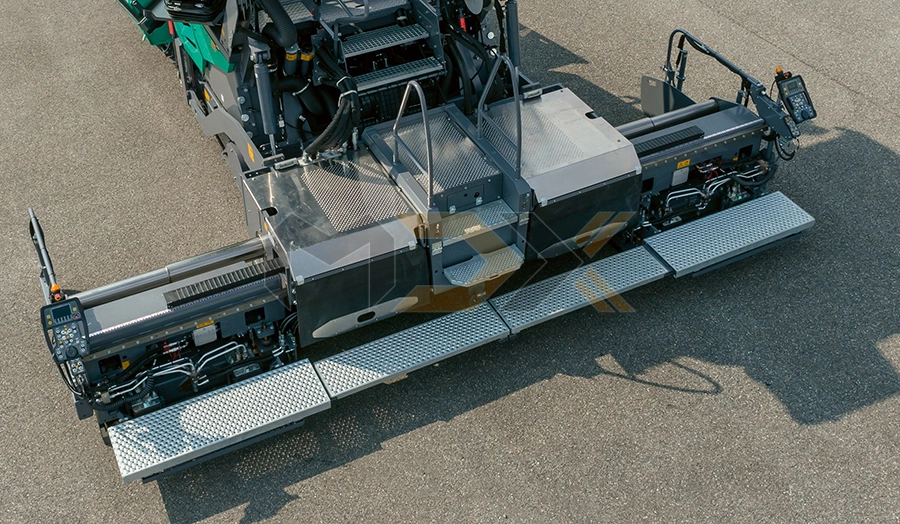

With the SUPER 1900-5(i) tracked paver, VÖGELE is taking two steps into the future at once: new operator ergonomics, more automated processes and faster set-up times, together with reduced noise and exhaust emissions.

The sum of further developments and new features make the SUPER 1900-5(i) a paver to equip our customers perfectly for the future. In addition to its technical features, the paver is also forward-looking in terms of sustainability – thanks to its economical consumption and low emissions.

|

|

| Power unit | |

| Engine | 6-cylinder diesel engine, liquid-cooled |

| Manufacturer | John Deere |

| Type | 6.8L PVN |

| Output | |

| Nominal | 149 kW at 2,000 U/min |

| ECO Mode | 163 kW at 1,700 U/min |

| Exhaust emissions standard | R96 Stage IIIa, Brazil MAR1 |

| Exhaust gas after-treatment | Exhaust silencer |

| Fuel tank | 400 litres |

| Undercarriage | |

| Crawler tracks | provided with rubber pads |

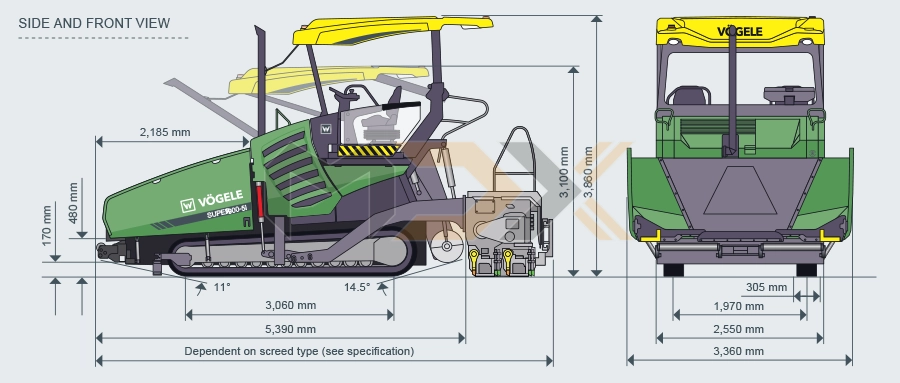

| Ground contact | 3,060 mm x 305 mm |

| Track tension adjuster | spring assembly |

| Track roller lubrication | lifetime |

| Traction drive | electronically controlled separate hydraulic drive provided for each crawler track |

| Speeds | |

| Paving | up to 25 m/min., infinitely variable |

| Travel | up to 4.5 km/h, infinitely variable |

| Material hopper | |

| Hopper capacity | 14 t |

| Width | 3,280 mm |

| Feed height | 590 mm |

| Push-roller | |

| Standard | oscillating, can be displaced forwards by 100 mm |

| Option | sprung and oscillating (PaveDock), displaceable longitudinally by 100 mm |

| Conveyor and augers | |

| Conveyor | 2, with replaceable feeder bars, conveyor movement temporarily reversible |

| Drive | separate hydraulic drive provided for each conveyor |

| Speed | up to 37 m/min., infinitely variable (manual or automatic) |

| Augers | 2, with replaceable auger blades, auger rotation reversible |

| Diameter | 400 mm / 320 mm |

| Drive | separate hydraulic drive provided for each auger |

| Speed | up to 95 rpm, infinitely variable (manual or automatic) |

| Auger height | infinitely variable by 15 cm, hydraulic |

| Lubrication | automatic centralized lubrication system with electrically driven grease pump |

| Screed |

Type | Basic Width | Maximum Width | Compacting Systems |

| AB 500 (More) | 2.55 m | 8.75 m | TV, TP1, TP2, TP2 Plus | |

| AB 600 (More) | 3 m | 9.75 m | TV, TP1, TP2, TP2 Plus | |

| SB 300 (More) | 3 m | 11.5 m | TV, TP1, TP2 | |

| SB 300 HD (More) | 3 m | 9 m | TV | |

| Layer thickness (up to) | 40 cm | |||

| Heating | electric, by heating rods | |||

| Power Supply | Three-phase AC generator | |||

| DIMENSIONS AND WEIGHT |

||

| Operating weight | Screed | Total weight |

| AB 500 TV | 22 400 kg | |

| Length | Screed | Total length |

| AB 500 TV | 6.68 m | |

| AB 500 TP1 | 6.81 m | |

| AB 500 TP2 | 6.81 m | |

| AB 500 TP2 Plus | 6.81 m | |

| AB 600 TV | 6.68 m | |

| AB 600 TP1 | 6.81 m | |

| AB 600 TP2 | 6.81 m | |

| AB 600 TP2 Plus | 6.81 m | |

| SB 300 TV | 6.53 m | |

| SB 300 TP1 | 6.53 m | |

| SB 300 TP2 | 6.53 m | |

| SB 300 HD TV | 6.53 m | |

| Maximum laydown rate | 900 t/h | |

We deliberately skipped a generation for the new “Dash 5” series of pavers and put all the features of our pavers on the test bench. The aim was to develop a generation of pavers which have maximum output whilst keeping pace with the breakneck speed of technical progress.

To be perfectly set up for both the present and the future requires a flexible, modular system which can accommodate requirements as they come up. We have taken a fresh look at our pavers and identified four central areas which have been, still are and will continue to be key for the development of our machines.

| User-friendly Operation | Process Automation |

| We always start with activities in the field, evaluating the experience of operating teams and integrating that knowledge in our new developments. We claim to deliver safety, maximum user-friendliness, self-explanatory handling and practical ergonomic features | Technology leadership is part of VÖGELE’s DNA: We develop our products innovatively on the basis of decades of experience, so that they meet global standards and keep on setting new benchmarks. Automating processes with assistance and control systems assures precision, efficiency and process stability. |

| Cost-efficiency | Sustainability |

| Time, money and cost-efficiency are key factors in the success of road construction. We keep an eye on our customers’ absolute costs and find solutions to reduce setup times, improve logistics and increase machine availability. | Environmental issues and legislation are challenges we are prepared to face. We use the latest drive systems and an efficient paver design to reduce fuel and noise emissions whilst maintaining output at the same level. |

With the SUPER 1900-5(i) tracked paver, VÖGELE is taking two steps into the future at once: new operator ergonomics, more automated processes and faster setup times, together with reduced noise and exhaust emissions.

The SUPER 1900-5(i) has a mighty power pack from John Deere with an output of 149 kW at 2,000 rpm. This engine is characterised by economical consumption and comparatively low noise emissions.

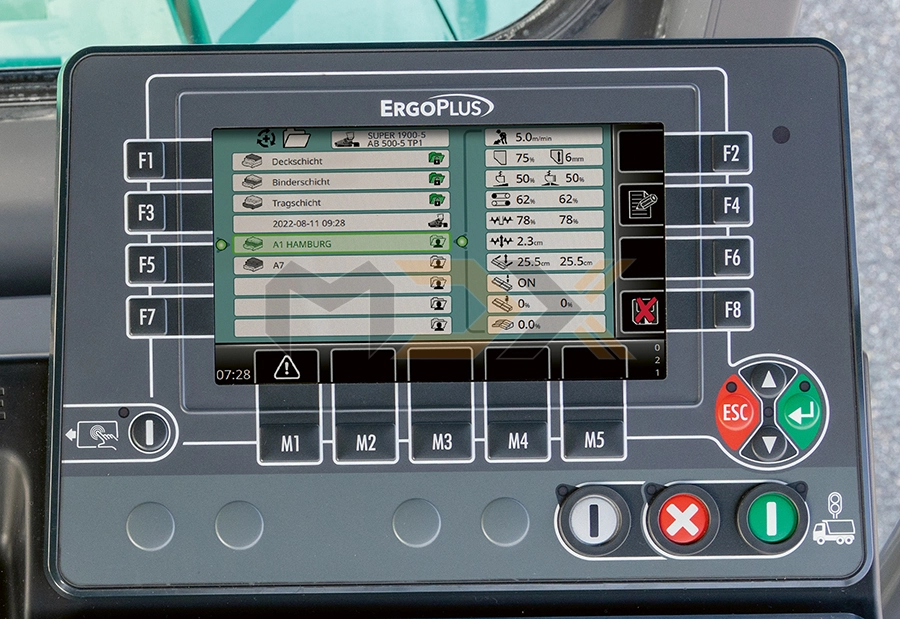

The ErgoPlus 5 operating system makes the SUPER 1900-5(i) simple and intuitive to operate. ErgoPlus 5 is characterised by a good overview, great convenience and perfect ergonomics. The optional touch display with expanded functionalities means the operating system is already fit for the future.

Numerous features automate the processes around paving and make it even more convenient and efficient.

Paver Access Control makes the paver ready for operation, AutoSet Plus ensures consistent paving quality and PaveDock facilitates transfer of material to the paver. The Power Tunnel optimises the head of mix in front of the screed and Logistic Plus simplifies the handling of screed and auger extensions.

The sum of further developments and new features make the SUPER 1900-5(i) a paver to equip our customers perfectly for the future. In addition to its technical features, the paver is also forward-looking in terms of its economical consumption and low emissions.

| 01 Pioneering, functional product design. | 02 ErgoPlus 5 with numerous convenience and automatic functions. |

| 03 AutoSet Plus for more convenient repositioning on the job site. | 04 Light Package Plus for optimum illumination of the operating area of the screed. |

| 05 PaveDock Assistant simplifies communication during transfer of material. | 06 Well-organised, ergonomic workstation. |

| 07 Safe, convenient step onto screed. |

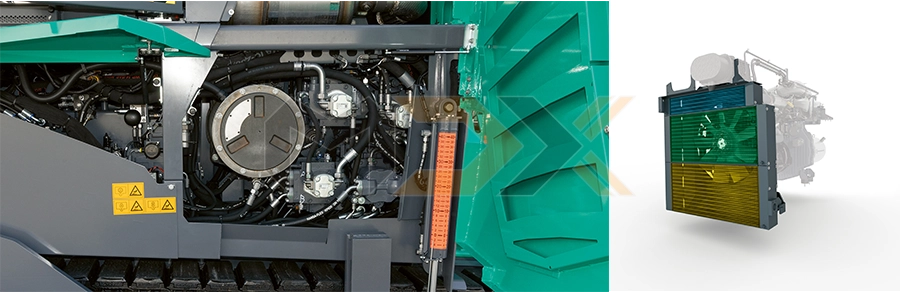

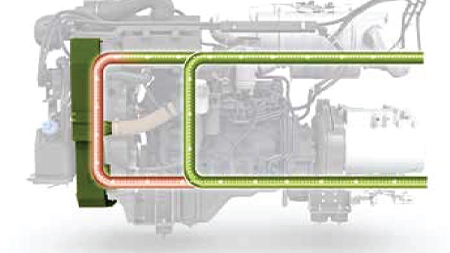

The drive technology of the SUPER 1900-5(i) includes the powerful John Deere engine, the large cooler assembly and the splitter gearbox flanged directly to the engine.

The powerful six-cylinder diesel engine from John Deere delivers 149 kW at 2,000 rpm. Fuel-saving ECO mode which delivers 163 kW at 1,700 rpm is adequate for many applications. This considerably reduces consumption as well as noise and exhaust emissions.

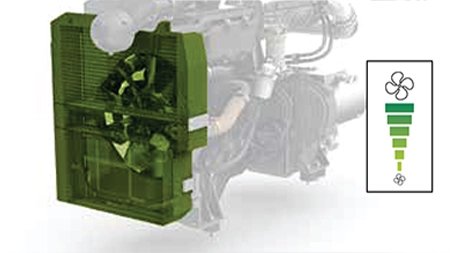

The large cooler assembly ensures that the drive unit always achieves maximum power. With innovative air routing and a variable-speed fan, engine temperatures are always maintained within the optimum range, perfectly equipping the machine for every climate.

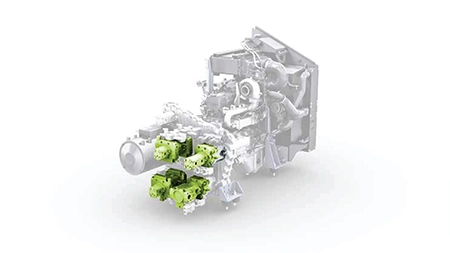

The splitter gearbox supplies all hydraulic consumers directly with hydraulic oil. The advantage is that all pumps and valves are centrally located, making them easily accessible. Even the powerful generator for screed heating is flanged directly onto the splitter gearbox, its integrated oil cooling making it completely maintenance-free.

The modern John Deere engine means that you now get full machine service from a single source - the WIRTGEN GROUP.

Exhaust emissions after-treatment, alternative fuels (HVO) and VÖGELE EcoPlus

On engines of exhaust emission Stage V, exhaust emissions after-treatment is provided by the diesel oxidation catalyst (DOC), a diesel particulate filter (DPF) and a selective catalytic reduction (SCR) catalytic converter. The SUPER 1900-5i is also approved for use with alternative fuels such as HVO (Hydrogenated vegetable oils)

VÖGELE EcoPlus furthermore significantly reduces emissions. This package is capable of reducing consumption and CO2 emissions by up to 25% and likewise reduces noise.

Not content with simply ensuring that our road pavers conform to the applicable emissions directives, we like to go much further. The machine concept for the “Dash 5” generation is based on environmentally engineering principles. An important component of this is VÖGELE EcoPlus to reduce consumption and emissions. The package consists of various features which reduce machine consumption. Depending on the application and utilization of the paver, VÖGELE EcoPlus can save up to 25% fuel. This not only means considerable financial savings for companies, but also a positive impact on the environment. That’s because every litre of fuel saved reduces carbon dioxide (CO2) emissions.

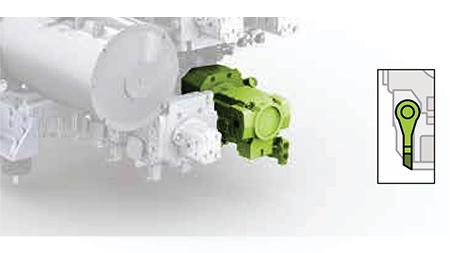

| Splitter gearbox with hydraulic pump disengagement feature | Energy-optimized tamper drive |

| When the paver is at a standstill, all the hydraulic pumps for “drive”, “transfer” and “compact” are switched off automatically. The result: reduced fuel consumption. | The tamper is driven by a variable displacement pump. This always delivers only the exact amount of oil needed for the current tamper speed. Not a drop more or less. |

|

|

| Controlled hydraulic oil temperature circuit | Media temperature-managed fan control |

| A bypass circuit gets the hydraulic oil to its optimum operating temperature very quickly, enabling rapid, fuel-saving operation of the paver | Media temperature-managed fan control adapts fan output automatically to suit the consumer being supplied. In other words, the temperatures of hydraulic fluid, engine charge air, cooling water and the ambient air are controlled within a closed control circuit and cooler output is adapted accordingly. |

|

|

High-quality separate hydraulic drives are essential components of our drive concept. They allow our pavers to operate to a very high standard and thus extremely cost-efficiently. Since the traction drive units are directly integrated into the sprockets of the crawler tracks, engine output is translated into pave speed without any loss of power.

- The hydraulic systems for the drive, for material handling and distribution and for the compacting systems are arranged in independent closed circuits and achieve the best possible degree of efficiency as a result.

- Long crawler tracks with a large footprint deliver maximum tractive effort, ensuring a constant forward speed even when operating on difficult terrain.

- Separate electronically-controlled drives in both crawler tracks ensure positive tracking when moving straight and accurate cornering.

PaveDock Assistant

Among other factors, a constant feed rate is essential for high-quality, even paving. PaveDock Assistant was developed specifically for this purpose. This assistance system handles communication between the paver operator and the truck driver.

The core of this communication system is formed by the signal lights mounted on the right and left of the paver’s hardtop and the associated controls on the paver operator’s ErgoPlus 5 console. The signal lights have two clear signals – green for “Dock” and red for “Stop”

| 1. Two signals which are easy to see, even from a distance: a red and a green diamond. | 2. Controls for the signal lights on the paver operator’s console. | 3. To make it easier for the material truck to dock, the rubber baffles to the left and right of the hopper front have reflective markings |

PaveDock

PaveDock ensures higher pave quality. The sprung push-rollers efficiently absorb jolts from material trucks to that these are not transmitted to the paver and thus to the asphalt. The push-rollers also oscillate, which even allows trucks to be pushed on bends.

| PaveDock Assistant facilitates communication during transfer of material to the paver | PaveDock sprung push-rollers guarantee reliable feeding with material without jolts |

Truck push-rollers which are especially wide and oscillating allow convenient, jolt-free feeding of material by material trucks, even on bends. The push-rollers can be adjusted fully in the longitudinal direction to adapt them to suit the geometry of the material truck.

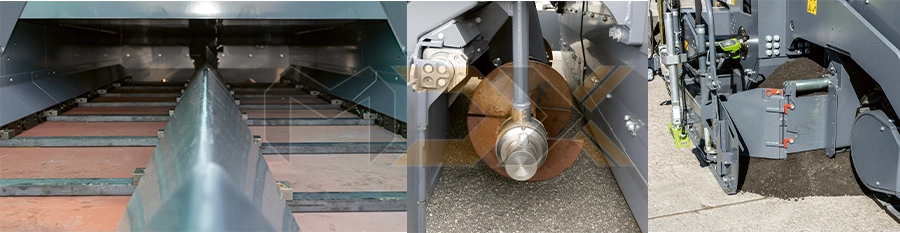

A continuous flow of material is key to ensuring uninterrupted, high-quality paving, which is why we attach such importance to perfect material management when designing our pavers.

All our development efforts focus on simple operation and the best possible overview for the paving team. Like all VÖGELE pavers, the SUPER 1900-5(i), too, is clean, reliable and quick to feed.

Deep and wide container walls and hard-wearing container front skirts make it easy for the truck to load the material. For easier docking of the mix truck, the container front protection skirts have reflective markings on the left and right.

The hydraulic hopper front flap ensures that the complete quantity of mix reaches the material conveying process. The large-volume receiving container offers a capacity of 14 tonnes. This means that even in difficult feeding situations, such as under bridges, sufficient mix is available for paving.

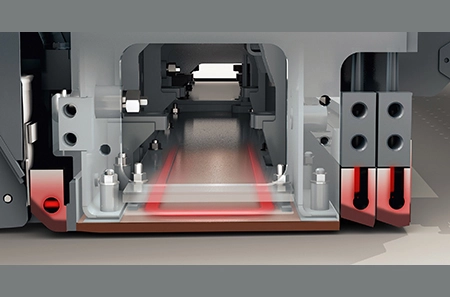

| 1. Proportionally controlled mix feed with permanent quantity monitoring ensures uniform, precisely fitting paving material. | 2. Optimised blades of the spreading auger ensure perfect distribution of the mix even with large working widths. | 3. The optional Power Tunnel is ideal for changing installation widths. |

The transverse material feed in front of the screed ensures an optimum supply of mix in every paving situation. Powerful individual hydraulic drives of the scraper belt and spreading auger enable high paving capacities of up to 900 tonnes per hour. The control signals of the scraper belt and distribution auger are combined so that a uniform material flow and a consistent mix feed are guaranteed. This not only avoids peak loads, but also reduces fuel consumption.

Power Tunnel

The Power Tunnel is perfect for changing widths when paving without widening. The hydraulically adjustable limiting plates automatically adjust to the screed width and ensure optimum mix placement in front of the screed, even when the screed extensions are fully extended. This increases the paving quality in terms of evenness and pre-compaction.

Heated auger plough

The heated plough on the centre bearing block of the spreading auger effectively prevents mix from sticking during paving and makes an important contribution to perfect paving results. In addition, the plough’s geometry distributes the mix evenly to both sides. The heated plough particularly facilitates the laying of low-temperature asphalt (NTA).

The two functions of AutoSet Plus automate routine tasks, allowing work processes to be carried out more quickly and with greater control. The transfer and transport function makes it much easier to switch between two construction sections. The memory function allows paving programmes created by the operator to be reactivated.

AutoSet Plus relocation function

AutoSet Plus is especially helpful when the machine frequently has to be moved on the job site.

With just one press of the Execute button, the distribution auger, the hydraulic hopper front flap and the track pre-scrapers are raised to the uppermost position. The screed and the screed tow point rams are moved into transport position.

And the screed is also locked hydraulically in transport position. The scraper belts are reversed for a short time, which prevents mix from falling off while driving. The machine is now ready for transport.

After repositioning, pressing the Execute button again returns everything to the previously stored working position. This ensures that no settings are lost when changing back and forth between Pave and Job Site modes. It also effectively prevents any damage to the machine.

Advantages of the paving programme function:

- Automated configuration of the paver.

- Stores all paving-relevant parameters.

- Selection of stored paving programmes.

- Reproducible quality

AutoSet Plus Paving Programmes

The automatic function for installation programmes allows the operator to create installation programmes. All important parameters for the paving of a specific layer can be saved, e.g. base course of asphalt concrete 18 cm thick.

On the display of his console, the paver operator saves the values set for the compacting systems (tamper and vibrator speed, pressure for the pressure bars), height of the augers, position of the tow point rams, pressure for Screed Assist and the pave speed in his program. He also enters the amount of crown and the screed temperature. The program is completed with additional information on the material being used, the layer thickness and the pave width.

The saved installation programmes can be recalled and activated via the menu. This ensures that exactly the same settings are always used and thus a consistent quality is achieved.

An innovative machine with the latest technology also includes an advanced operating concept. This must be easy and intuitive to use and at the same time ergonomic. Operating concept ErgoPlus 5 puts the operator at the centre. In this way, we ensure that they always have full control over the machine and the construction project.

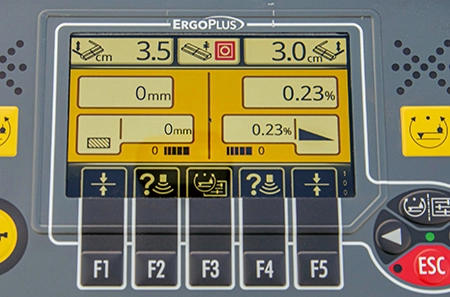

This starts with the ergonomic workplace on the operating platform, and extends to the intuitive and simple operation of the operator and screed console, right through to the integrated levelling system Niveltronic Plus.

ErgoPlus 5 supports the operator, is self-explanatory and, as it builds on the proven ErgoPlus 3, is easy to learn.

Compared to its predecessor, ErgoPlus 5 offers even greater ease of use and improved ergonomics. For example, the low profile driver‘s control console allows for more legroom and a more comfortable seating position.

| ErgoPlus 5 Paver operator's console | ErgoPlus 5 operator platform | Niveltronic Plus and Niveltronic Plus Assist |

| Next evolutionary step of the proven operating concept of VÖGELE | Better overview und more comfort and ergonomics | Improved system for automated grade and slope control with Niveltronic Plus assist |

| Niveltronic Plus and Niveltronic Plus Assist | ErgoPlus 5 Driver and screed control consoles | ErgoPlus 5 operator platform |

|

- Automated grade and slope control for a perfect paving result - Wide range of sensors enables flexible use - Particularly simple and user-friendly operation - Precision paving of predefined cross-sections - Constant monitoring of entered installation parameters |

- ErgoPlus 5 Driver control console with lower overall height - SmartWheel for steering, fine steering/steering trim via setpoint generator - Configurable in two expansion stages: with and without touch display on the left side |

- Perfect view of all important points - Ergonomic seating position due to individual adjustment options - Fixed roof for optimum weather protection - Convenient and secure access |

The paver operator‘s console is extremely clear and has been designed according to practical principles. All functions are combined into logical groups, so that the operator finds each function exactly where he would expect it to be. Even with ErgoPlus 5, the function keys can be felt and operated with gloves. Once a button is pressed, off you go. That is due to the “Touch and Work” principle. The desired function is therefore carried out directly - without further confirmation.

Storage options and a 24 V socket for charging mobile devices have also been thought of.

The operation of individual functions such as steering, fine steering, PaveDock Assistant and AutoSet is considerably simplified and logical to use. The SUPER 1900-5(i) is steered with an easy-to-grip SmartWheel. The fine steering is done via a potentiometer. With this, the paver can be finely controlled with extreme precision

| 1. Propulsion and steering | 2. Material management and material containers | 3. Screed |

| All functions for moving the paver are grouped here, for example, the main travel switch, the operating mode selector and the setpoint generator for the pave speed. | The material manager function group contains the controls for the hopper walls and for the scraper belt and distribution auger. The operating elements for the material container are also located here. | All operating elements of the paving screed are combined in this function group. |

| 4. Display | 5. ErgoPlus 5 Premium Touch | |

| The high-contrast colour display provides for brilliant readability even in poor lighting conditions. Vital information is shown on menu level 1. More paving settings, as well as information about the machine, can be found at the secondary levels. | The ErgoPlus 5 driver’s control console is optionally available with additional Premium Touch. The Premium Touch enables an even easier overview and operation of various functions. With Premium Touch, the machine is ideally prepared for digital road construction. The process automation solution Niveltronic Plus Assist and the temperature monitoring of the RoadScan are already clearly presented on the large touch display and can be conveniently operated there. |

ErgoPlus 5 operator’s console standard

The standard version has additional storage options instead of the touch display

Crucial for pavement quality is the screed. Therefore, easy and positive handling of all screed functions is of utmost importance for high-quality road construction.

With ErgoPlus 5, the screed operator masters the paving process perfectly, as all functions are easy to understand and clearly arranged.

Push-buttons are provided for regularly required functions operated from the screed operator’s console. These are watertight and enclosed in a perceptibly raised ring, so that they are identifiable blindfold simply by touch even when wearing work gloves. Important paver and screed data can be called up and adjusted from the screed operator’s console, too

| 1. The screed control panel can be connected during operation. With Quick Connect, no more cables are needed. | 2. The rear of the screed control panel has a powerful LED to illuminate the side shield area. |

| Quick connect | Simpler handling |

| No connection of a connecting cable necessary, simple and process-safe connection possible during ongoing paving operation | The flat design allows for easier stowage of the screed control panel |

| 01 Display of the screed operator’s console | 02 Ergonomic screed width control at two speeds |

| The display of the screed operator’s console allows the screed operator to control and monitor both the left and the right side of the screed. Machine-related parameters such as tamper speed or conveyor speed can be adjusted conveniently via the display panel of the screed operator’s console. The clear menu structure, combined with easily understandable, self-explanatory symbols neutral in language, makes operating the display panel both simple and safe. | The width adjustment of the paving screed is now carried out fatigue-free by means of the easy-grip SmartWheel. This can be done in two speeds: Slow, for precise screed width control along an edge, or fast, for rapid extension or retraction of the screed. |

Hydraulic height adjustment of the side shield

The hydraulically adjustable side plates are now operated via one remote control per side. Process-relevant functions can also be perfectly controlled via this remote control.

Niveltronic Plus

The system for automated grade and slope control Niveltronic Plus is an in-house development of JOSEPH VÖGELE AG and is based on years of experience in the field of levelling technology. Easy operation, precision and reliability are its hallmarks for perfect mastery of all grade and slope control jobs.

The fully integrated system is optimally matched to the machine technology of the VÖGELE pavers with ErgoPlus operating concept. All wiring and connections, for instance, are integrated in the tractor unit and screed, effectively eliminating any risk of damage to these components.

It goes without saying that VÖGELE offers a particularly large and practical selection of sensors to allow versatile use of the Niveltronic Plus system. Whether car parks, roundabouts or motorways need to be built or rehabilitated, VÖGELE offers the right sensor for every job-site situation.

Sensors can be changed quickly and easily, for Niveltronic Plus automatically detects which sensor is connected, thus simplifying the configuration process for the user.

Niveltronic Plus Assist (option)

Niveltronic Plus Assist automates additionally the canopy and transverse profileinstallation. The parameters for specified distances are entered on the ErgoPlus control consoles and can be monitored accordingly during installation. Niveltronic Plus Assist thus supports the operator in the precise paving of roads in predefined profiles. In addition, the integrated edge follower Edge Control automatically regulates the screed width along a reference.

| 1. The LED sighting crosses also fitted to the sensor provide continuous, clearly visible feedback to the screed operator indicating whether the actual values match the settings made. | 2. With the Niveltronic Plus Assist option, the parameters for roof and transverse profile installation can be preset and monitored on the screed control console and on the touch display of the driver’s control console. | 3. The two-way split display provides the screed operator with access to both sides of the screed. The symbols provide informationat all times, including on the height of the tow point rams, pre-set and actual values and the pre-set sensitivity of the grade and slope control sensors. |

| Slope sensor | Multi-cell sonic sensor |

| The slope sensor allows the transverse profile to be determined exactly and then paved accurately. The measuring range is ± 10%. | The multi-cell sonic sensor, with its four sensors, is highly versatile. By calculating an average, it can compensate for short irregularities in a reference. |

| Variable mechanical grade sensor | Big MultiPlex Ski |

| The variable mechanical grade sensor can be equipped with skis for referencing from the ground in 30 cm, 1 m and 2 m lengths. | The Big MultiPlex Ski compensates for extended undulations. Three multi-cell sonic sensors can be attached to its variable 5 to 13 m long carrier. |

| Single-cell sonic sensor | |

| The single-cell sonic sensor emits a sound cone. This allows it to copy references 1:1 without calculating an average. It can be used for referencing from the ground (Ground mode) or from a tensioned wire (Stringline mode). | |

An ergonomic workstation is of keyimportance to enable a paver operator to concentrate fully for long periods of time. This is why VÖGELE relies on the paver operator’s stand with ErgoPlus 5, too. The operator’s ErgoPlus 5 stand provides plenty of storage space, is clearly arranged and meets stringent health and safety requirements.

Outstanding all-round visibility also increases safety. The operator can monitor everything from his workstation: material feed, material supply and head of mix. With its intelligent design, the ErgoPlus 5 system proves that innovative technology can be controlled ergonomically, efficiently, intuitively and conveniently.

| 1. Comfortable operator‘s platform | 2. Control console and seats can be moved for an optimum seated position |

| The comfortable paver operator‘s platform gives an unobstructed view of all crucial areas on the paver such as the material hopper, steering guide and screed. |

The seats, which swing out to the sides, and the streamlined design of the operator‘s platform ensuremaximum visibility of the auger tunnel, allowing the paver operator to keep an eye on the head of mix in front of the screed at all times. The paver operator’s seat and console, as well as the screed consoles can now be adjusted even more easily to personal needs. |

| 3. Hardtop provides excellent protection | 4. Everything in its place |

| The modern hardtop made of glass fibre-reinforced polymer material shelters the operator, come rain or shine | The paver operator‘s platform, with its streamlined design, is well organized, offering the paver operator a professional workplace. The operator’s console can be protected by a shatter-proof cover to prevent wilful damage. In addition, the optionally available tool holder ensures order and safety on the screed. |

| 5. Safe and comfortable ascent | 6. Perfect access to the maintenance points |

| The walkway and comfortable middle ascent on the screed ensure safe and convenient access to the operator’s platform. | The very easily accessible maintenance points on the operating platform enable simple and convenient servicing. The large flaps make maintenance much easier. |

The comfort package makes the operation of the “Dash 5” road pavers even more comfortable, safe and ergonomic than ever before. The comfort package includes the PAC comfort access, Ergonomic Plus driver‘s seats, luggage nets and sound insulation in the roof as well as cup holders.

The Paver Access Control (PAC) convenience access included in the package makes daily commissioning and decommissioning of the paver faster, easier and safer. All necessary functions can be controlled safely and conveniently from the ground via the Paver Access Control Unit integrated in the screed.

| 1. Luggage nets in the roof and bottle holders on the seats keep the operating platform tidier. The insulation in the canopy reduces heat build-up and noise. | 2. The comfortable and ergonomic Ergonomic Plus driver’s seat has adjustable seat heating and can be rotated ± 20° |

When it is dark, the first thing to do is switch on the paver’s lighting. After opening the cover, the diesel engine can be started, the roof erected and the screed lowered for a comfortable climb. The roof is automatically locked and the machine control is booted. This ensures safety and saves time, as the paver operator cannot forget to lock the screed and can start heating the screed immediately after stepping onto the operating platform.

| Paver Access Control (PAC) For convenient and safe access to the paver | Hydraulically adjustable canopy with integrated luggage nets and sound insulation | Operator's seats Ergonomic Plus with adjustable seat heating and 20° rotatable |

Paver Access Control Unit

| 1. Ignition on and booting the machine control | 2. Starting and stopping the diesel engine | 3. Folding up and down of the roof including locking mechanism |

| 4. Raising and lowering of the screed including locking device | 5. Switching the lighting on/off |

Light Package

The Light Package makes working in the dark much easier and safer. Good illumination of the workplace reduces the risk of operating errors and accidents.

The Light Package includes the LED lighting of the operator’s platform, the two point rams and three freely positionable LED headlights. Also included is a 230 volt Schuko socket and the electrical connections for the light balloons. With the Light Package Plus, pave widths of up to 10 m and the area 4 m behind the screed are optimally illuminated.

Light Package Plus

The Light Package Plus provides even better illumination in the area of the paving screed. Powerful LEDs are integrated into a specially developed canopy extension that completely illuminates the entire working area up to a pave width of 10 metres.

The luminous efficacy of the LED spotlights is comparable to that of the light balloon, but they have the great advantage that assembly and separate transport are not required. This saves time and money. In addition, the lighting integrated in the canopy is always with you, robust and protected from wind and rain.

| 1. Perfect illumination of the working area | 2. Perfect illumination of the operator’s platform | 3. Optimum illumination of the tow point rams |

With the Light Package Plus, pave widths of up to 10 m and the area 4 m behind the screed are optimally illuminated.

| Integrated LED lighting | Illumination of the tow point rams | Perfectly illuminated access |

| The LED lighting integrated in the canopy and the transverse guide of the control panel optimally illuminate the driver‘s workplace and all service points accessible from the platform; this makes working in the dark more comfortable and safer. | The illumination of the tow point rams makes it easier to check their position in the dark. | In conjunction with the Comfort Plus Package, activating the comfort access from the screed activates the light in the canopy and optimally illuminates the access to the operator‘s platform |

Extending screeds

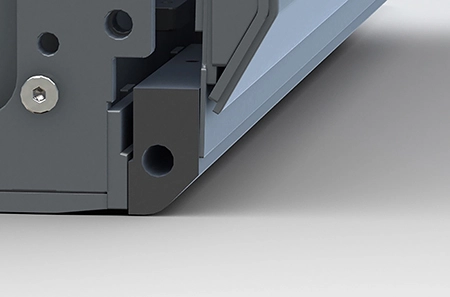

The extending screeds AB 500 and AB 600 are particularly variable and thus ideally suited for changing paving widths and uneven roadway courses. Their sturdy single-tube telescoping system permits top-precision screed-width control. Even with the screed set to its maximum width, the telescoping tubes are extended by no more than half, thus providing for superb screed stability and zero flexing.

| Logistic Plus: Better logistics - shorter set-up times | VÖGELE Single-tube telescoping system |

|

With Logistic Plus, all add-on parts of the distribution auger and screed plate, including accessories and fastening material, can be transported safely and tidily. Logistic Plus improves the logistics as well as the set-up time of the machine and thus contributes to economic efficiency. - Shorter set-up times when attaching bolt-on extensions > Process-safe and fast attachment of bolt-on extensions due to predefined positioning - No dismantling of the covers on bolt-on extensions - Higher paving quality due to fewer sources of error |

The hydraulic extensions are adjusted in all VÖGELE extending screeds with a single-tube telescoping guide. The three-part, large-diameter telescoping tube (150/170/190 mm diameter) is optimally stabilised even at maximum extension, as even then it is still half clamped. Thanks to the 3-point suspension of the screed’s extending units, torsional forces exerted to these units by pressure of the mix cannot affect the screed’s telescopic guidance system. Forces are absorbed at the telescoping tube’s (1) outer point of attachment to the extending unit, by a fixed guide tube (2) and a sliding restraint system (3). Thanks to this design, the screed’s extending units move in and out smoothly, nothing can jam or get stuck. |

Fixed-width screeds

Fixed-width screeds from VÖGELE deliver absolutely high-quality, perfectly even results. They show their strengths wherever large pave widths have to be handled, when laying down thick layers (e.g. crushed-stone bases) and where high degrees of precompaction have to be achieved. The SUPER 1900-5(i) can be combined with the fixed-width screeds SB 300 and SB 300 HD.

- Convenient and efficient: practical installation aid: To ensure that the SB screeds are quickly ready for use, even when paving large widths, the attachment of bolt-on extensions has been greatly simplified: a newly developed installation aid helps the operator mount the extensions correctly. As a result, the individual bolt-on extensions can be adjusted quickly and easily, considerably reducing set-up times.

| New heating system for fast and homogeneous heating of the compaction units | Higher efficiency through improved insulation of the screed heating | 24 volt socket for external light sources and charging smart devices |

| Dual power shift tamper | Measurement of screed width |

| The dual power shift tamper is available for extending screeds as well as fixed-width screeds in any width configuration and compaction variant. With this hydraulic tamper stroke adjustment, the tamper stroke can be adjusted quickly and easily. Two options are available: 2 and 4 mm or 4 and 8 mm tamper stroke. The benefits are optimum paving quality due to the correct adjustment to the respective layer thickness, reduced set-up times due to the hydraulic changeover and an extended range of paving applications. | The extending screeds and the hydraulic bolt-on extensions of the rigid screeds can be equipped with a screed width measurement. The exact position of the hydraulic extensions is recorded by means of an integrated path measurement in the hydraulic cylinders. Calibration of the system is no longer necessary. The current width is displayed on both the paver operator's and the screed paver operator’s consoles. |

|

|

| Innovative electric screed heating | Great flexibility for fixed-width screeds |

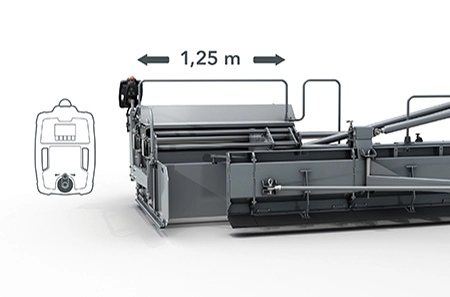

| In order to optimise compaction and produce a smoothsurface texture, all compacting elements are heated across full screed width. The screed plates are heated as standard with large-area heating elements. They are thoroughly insulated on top so that the heat is directed 100% to where it is needed: the areas of contact with the mix. Tamper bar and pressure bar(s) are fitted with heating rods for quick and uniform heating from inside. In combination with the latest control technology, this means the entire heating capacity can be controlled automatically | High flexibility during installation is offered by the two fixed-width screeds with the extra-wide hydraulic bolt-on extensions. On each side of the screed, the pave width can be adjusted by SmartWheel 1.25 m, thus hydraulically varying the total working width by 2.5 m. |

|

|

Tags: Super 1900 5, Vögele paver, asphalt paver machine, asphalt paver price, asphalt paver parts, small asphalt paver, mini asphalt paver, volvo asphalt paver, caterpillar asphalt paver, tracked paver, asphalt paver, wheel asphalt paver, asphalt paver specs, asphalt paver machine specifications, cat paver