Screeds apply the mix to the road, profile it and compact it. Their technology is critical for the quality and durability of a road, which is why VÖGELE has been heavily committed to investing in the further development of screeds for decades now. The result is a wide range of especially powerful extending and fixed-width screeds to provide the required flexibility for any road construction job.

VÖGELE extending screeds are particularly adaptable, making them ideal for paving varying widths and winding roads. They cover a huge range of applications, handling pave widths from 0.5 m to 9.5 m. They can be equipped with various compacting systems depending on the type of paver used. The screed versions range from the simplest design with vibrators (V) to the most powerful high compaction screeds with tamper (T) and 2 pressure bars (P2).

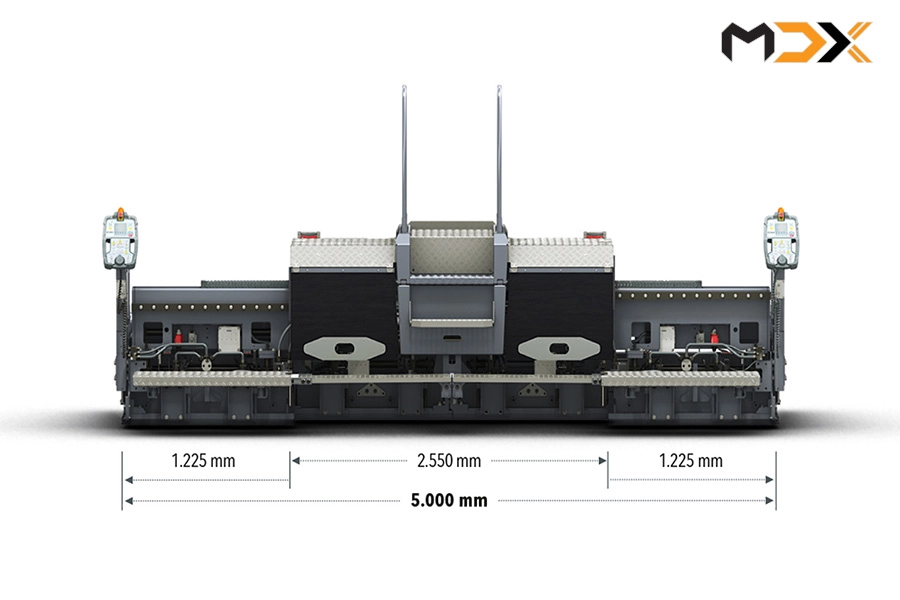

With a basic width of 2.55 m, Voegele AB 500 is the universal tool for all VÖGELE pavers of the Premium Class. Its infinitely adjustable single-tube telescoping system covers a wide range of applications from 2.55 m to 5 m and with bolt-on extensions, it extends to a maximum width of 8.5 m.

Extending Screed AB 500 is available with tamper and vibrators, as well as in two versions for high compaction - with tamper and optionally 1 or 2 pressure bars or, alternatively, in the TP2 Plus version for particularly high compaction.

The highlights of extending screeds

- Ergonomic screed operator's console: The height and orientation of the console are easy to adjust. The high-contrast colour display can be read clearly from all angles.

- Safe, convenient screed step: The walkway and convenient central step on the screed allow safe, convenient access to the paver operator's platform.

- Hydraulic crown adjustment: Crown can be conveniently adjusted at the touch of a button on the screed operator’s console.

- Outstanding paving characteristics: Optimized geometry of the tamper bar and the screed plates achieves particularly stable floating behaviour of the screed.

- Highly efficient screed heating: The modern three-phase AC generator rapidly heats all the components of the screed to the ideal operating temperature.

|

||

| Pave widths | ||

| Basic width | 2.55 m | |

| Hydraulically adjustable | 2.55 m to 5.00 m | |

| Maximum pave width | 8.5 m | |

| Minimum pave width | 2.55 m | |

| Bolt-on extensions | Length | |

| 25 cm | ||

| 75 cm | ||

| 125 cm | ||

| Profiles settings | ||

| Version | hydraulic | |

| Crown adjustment | -2.5 % to 5 % | |

| Height adjustment, extending units | -20 mm to 25 mm | |

| Slope, extending units (max.) | 2 % | |

| Compacting systems | ||

| Pressure bars (P) | ||

| Pressure bar drive (P) | pulsed hydraulic | |

| Hydraulic oil pressure (max.) | 120 bar | |

| Pressure bar pulse frequency (P) (max.) | 68 Hz | |

| Tamper (T) | ||

| Speed (max.) | 1,800 U/min | |

| Stroke (TP1, TP2) | 2 mm, 4 mm, 7 mm | |

| Stroke (TP2 Plus) | 4 mm, 7 mm, 9 mm | |

| Stroke (TV) | 4 mm | |

| Vibrators (V) | ||

| Frequency (max.) | 50 Hz | |

| Compacting systems | TV, TP1, TP2, TP2 Plus | |

| Vibrators (V) | eccentric vibrators | |

| Screed heating | ||

| Heating rods | on screed plates and in tamper bars | |

| Output generation | three-phase AC generator | |

| Optional screed heating | function monitoring of each individual heating rod | |

| Control | fully automatic, thermostat-controlled | |

| Dimensions and weights | ||

| Width (with side plate) | 2.55 m | |

| Basic screed weight | Screed | Weight |

| TV | 3 250 kg | |

| TP1 | 3 600 kg | |

| TP2 | 3 900 kg | |

| TP2 Plus | 4 220 kg | |

| Depth (in transport position) | Screed | Depth |

| AB 500 TV | 1.28 m | |

| AB 500 TP | 1.41 m | |

VÖGELE sets standards in compaction values during paving: cutting-edge technology and the most advanced materials guarantee the outstanding performance and reliability of VÖGELE compaction technology. This applies to all VÖGELE compacting systems, from vibrators all the way to the VÖGELE high compaction system with tamper and pressure bars.

This consists of the compacting systems tamper and vibrators and is already delivering convincing compaction values which are exceeded only by the VÖGELE high compaction system with pressure bars.

V is for vibrators: for optimum grain size distribution in the pavement

An eccentric vibrator makes the screed plate and frame vibrate to ensure optimum grain size distribution in the mix. This is a prerequisite for achieving a pavement with a particularly smooth surface texture. Just as with the tamper, vibration power can be controlled from the ErgoPlus screed console via the speed of the drive shaft.

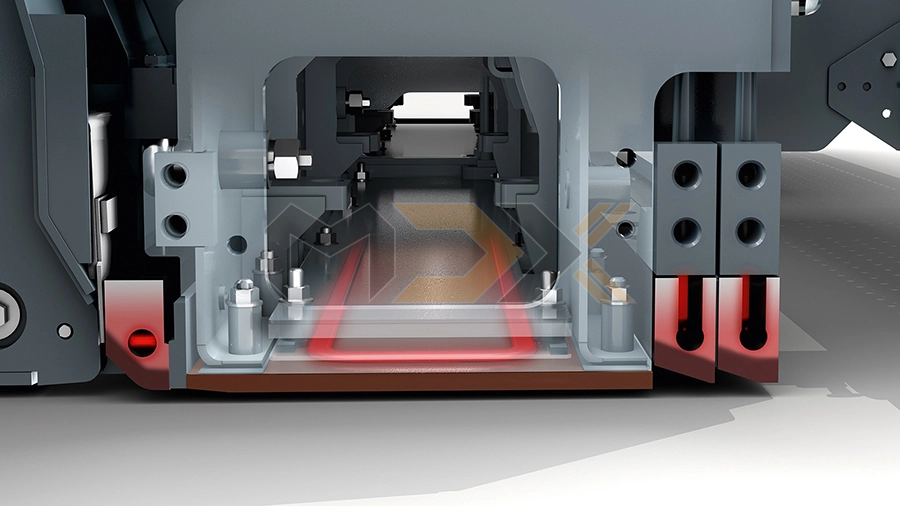

T is for tamper: compaction with a precisely adjustable stroke

A correctly-set tamper is of key importance for the compaction result and for the floating behaviour of screeds. To this end, speed on all VÖGELE screeds can be adjusted accurately and easily.

SB 300 and SB 350 Fixed-Width Screeds, together with the two large AB 500 and AB 600 Extending Screeds in the high compaction variants, also feature tamper stroke adjustment. This allows the tamper to be adjusted perfectly to suit the quantity and type of mix and the thickness of the pavement. Hydraulic tamper-stroke adjustment is even available as an option on fixed-width screeds.

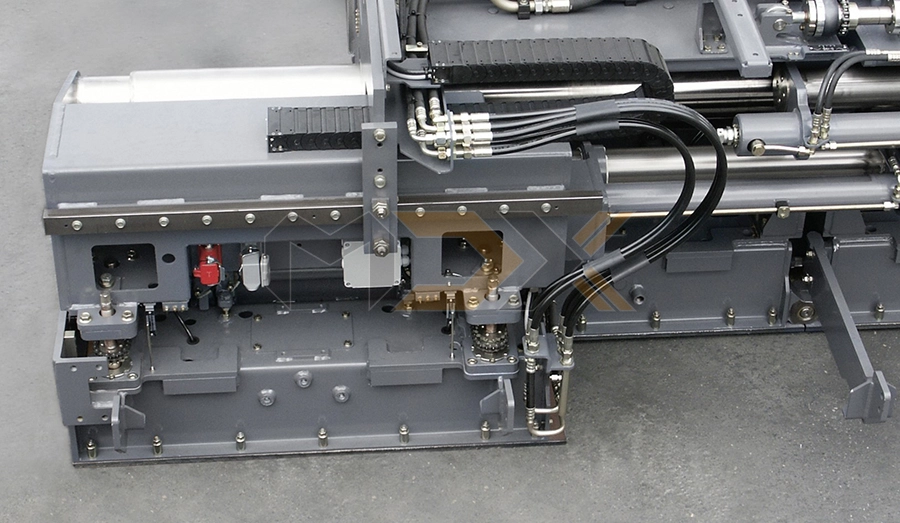

The operating principle of all VÖGELE extending screeds is the single-tube telescoping system. Even at maximum extension, half of the three-part, generously-sized telescoping tube is clamped, ensuring optimum stabilization. As the telescoping system is arranged at a high level, this prevents any contact with paving mix.

The 3-point support in VÖGELE extending screeds means that torsional forces acting on the hydraulic extensions as a result of the pressure of the mix do not have a negative influence on the telescoping system. The point at which the telescoping tube is attached, the bearing for the telescoping tube and the torque restraint system all absorb the forces acting here, guaranteeing strain-free extension and retraction of the hydraulic extensions – without any kind of tilting or jamming.

Adjust pave width accurately

The 3-point support, an especially resilient part, combines with low-wear sliding bearings inside the telescoping tubes for gentle, smooth adjustment of pave width.

VÖGELE has put its faith in electric screed heating for decades. This extensive experience, in combination with continuous further development, means that VÖGELE screeds are now brought to temperature quickly and evenly.

Quick to reach temperature, efficient in operation

During paving, the intelligent generator management system ensures that regardless of engine speed, the generator output required for an optimum temperature of the full pave width is always available – whether the machine is being operated with or without bolt-on extensions. This reduces both the energy required and fuel consumption.

For an even surface structure

The heating elements of the screed heating work where heat is required: at the point of contact with the material. Maximum insulation of the heating elements of the screeds is towards the top, directing 100% of the heat to where it is required. The compacting systems (tamper and pressure bars) are rapidly and evenly heated from the inside by heating rods. In combination with the latest control technology, this means the entire heating capacity can be controlled automatically.

Heated up quickly and evenly

Short heating-up time, constant and even heating capacity: the heat pattern of a screed clearly shows the contribution made by electric screed heating to high paving quality.

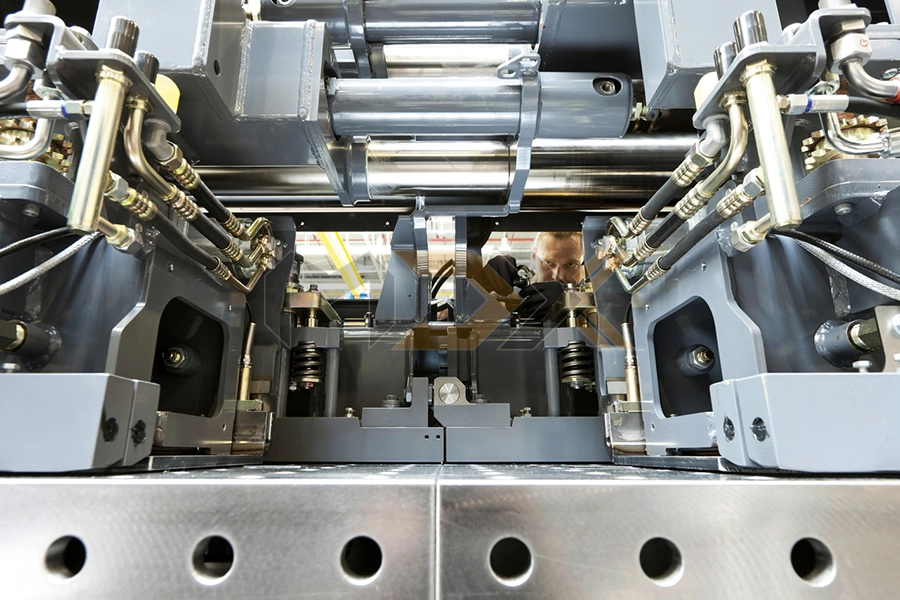

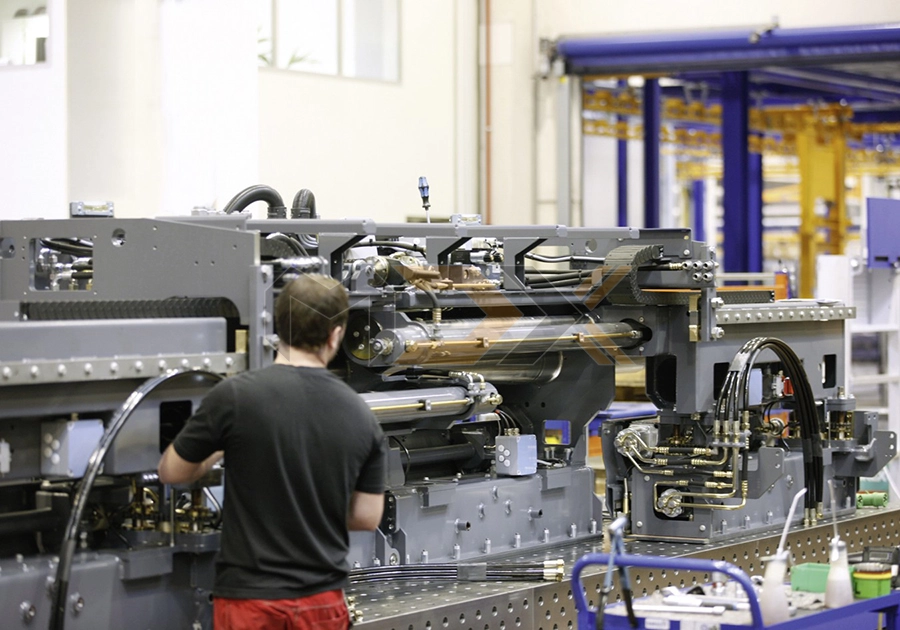

VÖGELE screeds feature leading-edge technology made possible by state-of-the-art production processes. The first of these processes, the precision cutting to shape of extremely wear-resistant sheet steel, takes place on laser cutting stations. Robots which operate continuously to a consistently high standard ensure long-lasting, stable welds.

Hardened for intensive material contact

Screeds are a key factor in the surface quality and evenness of asphalt layers. At VÖGELE, they are made of wear-resistant Hardox steel. The compacting systems (tamper and pressure bars), too, are ready for harsh operating conditions. As the whole of the heat treatment process is key for their quality and service life, the technology leader puts its faith in induction hardening. This is a process which reduces wear and guarantees longevity by means of greater effective hardening depth and maximum evenness.

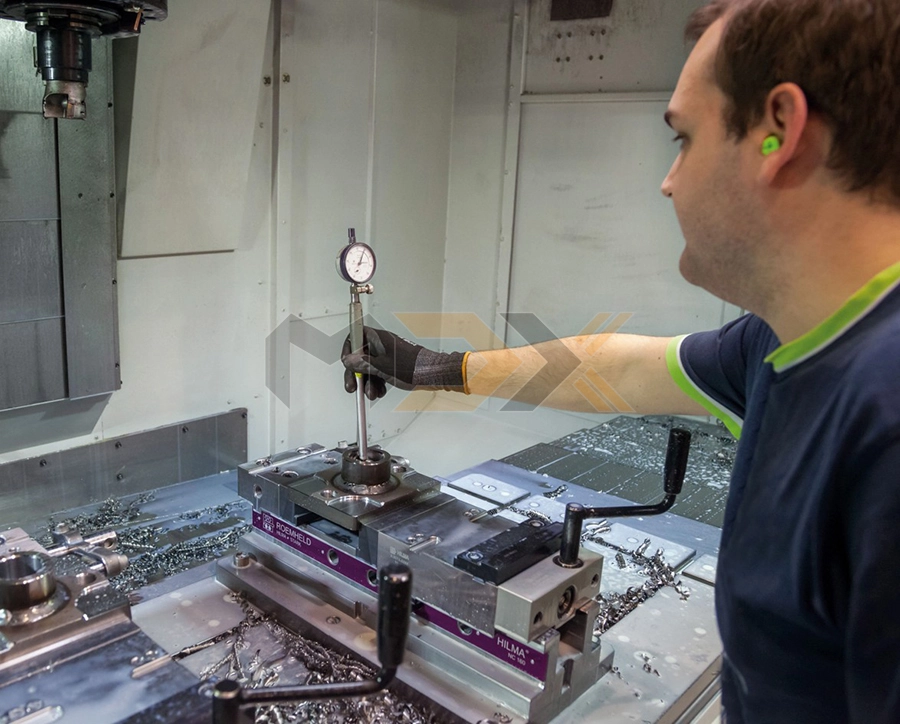

Comprehensive quality control

Once the screed and its electrical and hydraulic components have been assembled, all the functions are checked. This check comprises several hundred items including settings, filling levels and pressure tests. All the measured values are documented in a Final Inspection Record. Any discrepancies are remedied immediately by experienced VÖGELE experts.

Screed plates straightened free from tension and with maximum precision (error of no more than 2 tenths of a millimetre allowed) mean even wear and consequently a long service life.

All production stages are subject to thorough quality controls.

CNC machine welds threaded bolts to screed plates.

Induction hardening of tamper bar and pressure bars guarantees long service lives.

Tamper bar and pressure bars are hardened to a uniform depth of 5mm.

The telescoping tubes are manufactured with maximum precision on special machines.

Eccentric shafts for tamper drives.

20 times finer than human hair: inner surfaces of telescoping tubes are machined to the maximum possible precision.

Welding cell for screed frames. Robot-produced weld seams feature consistent, high quality and precision.

During final assembly, VÖGELE screeds undergo a variety of functional tests.

Tags: AB 500, Extending Screed, Voegele Screed