Innovative paving technology can come in compact packages, as Vögele Super 1603-3 proves. A member of the “Dash 3” paver family, it is one of the most advanced wheeled pavers in its class.

Naturally, this compact powerhouse benefits from all the “Dash 3” features. The Vögele EcoPlus package, for instance,significantly reduces both fuel consumption and noise levels. In addition, Vögele‘s ErgoPlus operating system has been supplemented by numerous ergonomic and functional features. The paver operator‘s console, for example, comes with a particularly large colour display which provides brilliant readability even in poor lighting conditions. In addition, the convenience functions AutoSet Plus and PaveDock Assistant make work with Vögele Super 1603-3 wheeled paver even easier.

With its compact dimensions and an extremely small outside turning radius thanks to the Pivot Steer steering brake, S1603-3 wheeled paver is particularly manœuvrable and hence suitable for a wide range of applications. It is the perfect paver in the Universal Class pavers.

| Screed | Type | Basic Width | Maximum Width | Compacting Systems |

| AB 500 (More) | 2.55 m | 7 m | TV | |

| Layer thickness (up to) | 30 cm | |||

| Heating | electric, thermostat-controlled | |||

| Power Supply | Three-phase AC generator | |||

| DIMENSIONS AND WEIGHT |

||

| Operating weight | Screed | Total weight |

| AB 500 TV | 17 500 kg | |

| Length | Screed | Total length |

| AB 500 | 6.04 m | |

| Maximum laydown rate | 600 t/h | |

|

|

| Wheeled Universal Class paver with a large range of applications and pave widths up to 7m | Powerful and economical drive concept with Vögele EcoPlus, the low-emissions package from Vögele |

| Maximum power transmission thanks to separate, hydraulic drives provided for both rear wheels and optional all-wheel drive (6x6) | Optimum feeding with mix thanks to the large material hopper and PaveDock Assistant communication system |

| Significantly smaller turning radius due to Pivot Steer steering brake | Easy operation with the ErgoPlus 3 operating system with numerous convenient and automatic functions |

Efficient and eco-friendly drive concept |

|

|

Vögele‘s modern drive concept guarantees full power whenever it is needed and superior technology makes this Universal Class paver exceedingly economical in everyday use. This is assured by intelligent motor management with ECO mode and the low-emissions package Vögele EcoPlus. Fuel consumption and noise levels of Vögele Super 1603-3 have been significantly reduced. The high-traction wheeled undercarriage of Vögele Super 1603-3 wheeled paver is also available on request with all-wheel drive (6x6). It offers an ideal combination of high paving performance and maximum mobility uring transport. |

Modern drive technologyThree main components define the power unit of Super 1603-3 wheeled paver: its modern, liquid-cooled diesel engine, a splitter gearbox flanged directly to the engine and a large cooler assembly. The driving force in this power pack from Vögele is its diesel engine. The four-cylinder engine delivers 116kW at 2,000rpm. Yet the uel-saving ECO mode is sufficient for many applications. And even then, Vogele S1603-3 paver still has a full 106kW at its disposal. Moreover, the machine generates even less noise when running at just 1,700rpm. A large cooler assembly ensures that the power unit always delivers its full output. With innovative air routing and a variable-speed fan, temperatures are continually maintained within the optimum range, significantly extending the service life of both the diesel engine and the hydraulic oil. A further advantage is that the machine can operate without difficulty in all climate regions worldwide. All hydraulic consumers are directly supplied with hydraulic oil via the splitter gearbox. Hydraulic pumps and valves are centrally located, making them optimally accessible for servicing. Even the powerful generator for screed heating is flanged directly onto the splitter gearbox, making it completely maintenance-free |

|

|

The large cooler assembly is made up of three parts. It ensures that engine coolant, charge air and hydraulic oil are maintained at the optimum temperature. Powerful diesel engine develops 116kW at just 2,000rpm. ECO mode for paver operation with 106kW at 1,700rpm is perfectly adequate for numerous applications. It cuts operating costs and allows superquiet operation. A powerful, air-cooled generator with direct drive ensures rapid, uniform heating of the screed |

Vögele EcoPlus: Less is moreIt goes without saying that our road pavers conform to the applicable emissions directives, but we like to go much further. That’s why the machine concept of the “Dash 3” generation uses environmentally friendly innovations in machine technology, resulting in lower consumption, lower emissions and lower costs. One of these innovations is the Vögele EcoPlus low-emissions package. Fuel savings of up to 25% can be achieved with Vögele EcoPlus, depending on the application and capacity utilization of the paver. That doesn’t just result in considerable savings for the contractor – it is good news for the environment, too. That’s because every litre of fuel saved reduces carbon dioxide (CO2) emissions. |

|

|

Splitter gearbox with ability to disengage hydraulic pumps When the paver is stationary, all the hydraulic pumps needed for “traction”, “conveyors and augers” and “compaction” are disengaged automatically. The result? Lower fuel consumption. Controlled hydraulic oil temperature circuit A bypass circuit gets the hydraulic oil to its optimum operating temperature very quickly, enabling rapid, fuel-saving operation of the paver Variable-speed fan The variable-speed fan automatically adapts to the engine load and the ambient temperature. This type of drive saves energy and reduces noise emissions. |

Mobility on wheelsWith its high tractive power, Vögele Super 1603-3 perfectly combines high paving performance with maximum mobility hen travelling. This is assured by powerful separate hydraulic drives in the powered wheels. They ensure maximum traction when paving and travelling on public roads at speeds of up to 20km/h. The paver operator can activate Pivot Steer whenever maximum manœuvrability is required |

|

|

Extreme manœuvrability thanks to Pivot Steer: The rear inside wheel is automatically slowed down hydraulically when Pivot Steer is activated. This minimizes the outside turning radius to not more than 3.5mfor positioning manœuvres and paving. Rapid transport under its own power at up to 20km/h - a feat Super 1603-3 paver is optimally equipped for. All paving functions are automatically deactivated when “Road Travel” mode is selected. In addition, the paver is equipped with the approved lighting for public traffic. As a result, this paver like all other wheeled pavers from Vögele meets the basic requirement for driving on public roads. Maximum power transmission thanks to separate, hydraulic drives provided for both rear wheels. Optionally, an additional two (6x4) or four front wheels (all-wheel drive 6x6) can be driven. Optimum traction is assured, even on difficult terrain, by electronic traction management and an electronic differential lock acting on the drives of the rear wheels. Continuous ground contact is assured by a front axle which oscillates both lengthwise and crosswise. In other words, the front axle is only firmly connected to the chassis at one point; in combination with the rigidly suspended rear wheels, this creates a static 3-point support. |

Large material hopper, easy feed with mixAs with all Vögele pavers, supplying Vögele Super 1603-3 with mix is a clean, safe and swift process. Thanks to a hydraulically operated hopper front (option), the mix inside the material hopper is directed right onto the conveyors and the entire mix properly conveyed in front of the screed |

|

|

The large material hopper holding 13t is amply dimensioned so that a sufficient quantity of mix is stored at all times. There is no problem tiding over difficult situations such as paving under bridges, for instance. Easy feeding with mix thanks to low material hopper, wide hopper sides and sturdy rubber baffles fitted to the hopper front. Especially large oscillating push-rollers for convenient and shock-free docking of feed vehicles even in curves. |

Perfect conveying and spreading of mix - The basis for perfect pavement qualityThanks to the perfect spreading of mix, Vögele Super 1603-3 wheeled paver provides for an optimal head of material in front of the screed in every paving situation. Powerful, separate hydraulic drives for conveyors and augers are installed achieving high laydown rates up to 600t/h |

|

|

The height of the auger complete with bearing boxes and limiting plates for the auger tunnel can be hydraulically adjusted by up to 15cm across the full pave width. This optimizes the head of mix in front of the screed, even when paving thin layers or when layer thickness varies. Proportional control and continuous monitoring provided for conveyors and augers guarantee a constant head of mix in front of the screed in line with requirements. Large diameter of auger blades (400mm) for excellent spreading of mix when paving in large widths. An auger tunnel, easily variable in depth, provides for an optimal flow of mix when large quantities are being laid |

AutoSet Plus Repositioning function |

|

AutoSet Plus is especially helpful when the machine frequently has to be moved on the job site. Simply pressing the “Execute” button raises the augers, the hydraulically operated hopper front and the deflectors in front of the crawler tracks to the uppermost positions. The screed and the screed tow point rams are brought into transport position. In addition, the screed is locked hydraulically in transport position. The conveyors are temporarily reversed, preventing mix from falling to the ground when the paver travels to the next work section on site. Once the paver has been repositioned, pressing the “Execute” button again returns all systems to the previously stored working positions. This ensures that no settings are lost when changing from paving to repositioning or transport. It also effectively prevents any damage to the machine. 1. The AutoSet Plus Repositioning function is activated just by pushing the “Execute” button. 2. Raise/lower screed. 3. lock/unlock screed. 4. Screed tow point rams in transport position/at last set value. 5. Raise/lower augers. 6. Conveyor movement reversible for a short time. 7. Raise/lower deflectors in front of the crawler tracks. 8. Raise hopper front. |

|

AutoSet Plus Paving Programs |

|

|

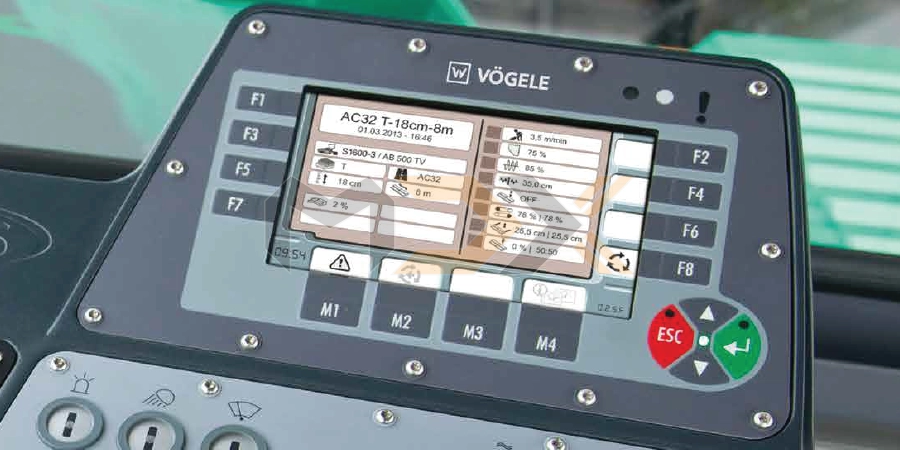

The automatic Paving Programs function allows the operating personnel to store their own paving programs. All key parameters for paving a specific layer (example: base course of asphaltic concrete, 18cm thick) can thus be saved. On the display of his console, the paver operator saves the values set for the compacting systems (tamper and vibrator speed), height of the augers, position of the tow point rams, pressure for Screed Assist and the pave speed in his program. He also enters the amount of crown and the screed temperature. The program is completed with additional information on the material being used, the layer thickness and the pave width. The stored paving programs can subsequently be selected and used at any time via the menu. In the event of a repeat situation, this ensures that work is carried out with exactly the same settings while maintaining a consistent quality. |

The ErgoPlus 3 operating conceptEven the very best machine with the most advanced technology can only really show its strengths if it can be operated easily and as intuitively as possible. At the same time, it should offer an ergonomic and safe working environment for the operating team. Therefore, the ErgoPlus 3 operating concept focuses on the operator. With Vögele pavers, the user consequently retains full control over the machine and construction project. On the following pages example illustrations will provide you with more detailed information on the extensive functions of the ErgoPlus 3 operating concept. ErgoPlus 3 encompasses the operator’s stand, the paver operator’s console and screed consoles and Niveltronic Plus, the System for Automated Grade and Slope Control |

|

The paver operator‘s ErgoPlus 3 consoleThe paver operator‘s console is extremely clear and has been designed according to practical principles. All functions are combined into logical groups, so that the operator finds each function exactly where he would expect it to be. On the ErgoPlus 3 console, all push-buttons are easily identifiable by touch even when wearing work gloves. Once a button is pressed, off you go thanks to the “Touch and Work” principle. This means that a function is executed directly without a need to confirm |

|

|

Lighting for travelling on public roads As a standard feature, all Vögele wheeled pavers are equipped with a lighting system approved throughout Europe for travelling on public roads. The push-buttons for indicating direction, warning lights, dipped lights and full beam are clearly arranged side by side on the paver operator‘s console. Pivot Steer The Pivot Steer steering brake can be switched on with a simple push of a button in the “Positioning” and “Pave” modes. When it is activated, the speed of the rear inside wheel is automatically slowed down hydraulically when a steering movement is carried out. This reduces the turning radius to a minimum. AutoSet Plus Repositioning function (option) With the AutoSet Plus Repositioning function, the paver is quickly and safely prepared for a move on the job site at the push of a button. After the move, all paver components are reset to their previous working positions, simply by pressing the button again. This ensures that no settings are lost when changing between “Pave” and “Job Site” modes. AutoSet Plus also effectively prevents damage during transport. Choice of operating modes for the paver All the main paving and machine functions can be controlled directly by individual push-buttons on the paver operator’s ErgoPlus 3 console. By pressing the arrow buttons, up or down, the operator changes modes in the following order: “Neutral“, “Job Site“, “Positioning“ and “Pave“. An LED indicates the mode selected Safe operation during the night Glarefree backlighting comes on automatically as darkness sets in so that the paver operator can also work safely on night-time jobs Display of the paver operator‘s console The high-contrast colour display provides for brilliant readability even in poor lighting conditions. Vital information is shown on menu level 1, such as the positions of the screed tow point rams or the material level in the conveyor tunnel. Further paver functions such as speeds of tamper and vibrators or feed rate of the augers can easily be set up via the display, too. And the display gives access to machine-related information such as fuel consumption or service hours. Pavedock Assistant (option) With the PaveDock Assistant signal lights, the paver operator can give the driver of the feed vehicle unmistakable signals, indicating what needs to be done (e.g. reverse, stop, dump mix). The lights are conveniently activated directly from the paver operator’s ErgoPlus 3 console. Choice of engine speed ranges For the engine, there is a choice of three modes to select from: MIN, ECO and MAX. To switch modes for engine rpm, all the operator needs to do is press the arrow buttons, up or down. In ECO mode, the engine delivers sufficient power for a great number of paving applications. Operating in ECO mode reduces noise emissions and fuel consumption considerably Screed Assist (option) This button switches Screed Assist on (LED lights up) or off. Screed Assist pressure and balance can be set via the display. Screed Assist is active only when the screed is floating. |

The ErgoPlus 3 screed consoleThe screed is crucial for pavement quality. Therefore, easy and positive handling of all screed functions is of the utmost importance for high-quality road construction. With ErgoPlus 3, the screed operator has the process of paving at his fingertips. All functions are easily comprehensible and all controls are clearly arranged. |

|

|

The screed console The screed console is designed in keeping with the conditions prevailing on the job site. Push-buttons are provided for the frequently used functions operated from the screed console. These are watertight and enclosed in palpably raised rings, so that they are identifiable blindfold simply by touch even when wearing work gloves. Important paver and screed data can be called up and adjusted from the screed console, too. The display of the screed console The display of the screed console allows the screed operator to control and monitor both the left and the right side of the screed. Machine-related parameters such as tamper speed or conveyor speed can be adjusted conveniently via the display panel of the screed console. The clear menu structure, combined with easily understandable, self-explanatory symbols neutral in language, makes operating the display panel both simple and safe. Crown adjustment at the press of a button The crown can be conveniently adjusted at the press of a button on the screed operator‘s console. When pressing the “plus” or “minus” keys, the set crown value is shown on the display. Ergonomic screed width control in two speeds The screed width can be effortlessly adjusted by means of the SmartWheel. This is done in two speeds: slow, for precise control e.g. along an edge, or fast, for rapid extension or retraction of the screed. Optimum visibility even in darkness The screed console is specially designed for night-time operation. To prevent operator errors, the buttons are backlit as soon as dusk falls or in darkness. What‘s more, the downward-angled high-power LED lighting gives the operator a perfect view of all processes associated with the side plate |

|

|

Vögele Niveltronic Plus Niveltronic Plus, the System for Automated Grade and Slope Control, is an in-house development by JOSEPH VÖGELE AG based on many years of experience in grade and slope control technology. Easy operation, precision and reliability are its hallmarks, ensuring perfect mastery of all grade and slope control jobs. This fully integrated system is optimally adapted to the machine technology of the SUPER pavers. All wiring and connections, for instance, are integrated into the tractor unit and screed, effectively eliminating all risk of damage to these components. Vögele naturally offer a particularly large and practical selection of sensors permitting versatile use of the Niveltronic Plus system. Whether car parks, roundabouts or highways need to be built or rehabilitated, Vögele offer the right sensor for every job site situation. Sensors can be changed quickly and easily, for Niveltronic Plus automatically detects which sensor is connected, thus simplifying the configuration process for the user. |

|

The ErgoPlus 3 operator‘s stand1. The comfortable operator‘s stand gives an unobstructed view of all crucial areas on the paver such as material hopper, steering guide or screed. 2. The seats swinging out to the sides and an operator‘s stand of streamlined design provide for maximum visibility of the auger tunnel, permitting the paver operator to keep an eye on the head of mix in front of the screed at all times. 3. Working comfort The paver operator’s seat and console, as well as the screed consoles can now be adjusted even more easily to personal needs. 4. A place for everything and everything in its place The operator‘s stand, with its streamlined design, is well organized, offering the paver operator a professional workplace. The operator’s console can be protected by a shatter-proof cover to prevent wilful damage. 5. Hardtop gives excellent protection The modern hardtop made of glass fibre-reinforced polymer material shelters the operator, come rain or shine. 6. Consistent service concept All “Dash 3” pavers have a consistent maintenance concept with identical service intervals. 7. Safe and comfortable ascent The walkway and comfortable middle ascent on the screed ensure safe and convenient access to the operator platform. 8. Ergonomic screed console The height and position of the console are easily adjusted. The high-contrast colour display can be read clearly from all angles. |

Tags: S1303 3, Wheeled Paver, Vögele paver, Vögele super 700, asphalt paver machine, asphalt paver price, asphalt paver parts, small asphalt paver, mini asphalt paver, volvo asphalt paver, caterpillar asphalt paver, tracked paver, asphalt paver, wheel asphalt paver, asphalt paver specs, asphalt paver machine specifications, cat paver