-

Your shopping cart is empty!

The Doosan Group - founded in 1896 and headquartered in Seoul, South Korea - is one of the fastest-growing companies in the world:

- With more than 37,500 employees in 38 countries, we are a major player in a variety of industries worldwide.

- A global leader in the Infrastructure Support Business (ISB), with 56 subsidiaries and 3,700 distributors worldwide.

- Dramatic growth over the past two decades, with an annual Doosan Group revenue rising from €2.4 billion in 1998 to €12.8 billion in 2016

- Doosan Infracore: Among the world's Top 5 manufacturers of construction equipment

- Doosan Bobcat: A leading company in the design, manufacture, marketing, distribution and service of small equipment and attachments for construction, agriculture, and landscaping. Leading position in the global compact equipment market. N° 1 in North America for SSL, CTL and MEX.

- Doosan Heavy Industries & Construction: World N° 1 in desalination plant construction, World N° 1 in heat recovery steam generator market, World N° 1 in mould & tool steel, World N° 3 in crankshafts

- Doosan Engineering & Construction: A pioneering leader in construction of residential and public buildings, civil works and industrial facilities. World N° 1 chemical process equipment products

Creating construction equipment for over 40 years. For over 40 years, we've been building a global production and business network to become one of the world’s foremost construction equipment manufacturers.

A solid partner, close to you. A truly global player in every respect, we have large-scale factories, sales subsidiaries and dealers all over the world.

To ensure the highest trade-in and residual values, our parts and service support professionals maintain the performance, productivity and reliability that you expect of our products throughout their lifetime.

As your local specialist, your dealer ensures that you receive the maximum benefit from our integrated package. Plan ahead to ensure the success of your equipment!

- Articulated Dump Trucks

- Doosan Wheel Loaders

- Doosan Wheeled Excavators

- Doosan Mini Excavators

- Doosan Crawler Excavators.

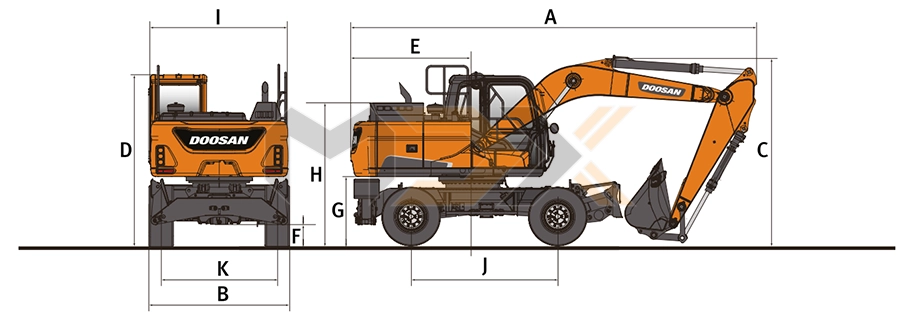

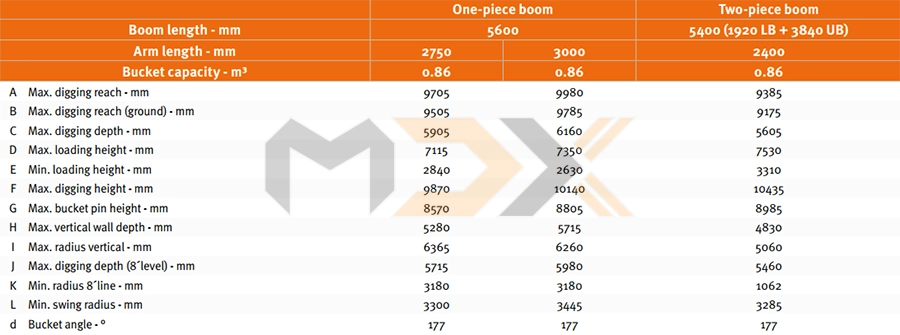

| DEMENSIONS | |

|

|

|

|

|

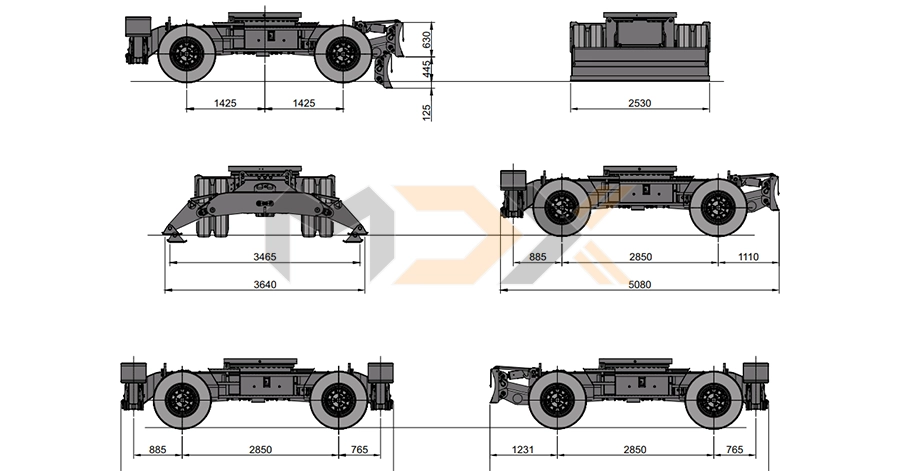

| WORKING RANGE | |

|

|

|

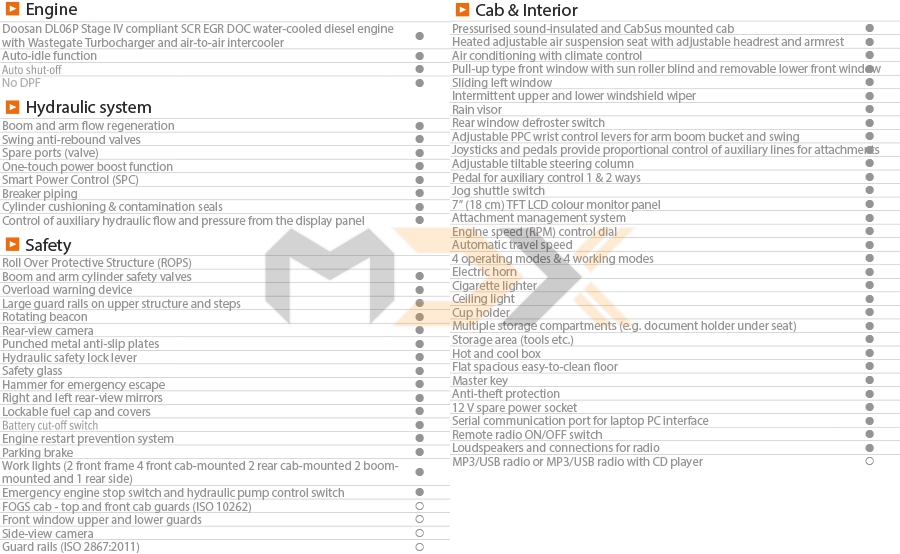

| ENGINE | |

| Designed to deliver superior performance and fuel efficiency the Doosan Stage IV diesel engine fully meets the latest emissions regulations. To optimise machine performance the engine uses high-pressure fuel injectors air-to-air inter-cooler and electronic engine controls. 4-Cycle Water-Cooled Wastegate Turbocharger Exhaust Gas Recirculation (EGR) DOC (Diesel Oxidation Catalyst) and AOC (Ammonia Oxidation Catalytic). | |

| Model | Doosan DL06P |

| No. of cylinders | 6 |

| Rated power at 1900 rpm | |

| (SAE J1995) | 129.4 kW (173.5 hp) |

| (SAE J1349) | 123.2 kW (165.2 hp) |

| Max. torque at 1400 rpm | 82 kgf·m (804 Nm) |

| Idle (low - high) | 800 [±10] - 2000 [±25] rpm |

| Piston displacement | 5890 cm³ |

| Bore × stroke | 100 mm × 125 mm |

| Starter | 24 V × 6 kW |

| Batteries - Alternator | 2 × 12 V 150 Ah - 24 V 80 Ah |

| Air filter | Double element air cleaner and pre-filtered Turbo dust separator |

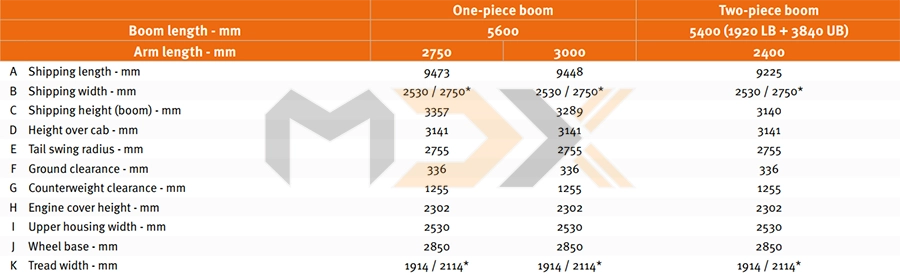

| UNDERCARRIAGE | |

| Extremely robust construction throughout - made of high-quality, durable materials, with all welded structures designed to limit stresses. Heat-treated connecting pins. 10.00-20-16PR (OTR) double tyres with tyre spacer. Heavy-duty front axle with automatic or operator-controlled (on/off/auto) front axle oscillation lock. | |

| Front axle oscillation | +/- 8° with automatic ram lock |

| HYDRAULIC SYSTEM | |

|

The e-EPOS (Electronic Power Optimising System) is the brain of the excavator minimising fuel consumption and optimising the efficiency of the hydraulic system for all working conditions. To harmonise the operation of the engine and the hydraulics the e-EPOS is connected to the engine’s electronic control unit (ECU) via a data transfer link. - The hydraulic system enables independent or combined operations - 2 travel speeds offer either increased torque or high speed - Cross-sensing pump system for fuel savings. - Auto-deceleration system. - 4 operating modes 4 power modes. - Flow and pressure control of auxiliary hydraulic circuits from control panel - Computer-aided pump flow control |

|

| Implement | 38 MPa |

| Travel/Work | 35 / 35 MPa |

| PUMPS | |||

| Pump | Type | Max. flow @ 2000 rpm | Relief valve pressure |

| Main (2) | Parallel bent-axis axial piston | 2 × 236 l/min | |

| Pilot | Gear | 27.4 l/min | 4 MPa |

| Steering | Gear | 69 l/min | 18 MPa |

| Brake | Gear | 22.4 l/min | 15.4 MPa |

| HYDRAULIC CYLINDERS | ||

| High-strength steel piston rods and cylinder bodies. Shock-absorbing mechanism fitted in all cylinders for shock-free operation and extended piston life. | ||

| One-piece boom | 2 | 120 × 85 × 1240 |

| Arm, one-piece boom | 1 | 135 × 95 × 1450 |

| Two-piece boom, lower | 2 | 120 × 85 × 1045 |

| Two-piece boom, upper | 1 | 170 × 105 × 748 |

| Arm, two-piece boom | 1 | 135 × 95 × 1450 |

| Bucket | 1 | 120× 80 × 1060 |

| Blade | 2 | 130 × 80 × 160 |

| Stabilisers | 2 | 130 × 80 × 391 |

| SWING MECHANISM | |

|

The swing mechanism uses an axial piston motor driving a 2-stage planetary reduction gear bathed in oil for maximum torque. - Swing bearing: single-row shear type ball bearing with induction hardened internal gear - Internal gear and pinion immersed in lubricant - Increased swing torque reduces swing time - The swing brake for parking is activated by spring and released hydraulically |

|

| Maximum swing speed | 9.8 rpm |

| Maximum swing torque | 6387 kgf·m |

| DRIVE | |

| The wheels are driven by an bent axial piston engine via a two-speed powershift transmission. In addition to the two-speed powershift transmission there is also an economy mode and a switch for the creep speed. A button makes it possible to pass from high to low in work mode. Two travel speed ranges offer a choice between increased torque or high speed | |

| Travel speed (creep / low / high) | 4 - 9 - 35 km/h |

| Maximum traction force | 12 ton |

| Minimum turning radius | 7.2 m |

| Gradeability | 65% (33°) |

| FLUID CAPACITIES | |

| Fuel tank | 300 l |

| Cooling system (radiator) | 24 l |

| Hydraulic oil system | 205 l |

| Engine oil | 25 l |

| Swing drive | 5 l |

| Front axle hub | 2 x 2.5 l |

| Rear axle hub | 2 x 2.5 l |

| Front Axle Case | 11 l |

| Rear Axle Case | 14.5 l |

| Transmission | 2.5 l |

| Urea tank | 31.5 l |

| CABIN | |

| ROPS cab large and roomy interior. Travel pedal with FNR switch on the right joystick. Audio system with remote control independently adjustable joystick consoles. Excellent all-round visibility transparent roof hatch 2-piece sliding door window narrow and easily adjustable steering column. The removable lower front glass can be stored behind the seat. Interior lighting. The pressurised and filtered cab air is supplied by numerous vents. Climate-control provides fast defrosting and high cooling and heating performance. Viscous/spring mounted suspension cushions reduce vibrations. Heated air suspension seat with adjustable seat suspension height tilt recline and forward-backward settings. Adjustable easy to read 7 LCD colour monitor provides real-time information on machine functions and diagnostic information and is switchable to rear view camera (std) and side view camera (optional). | |

| A-weighted emission sound pressure level at the operator’s position LpAd (ISO 6396:2008) | Declared : 72 dB(A) |

| A-weighted sound power level LwAd (2000/14/EC) | Guaranteed : 102 dB(A), Measured : 99.8 dB(A) |

| Note - Declared single-number noise emission values are the sum of measured values and the associated uncertainty and they represent upper boundaries of the range of values which is likely to occur in measurements. | |

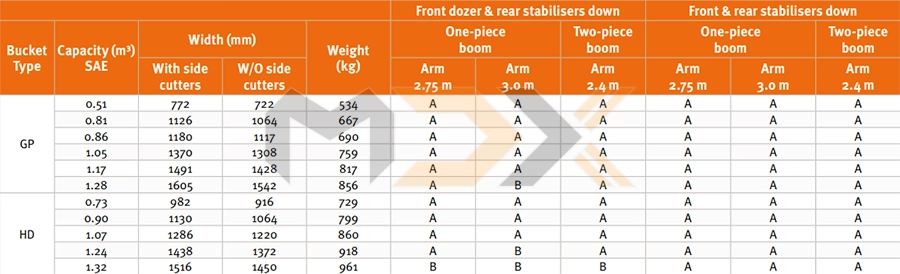

| BUCKETS | |

|

|

|

A: Suitable for materials with a density less than or equal to 2100 kg/m³. B: Suitable for materials with a density less than or equal to 1800 kg/m³ C: Suitable for materials with a density less than or equal to 1500 kg/m³ D: Suitable for materials with a density less than or equal to 1200 kg/m³ Based on ISO 10567 and SAE J296 arm length without quick-coupler. For reference only |

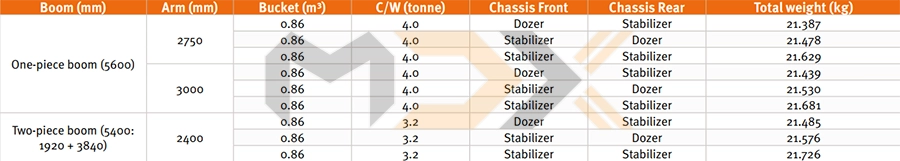

| WEIGHT | |

|

|

| + 100 kg for wide axles versions |

Raise profits, productivity & fuel efficiency |

||

|

High productivity & low cost of ownership Delivers higher productivity & reduced fuel consumption in an efficient & comfortable work environment. Reliability: Reinforced castings and forged steel pivot points and reinforced heavy-duty arm and boom to withstand high-impact materials. Large, robust boom and arm cylinders for smooth, powerful operation. Advanced pin & bushing technology. Productivity: State-of-the-art bucket and arm digging forces. Plug & play: Machine Guidance options available with major brands' ready kits (Trimble, Leica, Xsite etc.) and can differ by model and region. ̮Safety: Rear camera and large side mirrors, powerful lighting, & anti-slip steps and platforms. Guard rails on upper structure. Special applications: Two-piece boom and dozer blade configurations are ideally suited for special applications. Additionally, rubber pads are available as option Easy-to-use attachments: Set flow & pressure of the auxiliary lines directly from the control panel. Additionally, 10 pre-sets are available to record specific settings. Comfort: One of the most spacious cabs in the market, with low noise & vibration levels and excellent all-round visibility. Fully adjustable heated air suspension seat, air conditioning with climate control as standard. ̮Controllability: Exclusive jog shuttle switch, 4 work & 4 power modes, proportional control, user-friendly 7” TFT LCD colour monitor. Power: Exceptionally powerful - with high torque at low revs - the Stage IV compliant Perkins engines are free from Diesel Particulate Filter (DPF) and associated regeneration system for more fuel efficiency Efficient fuel management: A new SPC (Smart Power Control) system, combined with settable engine shut-off, provides an additional reduction of up to 3%. Electric fan clutch: For optimum cooling, fan speed is controlled electronically by a fan clutch, resulting in lower fan noise and better fuel efficiency. Advanced filtration: Highest efficiency filters & cleaners remove water, dust & particles to protect your investment optimally ̮Easy maintenance: Easy access to all compartments. Maintenance data directly available from control panel. Undercarriage durability: Forged steel and deephardened top rollers – oil-lubricated rollers – heattreated sprockets – deep-hardened, heat-treated, grease lubricated & longer life track chains. Rubber pads: Ideal for urban applications with their low ground disturbance, rubber pads are available as option. |

Top performance and fuel efficiency |

|

The power to raise productivityDoosan DX210W-5 takes even the heaviest tasks in its stride with efficient, dependable performance that saves you time and money: - Improved hydraulic system uses the engine power more effectively, maximising pump output and offering more comfort, smoothness and accuracy - Increased digging power, lifting capacities and traction force combine for performance you can rely on, day after day - Greater fuel efficiency means you can keep costs down and reduce environmental impact |

OPTIMISED POWER MANAGEMENTDoosan Wheel Excavator DX210W-5 is equipped with a Perkins engine. Famous for excellent fuel efficiency, reliability and long service life, it combines exceptional power output and high torque at low revs. Engine is fitted with common rail fuel injection combined with an wastegate turbocharger which increases the density of the air enabling the engine to produce more power. Selective Catalytic Reduction (SCR) technology - combined with a Diesel Oxidation Catalyst (DOC) - ensures compliance with Stage IV regulations. As there is no need for a particulate filter, there is no need for regeneration. If the engine is the heart of the excavator, the e-EPOS is its brain - providing a perfectly synchronised communication link between the engine’s ECU (Electronic Control Unit) and the hydraulic system. A CAN (Controller Area Network) system enables a constant flow of information between engine and hydraulic system, so that power is delivered exactly as needed. |

EFFICIENT FUEL MANAGEMENTChoice between 4 power modes and 4 working modes guarantees optimum performance in all conditions SPC (Smart Power Control): reduces engine RPM during low load demand & ensures pump torque control, thus ensuring fuel efficiency and low emissions Engine auto-shut-off: shuts down the engine after the machine has been idling for a specified time Electronic control of fuel consumption optimises efficiency Auto-idle function saves fuel Eco guidance in real time: eco gauge provides information about fuel consumption relative to machine performance in real-time. By trying to keep the right-hand LED bar from rising, the operator can teach himself how to save fuel and work efficiently For optimum cooling, fan speed is controlled by a viscous clutch resulting in a lower fan noise & better fuel efficiency |

|

Wastegate turbocharger: Allows diverting of exhaust gases away from the turbine wheel to better regulate max boost pressure & protect engine. It also results in less lag time before turbo begins to spool/create boost maximizing torque, plus reduce wear in high rpm & low load conditions. Turbocharger increases the density of the air, enabling the engine to produce more powerwith few effects from altitude. Electronic viscous fan clutch: For optimum cooling, fan speed is controlled electronically by a fan clutch, resulting in lower fan noise and better fuel efficiency. |

Operating in comfort |

|

Best-in-class operator environmentDoosan DX210W-5 are powered by industry-leading engines that save on fuel and meet the latest Stage IV European regulations in addition to all noise regulations. The low levels of cab vibration and noise provide exceptional operator comfort - and the cab air is filtered to ensure a healthy work environment. Straight travel pedalFor straight machine movement – ensures comfort during on hill operation or front equipment combined movements such as boom/arm or boom/swing. Two-way proportional pedalFor maximum comfort when operating attachments - operator can easily set his preference in the control panel to operate with the rollers on joystick or with the pedal. |

|

|

- Large sun roof - Sun visor - Storage compartment for sunglasses - Window grip - Hot/cool box - Upper front window is strut-assisted for easy, reliable adjustment and integrates a sun shade - Photo sensor detects radiant energy from the sun and adjusts temperature automatically - Improved visibility on the bottom right - Joysticks and switches are integrated in adjustable control consoles - Separate seat height adjustment lever and cushion tilting function - Pedal for auxiliary control 1 & 2 ways - Straight ergonomic pedals - Flat, spacious, easy-to-clean floor - Engine emergency stop switch - Two-piece boom or straight travel pedal |

The highest standards of efficiency at your fingertipsThe advanced & user-friendly technologies are just some of the many advantages of this generation. The ergonomic controls and the easy-to-view colour monitor place the machine firmly in your hands. - The new multi-function 7" TFT LCD monitor displays a comprehensive range of useful technical information, allowing you to check the machine’s status and settings at a glance - Highly sensitive & low-effort joysticks and clear convenient controls enable you to work safely, smoothly & confidently with minimum effort for increased comfort, efficiency and production - Doosan’s unique jog shuttle switch gives you easy, precise control over all machine functions - Proportional auxiliary flow means precision control, smoothness & efficiency when using attachments |

|

TFT LCD colour monitor panelThe upgraded 7” Thin-Film-Transistor (TFT is a technology that improves image quality) LCD panel features a day and night display. The userfriendly monitor gives full access to machine settings and maintenance data. Any abnormality is clearly displayed on the screen, allowing you to work safely and confidently with an accurate overview of all conditions. All functions are totally controllable, directly via the screen or using the exclusive jog shuttle switch. 1. Fuel consumption level: current, total & daily average fuel consumption 2. Fuel level 3. AdBlue® level 4. Eco symbol: changes colour when operating conditions change (idle, normal or loading) 5. Eco gauge: shows the average fuel efficiency 6. Engine coolant and hydraulic oil temperatures 7. Warning symbols 8. New shortcut menu: displayed on the right for rapid access to main functions 9. Optional anti-theft password-controlled starting 10. Filter oil information 11. Attachment management: stores up to 10 different attachment presets, enabling the operator to set hydraulic flow & pressure according to his needs Dynamic power managementAutomatic travel speed function Activating the power boost control system increases digging force by 10% A one-touch deceleration button immediately reduces engine speed to low or idle Auto-idling starts 4 seconds after all controls are returned to neutral - decreasing fuel consumption and reducing noise levels in the cab Intelligent floating boom mode (optional).The "intelligent floating boom" function allows the boom to move up & down freely according to application: Hydraulic breaker setting: during boom down operation the boom moves down freely under its own weight, which reduces vibration, stress on the machine & increases breaker life Fully floating mode: during boom down selection the boom is allowed to rise & fall as required while the bucket is drawn across the ground 4 Work modes & 4 Power modesDeliver the needed power according to your specific application while minimising fuel consumption: 1-way mode, 2-way mode, Digging mode and Lifting mode Power-plus mode, Power mode, Standard mode, Economy mode |

|

|

Tags: Doosan DX210W 5, Doosan DX190W 5, Doosan DX165W 5, Doosan DX160W 5, Doosan DX140W 5, Doosan DX530LC 7, Doosan DX490LC 7, Doosan DX350LC 7, Doosan DX300LC 7, Doosan DX255LC 5, Doosan DX235LC 5, Doosan DX180LC 5, Doosan DX160LC 5 HT, Doosan DX140LCR 5, doosan DX140LC 5, Máy đào bánh xích DOOSAN DX140LC 5, máy đào, máy đào bánh xích, xe đào bánh xích, máy đào bánh xích chính hãng, máy đào bánh xích cũ, máy đào bánh xích đã qua sử dụng, xe đào bánh xích mới, xe đào bánh xích cũ, máy đào bánh xích hiatchi, máy xúc đào, xe đào bánh xích đồng nai