Truck Crane Tadano GT-750EL-3

Tadano Truck Crane GT-750EL-3 redefines what truck cranes should be by offering enhanced safety and performance in all crane operations. The newly designed carrier also boasts refined performance, enabling it to withstand even the harshest running test conditions. Tadano has utilized yearsof development experience to craft this cutting-edge, Japanese-manufactured truck crane.

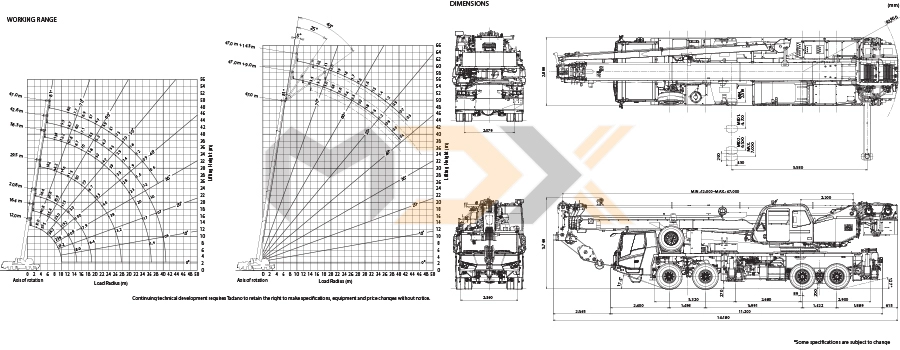

| DIMENSIONS AND WORKING RANGE CHART |

|

| CRANE SPECIFICATIONS | ||

|

||

| Maximum lifting capacity | boom | 75 t tại 2.7 m |

| Maximum lifting height | boom | 47.3 m |

| boom+jib | 61.2 m | |

|

Maximum load radius: |

boom | 40 m |

| boom+jib | 48 m | |

| Maximum boom length | 12 m - 47 m | |

|

|

Two-person, full-width cabin The full-sized cabin accommodates two passengers, allows comfortable traveling for the operator |

|

|

Operator Comfort The crane cab provides improved livability and a more comfortable working environment. The crane operating levers are of finger control type and surely and steadily respond to the operator |

| Automatic moment limiter [AML-C] |

|

| Tadano's AML-C is easy to use, innovative in design, displays important information to the operator and enables the operator to preset a custom working environment. For example, the AML-C shows the boom angle, boom length, load radius, operating pressure of the elevating cylinder, the extension width of the outriggers, slewing position, rated lifting capacity and present hook load. These features allow the AML-C to move seamlessly through all lifting operations without having to change configurations or input new codes to make the lift. The AML-C safety features provide both audible and visual warnings. When an operation approaches the load limit Tadano's slow stop function engages to avoid shock loads |

| ENGINE |

|

|

Daimler OM457LA, 4-cycle, turbo charged and after cooled Max. output: 260 kW {353 PS} Max. torque: 1,850 Nm {188 kgf-m} |

|

Automatic mechanical transmission Push forward: Shifts up a gear. Switches to manual when driving in automatic Push once to the right:Changes the shift position according to your speed when driving in manual. Automatic/Manual Push to the left: Switches between automatic and manual (switchable at all times). Pull backward: Shifts down a gear. Switches to manual when driving in automatic |

| TRANSMISSION |

|

Model ZF AS-Tronic 12AS2302 Type Automatic mechanical transmission, electro-pneumatically operated dry-type clutch and automatic gear shifting with 12 forward gears and 2 reverse gears. |

|

|

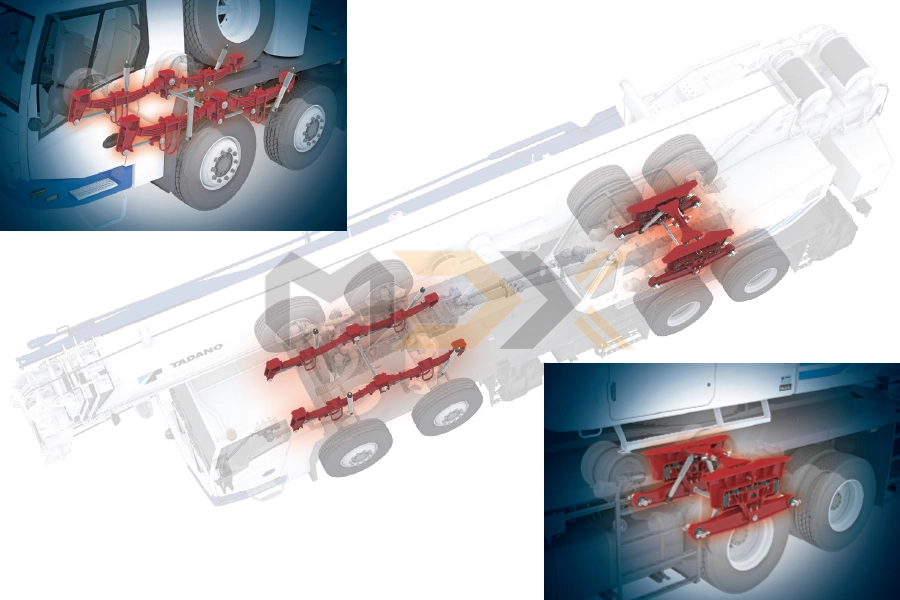

New suspensions for the carrier The ride quality has been optimized to ensure the driver's comfort and protect the carrier Front: Reyco leaf-type suspensions Sachs shock absorbors: Improved ride comfort and operability Rear: Rubber suspension mounts Featuring rubber suspension co-developed with Hendrickson. Extreme durability proven in the harshest environments. Improved ride comfort and maintainability. |

|

Rear view camera and monitor Cruise control A system that automatically controls the speed of the carrier High-speed driving and durability performance tests for the new truck crane - Maximum speed test - Road-holding ability test - ABS test - Brake performance test - Road driving durability test: 15 000 km |

| STEERING |

| ZF Servocom. hydraulic steering with emergency steering pump mechanical hydraulically-assisted of front two axles. |

| SUSPENSION |

|

Front: Load sharing tandem with leaf springs. Double acting shock absorbers. Rear: Hendrickson ULTIMAAX, Rubber mounted tandem with walking beam. |

|

The rounded boom is made of high tensile steel which decreases its weight while increasing its strength to realize smooth and powerful crane operation, while the high-performance AML-C assists with safe and comfortable operation. In addition, the newly developed Smart Chart expands workability into whole new areas to improve operation efficiency Rounded construction boom The rounded boom constructed of high tensile steel contributes to decreased boom weight and increased boom strength. Two telescoping modes [Ⅰ] & [Ⅱ] The operator can select either of the two boom telescoping modes based on the designated job plan. This provides enhanced crane capabilities in accordance with work needs Mode [Ⅰ] is extension of 2nd section only. Then synchronized extension of 3rd, 4th and 5th sections. Mode [Ⅱ] is synchronized extension of 3rd, 4th and 5th sections. Then 2nd section independently Two winches with cable follower Both the main winch and the auxiliary winch have powerful 4.5-ton line pull and operate at high speeds for increased work efficiency. Winch drum camera and monitor |

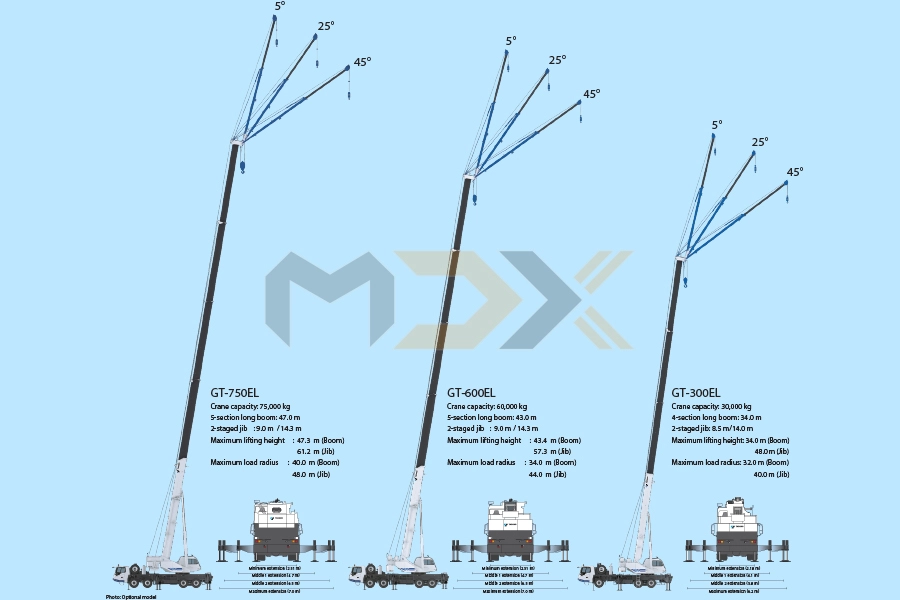

| A two-stage, side up jib makes installation in narrow spaces possible. |

| BOOM + JIB |

|

5-section long boom: 47.0 m 2-staged jib: 9.0 m/14.3 m Maximum lifting height: 47.3 m (Boom) 61.2 m (Jib) Maximum load radius: 40.0 m (Boom) 48.0 m (Jib) |

| Two winches with cable follower |

| Both the main winch and the auxiliary winch have powerful line pull (GT-750EL: 5.6-ton, GT-600EL / 300EL: 4.5-ton) and operate at high speeds for increased work efficiency. |

| SLEWING |

|

Hydraulic axial piston motor driven through planetary slewing speed reducer. Continuous 360˚ full circle slewing on ball bearing. Equipped with manually locked/released slewing brake. A positive slewing lock for travel modes, manually engaged in cab. Twin slewing system : Free slewing or lock slewing controlled by selector switch in cab. Slewing speed................. 1.8 min-1 {rpm} |

| HYDRAULIC SYSTEM |

|

PUMPS: 2 variable piston pumps for crane functions. Tandem gear pump for, slewing and optional equipment. Powered by carrier engine. Pump disconnect for crane is engaged/disengaged by switch from driver's cab. CONTROL VALVES: Multiple valves actuated by pilot pressure with integral pressure relief valves. RESERVOIR: 737 liters capacity. External sight level gauge. FILTRATION: BETA10=10 return flter, full flow with bypass protection, located inside of hydraulic reservoir. Accessible for easy replacement. OIL COOLER - Air cooled fan type. |

|

|

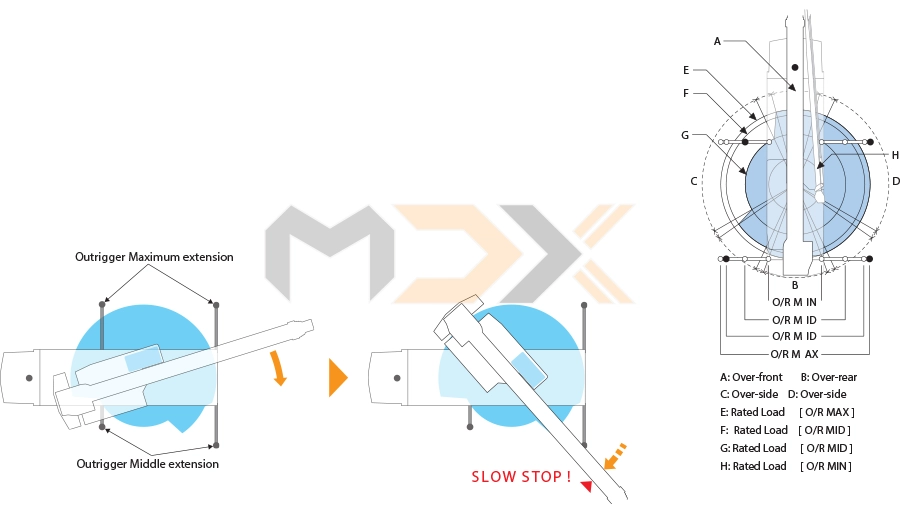

Outrigger Asymmetric Extension Width Control When operating the crane with the asymmetric outriggers extended, the AML-C detects the extension width of all of the crane's outriggers (front, rear, left and right) to measure maximum work capacity in each area. When slewing the boom from the longer outrigger area to the shorter outrigger area, the AML-C detects the motion and displays The maximum capacity according to the extension width of each of the outriggers,and brings the motion to a slow stop before it reaches the maximum capacity. Therefore, even in the case of operator error, the AML-C's slow stop function will help to minimize any safety risk. |

| OUTRIGGERS |

|

Hydraulically operated H-type outriggers. Vertical jack cylinders equipped with integral holding valve. Each outrigger beam and jack is controlled independently. Outrigger jack floats are attached thus eliminating the need of manually attaching and detaching them. Controls and sight bubble located either side of carrier. 4 outrigger extension lengths are provided with corresponding "RATED LIFTING CAPACITIES" for crane duty in confined areas. Min. Extension 2.51 m center to center Mid. Extension 4.7 m center to center Mid. Extension 6.5 m center to center Max. Extension 7.0 m center to center Float size 0.45 m x 0.29 m |

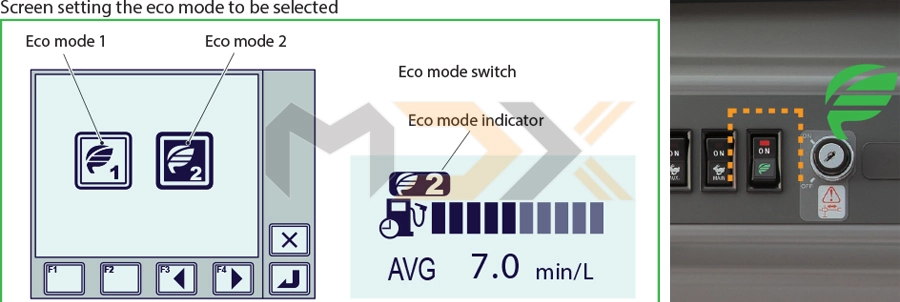

| ECO MODE SYSTEMS |

|

| The Eco Mode System controls the maximum engine speed at the time of crane operation. To prevent an unnecessary rise in engine speed when there is excessive acceleration, the system enables fuel consumption and CO2 emissions to decrease by Max. 22% with Eco mode 1, and Max. 30% with Eco mode 2, and the noise level is reduced. |

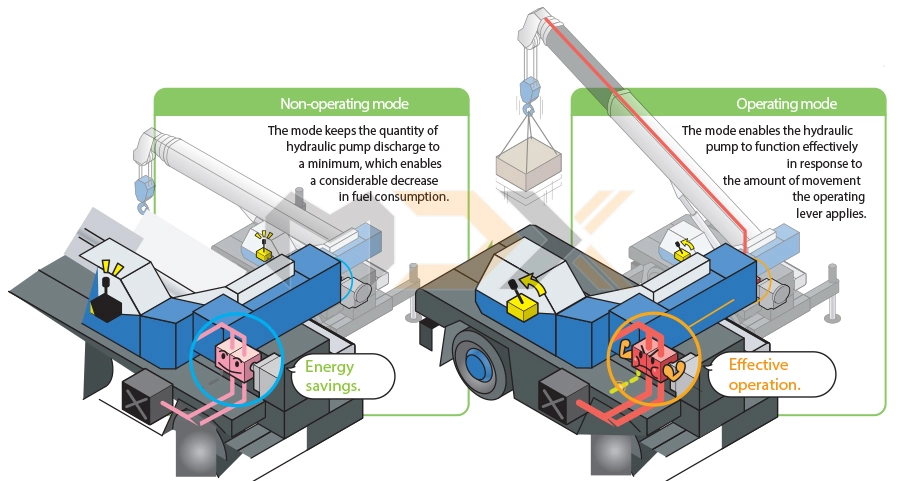

| POSITIVE CONTROL SYSTEM |

|

|

The Positive Control System effectively controls the quantity of hydraulic pump discharge during crane operation in response to the amount of movement applied by the operating control lever. When the crane is in a state of idling, the Positive Control System keeps the quantity of hydraulic pump discharge to a minimum, reducing fuel consumption and CO2 emissions by up to 20%. Non-operating mode The mode keeps the quantity of hydraulic pump discharge to a minimum, which enables a considerable decrease in fuel consumption. Operating mode The mode enables the hydraulic pump to function effectively in response to the amount of movement the operating lever applies. |

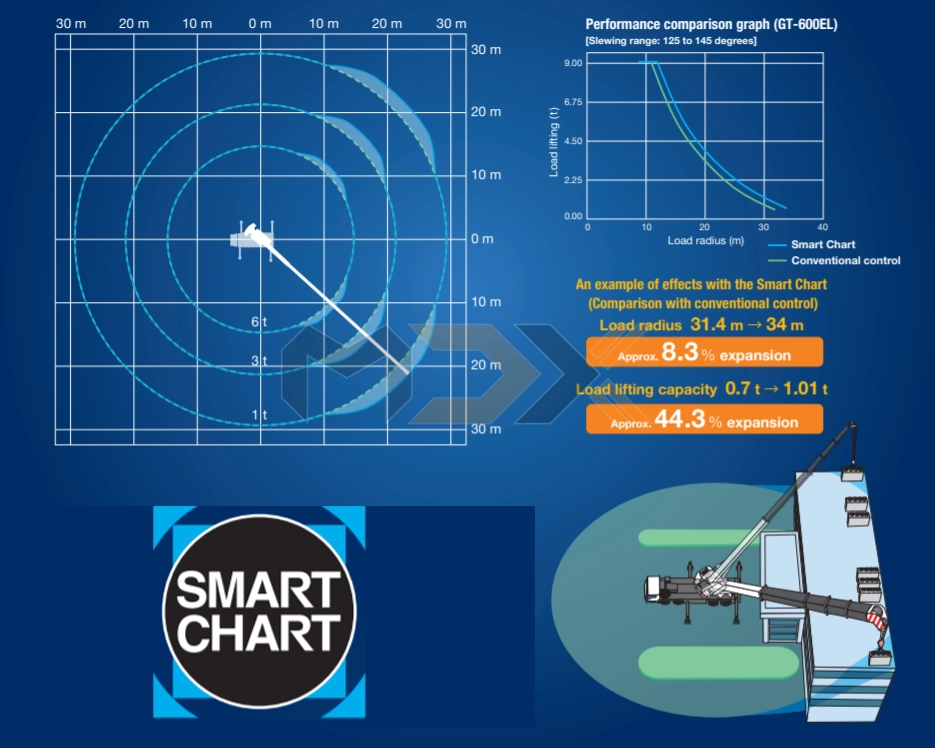

| SMART CHART SYSTEM |

|

|

The newly developed Smart Chart expands the working area, allowing you to get the best crane performance in any outrigger extension setup. Tadano's new Smart Chart taps into a crane's full potential by expanding the rear part of the conventional circular work area into a square for increased load radius when the outriggers are extended to improve safety and efficiency. |

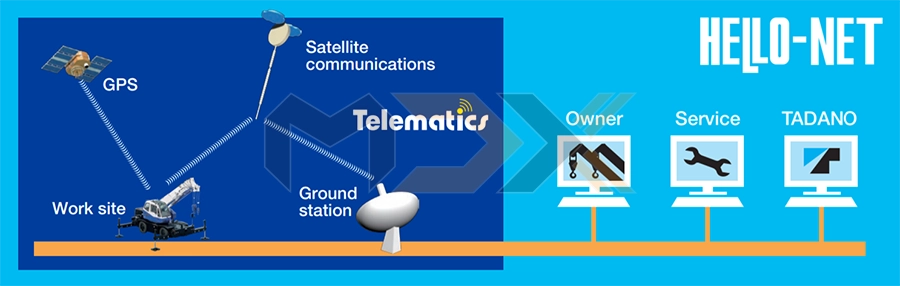

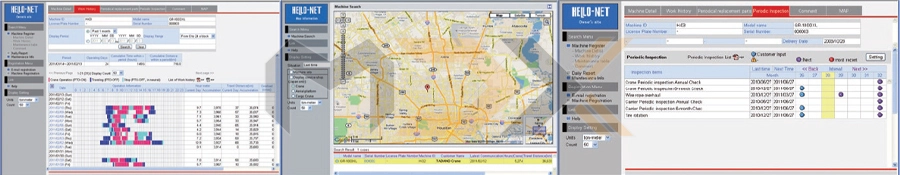

| HELLO - NET |

|

|

|

TADANO supports your crane management via the Internet, providing information about operational status, position and maintenance. Monitoring machine information from your computer 1. Work History HELLO-NET Owner’s Site displays the day-to-day operational status, mileage and remaining fuel for each machine equipped with a communication terminal. In addition, you can view a list displaying the number of hours of operation and the mileage of all your machines for any specified month. 2. Machine Position Data Using HELLO-NET Owner’s Site, you can check a machine's latest position (up until the previous day) on a map. Two types of position data, listed below, are transmitted automatically from your machine once every day. Work Site: The location where the machine’s PTO has been activated (for one hour or more). Position at Day’s End: The final location from which GPS was able to receive data on a given day. 3. Maintenance Information You can check the maintenance timetable of your machines for periodical replacement parts and inspection schedule. HELLO-NET supports the maintenance of your machine. Telematics (machine data logging and monitoring system) with HELLO-NET via internet (*availability depends on the situation). DETAILS: The availability of data communication systems, such as satellite or mobile communications which serve to widen the service area differs according to individual countries. Besides, there are some countries where the system itself is not in use yet. For details, please contact your distributor or our sales staff in charge. |

| Options |

|

Tags: GT 750EL 3, tadano crane, tadano cranes specifications, biggest tadano crane, tadano truck crane, tadano crane 55 ton, tadano crane 50 ton, tadano crane 25 ton, tadano 100 ton crane, tadano 160 ton crane, tadano 120 ton crane, tadano 80 ton crane, tadano 60 ton crane, tadano 25 ton crane, tadano mobile crane, tadano 130 ton crane, demag mobile cranes, demag crawler cranes, atf 220g 5, tadano faun, kato crane, grove crane, all terrain crane hire, xcmg all terrain crane, 100 ton all terrain crane, rough terrain crane