N) and water vapor emitting from the system. The SCR canister also acts as the silencer or muffler.

Diesel Exhaust Fluid (DEF)

DEF is a solution of pure urea and deionized water. A minimum level of DEF is required for proper machine operation, and the DEF supply tank is heated for proper operation in cold weather. DEF is available from your Doosan dealer in various container sizes.

FNR Joystick

Direction changes don’t get any simpler. Just push the joystick buttons to switch between forward, neutral and reverse without even removing your hands from the controls.

Optional Load Isolation System

The load isolation system, sometimes referred to as ride control, cushions the lift arm while traveling over rough terrain, minimizing the loss of material while carrying a load and reducing operator fatigue. It also comes in handy when your customers pay for material by the bucket

Auto Idle

The standard auto idle feature automatically reduces the engine rpm to standby idle a few seconds after the steering wheel, gearshift control lever and accelerator cease movement. This reduces noise, improves jobsite communications and saves fuel. When you move the controls, the loader automatically returns to working idle.

Fuel Efficiency

Fuel use is a significant cost of operation, and Doosan efficiently delivers more work for the money. In our fuel efficiency tests against equivalent machines from other manufacturers, Doosan DL280-5 consistently moves more material per gallon of fuel.

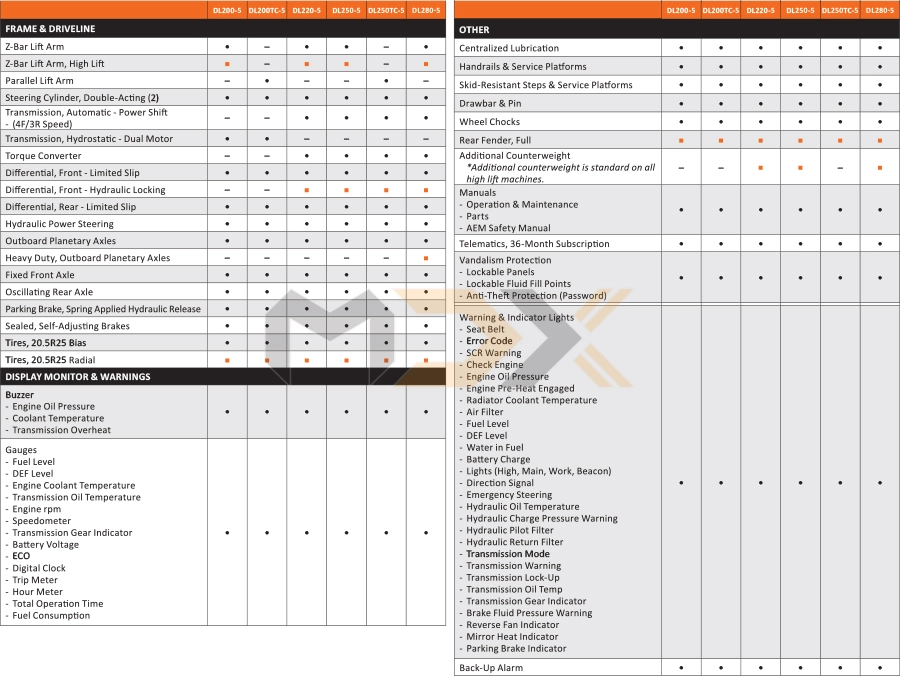

Z-Bar Lift Arm Linkage is designed for heavy lifting in loading applications, with geometry that enables rapid bucket movement and proper angle positioning in every situation.

Standard Lift vs. High Lift

Standard Z-Bar Linkage has excellent breakout forces for easier digging and penetration into tough materials. It increases the lifting capacity of every Doosan loader for best-in-class performance.

Optional High-Lift Z-Bar Linkage is designed for applications requiring the highest possible dumping height and reach. It’s ideal for cement plants, scrap, mulch or wastewater transfer stations.

Parallel Lift Linkage is designed to give you precise control over the movement of buckets, pallet forks and other attachments in applications other than loading. This design keeps the attachment level, allowing for faster lifting and placing of materials.

Return to Dig

Sensors on the lift arm and bucket linkage allow you to change your “return to dig” setting from inside the cab. The cylinders and cutting edge return to the same position every time, enabling more efficient, consistent work.

Lift Kickout

Set the maximum lift height for working inside buildings or other areas with height restrictions. Simply pull back on the control stick to override.

Optional Hydraulic Coupler

This feature increases your productivity with nonhydraulic attachments, such as the pallet fork, saving you time by enabling you to switch from one attachment to the next without even leaving the cab.

Driveline Comparison

The drive shafts and axles* visually remain similar between the two driveline designs; however, the torque converter and four-speed transmission is replaced by a hydrostatic pump and two hydrostatic motors along with a gearbox.

*Front and rear differential configurations may differ between the two systems based on options selected.

Torque Converter Transmission

The automatic powershift torque converter transmission in the DL220-5, DL250-5, DL250TC-5 and DL280-5 is optimized with engine power providing efficiency in load and carry operations. With four gears and three drive modes, the operator has the flexibility to configure the machine to the application. A transfer case is eliminated as the inter-axle differential is integrated in the transmission housing.

Transmission Mode

Choose from three transmission modes manual, auto 1-4 and auto 2-4 with manual kickdown to match the working conditions you face, and tailor performance for better productivity.

Transmission Optimization is a key feature of the automatic transmission modes. It calibrates different shift points to tailor the amount of power and engine torque per gear. When you engage either auto 1-4 or auto 2-4 in power mode or normal mode, the transmission shift point occurs 20 percent later allowing more torque and power within each gear range. In economy mode, the automatic transmission shifts 20 percent earlier for increased fuel efficiency.

Manual is ideal when the job requires precise speed control. Auto 1-4 automatically shifts up when you need more speed and downshifts when the job demands more power or torque. It’s excellent for heavy-duty applications.

Auto 2-4 with Manual Kickdown gives you automatic shifting between gears 2 through 4, with a manual downshift into first gear when you need it. It provides the best performance for less demanding work conditions.

Transmission Cutout

Need more engine power for lift arm speed? In lower gears, simply depress the left brake pedal to disengage the transmission. Disengage transmission cutout with your switch panel to start moving on an incline with greater ease

Hydrostatic Drive System

The new hydrostatic drive system in the Doosan DL200-5 and DL200TC-5 delivers higher performance at lower engine rpm, which also improves fuel efficiency. Additional features include the ability to control the traction characteristics and configure speed management to increase your productivity, and dynamic braking that automatically slows the machine and reduces wear on the brakes.

Single Pump, Dual Motor Hydrostatic System

A single hydrostatic pump directs oil flow to two separate hydrostatic piston motors: one low-speed and one high-speed. These motors are connected to a gearbox that seamlessly transfers power to the driveline from the low-speed or highspeed motor, depending on the demands of the job. If the task demands it, both can power the driveline together. This provides optimal power at all times and automatic torque delivery to the driveline in every kind of application.

Traction Control Management

With traction control management, three modes allow you to easily match traction to the jobsite conditions, so you can prevent wheel slippage while digging, stockpiling and loading.

Max provides maximum traction force.

Traction Control allows you to choose from three intermediate levels of traction force.

Slip is optimized primarily for slippery roadway conditions.

To instantly return to the max traction mode, just press the kickdown button on the joystick control or directional control lever.

Speed Management

A variable speed control feature allows you to obtain full engine rpm for optimal lift arm and hydraulic attachment performance while fine-tuning the maximum machine travel speed in the first gear range. This gives you precise travel control without sacrificing hydraulic power for the job.

Doosan builds its machines so they’re ready to work when you are. Whether it’s solid construction, heavy-duty parts and materials, or innovative features that keep you on the job with fewer service intervals, your wheel loader ranks among the toughest and most profitable in the industry.

When you get up close to a Doosan wheel loader, you can see that this machine is built to last. With heavy-duty parts, quality materials and superb construction, you can rely on performance, productivity and profit day after day. Plus, innovative designs keep you on the job with fewer service intervals so you spend less time in the shop.

Tough, Rigid Frame

Each frame section is designed to maximize the life of the machine. Thick steel plates, cross members and gussets join to form a strong, durable articulation joint that stands up to years of difficult work

Double Roller Articulation Joint Bearing

To create an articulation pivot point with superior strength, tough double roller bearings are used at both the top and bottom hinge points between the front and rear frames.

Lift Arm Pin Protection

Lift arm pins are protected with bushings and dust covers to increase pin life and reduce maintenance.

Variable Speed Cooling Fan

The variable speed fan slows and speeds up as required by the work demands of your loader. In lighter-duty conditions, the coolant temperature is low and the fan slows saving fuel and extending the life of your cooling system.

Reversible Cooling Fan

By pressing a console switch, the cooling fan can be reversed to assist in keeping the cooling system clean in extremely dusty applications. Press it to keep the machine running at optimal temperature. You can also set it to auto reverse for a few minutes at a time at different intervals at 30, 60, 90 or 120 minutes depending on work conditions.

Separate Cooling and Engine Compartments

Doosan isolates the wheel loader engine from the cooling system. This design increases cooling capacity and extends the life of your engine components.

Large Center Driveline Bearing

An oversized bearing, that is vented to prevent over greasing, increases durability of the front drive shaft.

Thick Lift Arm Plates

Thick, solid-steel lift arm plates provide maximum durability in harsh conditions along with improved lift capacities. A narrower arm design overall increases your visibility.

All-Steel Panels

Access panels on Doosan DL280-5 wheel loader allow easy maintenance access, and they’re made of durable formed metal to protect critical engine, hydraulic and electrical components.

Exhaust Heat Exchanger

As exhaust leaves the muffler on your DL280-5 wheel loader, it enters a larger external riser pipe with rain shield. This design creates a vacuum that pulls hot air out of the engine compartment, making your engine and cooling system run more efficiently.

You can’t overlook the relationship between comfort and productivity. That’s why comfort is central to the Doosan cabin design. It’s packed with high-end comfort that enables you to retain a team of productive, experienced and satisfied employees.

Quiet Operation

Operators stay relaxed and focused on the job with a quiet operating environment. Noise levels in the cabin stay below a comfortable 72 decibels thanks to the variable speed cooling fan, double-walled muffler, soundproof materials throughout the engine compartment, and tightly sealed and pressurized cabin.

Excellent Visibility

Large front and rear glass surface areas provide an excellent view to the loader workgroup and jobsite. Narrow corner pillars and small window joints increase visibility to the front of the machine. Heated mirrors

provide visibility to the sides and rear of the machine, even in cold temperatures.

Easy Entry and Exit

Grab handles and offset steps with slip-resistant surfaces provide easy access to the cabin and easy exit when work is finished. A 180-degree swinging door that can lock to the open position provides a wide opening to move in and out of the machine. Inside, ample floor space gives you room to work and exceptional comfort.

Ergonomic Controls

From the steering wheel and joystick to the switches for optional equipment, all controls are located within easy reach for intuitive, easy operation.

Optional Rearview Camera

Provides the operator with an additional means to view the machine’s surroundings, allowing for increased productivity.

Automotive-Style Heat and Air Conditioning

Stay comfortable all year with high-capacity heating and cooling vents and an easy-to-control temperature. Automatic temperature control senses and adjusts to the temperature setting automatically. A memory

function returns it to your preferred temperature if you shut the machine off and restart later.

Easy-to-Read LCD Display Panel

An easy-to-read LCD display panel is placed within easy view for monitoring critical machine data and receiving machine warnings.

Standard Radio with CD Player and MP3 Port

Tune into your favorite over-the-air stations, or take your favorite digital music format with you to work, to make every hour on the job more enjoyable. Adjustable Comfort The standard air suspension seat has multiple adjustment points, allowing you to select the most comfortable position.

A Seat Height - B Seat Fore/Aft - C Back Recline - D Lumbar Support - E Armrest Angle - F Seat Heater (Opt.) - G Headrest Up/Down

If it’s easy to do, regular maintenance gets done and you’ll get more production and efficiency from your loader. That’s how Doosan approaches maintenance. First, we build the machine tough for long-lasting performance and longer service intervals. Next, we make machine care second nature to every operator with centrally located maintenance points, onboard diagnostic systems and easy component access. If you want durability and simple maintenance, Doosan delivers.

Easy Component Access

Big, easy-to-open access covers and fold-up panels provide fast, ground-level access to critical engine and hydraulic components. When it’s easy to reach and service components, you save time on maintenance and reduce your operating costs.

Durable monitoring hardware is built into your Doosan DL280-5, and it collects reliable, accurate and robust data with every minute of operation. The data is uploaded automatically to the Doosan Connect online system using dual-mode communications (cellular and satellite) for maximum coverage. Your designated users can monitor the machine status from anywhere using the Doosan Connect website and mobile application. Key benefits include:

- Critical code awareness or proactive service.

- Preventative maintenance planning

- Operational efficiency management.

- Location visibility

Sight Glass for Major Fluid Levels

Sight glasses on the machine provide quick, easy fluid-level checks. All it takes is a quick visual check to know if your fluid reservoirs are properly filled.

Centralized Remote Hydraulic Diagnostic Ports

You can review pressure and troubleshoot hydraulic issues from one check port bank. In minutes you can review pilot charge, brake system charge, load sensing, steering system, fan and steering pressures, along with the main relief setting.

Color-Coded, Labeled Wiring and Hydraulic Hoses

Strategically labeled wiring enables plugand-play installation of electrical accessories, such as the rotating beacon. It also allows quicker, easier electrical troubleshooting of the electrical and hydraulic systems.

Self-Diagnostics

The LCD monitor helps you monitor critical systems in real time. Plus, you can access historical machine alerts right from the screen in the cabin.

Remote Grease Points

For a long-lasting machine, daily maintenance is critical. Remote grease points make it easier to lubricate hard-to-reach pins on the lift arm and articulation system. Daily greasing happens on the ground and it’s more likely to get done.

Doosan Monitoring System with Laptop Access

The Doosan Monitoring System is a diagnostic program that gives your dealer’s technician a direct communications link with your wheel loader. During operation, it monitors all critical data and provides a complete history of operation and a realtime log of machine failures. Armed with information like this, your dealer service personnel can fix issues fast and you can get back to work.

Remote Drain Ports

Easy-to-access remote drain valves make for fast, convenient exchanges of engine oil and cooling system coolant.

Do more with your machine. Doosan DL280-5 wheel loader is optimized for attachment versatility bringing you more opportunities to utilize your equipment investment, and possibly enabling you to expand your business. Our tough attachments are matched to your machine’s operator weight and load settings so you can rely on epic productivity with every job.

Selectable Engine Power Modes

The Doosan wheel loader has three engine power modes economy, normal and power to further adapt your loader’s performance to the application and deliver the right balance of power and fuel economy.

Standard Attachment Hydraulics

For hydraulic attachments, like the multipurpose bucket, an auxiliary spool comes standard. No extra installation required. Hydraulic lines down the boom are optional.

Optional Quick Coupler

Quickly change many of your wheel loader’s non-hydraulic attachments without leaving the seat. A four-point style pick-up means you can hook up attachments easily, even on irregular terrain

Boom Float

The boom float allows your bucket to follow the ground contours, which saves you time and increases productivity when backdragging during snow removal.

General Purpose Bucket

With a sloped bottom for maximum filling and material retention, this is the perfect bucket for day-to-day material handling. Capacities range from 4 to 6.5 yd3. Available for DL200-5, DL200TC-5, DL220-5, DL250-5, DL250TC-5 and DL280-5 wheel loaders. All available with bolt-on cutting edge or teeth.

Light Material Bucket

When you need to move snow, mulch or other light material in a hurry, the light material bucket is the economical choice. Comes standard with bolt-on cutting edge. Available for DL200-5, DL200TC-5, DL220-5, DL250-5, DL250TC-5 and DL280-5 wheel loaders. All available with bolt-on cutting edge.

Multi-Purpose Bucket

Leveling, dozing, digging, grappling, loading and dumping this multi-purpose bucket is ready for whatever you’ve got. Capacities range from 3.5 to 4 yd3. Available for DL200-5, DL200TC-5, DL220-5, DL250-5, DL250TC-5 and DL280-5 wheel loaders. All available with bolt-on cutting edge or teeth.

Pallet Fork

Easily lift, carry and place materials. Available with with 48" or 60" tines for DL200-5, DL200TC-5, DL220-5, DL250-5, DL250TC-5 and DL280-5 wheel loaders.

Tags: doosan wheel loader DL280 5, wheel loader, caterpillar wheel loader, hitachi wheel loader, Komatsu wheel loader, Doosan loader, caterpillar wheel loader, wheel loader specifications, wheel loader Komatsu, wheel loader for sale, wheel loader capacity, wheel loader vs excavator, wheel loader caterpillar, wheel loader liugong, kubota wheel loader, volvo wheel loader, compact wheel loader, bobcat wheel loader, wheel loader volvo, wheel loader jcb, hitachi wheel loader dealers, hitachi wheel loader models, hitachi wheel loader specifications, hitachi wheel loader zw80, hitachi wheel loader parts, hitachi wheel loader zw180, used hitachi wheel loader, hitachi wheel loaders usa, hitachi 310 wheel loader, hitachi 220 wheel loader, hitachi 140 wheel loader, hitachi 370 wheel loader, hitachi 310 wheel loader specs, hitachi zw140 6 wheel loader specs