| BOOM |

|

4-section full power telescoping boom with 2 extension modes. System consists of two double acting hydraulic cylinders with load holding valves and extension and retraction cables.

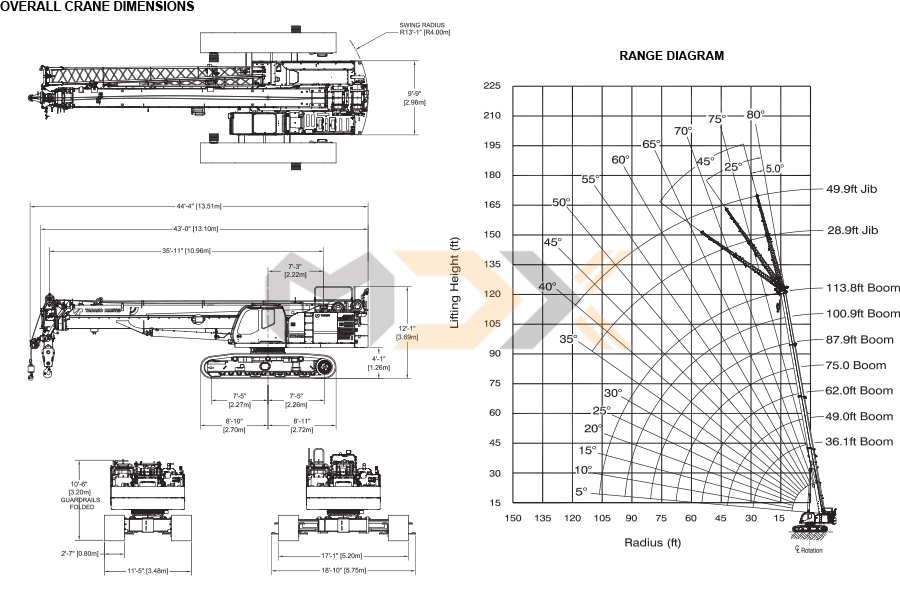

- Retracted Length: 36’ 1” (11.0m)

- Extended Length: 113’ 10” (34.7 m)

- Extension Time: 114s

- Elevating Angles: -1.5° to 80.5°

- Elevating Time: 67 s

- Max Lifting Height: 111’ 1” (33.9 m)

- Boom Head: Six, 14.7 inch (373 mm) diameter main sheaves on heavy-duty roller bearings. Two, 14.7 inch (373 mm) diameter lead in sheaves on heavy-duty roller bearings. Designed for quick reeving of head and load block

|

| WINCHES |

|

Planetary geared two-speed winch includes a hydraulic motor, multidisc internal brake and counterbalance valve. Drum rotation indicator is included

- Main Winch

+ Rope Diameter and Length: 5/8 in x 615 ft (16mm x 187m)

+ Single line pull: 13,311lb (59.2 kN) (first layer)

+ Single line speed: 347 ft/min (105.8 m/min) (4th layer)

- Auxiliary Winch

+ Rope Diameter and Length: 5/8 in x 350 ft (16mm x 107m)

+ Single line pull: 13,311lb (59.2 kN) (first layer)

+ Single line speed: 347 ft/min (105.8 m/min) (4th layer)

|

| AUXILIARY BOOM HEAD |

| Quick reeve, single sheave mounted on a heavy-duty roller bearing. Allows single part reeving |

| COUNTERWEIGHT |

|

2 piece Standard counterweight design. Two upper counterweight configurations

- Standard Configuration = 17,400lb (7893 kg)

- Optional Heavy Configuration = 28,200lb (12,791 kg)

|

| TRAVEL |

|

Each side frame contains a two-speed track drive with hydraulic axial piston motor and parking brake. Travel system provides skid steering and counter rotation.

- Travel speed - Low: 0.8 mph (1.3 km/hr) High: 1.8 mph (2.9 km/hr)

- Gradeability (unladen): 85%

- Unladen Ground Pressure: 9.3 psi (0.65 kg/cm2)

|

| SWING |

|

Gear motor driving a planetary gear reducer with a shaft mounted pinion, external gear shear ball slew bearing bolted to the superstructure and the carbody allows the superstructure to rotate 360°

- Swing Speed: 0 - 2.0 rpm

- Swing Parking Brake: Spring applied failsafe brake with hydraulic release that is controlled from the operators cab

- Swing Service Brake: Hydraulically applied, controlled through foot actuated pedal

- House Lock System: 2-position house lock (boom over front or rear). Actuated from the operator’s cab.

|

| LOAD MOMENT INDICATOR |

|

TADANO AML-C Rated Capacity Limiter and Anti-Two Block system

- OPTI-WIDTH™ - OPTIMAL lifting performance at any track WIDTH

- Control function shutdown. Audible and visual warnings

- LCD screen provides a continuous display of working boom length, boom angle, working load radius, tip height, swing position, partsofline (operator set), machine track configuration, relative load moment, maximum permissible load and actual load.

- Anti-two block weight allows quick reeving of hook block

- Operator configurable working range limits with automatic soft stop

|

| OPERATORS CAB |

|

Fully-enclosed, air conditioned all-steel modular cab with lockable sliding door, acoustical lining, anti-slip floor and tinted safety glass.

- Cab tilts 20°.

- Rear view, winch view and right side view video cameras

- Three remote control work lights.

- Vent window in the rear of the cab.

- Grab bars and steps are located for easy access to the cab.

- Defroster, heater, circulating fan

- 2-speed windshield wiper, top glass wiper

- Six-way adjustable fabric seat with headrest, seat belt

- Dome light

- Dry-chemical fire extinguisher

- Four-way electronic armrest mounted joysticks control swing, main winch, auxiliary winch, boom hoist and boom extend. Foot pedals control the travel and swing service brake functions. Swing brake pedal is hydraulic.

- Selectable modes for Fine Control and Travel. Travel function can be operated by foot pedals or joystick.

- Seat termination switch immediately disable all hydraulic functions as the operator rises from the seat. Functions can also be disabled by switch on console.

- Dash instrumentation: tachometer, hour meter, fuel gauge, and DEF level gauge. Indicators are provided for crane level, swing position, load moment, drum rotation, air filter restriction, engine oil temperature and pressure, hydraulic oil temperature and level, and hydraulic and air filter restriction, and low voltage

|

| ENGINE |

|

High power engine provides superior travel and multi-function performance

- Make/ Model: Cummins QSB6.7

- Type: 6 Cylinder, Water cooled, 4 Cycle

- Aspiration: Turbocharged and Aftercooled

- Max.Output: 260 hp (194 kW) @ 2200 RPM

- Max Torque: 730 Lb-ft (990 Nm) @ 1500 RPM

- Piston Disp: 6.7 L

- Emission Cert: U.S. EPA Tier 4f, Euromot Stage IV

- Alternator: 70 amp

|

| Automatic moment limiter [AML-C] |

|

| Tadano's AML-C is easy to use, innovative in design, displays important information to the operator and enables the operator to preset a custom working environment. For example, the AML-C shows the boom angle, boom length, load radius, operating pressure of the elevating cylinder, the extension width of the outriggers, slewing position, rated lifting capacity and present hook load. These features allow the AML-C to move seamlessly through all lifting operations without having to change configurations or input new codes to make the lift. The AML-C safety features provide both audible and visual warnings. When an operation approaches the load limit Tadano's slow stop function engages to avoid shock loads |

| ELECTRICAL SYSTEM |

| 24 VDC |

| FUEL SYSTEM |

|

Capacity: 85 gallon (321 liter)

Filtration: Inline fuel/water separator and engine mounted fuel filter

|

| SIDE FRAMES |

|

Two welded steel side frames are paired with a track group. The side frames extend and retract hydraulically and are controlled from the cab.

- Track Rollers: Three top and twelve bottom sealed rollers on each track frame Idler: Oil filled, self lubricating with spring type tensioner

- Track Shoes: 31.5 inch (800 mm), 3-bar semi grouser

|

| HYDRAULIC SYSTEM |

|

Hydraulic Pumps: Two high pressure, variable axial piston pumps with load sense and power limiting control for crane functions. One gear pump for cooling loop.

- Directional Valves: Multiple pressure and flow compensated valves with integrated relief valves controlled by electrical signals.

- Pump output: 154 gpm (582 l/min) @ 2200 RPM engine speed. 5,000 psi (345 bar) maximum pressure

- Reservoir: 185 gallon (700 liter) capacity, filler/ breather, sight gauge, cleanout, and sump drain.

- Filtration: Three 5 micron, full flow tank mounted return filters with electrical clogging indicator. Two 2 micron pilot oil in-line pressure filters

- Diagnostic Ports: Provided for system, load sense, and pilot pressure

|

| BI-FOLD JIB |

|

Main jib

- Total Length: 28.9 ft (8.8m) o Offset Angles: 5°, 25° & 45°

- Max. Lifting Height: 140.7 ft (42.9 m)

Fly jib

- Total Length: 49.9 ft (15.2m) o Offset Angles: 5°, 25° & 45°

- Max. Lifting Height: 161.0 ft (49.1m)

|

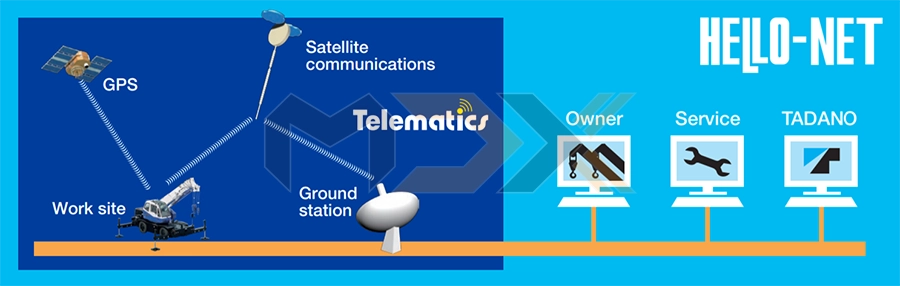

| HELLO - NET |

|

|

|

TADANO supports your crane management via the Internet, providing information about operational status, position and maintenance.

Monitoring machine information from your computer

1. Work History

HELLO-NET Owner’s Site displays the day-to-day operational status, mileage and remaining fuel for each machine equipped with a communication terminal. In addition, you can view a list displaying the number of hours of operation and the mileage of all your machines for any specified month.

2. Machine Position Data

Using HELLO-NET Owner’s Site, you can check a machine's latest position (up until the previous day) on a map. Two types of position data, listed below, are transmitted automatically from your machine once every day. Work Site: The location where the machine’s PTO has been activated (for one hour or more). Position at Day’s End: The final location from which GPS was able to receive data on a given day.

3. Maintenance Information

You can check the maintenance timetable of your machines for periodical replacement parts and inspection schedule. HELLO-NET supports the maintenance of your machine.

Telematics (machine data logging and monitoring system) with HELLO-NET via internet (*availability depends on the situation).

DETAILS: The availability of data communication systems, such as satellite or mobile communications which serve to widen the service area differs according to individual countries. Besides, there are some countries where the system itself is not in use yet. For details, please contact your distributor or our sales staff in charge.

|

| OPTIONAL EQUIPMENT |

|

Hook blocks

- 55 ton (50t) quick reeve hook block – Six, 16.1 in (410mm) steel sheaves, swivel hook and safety latch

- 33 ton (30t) – Three, 16.1 in (410mm) steel sheaves, swivel hook and safety latch

- Overhaul ball – 7.7 ton (7t) with swivel hook & safety latch

- 360 degree house lock. Actuated from the operator’s cab.

- Track Shoes: 35.4 inch (900 mm) 3-bar semi grouser

- Auger: Hydraulic auger boom package includes auger motor, hoses, fasteners, and stowage bracket assembly mounted to the 2nd stage section of boom for variable radius drilling.

- Tool Circuit: Provides 5 gpm (23 l/min) and 10 gpm (45 l/min) at 2,500 PSI (176 bar) through a 50 foot (15.2m) twin hose reel with quick disconnect fittings to operate open center tools.

- High Flow Tool Circuit: Provides 45 gpm (170 l/min) at 4800 PSI

- (330 bar)

- Controlled Free Fall Hoists: Winches are available in controlled free fall configurations.

- Cold Weather Packages: Cold weather options are available for operation to -40°C (Consult factory for application support)

- Work Platform: Model WP750 – 36 in x 72 in (0.9m x 1.8m) , all steel, welded, two person platform with maximum capacity of 750 lbs (340 kg).

- Full function Radio remote control package.

- Anemometer: boom mounted wireless anemometer with cab display.

- Automatic Central lubrication system.

|