-

Your shopping cart is empty!

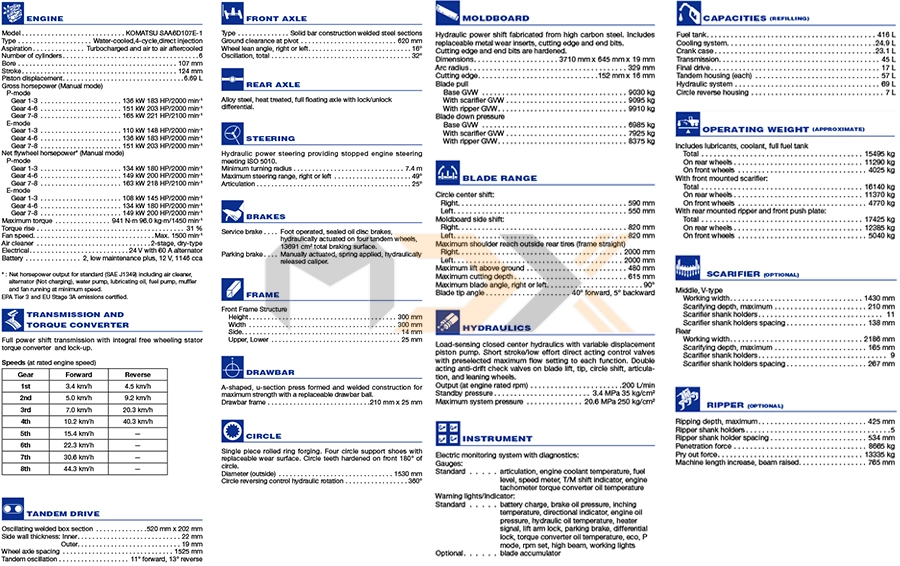

Komatsu motor grader GD655-5

The Perfect Fit for the Jobsite

Most of motor grader applications requires accuracy and versatility. For that, motor graders should be easy to operate in any situations of work. To realize this ease of operation, Komatsu Dash 5 Series Motor Graders are totally improved from overview design down to each element. Our design philosophy contributes to our motor graders fitting in every jobsites from road construction to snow removal, and brings more productivity to every operators from beginner to expert.

Get More Versatility

Komatsu GD655-5 attempts to get more versatility in the middle class graders which are used in various jobsites. With variety of work equipments and stretched wheelbase that is easier to accommodate longer blade, all elements are enhance job efficiency. Moreover, the torque converter transmission provides easy control, resulting in more precise operation in any application.

Long Wheelbase & Short Turning Radius

The long wheelbase enables high leveling performance with a long blade and easier to set the blade position. Long wheelbase also contributes to expanding blade reach in combination with large articulation angle. Additionally the minimum turning radius still short with wide steering angle, serves high maneuverability.

Optimized Hydraulic & Cooling System

Control valve

Komatsu Multifunctional Control Valve with Closed Load Sensing System (CLSS) Hydraulic System enable the constant cylinder speed, excellent multifunctional operation ability and fine control.

Low operating effort

Implement controls are designed to reduce operator fatigue. They feature short lever throws and effort in both directions. Properly spaced control levers and short lever throws allow the operator to use multiple controls with one hand.

Balanced flow

When the operator uses several controls at the same time, flow is proportional to ensure several implements can operate simultaneously.

Constant implement speed

Implement speed is constant regardless of engine speed because of the large pump output and proportional flow control function.

Power on demand

Normally, the variable displacement pump idles at low output. When it senses a load requirement, the pump supplies quick flow and pressure to match the demand. The result is less hydraulic system heat, quick response and lower fuel consumption.

Hydraulic cooling fan

The newly designed cooling fan eliminates excessive cooling capacity by controlling air flow rate according to work load.

Outstanding Power Transmitting System

Komatsu motor grader GD655-5 features Lock-up Torque Converter Transmission for pursuing ease of operation. This unique system provides both efficiency of direct drive and controllability of Torque Converter drive. With this outstanding power transmitting system, the GD655-5 delivers advanced productivity in any applications from fine grading to heavy grading.

Torque Converter Features

High controllability

- Eliminates engine stalling and inching pedal operation.

- Smooth starting, good controllability in fine grading

- Easy travelling, automatic gear shifting.

- Reduce excessive tire slipping

Torque multiplication

- Multiply over twice torque, provides much torque in heavy grading, ditching and ripping

- Stable engine speed, reduce shift changing during road maintenance and snow removal

Lock-up function

- Prevents loss of efficiency

Spacious Interior

Low noise

New hydraulically driven fan and redesigned layout of the cooling system achieve a low noise level.

Operator’s ear dynamic noise level (ISO6396) 74dB (A)

Suspension seat

The suspension, fabric covered seat which is adjustable to the operator’s weight is provided as standard. The suspension seat dampens vibrations transmitted from the machine and reduces operator fatigue. The seat features fold-up armrests and a retractable seat belt.

Electric throttle control

The RPM mode select switch allows the operator to perfectly match the working condition by selecting between three modes: Auto, Off and Manual. The engine speed set by throttle switch is temporarily cancelled when operating the brake/acceleration pedal at Auto mode

Storage space

The cab includes built-in storage space for personal items such as a lunch box, coffee cup, and a coat hook.

Air conditioner

Well-positioned air conditioning vents keep the operator comfortable through a wide range of outside conditions.

Adopted DC 12 V electrical outlet (Optional)

12 V DC outlets is included in the operator’s cab.

Adjustable control console

The control console is adjustable backward and forward to facilitate entry and exit from the cab. The steering wheel also tilts to the operators preference.

Machine Monitoring System

The machine monitor displays various machine information and allows for various settings of the machine. Displays maintenance information, operation records, etc. By using the switch panel, you can display various user menus on the Liquid Crystal Display (LCD) unit screen and perform the settings of the machine.

Clear character display

During normal operation, the service meter/odometer is displayed in this area. If an abnormality or machine overload occurs, or if machine maintenance and inspection are required, action codes appear on the display to allow the operator to take appropriate action

Easy Maintenance Design

Accessibility to service areas

- Easy and more safety refueling from the ground.

- Large hinged service door serves wide inspection area.

- Service meter is integrated with the machine monitor.

- Ditinguishable fuse panel in the cab.

- Tandem oil check points is easy to access.

- Spin-on filters for quick replacing.

- Oil drains located near ground

Power train components

With a modular design, you can remove the engine, transmission or final drives independently for quick service.

Disconnect switch

For inspection and maintenance, the batteries can be disconnected with this switch when repairing the machine or checking batteries

Komatsu Total Support

To keep your machine available and minimize operation cost when you need it, Komatsu Distributor is ready to provide a variety of supports before and after procuring the machine.

Fleet recommendation

Komatsu Distributor can study the customer’s job site and provide the most optimum fleet recommendation with detailed information to meet all of your application needs when you are considering to buy new machines or replace the existing ones from Komatsu

Product support

Komatsu Distributor gives the proactive support and secures the quality of the machinery that will be delivered.

Parts availability

Komatsu Distributor is available for emergency inquiry by the customers for genuine, quality guaranteed Komatsu parts.

Technical support

Komatsu product support service (Technical support) is designed to help customer. Komatsu Distributor offers a variety of effective services to show how much Komatsu is dedicated to the maintenance and support of Komatsu machine.

- Preventive Maintenance (PM) clinic

- Oil & Wear analysis program

Repair & maintenance service

Komatsu Distributor offers quality repair and maintenance service to the customer, utilizing and promoting Komatsu developed programs.

Komatsu Reman (Remanufactured) components

Komatsu Reman products are the result of the implementation of the Komatsu global policy which establishes and agrees to reduce the owning, operating and total Life Cycle Costs (LCC) to Komatsu’s customer through high quality, prompt delivery and competitively priced in own remanufactured products (QDC)

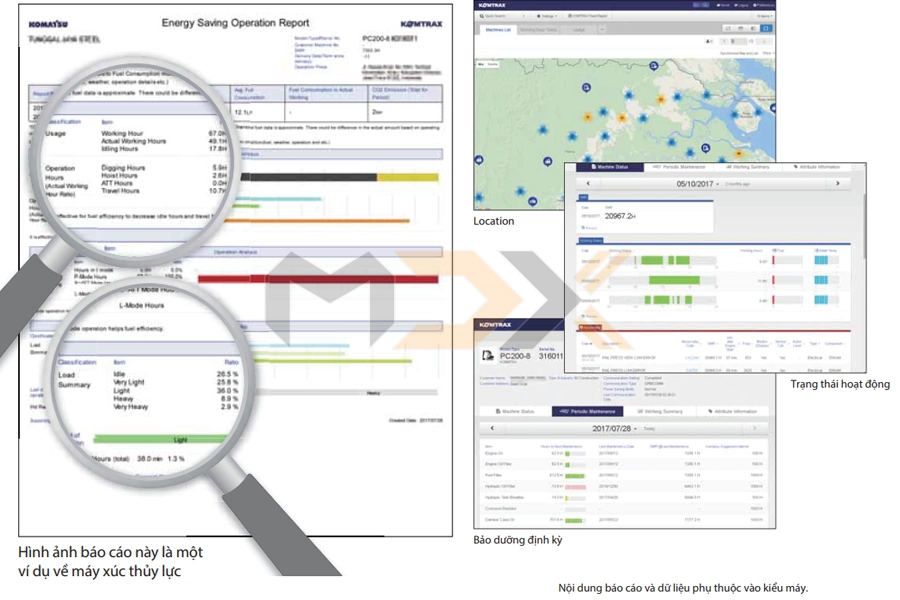

The Komatsu remote monitoring and management technology provides insightful data about your equipment and fleet in user-friendly format.

Energy Saving Operation Report

KOMTRAX delivers the energy-saving operation report based on the operating information such as fuel consumption, load summary and idling time, which helps you efficiently run a business.

Equipment Management Support

Through the web application, a variety of search parameters are available to quickly find information about specific machines based on key factors. Moreover, KOMTRAX finds out machines with problems from your fleet and shows you through an optimal interface

Optimal Strategy for Efficient Work

The detailed information that KOMTRAX puts at your fingertips helps you manage your fleet conveniently on the web anytime, anywhere. It gives you the power to make better daily and long-term strategic decisions.

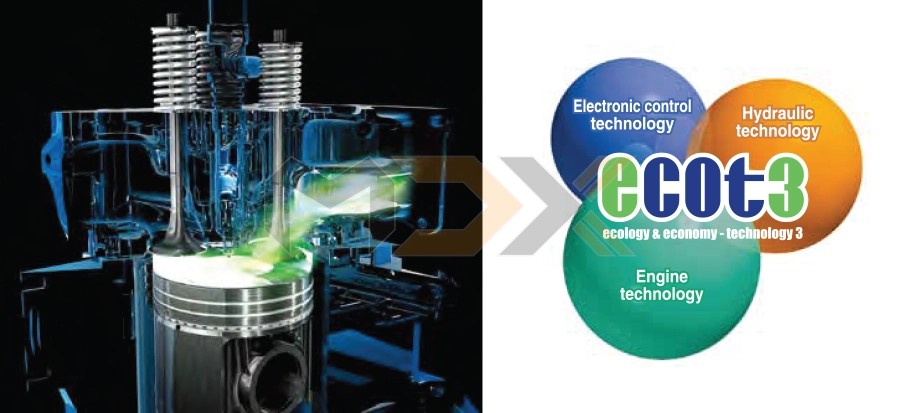

Komatsu uniquely develops all major components including total control system, like engines, electronics, and hydraulic components. With this “Komatsu technology” and continuous customer feedback, Komatsu has been achieving great advancements of technology. This resulted in new generation of high performance and environmentally friendly products.

High performance engine

Powerful turbocharged and air-to-air aftercooled Komatsu SAA6D107E-1 engine provides 163 kW 218 HP. This engine realizes high power with low fuel consumption by Common Rail Injection system (CRI), and thus it delivers higher work speeds with high horsepower. In addition, high torque at low speed, impressive acceleration, and low fuel consumption ensure maximum productivity. This engine is U.S. EPA Tier 3 and EU Stage 3A emissions certified.

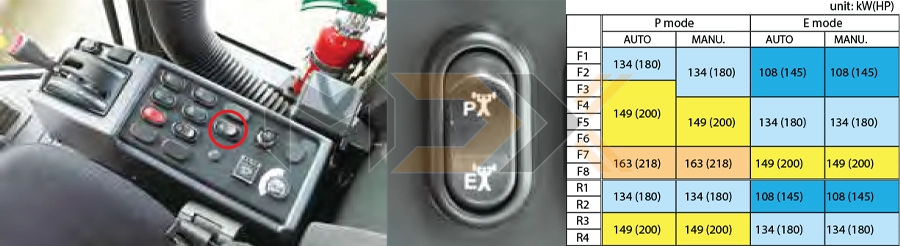

Engine power mode selection system

The system allows selection of the appropriate mode between two modes E or P mode according to each working condition. The mode is easily selected with a switch in the operator’s cab.

P mode: Greater productivity can be attained by taking full advantage of high output power. It is appropriate for job sites where the motor grader meets high resistance.

E mode: This mode is selected for maximum economy and lighter work applications. This feature provides the appropriate power and better fuel consumption.

Circumference dynamic noise

The dynamic circumference noise is lowered by various kind of countermeasures like the hydraulic driven cooling fan,the variable displacement pump and etc.

Circumference dynamic noise level (ISO6395) 111.4dB (A)

Double seal cylinder (Blade side shift cylinder)

A double-seal design is used for the blade side shift cylinder, which is installed near the ground, and thus susceptible to damage by dirt. Environmentally friendly by preventing oil leakage from the cylinder

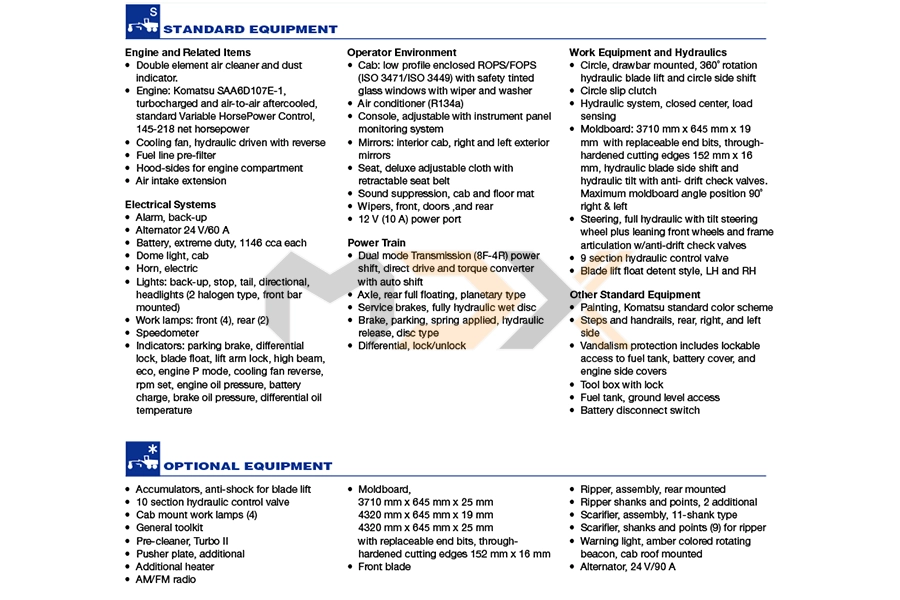

Komatu Genuine Work Equipment

Moldboard options

Available both 3.7 m (12 ft) and 4.3 m (14 ft) moldboards. Optional thicker blades are also available for heavy duty application.

Front blade

The front blade is a front mounted equipment used for spreading materials such as gravel piles or blading at the front of the machine where is difficult to access with the moldboard.

Ripper and scarifier

Digs up hard material cannot be removed by the moldboard. The scarifier can accommodate up to 11 teeth, the ripper also accommodate up to 5 shanks and 9 scarifier teeth.

Standard equipment may vary for each country, and this specification sheet may contain attachments and optional equipment that are not available in your area. Please consult your Komatsu distributor for detailed information