When you sit inside the cab of a ZW wheel loaderr, you’ll see that it offers exceptional all-round visibility. Switch on the engine and you’ll hear that it’s the quietest machine on the market. When you start work, you’ll feel the benefit of the comfortable seat, easy-to-use controls and smooth operation.

We know our compact, medium and large wheel loaders not only appeal to your senses, but also make sense for your business. With substantial loading capacity, powerful digging force and impressive travel speeds, they’re extremely productive. Fuel-efficient and easy to maintain, they offer reduced running costs. Used with a variety of attachments, they are easily adaptable for different tasks.

We understands very well the types of construction machinery and equipment suitable to the construction, financial and operational conditions of Vietnamese contractors. We currently supply all kinds of Hitachi equipment such as Mini excavators (with a working load of 800kg) to large mines (up to 533 tons largest), wheel loaders, Ben runs in the mine with a load of 180t or more.

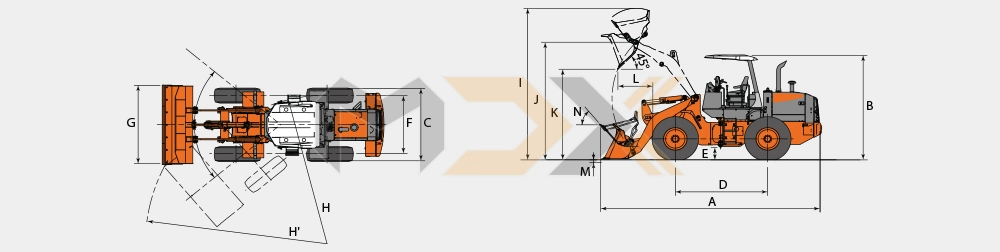

|

|||||||

| Bucket type | ZW310-5A | ||||||

| Standard arm | High lift arm | ||||||

| General purpose | Rock bucket | General purpose | |||||

| Bolt-on cutting edge | Bolt-on teeth | Bolt-on teeth | Bolt-on cutting edge | ||||

| Bucket capacity | |||||||

| ISO heaped | m3 | 4.0 | 4.5 | 3.8 | 4.3 | 3.4 | 4.0 |

| ISO struck | m3 | 3.5 | 4.0 | 3.3 | 3.8 | 2.9 | 3.5 |

| A Overall length | mm | 8 790 | 8 910 | 8 930 | 9 050 | 8 900 | 9 240 |

| B Overall height | mm | 3 470 | |||||

| C Width over tires | mm | 2 930 | |||||

| D Wheel base | mm | 3 450 | |||||

| E Ground clearance | mm | 505 | |||||

| F Tread | mm | 2 230 | |||||

| G Bucket width | mm | 3 100 | 3 100 | 3 120 | 3 120 | 3 120 | 3 100 |

| H Turning radius (Centerline of outside tire) | mm | 6 270 | |||||

| H' Loader clearance radius, bucket in carry position | mm | 7 330 | 7 360 | 7 385 | 7 415 | 7 375 | 7 520 |

| I Overall operating height | mm | 6 100 | 6 215 | 6 100 | 6 215 | 5 775 | 6 555 |

| J Height to bucket hinge pin, fully raised | mm | 4 410 | 4 865 | ||||

| K Dumping clearance 45 degree, full height | mm | 3 095 | 3 010 | 2 975 | 2 890 | 3 000 | 3 550 |

| L Reach, 45 degree dump, full height | mm | 1 215 | 1 300 | 1 280 | 1 370 | 1 235 | 1 245 |

| M Digging depth (Horizontal digging angle) | mm | 95 | 95 | 125 | 125 | 125 | 95 |

| N Max. roll back at carry position | deg | 50 | 48 | ||||

| Static tipping load * | |||||||

| Straight | kgf | 17 090 | 16 940 | 17 260 | 17 120 | 17 280 | 14 100 |

| Full 37 degree turn | kgf | 14 910 | 14 780 | 15 060 | 14 930 | 15 080 | 12 300 |

| Breakout force | kN (kgf) | 184 18 770 | 169 (17 240) | 198 (20 200) | 181 (18 460) | 202 (20 600) | 184 (18 770) |

| Operating weight* | kg | 22 540 | 22 670 | 22 410 | 22 540 | 22 620 | 22 860 |

Note: All dimensions, weight and performance data based on ISO 6746-1:1987,ISO 7131:2009 and ISO 7546:1983

*: Static tipping load and operating weight marked with* include 26.5-25-16PR(L3) tires (No ballast) with lubricants, full fuel tank, 2 080kg counterweight, ROPS cab and operator. Machine stability and operating weight depend on counterweight, tire size and other attachments.

| ENGINE | ||

| Model | CUMMINS QSM11 | |

| Type | 4-cycle water-cooled, direct injection | |

| Aspiration | Turbocharger and intercooled | |

| Maximum power | ||

| SAE J1995/ISO14396, gross | kW (HP) | 239 kW (320 HP) at 1 800 rpm |

| SAE J1349/ISO 9249, net | kW (HP) | 236 kW (316 HP) at 1 800 rpm |

| Rated power | ||

| SAE J1995, gross | kW (HP) | 216 kW (290 HP) at 2 100 rpm |

| Maximum torque | Nm | 1 478 Nm at 1 000 - 1 400 min-1 (rpm) |

| No. of cylinders | 6 | |

| Bore and stroke | mm | 125 X 147 |

| Piston displacement | L | 10.82 |

| Batteries | 2 X 12 V | |

| Air cleaner | Double element dry type with restriction indicato | |

| AXLE AND FINAL DRIVE | ||

| Drive system | Four-wheel drive system | |

| Front & rear axle | Semi-floating | |

| Front | Fixed to the front frame | |

| Rear | Trunnion support | |

| Reduction and differential gear | Single stage reduction with torque proportioning differential (std) / limited slip differential (optional) | |

| Oscillation angle | Total 20˚ (+10˚,-10˚) | |

| Final drives | Heavy-duty planetary, mounted outboard | |

| TIRES | ||

| Tire size | 26.5-25-16PR (L3) | |

| Optional | Refer to standard & optional equipment list | |

| BRAKES | ||

| Service brakes | Inboard mounted fully hydraulic 4 wheel wet disc brake. Front & rear independent brake circuit | |

| Parking brakes | Spring applied, hydraulically released, dry disc type with external output shaft | |

| STEERING SYSTEM | ||

| Type | Articulated frame steering | |

| Steering angle | Each direction 37° ; total 74° | |

| Cylinders | Double-acting piston type | |

| No. x Bore x Stroke | 2 x 70 mm x 542 mm | |

| HYDRAULIC SYSTEM | ||

| Arm and bucket are controlled by independent control lever | ||

| Arm controls | Four position valve ; Raise, hold, lower, float | |

| Bucket controls with automatic bucket return-to-dig control - Three position valve ; Roll back, hold, dump | ||

| Main pump (Serve as steering pump) | Variable Displacement Axial Plunger Pump | |

| Maximum flow | L/min | 323 L/min at 2 000 min-1 (rpm) |

| Maximum pressure | MPa | 29.4 MPa |

| Fan pump | Fixed Displacement Gear Pump | |

| Maximum flow | L/min | 84.9 L/min at 2 000 min-1 (rpm) |

| Maximum pressure | MPa | 17.4 MPa |

| Hydraulic cylinders | ||

| Type | Double acting type | |

| No. x Bore x Stroke |

Arm : 2 x 145 mm x 930 mm Bucket : 1 x 185 mm x 510 mm |

|

| Filters | Full-flow 15 micron return filter in reservoir | |

| Hydraulic cycle times | ||

| Lift arm raise | s | 6.2 s |

| Lift arm lower | s | 3.2 s |

| Bucket dump | s | 1.2 s |

| Total | s | 10.6 s |

| * Data at power mode are the same as data at standard mode. | ||

| SERVICE REFILL CAPACITIES | ||

| Fuel tank | L | 370 |

| Engine coolant | L | 40 |

| Engine oil | L | 34 |

| Torque converter & transmission | L | 52 |

| Front axle differential & wheel hubs | L | 48 |

| Rear axle differential & wheel hubs | L | 48 |

| Hydraulic oil tank | L | 123 |

| POWER TRAIN | ||

| Transmission | Torque converter, countershaft type powershift with computer-controlled automatic shift and man ual shift features included. | |

| Torque converter | Three element, single stage, single phase | |

| Main clutch | Wet hydraulic, multi-disc type | |

| Cooling method | Forced circulation type | |

| Travel speed* Forward / Reverse | ||

| 1st | 6.8 / 6.8 km/h | |

| 2nd | 11.5 / 11.5 km/h | |

| 3rd | 21.6 / 21.6 km/h | |

| 4th | 34.7 / 34.7 km/h | |

| * With 26.5-25-16PR (L3) tires. Data at power mode are the same as data at standard mode. | ||

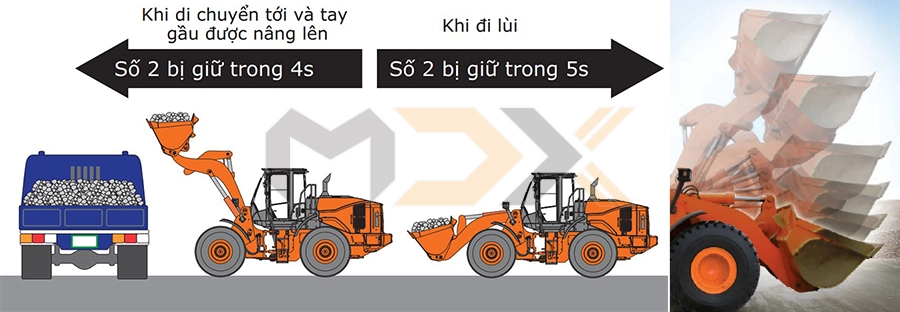

Note: standard or optional equipment depends on the standard of each country. Please contact us for the answer.

Operators can choose between 2 modes according to job site requirements.

Extra Power with Power Mode

Standard mode is preselected and sufficient for ordinary work. On the other hand, the power mode gives extra power when needed. It is particularly useful on sites where strong traction or acceleration is required.

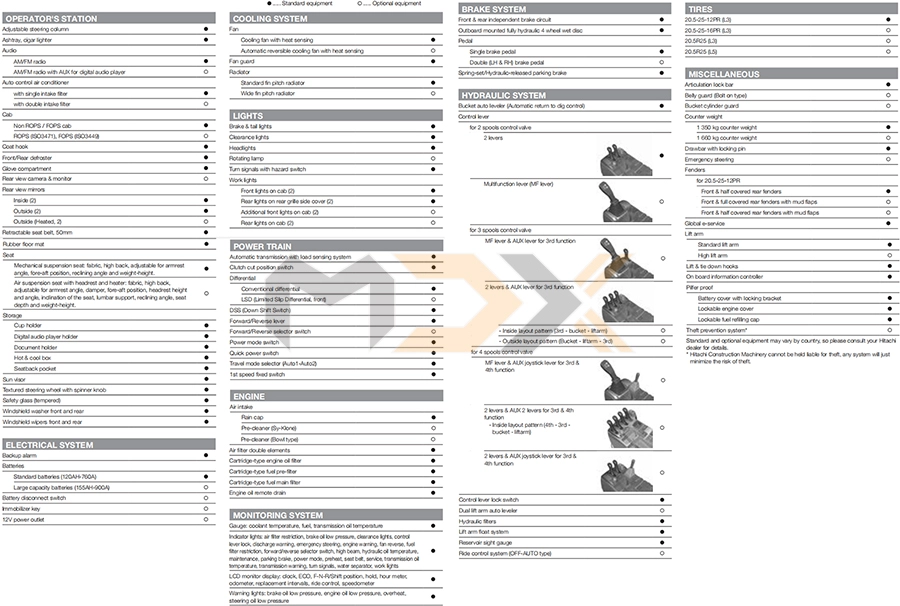

Active Engine Control System for Economical Operation and Easy Control

The “Active Engine Control System” plays a key role achieving economical operation. Strategically positioned sensors detect movements throughout the machine and adjust engine speed accordingly to eliminate energy losses to maximize fuel conservation. This delivers smooth, fuel-efficient operation.

Parallel Tandem for Smooth Operation

The parallel tandem circuit carries out simultaneous operations of the bucket and the lift arm. Front work such as excavation and loading can be done smoothly and boosts the efficiency.

2 Ways to Activate Power Mode

Power mode can be activated by 2 ways and operators can choose either switch depending on the site required.

A: Quick Power Switch (QPS)

Use the QPS on the lever when extra power is needed temporarily, such as climbing a steep slope. When switching forward/reverse or when the travel load reduces, the power mode selected via the QPS automatically reverts to the standard mode. By using the QPS, the power mode is activated only when needed and this helps to reduce fuel consumption.

B: Power Mode Switch

Use the power mode switch when extra power is needed constantly, such as moving heavy materials like rocks, and getting the job done quickly. When the power mode is activated via the power mode switch, the mode will remain on until the engine is turned off.

ECO Mark Indicator for Fuel-Efficient Operation

Monitor indication items: Speed meter, clock, hour meter, odometer, oil/filter hour meter

The ECO mark indicator turns on when fuel-efficient operation is activated. This function encourages operators to utilize fuel efficient operation.

Hitachi analyzed various wheel loader operations including digging, approach to a dump truck, operation after dumping and travel. This led to the development of strategies to improve wheel loader controllability.

New Transmission with 5 speed gears

The new transmission comes standard with the Auto mode* that can automatically select an optimum gear according to the load, thereby reducing fuel consumption. Especially, the new transmission has 5 speed gears which can keep fuel efficient engine rpm more easily compared to the conventional transmission with 4 speed gears.

* AUTO1 (1st-5th gear) and AUTO2 (2nd-5th gear) are selectable using travel mode selector.

Levers for Easy Operation

In order to offer more efficient and comfortable operation, a new type of lever is employed to suit both fingertip control and grip control.

* A variety of lever patterns are available depending on job needs and operator’s preference.

Speed-responding Clutch Cut-off System

Clutch cut-off timing is adjusted by sensing travel speed and pedal depression for smooth, efficient truck loading. The Flat mode, Slope mode and OFF are selectable by switch control according to job requirements.

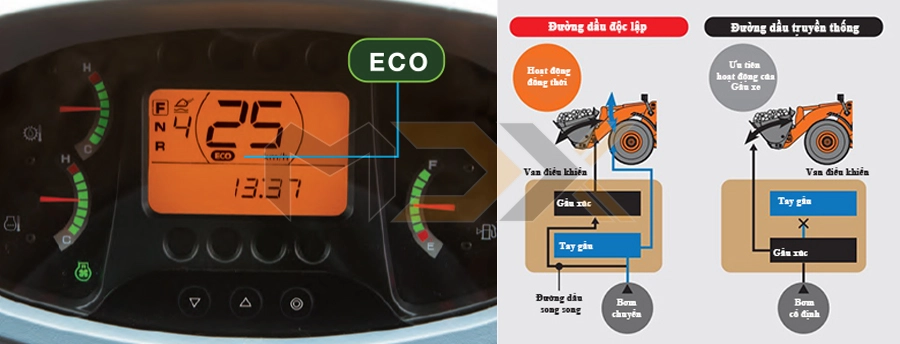

Delay Mode (Optional)

Shift change delay mode is provided to avoid an excessive rise in travel speed during digging and loading. When moving forward with the lift arm up, the second gear is kept for four seconds to prevent over-speed. When reversing, the second gear is kept for five seconds. These delays to third gear help to keep fuel consumption down ensuring smooth loading.

Lift Arm restriction valve

This restriction valve suppresses the shaking of the machine when the lift arm stops to improve operator comfort and avoid load spills.

Lift Arm Auto Leveler (Optional)

The lift arm can be automatically stopped at an preset level for efficient truck-loading, and lowering the bucket after dumping. The operator can concentrate on traveling without worrying about the lift arm.

The cab is both comfortable and functional with a series of features aimed at reducing operator fatigue.

Bi-Level Auto Air Conditioner

This auto air conditioner has bi-level control function: warming at foot space and cooling at overhead. The pressurized cab shuts out dust, keeping the cab interior clean. In dusty environments, optional external double-filters are available for the air conditioner.

Panoramic Cab

The spacious panoramic cab offers near all-round visibility through pillar-less bonded windows. The seat and steering wheel can be adjusted to suit the operator, keeping the operator in an optimum position. In-cab noise is suppressed further. Even when the going gets tough, the operator can feel comfortable.

Tiltable Steering Wheel

The steering wheel is tiltable to fit the wheel to the operator for comfortable operation.

Comfort-Designed Suspension Seat

The mechanical suspension seat absorbs shocks and vibration from the machine in order to reduce operator’s physical stresses to the operator.

* The air suspension seat is available as an option.

AM/FM Radio with 2 Speakers

The AM/FM radio has an auto tuning feature and the 2 speakers stereo system provides excellent sound quality. The player pocket can hold a cell phone.

* An AUX port (stereo mini jack) is an option for connection with a mobile music player for entertainment during breaks.

Rearview Monitor (Optional)

The rearview monitor allows the operator to see the rear of the machine, including a view behind the counterweight. This rearview monitor enhances safe operation.

An Array of Convenient Accessories

Hitachi Support Chain offers a comprehensive suite of support services for customers.

Simplified Maintenance

The engine cover swings up to provide a wide service space. Filters are concentrated for easy inspection and servicing from the ground.

A Fuel pre-filter

B Main fuel filter

C Engine oil gauge

D Window washer tank

Robust Frame

The main frame and its joins are thoroughly strengthened. The box section structure is adopted around center pins, where concentrated forces are applied, for reinforcement. Frame plate thicknesses are optimally determined by 3D stress analysis.

Wide Fin Pitch Radiator (Optional)

Wide fin pitch radiator is available for use in dusty environments, where there are large amounts of airborne debris, to avoid dust clogging and overheating as a result. Air blowing is easy and simple.

Automatic Reversible Cooling Fan (Optional) to Reduce Dust Deposits

The automatic reversible cooling fan is available to keep the radiator clean at all times. The cooling fan is automatically self reversed every 30 minutes to blow dust off the radiator. The cover swings up for efficient air blowing.

Parts

Hitachi Global Online Network, a parts supply system, is linked with CPD (Central Parts Depot), overseas depots and dealers abroad to deliver on-line parts information, including in-stock parts, order receptions, shipments and delivery period of over one million parts and components.

Genuine Hitachi Parts

Genuine Hitachi parts, meeting Hitachi stringent quality standards, are guaranteed according to Hitachi warranty standards. The use of genuine Hitachi parts, including engine, fuel, hydraulic oil and filters, may slash running costs, and extend machine life.

Service

ConSite is a full-package service menu which is designed for Hitachi’s machines used around the world. We closely monitor and support each machine working at each job site from various aspects, ensuring the best-tuned machines that are accommodated for the site condition and meet your specific needs.

On-site servicing matters despite locations to keep the machine at peak performance and reduce downtime. Technical Training Center (TTC), located in Japan, educates and trains service technicians and service support personnel coming from Hitachi dealers and factories on the globe according to the international training programs.

Tags: wheel loader, caterpillar wheel loader, hitachi wheel loader, Komatsu wheel loader, Doosan caterpillar wheel loader, wheel loader specifications, wheel loader Komatsu, wheel loader for sale, wheel loader capacity, wheel loader vs excavator, wheel loader caterpillar, wheel loader liugong, kubota wheel loader, volvo wheel loader, compact wheel loader, bobcat wheel loader, wheel loader volvo, wheel loader jcb, hitachi wheel loader dealers, hitachi wheel loader models, hitachi wheel loader specifications, hitachi wheel loader zw80, hitachi wheel loader parts, hitachi wheel loader zw180, used hitachi wheel loader, hitachi wheel loaders usa, hitachi 310 wheel loader, hitachi 220 wheel loader, hitachi 140 wheel loader, hitachi 370 wheel loader, hitachi 310 wheel loader specs, hitachi zw140 6 wheel loader specs