Vögele’s SprayJet technology has proved its value for many years and is used for pavement rehabilitation and construction in markets around the world.

The new Vögele SprayJet comes with a large array of impressive innovations. One feature of fundamental importance is that operation of the spray module has been integrated into the ErgoPlus 3 operating concept. The module is designed as a completely self-contained functional unit. This modular design makes Vögele S1800-3 SprayJet simple to service and allows it to be used both as a spray paver and as a conventional asphalt paver.

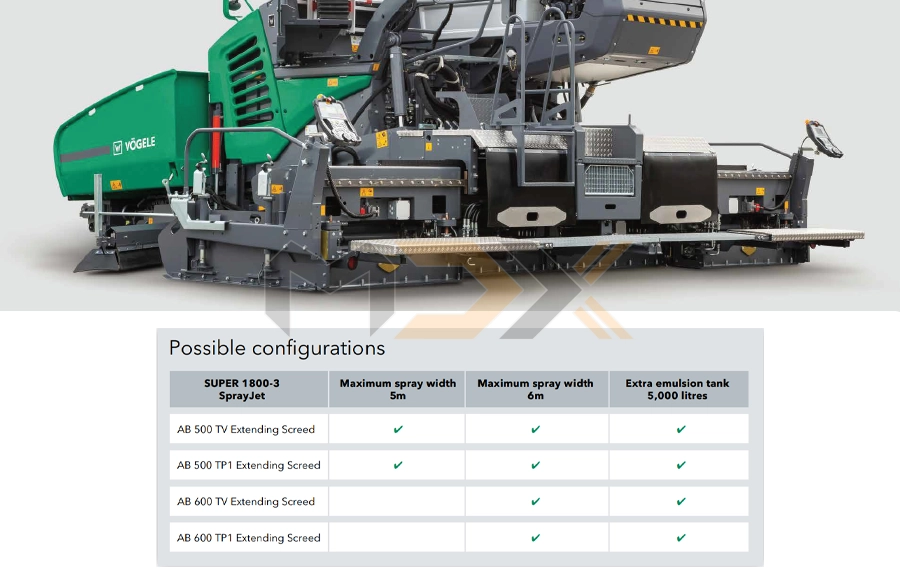

The paver has a maximum spray width of 6m. As a conventional paver without spray function it can even pave widths of up to 9m.

It goes without saying that the paver also includes all the “Dash 3“ features. The Vögele EcoPlus package, for instance, significantly reduces both fuel consumption and noise levels. The new AutoSet Plus functions allow quick and safe relocation of the paver on the job site and make it possible to store frequently recurring paving programs.

Super 1800-3-SJ is the world‘s unique spray paver for placing thin asphalt overlay as well as conventional binder and surface courses.

| Screed | Type | Basic Width | Maximum Width | Compacting Systems |

| AB 500 (More) | 2.55 m | 6 m | TV, TP1 | |

| AB 600 (More) | 3 m | 6 m | TV, TP1 | |

| Layer thickness (up to) | 30 cm | |||

| Heating | electric, thermostat-controlled | |||

| Power Supply | Three-phase AC generator | |||

| DIMENSIONS AND WEIGHT |

||

| Operating weight | Screed | Total weight |

| AB 500 TV | 22 020 kg | |

| AB 500 TP1 | 22 370 kg | |

| AB 600 TV | 22 420 kg | |

| AB 600 TP1 | 22 770 kg | |

| Length | Screed | Total length |

| AB 500 TV | 6.04 m | |

| AB 600 TV | 6.04 m | |

| AB 500 TP1 | 6.17 m | |

| AB 600 TP1 | 6.17 m | |

| Maximum laydown rate | 700 t/h | |

|

|

| World‘s unique spray paver for placing thin asphalt overlay as well as conventional binder and surface courses | The Vögele EcoPlus low-emissions package significantly reduces fuel consumption and noise levels |

| Cutting-edge ErgoPlus 3 operating concept for paver and spray module | Emulsion sprayed at a rate of 0.3 to 1.6kg/m²* in a clean and controlled process |

| Uniform “dash 3” service concept ensures easy maintenance and cuts training costs | AutoSet Plus automatic functions for rapid relocation of the paver on the job site and storing paving programs |

| ErgoPlus 3 screed console with SmartWheel for convenient screed width control | Pavedock Assistant for better and safer communication when feeding the paver with mix |

| Advanced and precise screed technology for perfect high-quality pavements | |

Range of applications for the Vögele spray paver |

|

|

For many road construction and civil engineering contractors, Vögele S1800-3-SJ offers an excellent opportunity to employ their paver in a variety of applications, be it as a classical upper mid-range paver or as a special machine for particular jobs. The machine technology of Super 1800-3 spray paver is ideal in all cases. It is based on the modular machine concept developed by Vögele . As a result, the paver can be used either with the SprayJet module or, with only minor conversions, as a classical asphalt paver without SprayJet module. |

Paving thin overlay on spray seal, “hot on hot”This is a cost-effective asphalt paving method for rehabilitation or renewal of the surface course. It can be used on all traffic areas. The layer thickness is normally no more than 1.2 to 2cm. The method owes its cost-effectiveness to saving expensive surface course material. The procedure is ideal in municipal areas, as paving thin overlay does not require any costly adaptation of kerbs or other pavement fittings. With Vögele Super 1800-3 SprayJet, thin overlay can be paved on a spray seal three to five times faster than with conventional equipment. The bitumen emulsion is sprayed and the asphalt layer placed by the Vögele machine in a single pass. This way, job site vehicles do not drive over the sprayed surface and never damage the emulsion film. |

|

Advantages of the techniqueSaving of cost 1 Thin layer saves up to 50% of material cost. 2 no costly adaptation or new installation of kerbs are required. 3 When a spray paver is used, there is no possibility of job site vehicles driving over the sprayed area. This means that other roads in the area are not soiled and need not be cleaned after completion of the job. 4 Short construction time due to fast progression of the roadworks and quick reopening of the road to traffic. High quality 5 An excellent bond between layers, perfect sealing and effective protection of the existing base add up to a long service life for the road. 6 high initial and permanent roughness of the resurfaced road are guaranteed |

Paving binder and/or surface course on spray sealThis classical method is widely used in many countries when rehabilitating traffic areas. So far, it has been common practice to spray the surface with bitumen emulsion beforehand so that the water could evaporate over night. This left a bitumen coat subsequently overlaid with a binder course or surface course. however, the time and equipment required has been a considerable disadvantage of this method. Another problem that should be avoided wherever possible is that surrounding areas, roads and kerbs are fouled by crossing job site vehicles. These problems are now a thing of the past, thanks to Super 1800-3-SJ technology.

On innumerable construction projects around the world, the Vögele paver with SprayJet module has proved that its special spray technology makes it the perfect machine as regards both quality and cost-efficiency for all road building contractors |

What happens when bitumen emulsion “breaks”?The water begins to evaporate as soon as the hot bitumen emulsion is sprayed at a temperature of 70 to 80 °c. The remaining water evaporates spontaneously when the emulsion comes into contact with asphalt heated to more than 100 °c. In this way, the emulsion “breaks” when using S1800-3-SJ technology. |

|

|

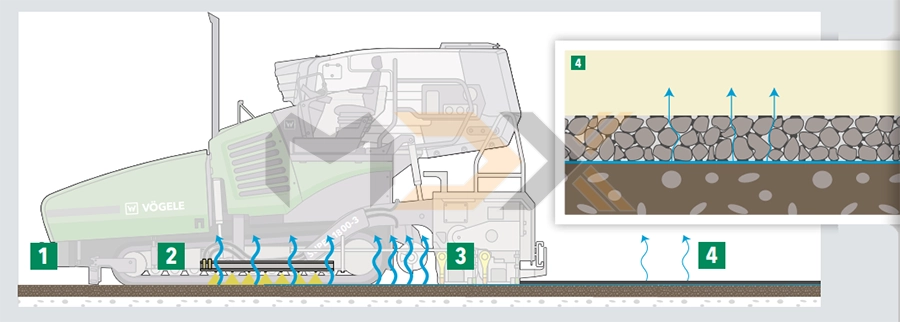

1 The prepared base is either a milled surface or a freshly laid binder course. 2 hot bitumen emulsion at a temperature between 70 and 80 °c is applied by the spray paver. 3 Paving of a binder or surface course starts. The bitumen emulsion “breaks” immediately as the hot asphalt causes the water to evaporate, leaving a firmly adhering film of bitumen. 4 Any water still remaining in the emulsion evaporates through the “open pores” of the asphalt overlay |

VÖGELE spray technology |

|

|

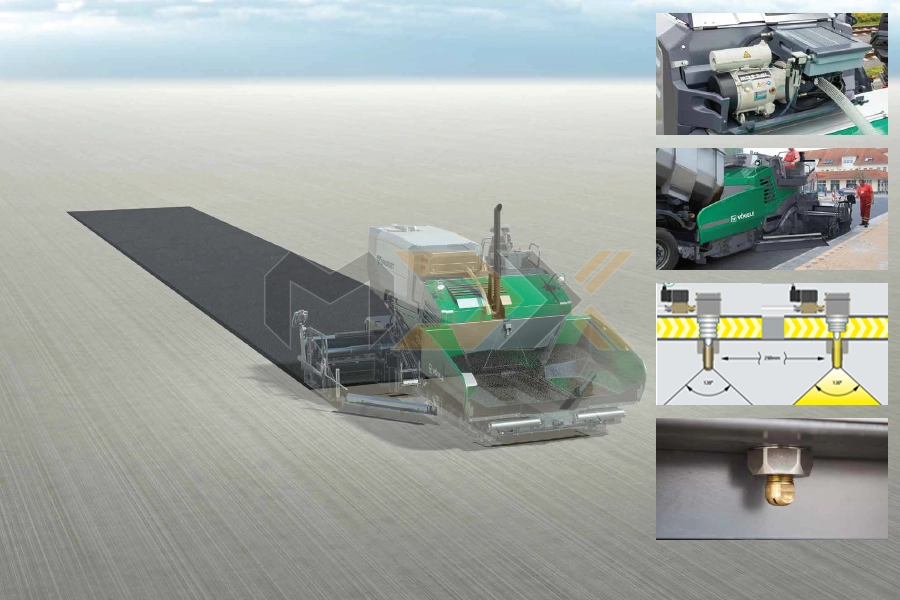

Vögele S1800-3 spray paver is equipped with five spray bars. The front spray bar has six spray nozzles and is located between the machine’s crawler tracks right behind the push-rollers. An articulated spray bar installed on each side of the paver comes with 7 nozzles per side. Finally, a short spray bar with two nozzles is provided right behind each crawler track. This arrangement of the spray bars allows full coverage of the existing surface with emulsion, even when the pave width varies. The rate of spread can be selected accurately within the range of 0.3 and 1.6kg/m²*. The SprayJet nozzles do not spray the emulsion continuously, but operate instead in pulsed mode. The frequency of the spray pulses is adjusted automatically as a function of the selected rate of spread, pave speed and pave width. As a result, complete coverage of the existing surface with a uniform film of emulsion is achieved, without any overlaps. Emulsion is applied at an exceedingly low spray pressure of no more than 3 bar. In combination with the high-quality spray nozzles, this allows the emulsion to be sprayed cleanly and without burdening the environment. 1. The spray nozzles are opened and closed pneumatically. A compressed air system is integrated into the SprayJet module for this purpose. 2. The nozzles do not spray the emulsion continuously,but operate instead in pulsed mode. The frequency of the spray pulses is adjusted automatically as a function of the selected rate of spread, pave speed and pave width. 3. A very low spray pressure of no more than 3 bar allows absolutely uniform spreading of bitumen emulsion and a clean result when spraying along kerbs. 4. The particularly high quality of the spray nozzles guarantees perfect spraying. |

Perfect spraying even at smallest rates of spread |

|

|

The Vögele SprayJet module allows to precisely select a rate of spread ranging from a very small quantity of emulsion through to a large quantity. The range extends fom 0.3 to 1.6kg/m²*. Rate of spread and pave width can be selected independently of the pave speed. The possibility of spreading emulsion accurately at a very small rate of just 0.3kg/m²* makes Vögele Super 1800-3 SprayJet technology unique in the market. Attention shall be paid to the fact that the spread rates are dependent upon the kind of emulsion used, the emulsion viscosity and the temperature when applied. S1800-3-SJ module‘s colour touchscreen display provides the operator with all important information and allows him to easily set the desired rate of spread. Three different types of spray nozzles are available for the spray bars of the SprayJet module: nozzles of the sizes 07, 10 or 16. nozzles size 10 are fitted as standard. The spray nozzles size 07 have a throughput of 70% compared to the nozzles of size 10 (100%). The nozzles size 16 have a throughput of 160%. |

Modern drive technologyThree main components define the power unit of Super 1800-3 SprayJet: its modern, liquid-cooled diesel engine, a splitter gearbox flanged directly to the engine and a large cooler assembly. The driving force in this Vögele power pack is its diesel engine. The six-cylinder engine delivers 127kW at 2,000rpm. yet the fuel-saving EcO mode is sufficient for many applications. Even in EcO mode, Vögele S1800-3-SJ still has a full 116kW at its disposal. Moreover, the machine generates less noise when running at just 1,700rpm. A large cooler assembly ensures that the power unit always delivers its full output. With innovative air routing and a variable-speed fan, temperatures are continually maintained within the optimum range, Significantly extending the service life of both the diesel engine and the hydraulic oil. A further advantage is that the machine can operate without difficulty in all climate regions worldwide. All hydraulic consumers are directly supplied with hydraulic oil via the splitter gearbox. hydraulic pumps and valves are centrally located, making them easily accessible for servicing. Even the powerful generator for screed heating is flanged directly onto the splitter gearbox. Its integrated oil cooling system makes it completely maintenance-free and very quiet. |

|

|

The large cooler assembly is made up of three parts. It ensures that engine coolant, charge air and hydraulic oil are maintained at the optimum temperature. Powerful diesel engine rated at 127kW. ECO mode with 116kW cuts operating costs and supports super-quiet operation. A powerful, oil-cooled generator with direct drive ensures rapid, uniform heating of the screed |

Advantages of the “dash 3“ generation |

|

Vögele Super 1800-3 SprayJet can be used both as a spray paver and as a conventional paver at any time. Regardless of the application, the machine always offers its operators all the various advantages resulting from the innovative edge of the “Dash 3“ paver generation. These advantages are of particular significance for construction projects in urban areas. The functions of AutoSet Plus automate on-site relocation and transport of the machine on the one hand, and store individual paving programs on the other. This not only saves time, but also enhances process safety and the pavement quality. Despite all their differences, the “Dash 3“ features have one thing in common: they are all consistently designed to improve the operator‘s control of the machine and the paving process, as well as to make the paver more eco-friendly. As a result, Super 1800-3-SJ is also ideal for use as a powerful and versatile standard paver. |

|

|

Vögele EcoPlus The innovative Vögele EcoPlus low-emissions package includes a number of features for reducing both noise levels and fuel consumption. fuel costs are cut by around 25% through the combination of an energy-optimized tamper drive, variable-speed fan, controlled hydraulic oil temperature circuit and splitter gearbox with ability to disengage hydraulic pumps. Pavedock Assistant PaveDock Assistant is the communication system between the paver operator and the feed vehicle driver. It allows particularly fast and reliable transfer of mix to the paver. The PaveDock Assistant communication system contributes greatly to process safety during transfer of the mix. AutoSet Plus AutoSet Plus incorporates two handy automatic functions: the Repositioning and Transport function makes it easier to change between work sections on the job site. The paver is automatically set to transport mode at the push of a button and the current settings are saved. The Paving Programs function allows to save paver and screed settings, which can be called up when required at a later date, for instance on job sites with comparable conditions. |

The ErgoPlus 3 operating conceptEven the very best machine with the most advanced technology can only really show its strengths if it can be operated easily and as intuitively as possible. At the same time, it should offer an ergonomic and safe working environment for the operating team. Therefore, the ErgoPlus 3 operating concept focuses on the operator. With Vögele pavers, the user consequently retains full control over the machine and construction project. On the following pages example illustrations will provide you with more detailed information on the extensive functions of the ErgoPlus 3 operating concept. for the SUPER 1800-3 SprayJet, ErgoPlus 3 encompasses the paver operator’s console, the screed consoles and the control panel for Vögele Super 1800-3-SJ module. |

|

The paver operator‘s ErgoPlus 3 consoleLike all “dash 3” generation pavers, Super 1800-3 spray paver comes with the Vögele ErgoPlus 3 operating concept which substantially facilitates the paver‘s handling. In this way, Vögele offer the operators every conceivable convenience expected of a modern operating system. All the important, regularly used functions are clustered in logical groups. This makes their operation easy to learn. Important spraying functions have been integrated into the large colour display on the paver operator‘s console which offers outstanding legibility even in poor lighting conditions. The maximum possible pave speed is displayed here for the paver operator as a function of the set rate of spread. In addition, the handy automatic functions “Start of Job” and “End of Job” can be activated at the push of a button. |

|

|

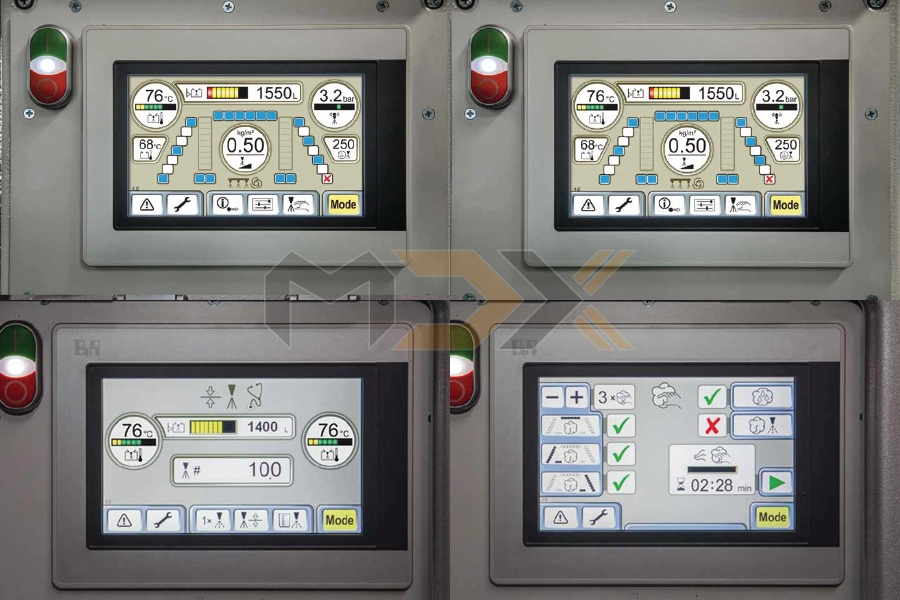

1. Indication of maximum pave speed The display shows the maximum possible pave speed at which full coverage of the existing surface with emulsion is still ensured. 2. “Start of Job” and “End of Job” The comfort functions “Start of Job” (f6) and “End of Job” (f8) are provided so that spraying always starts and ends at exactly the required point and continues over the full pave width. |

The ErgoPlus 3 screed consoleSafe and easy handling of all screed functions is a factor of utmost importance for high-quality road construction. All the essential data are displayed on the two ErgoPlus 3 screed consoles. Self-explanatory symbols make it easy to set or adjust parameters for the screed, conveyors and augers or grade and slope control. The Vögele SmartWheel is an exceedingly practical innovation. With it, the pave and spray width can be conveniently adjusted in two speeds: slow, for precise screed width control along an edge, or fast for swift extension and retraction of the screed. The two outermost nozzles on the spray bars at the sides can be switched on and off via the screed console to obtain precise spraying along an edge. The ErgoPlus 3 control panel for the SprayJet moduleOperation of the SprayJet module has been consistently integrated into the ErgoPlus 3 operating concept. This applies not only for the icons used on the operator interface, but also for the “Touch and Work“ principle. All functions for preparation, spraying and cleaning are conveniently selected and started via the touchscreen mounted directly on the module. Work sequences pass off automatically in accordance with the function which has been selected. All this makes operation of Vögele Super 1800-3-SJ module extremely safe and simple. |

|

|

3. Outer spray nozzles The two active outer spray nozzles can be switched on and off via the screed console. In this way, even more challenging job sites can be mastered by the screed operator and a perfect result produced. 4. SmartWheel Both the pave width and the spray width are conveniently adjusted in two speeds by means of the SmartWheel 5. Preparation All the functions needed to prepare for spraying can be set via the menus 5.1 to 5.3. Menu 5.1 controls the process of filling the emulsion tank, menu 5.2 is used to set-up the nozzles, while the parameters for heating and circulating the emulsion are set in menu 5.3. 6. Cleaning The ErgoPlus 3 SprayJet module includes an all-automatic cleaning program ensuring that the lines and valves are thoroughly cleaned. 7. Spraying The paver operator can set up and monitor all relevant spraying parameters, such as the filling level of the emulsion tank, temperature, spray pressure and rate of spread, as well as nozzle activity. |

The ErgoPlus 3 control panel for the SprayJet moduleOperation of the SprayJet module is effected entirely via the ErgoPlus 3 control panel on the spray module. clearly legible in all weather conditions, the touchscreen assures the operator of full control over the spraying process at all times. The “Dash 3” generation Vögele spray paver offers a large number of convenient automatic functions meeting practical needs. for the operator, they fundamentally simplify preparation of the spray module, the spraying process itself and maintenance of the spray module: - All the settings required for replenishing, circulating and heating the emulsion can be entered and monitored directly via the touchscreen. - Depending on the installed nozzle size and the selected rate of spread, the maximum pave speed is calculated by the SprayJet module’s control unit and displayed on the paver operator‘s ErgoPlus 3 console. This ensures uniform application of the emulsion. - The rate of spread can be set here just as easily and the nozzles calibrated or switched on and off individually. correct operation of the front spray bar is monitored electronically, as it is out of sightof the screed operator. - Lines and valves are cleaned in a fully automated process controlled by a separate program. |

|

|

Menu for “Spraying” The entire spraying process is monitored here. The operator can monitor all settings and values at a glance, such as spray nozzle activity (active/inactive/switched off) and spray pressure. Menu for “Nozzle set-up” The installed nozzle size can be entered via this menu, and nozzles can be tested and the rate of spread checked here. Menu for “Cleaning” The number of cleaning cycles is shown here as a function of the degree of fouling. The circuits to be cleaned are actuated individually. A preservative can be added to the final cleaning cycle. Once started, the cleaning process is executed entirely automatically. |

Vögele extending screeds for perfect pavement quality |

|

|

For Vögele S1800-3-SJ, two screed options are available: AB 500 and AB 600. Either of the extending screeds handles pave widths up to 6m. The AB 600 comes with a basic width of 3m and extends hydraulically up to 6m. The AB 500 builds up to its maximum width of 6m with additional bolt-on extensions (75cm). The widths of the screeds are limited electronically to a maximum of 6m. Either screed is available in the TV version (with tamper and vibrators) or in the TP1 version (with tamper and 1 pressure bar). Like all Vögele screeds, the AB 500 and AB 600 Extending Screeds, too, feature effective electric heating. Screed and emulsion tank are heated independently, so that heating of the emulsion can take place without having to heat the screed. On the two ErgoPlus 3 screed consoles for the operators, all vital information is displayed. Thanks to self-explanatory symbols, set-up and adjustments can easily be made. |

Tags: SprayJet S1800 3 SJ, S1303 3, Wheeled Paver, Vögele paver, Vögele super 700, asphalt paver machine, asphalt paver price, asphalt paver parts, small asphalt paver, mini asphalt paver, volvo asphalt paver, caterpillar asphalt paver, tracked paver, asphalt paver, wheel asphalt paver, asphalt paver specs, asphalt paver machine specifications, cat paver