ZAXIS EMPOWER YOUR VISION

Hitachi Material Machine ZX240LC-5G CLAMSHELL BUCKET

Under tough working environments, the Hitachi material handling machine can work dynamically with less jerking, increasing productivity, fuel efficiency, safety and maintainability. The machine is purpose built for extra-wide working ranges using the long reach front. The high lift cab gives a clear view of work places. A wide selection of attachments also gives the machine excellent versatility to suit diverse job needs on different job yards, including scrap yards, auto wrecking yards and log yards.

TECHNICAL DATA

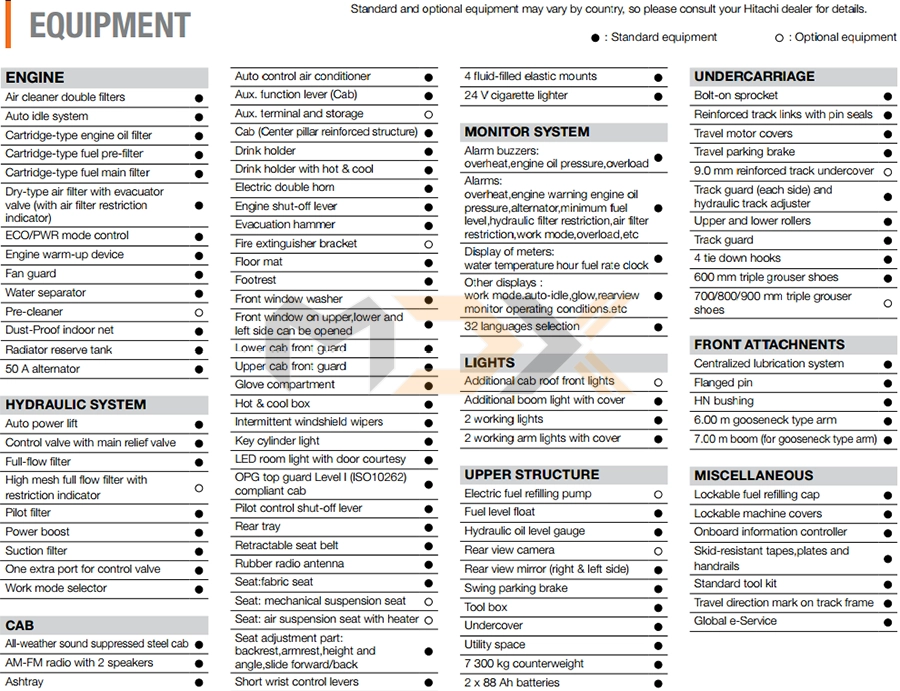

| DIMENSIONS |

|

| |

|

ZX240LC-5G |

| A Distance between tumblers |

mm |

3 850 |

| B Undercarriage length |

mm |

4 640 |

| C Counterweight clearance (*) |

mm |

1 050 |

| D Rear-end swing radius |

mm |

3 140 |

| E Overall width of upperstructure |

mm |

3 140 |

| F Overall height of cab |

mm |

3 040 |

| *G Min. ground clearance |

mm |

460 |

| H Track gauge |

mm |

2 590 |

| I Track shoe width |

mm |

600 / 700 / 800 / 900 |

| J Undercarriage width |

mm |

3 190 / 3 290 / 3 390 / 3 490 |

| K Overall width |

mm |

3 390 / 3 390 / 3 390 / 3 490 |

| L Overall length |

mm |

10 320 |

| M Overall height of boom |

mm |

3 330 |

| *N Track height with triple grouser shoes |

mm |

890 |

| O Overall height |

mm |

3 090 |

| * Excluding track shoe lug |

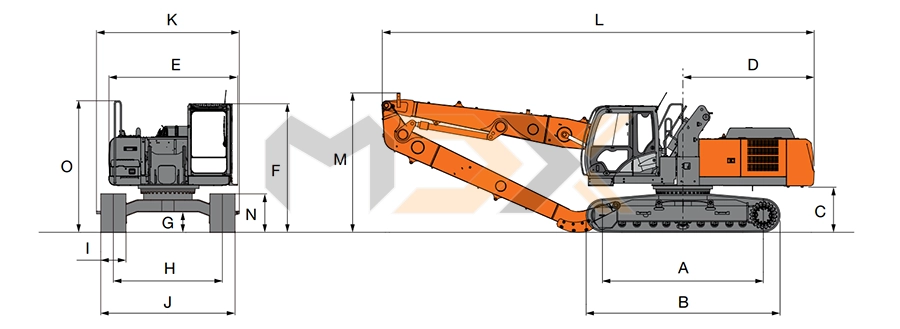

| LINKAGE CAB |

|

| A Overall height of cab |

mm |

3 040 - 5 520 |

| B Operator's view point |

mm |

2 580 - 5 060 |

| C Lift stroke |

mm |

2 480 |

| D Operator's view between swing center |

mm |

1 480 |

| E Overall width upperstructure (Including cab sidewalk) |

mm |

3 040 |

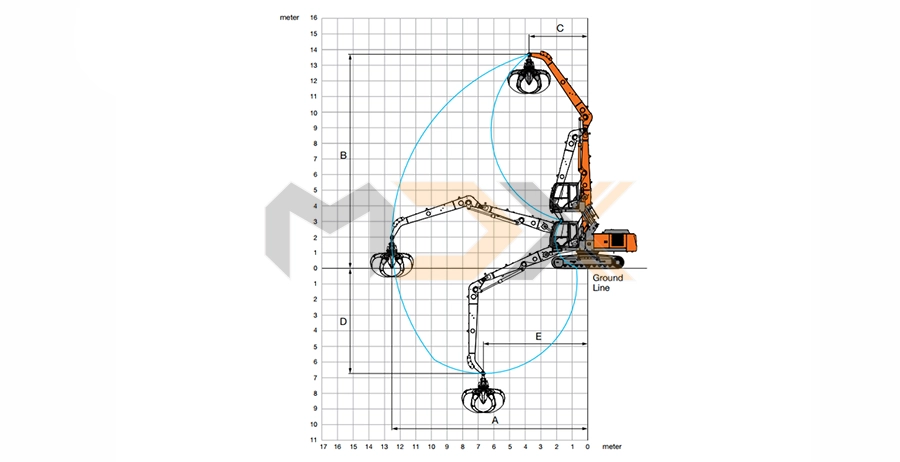

| WORKING RANGES |

|

| Boom length |

m |

7 |

| Arm length |

m |

6 |

| A Max. arm point reach |

mm |

12 530 |

| B Max. arm point height |

mm |

13 700 |

| C Min. swing radius at max. height (arm point) |

mm |

3 740 |

| D Max. arm point depth |

mm |

6 730 |

| E Max. arm point depth reach |

mm |

6 680 |

| * Excluding track shoe lug ** When selecting the attachment, the total weight of the attachment and the load should be below the specification is for the maximum reach. ZX240LC-5G : 2 320 kg |

| TECHNICAL DATA |

|

| Model |

|

F645HD / RT-322 |

| Practical capacity (m2) |

m2 |

0.8 |

| Maximum opening (cm) |

cm |

246 |

| Minimum closing (cm) |

cm |

17 |

| Height closed, including rotator (cm) |

cm |

135 |

| Height opened, including rotator (cm) |

cm |

162 |

| Weight (kg) (including rotator) |

kg |

925 |

| Excavator type (tons) |

tons |

18 - 20 |

| SPECIFICATIONS |

| ENGINE |

| Model |

Isuzu CC-6BG1T |

| Type |

4-cycle water-cooled, direct injection |

| Aspiration |

Turbocharged, intercooled |

| No. of cylinders |

6 |

| Rated power |

|

|

| ISO 9249, net |

kW |

132 kW (177 HP) at 2 150 min-1 (rpm) |

| SAE J1349, net |

kW |

132 kW (177 HP) at 2 150 min-1 (rpm) |

| Maximum torque |

Nm |

637 Nm (65 kgfm) at 1 800 min-1 (rpm) |

| Piston displacement |

L |

6.494 |

| Bore and stroke |

mm |

105 x 125 |

| Batteries |

|

2 x 12 V / 88 Ah |

| HYDRAULIC SYSTEM |

| Hydraulic Pumps |

|

|

| Main pumps |

2 variable displacement axial piston pumps |

| Maximum oil flow |

L/min |

2 x 223 |

| Pilot pump |

1 gear pump |

| Maximum oil flow |

L/min |

32 |

| Hydraulic Motors |

|

|

| Travel |

2 variable displacement axial piston motors |

| Swing |

1 axial piston motor |

| Relief Valve Settings |

|

|

| Implement circuit |

MPa (kgf/cm2) |

34.3 (350) |

| Swing circuit |

MPa (kgf/cm2) |

32.4 (330) |

| Travel circuit |

MPa (kgf/cm2) |

34.3 (356) |

| Pilot circuit |

MPa (kgf/cm2) |

3.9 (40) |

| Power boost |

MPa (kgf/cm2) |

38.0 (388) |

| UNDERCARRIAGE |

| Tracks |

Heat-treated connecting pins with dirt seals. Hydraulic (grease) track adjusters with shock-absorbing recoil springs |

| Numbers of Rollers and Shoes on Each Side |

|

|

| Upper roller |

|

2 |

| Lower rollers |

|

9 |

| Track shoes |

|

51 |

| Track guard |

|

1 |

| Travel Device |

Each track driven by 2-speed axial piston motor. Parking brake is spring-set/hydraulic-released disc type. |

| Automatic transmission system |

High-Low |

| Travel speeds |

km/h km/h |

High : 0 to 5.5 km/h Low : 0 to 3.4 km/h |

| Maximum traction force |

kN (kgf) |

222 kN (22 600 kgf) |

| Gradeability |

% (degree) |

70 (35) |

| SERVICE REFILL CAPACITIES |

| Fuel tank |

L |

510 |

| Engine coolant |

L |

26 |

| Engine oil |

L |

25 |

| Swing device |

L |

9.1 |

| Travel device (each side) |

L |

7.8 |

| Hydraulic system |

L |

280 |

| Hydraulic oil tank |

L |

156 |

| UPPERSTRUCTURE |

| Revolving Frame |

D-section frame skirt for resistance to deformation |

| Swing Device |

Swash plate piston motor with planetary reduction gear is bathed in oil. Swing circle is single-row. Swing parking brake is spring-set/hydraulicreleased disc type. |

| Swing speed |

min-1 |

11 |

| Swing torque |

kNm (kgfm) |

77.5 kNm (7 900 kgfm) |

| Operator's Cab |

Independent spacious cab, 1 005 mm wide by 1 675 mm high, conforming to ISO* Standards. * International Organization for Standardization |

| HYDRAULIC CYLINDERS |

| |

|

Quantity |

Bore |

Rod diameter |

| Boom |

mm |

2 |

125 |

90 |

| Arm |

mm |

1 |

140 |

100 |

| WEIGHTS AND GROUND PRESSURE |

| Shoe type |

Shoe width (mm) |

kg |

kPa(kgf/cm 2) |

Triple grouser

|

600 |

27 600 |

56 (0.57) |

| 700 |

28 000 |

49 (0.49) |

| 800 |

28 300 |

43 (0.44) |

| 900 |

28 800 |

39 (0.40) |

| Equipped with 7.00 m boom, 6.00 m gooseneck type arm, 7 300 kg counterweight |

| WEIGHT: BASIC MACHINE and COMPONENTS |

| Shoe width |

Weight |

Overall width |

| 600 mm |

22 500 kg |

3 390 mm |

| 700 mm |

23 000 kg |

3 390 mm |

| 800 mm |

23 300 kg |

3 390 mm |

| 900 mm |

23 800 kg |

3 490 mm |

| COMPONENT WEIGHTS |

| Disassembly Conditions |

Weight (kg) |

Length (mm) |

Height (mm) |

Width (mm) |

| Counterweight |

7 300 |

710 |

1 200 |

2 840 |

| 7.00 m boom (With arm cylinders) |

2 470 |

7 220 |

980 |

1 020 |

| 6.00 m gooseneck type arm |

1 310 |

6 200 |

1 160 |

930 |

HIGHLIGHTS

INTRODUCING THE NEW COMBINATION GRAPPLE

|

|

| Used to handle short wood, logs or tree length wood. These grapples are used when a combination of wood types must be handled by one grapple. Grapple jaws bypass - Heavy Duty rotators to match machine capacity and operation requirements for maximum life and productive time - Cylinder confguration allows superior closing force - Grapples structure designed with FEA (Finite Element Analysis) to get optimal strength to weight ratio - Easy maintenance with easy access greasing points - Box construction for extra sturdiness - Heavy duty single pivot pin with sealed bushings, for extended greasing intervals and low maintenance cost - Mechanical stops, on most models, for opening and closing of grapple’s jaws, to eliminate impacts to hydraulic cylinders - Jaw curvature and shape allows optimal rolling of logs. The jaws bypass to hold small logs - Replaceable round tips, on most models, made of a special abrasive resistance material - High pressure cylinder with bolt-on gland and sealed bushings These NEW Combination grapples highlight the tradition of durability, reliability and productivity renown for Rotobec products |

|

|

Pursuits of Performance and Durability

|

|

| Durable, Reliable Engine (Non-Common Rail Type) This green engine has a track record of working on countless job sites around the world, meeting the EU stage II and US EPA Tier 2 emissions regulations. It is a noncommon rail type, featuring high durability and reliability, teamed up with a direct fuel injection system and an advanced governor to deliver plenty of power. The cooling package is well designed to keep the engine cool. The engine cover has a wide air suction aperture, and radiators are arranged in parallel for effective cooling. Gooseneck Type Front The gooseneck type front brings about high production in handling long materials. Arm lifting force is boosted even more with double arm cylinders on boom sides, helping reduce falling objects. Structures are strengthened with reinforced plates at key areas, and welded in a new way to build up more suitable weld beads, avoiding stress concentration. Hydraulic piping and hoses at the front are streamlined using new clamps to increase durability. High controllability – a Hitachi tradition helps increase production in tough material handing applications with smooth starts and stops of swing Fuel-Efficient Operation New ZAXIS achieves fuel-efficient operation thanks to the HIOS III hydraulic system and engine control system |

|

| Double Arm Cylinders Double arm cylinders are positioned optimally to give the arm more lifting power in wider working ranges, increasing productivity High Lift Cab The linkage cab is redesigned for higher stability and rigidity by strengthening the linkage itself and repositioning lift cylinders. This design approach can reduce cab shaking significantly, especially at starts and stops of cab rising. |

Safety and Simplified Maintenance

|

|

|

|

| Dust-Proof Indoor Net The air conditioner condenser package is redesigned for ease of cleaning. A dust-proof indoor net, provided at the front of the air conditioner condenser, can be easily removed, and cleaned with compressed air. The rear of the radiator can also be cleaned by air blowing through a one-touch open cover. The air conditioner condenser is openable at its rear for easy cleaning. |

| Emergency Linkage Cab Lowering System (Operable from within cab and ground-level) Even if the hydraulic system or the electric system fails, the high lift cab can be safely lowered with dual safety measures – an emergency switch within cab and one at the linkage foot Emergency Evacuation Ladder Even if the engine fails, or the lift cylinders or linkage is damaged, the operator can get out of the cab by breaking the rear window with an evacuation hammer, and descend on to the ground through an emergency evacuation ladder provided at the linkage top Hose Rupture Valves for Arm and Boom Hose rupture valves are utilized to hold the front in position, even if piping or hose is ruptured, avoiding its free fall Rear View Camera (Optional) A rear view camera is provided optionally behind the counterweight. The operator can always check the view from the camera through a 7-inch high definition color monitor in the cab. Remote Centralized Greasin Lubricating points are centralized at the boom foot for safe, easy greasing. Also, the linkage cab lubricating points can be remotely greased from the ground Openable Cab Front Upper Guard The cab front upper guard can be opened for convenient cleaning of the windshield glass window |

|

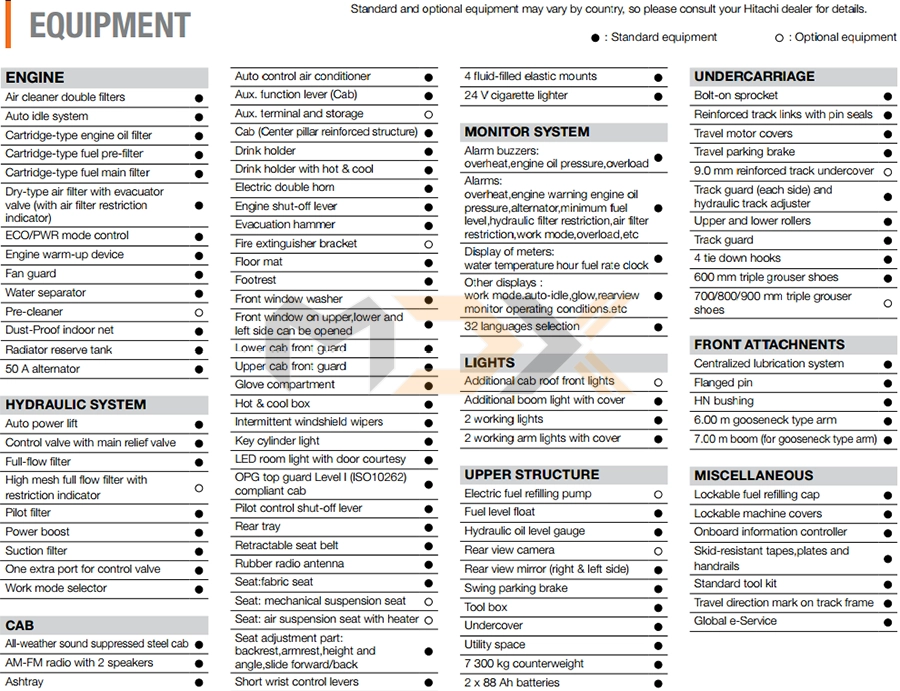

EQUIPMENTS