When you sit inside the cab of a ZW wheel loader, you’ll see that it offers exceptional all-round visibility. Switch on the engine and you’ll hear that it’s the quietest machine on the market. When you start work, you’ll feel the benefit of the comfortable seat, easy-to-use controls and smooth operation.

We know our compact, medium and large wheel loaders not only appeal to your senses, but also make sense for your business. With substantial loading capacity, powerful digging force and impressive travel speeds, they’re extremely productive. Fuel-efficient and easy to maintain, they offer reduced running costs. Used with a variety of attachments, they are easily adaptable for different tasks.

The ZW140 is packed with numerous innovative technologies and mechanisms. The electronic control HST system makes possible light, agile footwork. Four work modes can be selected according to job needs, with best matching of traction force and breakout force. What’s more, the ZW140 offers more impressive features: operating ease, enhanced safety, increased durability, and simplified maintenance.

|

||||||

| Bucket type | ZW140 | |||||

| Standard Lift Arm | High Lift Arm | |||||

| General Purpose | ||||||

| With bolt-on cutting edges | With bolt-on teeth | With bolt-on cutting edges | With bolt-on cutting edges | With bolt-on teeth | ||

| Bucket capacity | ||||||

| ISO heaped | m3 | 2.0 | 1.9 | 2.3 | 1.6 | 1.5 |

| ISO struck | m3 | 1.6 | 1.6 | 1.9 | 1.3 | 1.2 |

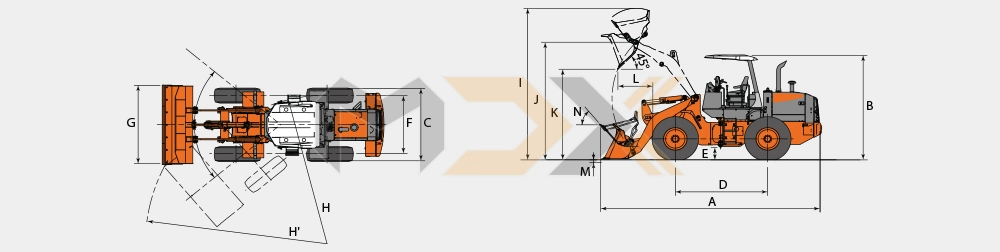

| A Overall length | mm | 6 910 | 7 040 | 7 010 | 7 240 | 7 360 |

| A' Overall length (Traveling figure) | mm | 6 870 | 6 960 | 6 930 | 7 220 | 7 300 |

| B Overall height | mm | 3 170 | ||||

| C Width over tires | mm | 2 390 | ||||

| D Wheel base | mm | 2 900 | ||||

| E Ground clearance | mm | 380 | ||||

| F Tread | mm | 1 930 | ||||

| G Bucket width | mm | 2 480 | ||||

| H Turning radius (centerline of outside tire) | mm | 4 950 | ||||

| H' Loader clearance circle, bucket in carry position | mm | 5 740 | 5 770 | 5 760 | 5 890 | 5 930 |

| I Overall operating height | mm | 4 950 | 4 950 | 5 040 | 5 140 | |

| J Height to hinge pin, fully raised | mm | 3 730 | 3 730 | 3 730 | 4 090 | |

| K Dump clearance 45 degree, full height | mm | 2 790 | 2 700 | 2 720 | 3 250 | 3 160 |

| L Reach, 45 degree dump, full height | mm | 950 | 1 030 | 1 020 | 1 020 | 1 090 |

| M Digging depth (horizontal digging angle) | mm | 110 | 120 | 110 | 200 | 220 |

| N Max. roll back at carry position | deg | 50 | ||||

| Static tipping load* | ||||||

| straight | kgf | 8 050 | 8 170 | 7 990 | 6 300 | 6 410 |

| Full 40 degree turn | kgf | 6 970 | 7 090 | 6 910 | 5 430 | 5 530 |

| Breakout force | kN(kgf) | 96 (9 790) | 104 (10 600) | 87 (8 870) | 114 (11 620) | 124 (12 640) |

| Operating weight | kg | 10 290 | 10 240 | 10 330 | 10 540 | 10 480 |

Note:

1. All dimensions, weight and performance data based on ISO 6746-1:1987, ISO 7137:1997 and ISO 7546:1983

2. Static tipping load and operating weight marked with* include 17.5-25-12PR (L3) tires (No ballast) with lubricants, full fuel tank and operator. Machine stability and operating weight depend on counterweight, tire size and other attachments.

| ENGINE | ||

| Model | Cummins QSB4.5 | |

| Type | 4-cycle water-cooled,direct injection | |

| Aspiration | Turbo charger | |

| No. of cylinders | 4 | |

| Maximum power | ||

| SAE J1349, with Fan net | 96 kW (129 HP) at 2 000 min-1(rpm) | |

| ISO 9249, with Fan net | 96 kW (129 HP) at 2 000 min-1(rpm) | |

| EEC 80/1269, with Fan net | 96 kW (129 HP) at 2 000 min-1(rpm) | |

| Bore and stroke | mm | 107 x 124 |

| Piston displacement | L | 4.46 |

| Batteries | 2 x 12 V 620CCA, 80Ah | |

| Air cleaner | Double stage dry type | |

| POWER TRAIN | ||

| Transmission controls |

Electrical-controlled 2 motor hydrostatic transmission with summation gear box Gear box: Fixed gear ratio, powershift countershaft type |

|

| Cooling method | Forced circulation type | |

| Travel speed : Forward & Reverse | * With 17.5-25-12PR (L3) tires | |

| 1st | 7.0 / 7.0 (km/h) | |

| 2nd | 13.0 / 13.0 (km/h) | |

| 3rd | 20.0 / 20.0 (km/h) | |

| 4th | 39.0 / 39.0 (km/h) | |

| AXLE AND FINAL DRIVE | ||

| Drive system | Four-wheel drive system | |

| Front & rear axle | Semi-floating | |

| Front | Fixed to the front frame | |

| Rear | Center pivot | |

| Reduction and differential gear | Two stage reduction with torque proportioning differential | |

| Oscillation angle | Total 20˚ (+10˚,-10˚) | |

| Final drives | planetary final drive | |

| TIRES (TUBELESS, NYLON BODY) | ||

| Standard | 17.5-25 12PR (L3) | |

| BRAKES | ||

| Service brakes | Inboard mounted fully hydraulic 4 wheel wet disc brake. HST(Hydro Static Transmission) system provides additional hydraulic braking capacity | |

| Parking brake | Spring applied, hydraulically released, wet disc type with drive through prevention mechanism | |

| STEERING SYSTEM | ||

| Type | Articulated frame steering | |

| Steering mechanism | Fully hydraulic power steering with orbitrol | |

| Steering angle | Each direction 40° ; total 80° | |

| Relief pressure | 19.6 MPa (200 kgf/cm2) | |

| Cylinders | Two double-acting piston type | |

| No. x Bore x Stroke | 2 x 65 mm x 419 mm | |

| Minimum turning radius at the centerline of outside tire | 4 950 mm | |

| HYDRAULIC SYSTEM | ||

| Arm and bucket are controlled by Joystick lever | ||

| Arm controls | Three position valve ; Raise, lower, float | |

| Bucket controls with automatic bucket return to-dig controls | Three position valve ; Roll back, hold, dump | |

| Main pump (Load & steer | Gear type 159 L/min @2 200 min-1 (rpm) at 20.6 MPa (210 kgf/cm2 | |

| Relief pressure setting | 20.6 MPa (210 kgf/cm2 | |

| HST charging pump | Gear type 41L /min @2 200 min-1 (rpm) at 2.5 MPa (25 kgf/cm2) | |

| Transmission charging pump | Gear type 17 L/min @2 200 min-1 (rpm) at 1.96 MPa (20 kgf/cm2) | |

| Fan pump | Gear type 30 L/min @2 200 min-1 (rpm) at 11.8 MPa (120 kgf/cm2) | |

| Hydraulic cylinders | ||

| Type | Two arm and one bucket, double acting type | |

| No. x Bore x Stroke |

Arm : 2 x 125 mm x 620 mm Bucket : 1 x 150 mm x 445 mm |

|

| Filters | Full-flow 10 micron return filter before reservoir | |

| Hydraulic cycle times | ||

| Arm raise | s | 6.0 |

| Arm lower | s | 3.0 |

| Bucket dump | s | 1.3 |

| SERVICE REFILL CAPACITIES | ||

| Fuel tank | L | 180 |

| Engine coolant | L | 25 |

| Engine oil | L | 14 |

| Front axle differential & wheel hubs | L | 24 |

| Rear axle differential & wheel hubs | L | 25 |

| Hydraulic reservoir tank | L | 80 |

Note: standard or optional equipment depends on the standard of each country. Please contact us for the answer.

| ENGINE | POWER TRAIN |

| Coolant recovery tank | Electrically controlled HST system |

| Hydraulically operated cooling fan with heat sensing system | Torque proportioning differentials, front and rear |

| Fan guard | HYDRAULIC SYSTEM |

| Muffler, under hood with large exhaust stack | Bucket auto leveler |

| Quick-release fuel pre-filter with water separator function | Hydraulic filters, vertical mounting |

| Air heater (For cold start) | O-Ring Seal joints |

| Air filter double element | Two-spool main control valve |

| Environmentally friendly engine oil drain | Joystick lever |

| Engine oil cooler | Reservoir sight gauge |

| Fuel Filter | Float system |

| ELECTRICAL | OPERATOR'S STATION Cab |

| 24-volt AM/FM stereo radio with clock | Sun visor |

| Indicator lights: Turn signals / High beam / Working lights / Service / Parking brake / Stop / Brake oil low pressure / Brake oil low level / Seat belt / Glow signal / Maintenance / Forward / Reverse switch / Water separator / Over heat / Engine oil low pressure / Air filter restriction / Hydraulic oil temperature / | Seat(Kab), fabric, high back, mechanical suspension, adjustable for weight-height, fore-aft position,backrest tilt, and armrest angle |

| Monitor and alarm system, multi-function electronic audible and visual warning include | Handrails and steps, ergonomically located and slip resistant |

| LCD monitor display: Speedometer / Clock / Hour meter / Odometer / Replacement intervals / Ride control / Speed range | ROPS* / FOPS** / Multi-plane isolation mounted for noise / Vibration reduction / Front and rear windshield washers / Safety glass |

| Warning lights: Engine / Transmission / Discharge warning | Steering wheel, textured with spinner knob |

| Gauges: Engine coolant temperature / Fuel level | Adjustable steering column |

| Reverse warning alarm | Large tray and drink holder |

| Horn, with push button in center of steering wheel and switch on joystick lever knob or right console | Rubber floor mat |

| Work lights, rear (2) | Retractable seat belt, 50 mm |

| Work lights on cab, front (2) | Coat hook |

| Lights: Driving with guards / Turn signals with hazard switch / stop, tail and back-up lights | Seatback pocket |

| Alternator, 65 A and 24-volts | Adjustable armrest |

| Standard batteries (2), 12-volt with 620CCA, 80 Ah | Rear view mirrors, outside (2) and inside (2) |

| 24-volt electrical system | Bi-level auto air conditioner and pressurize cab |

| OTHERS | Front / Rear defroster |

| Fenders, front and rear | Hot and cool box |

| Articulation locking bar | LOADER LINKAGE |

| Anti-vandal protection, includes lockable engine enclosure, and fuel fill | Z-bar loader linkage provides (High bucket breakout) |

| Counterweight, built-in | BUCKETS AND ATTACHMENTS |

| Drawbar, with rocking pin | General purpose bucket with bolt-on cutting edges: 2.0 m3 (ISO heaped) |

| Lift and tie-down hooks | TIRES |

| Open type rear grill | 17.5-25-12PR (L3) |

| Single-piece rims |

| ENGINE | POWER TRAIN |

| Air pre-cleaner | Limited slip differential |

| Reverse rotating cooling fan | ELECTRICAL |

| HYDRAULIC SYSTEM | Front Working Lamps on Cab (2) |

| Three-spool main control valve | Rear Working Lamp on Cab (2) |

| Third spool piping | 12-volt outlet |

| Joy stick-lever and auxiliary lever for third function | BUCKETS AND ATTACHMENTS |

| Multi-functional joystick lever | High lift arm |

| Multi-functional joystick lever and auxiliary lever for third function | Buckets |

| Ride control system, automatic type | OPERATOR’S STATION |

| Lift arm kick-out system | Seat(Grammer), fabric, high back, air suspension, seat heating, adjustable for weight-height, fore-aft position, backrest tilt, and armrest angle, seat cushion length and angle, headrest height and angle adjustment, lumber support |

| Lift arm auto leveler | Headrest for Grammer seat |

| OTHERS | Headrest for Kab seat |

| Full rear fender and mud guard | Retractable seat belt, 76 mm |

| Rear license plate bracket | |

| Wheel blocks | |

| High lift arm | |

| Emergency steering system | |

| Bottom guards, front frame and transmission |

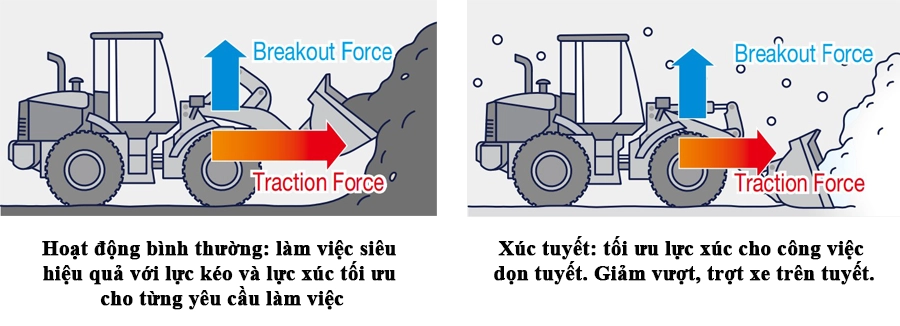

Optimum traction force can be selected to suit job needs by electronic matching control. The HST system is further improved for increased job efficiency.

Normal Operation (Work P, N and L Modes): Efficient loading with optimum traction force to suit job needs

Snow Plowing (Work S Mode): Efficient snow plowing with optimum traction force, reducing slippage on snow

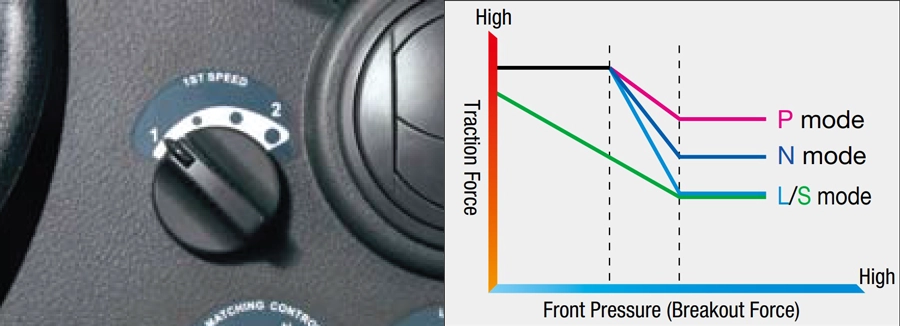

Four work modes selectable to suit job needs - Work mode select switch

On Hitachi ZW140, four work modes are selectable according to job requirements and operator’s preference. In each work mode, electronic matching control, originally developed by Hitachi, detects the pressure of the implement, and controls the torque of travel motor to best match traction force and breakout force. This increases production per unit of fuel.

Four Work Modes:

- P mode (Scooping up and crowding):

+ Relatively large crushed stones

+ Concrete slag

+ Stone with large specific gravity, clayey soil

- N mode (Normal operation) - L mode (Loading and light excavation)

+ Small crushed stones

+ Gravel

+ Cobble

+ Sand

+ Plastics, industrial wastes, chips

- S mode (Snow plowing and swamp operation): Snow

Matching Control

Traction force and front pressure are well balanced by work mode. If you need big traction force, select the P mode

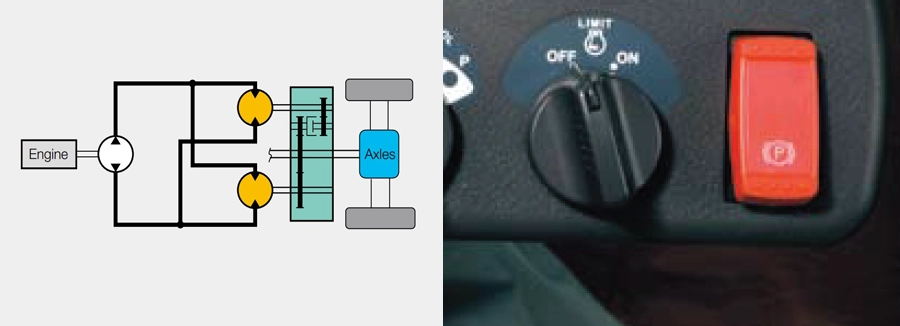

2-Motor HST System for Powerful Acceleration and Higher Travel Speed (Maximum 39 km/h)

The two-motor HST system is newly developed to achieve high-efficient operation in a wide speed range. For instance, at a low speed, two motors yield high traction torque, while at a high speed, a single motor allows for high travel speed of 39 km/h. Moreover, this system makes possible easy slope climbing and smooth acceleration/deceleration with the accelerator pedal only.

Throttle Limit for Higher Fuel Efficiency

The throttle limit cuts maximum engine speed by 10% for higher fuel efficiency. For the HST system, maximum traction force is not reduced with the reduction in engine speed.

Throttle limit switch - *ON

- Fuel consumption (L/h): 88 %

- Production (m3/h): 93 %

- Fuel efficiency (m3/L): 106 %

*Index: 100 = Throttle limit switch OFF. Note: Data shown is Hitachi test data, and may vary depending on job conditions.

Improved Fundamental Performance

Big Traction Force:

- Traction force: 87kN

- Bucket breakout force: 92kN

Big Dumping Clearance and Reach (when 2.0 m3 bucket with BOC is fitted)

- Dumping clearance: 2 840 mm

- Dumping reach: 900 mm

Smooth Speed Shift by Electronic ControlSpeed shift can be continuously made by electronic control through the 2-motor HST system comprising helical gears. This allows for speedy job-to-job travel with less soil spills in load-and-carry operation.

High-Torque Engine

Max. output : 96 kW (129 HP)

Max. torque : 540 N∙m (55 kgf∙m)

The new engine is ruggedly designed to yield big torque with less vibration for increased durability. This facilitates climbing steep slopes and long uphills with limited speed drop. This engine is a clean engine that complies with the latest global emission regulations.

Torque Proportional Differential (Standard)

The torque proportional differential adjusts driving forces to both wheels. When road resistances under both wheels are different, this feature minimizes slippage of a wheel on softer ground, unlike conventional differentials. This feature enables the ZW series to get out of swamps or rough terrain easily.

Limited Slip Differential (Optional)

On snowy roads and rough terrain, the limited slip differential can work instead of the torque proportional differential. This delivers effective driving force to both wheels for enhanced grip and less slippage during travel.

Fast, light footwork. Speed selection to suit job needs. Improved controllability and combined operations. Those bring about high productivity

Sophisticated Mechanisms for Higher Job Efficiency

Float System: The float system lets the lift arm follow up road irregularities by using its self weight only, without using its hydraulic circuit. This system is useful in soil-spill collecting during loading, and snow removing

Lift Arm Kick-Out System (Optional): The lift arm can automatically be raised up to the preset level. This function is convenient when loading onto a dump truck, and when operating at confined job sites with restricted working height.

Bucket Auto Leveler: The bucket can automatically be leveled parallel to the ground after dumping the bucket. This can eliminate cumbersome bucket repositioning for efficient loading.

Operator-Friendly Designs for Higher Job Efficiency

Restriction Valve: The restriction valve can effectively reduce shocks when stopping the lift arm. The bucket does not have a shockless circuit to allow efficient mud removal.

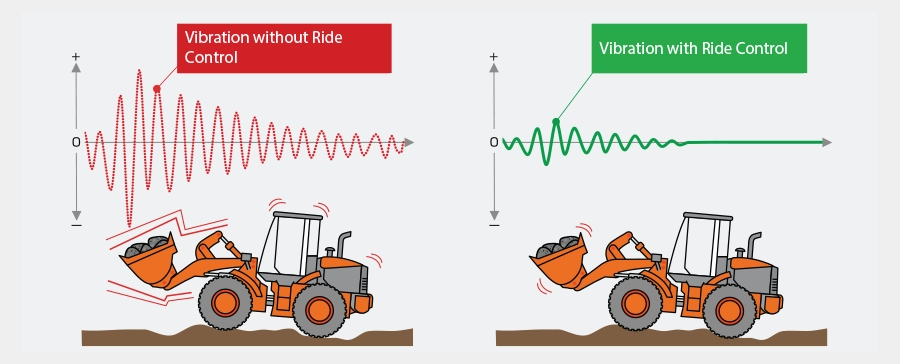

Ride Control System (Optional): The ride control reduces pitching and bouncing during traveling on rough terrain and snow road by automatic control of the implement. Shocks and vibration can be well suppressed for riding comfort

Advanced Speed Selector for Four Maximum Speeds

The fully automatic HST system is utilized for the selection of four maximum speeds according to job needs. Optimum speed can be selected with less shocks for smooth travel.

The First Speed Selector for Efficient Loading and Operations in Confined Space

When the first speed range is selected, four travel speeds can be further selected to suit job needs and jobsite conditions. No need for skilful control of the accelerator and brake.

Inching Pedal for Easy Positioning in Confined Space

The operator can easily control travel speed with the inching pedal, regardless of the accelerator pedal, by adjusting the delivery flow from the hydraulic pump. This eases positioning in loading operation.

New Hydraulic Circuit for Smoothly Combined Operation

With the new parallel/tandem hydraulic circuit, the lift arm and bucket can be operated simultaneously. This is a new function to increase loading and excavating efficiency

Panoramic Cab

The panoramic cab gives almost all round visibility with the widened front glass window and pillar less cab rear corners. Front wheels are always in the operator's vision, enhancing safety and increasing loading efficiency.

Enhanced Upward Visibility

The front curved glass window gives good upward visibility, so the operator can directly see the movement of the bucket for safer loading.

Good Rear Visibility

The engine cover is low profile, and rounded for better rear visibility, so the operator can directly see the rear wheels and counterweight.

Comfort-Designed Suspension Seat

The mechanical suspension seat well absorbs shocks and vibrations from the machine body to reduce operator's physical stresses for enhanced comfort. The air suspension seat is an option.

Ergonomically Positioned Switches and Controls

The switches for pre-operation setting are on the right console, and the switches for operation and travel on the front console. They are functionally laid out for ease of operation.

Multi-Functional Joystick Lever (Optional)

The multi-functional joystick lever is provided atop of the control lever for operating ease.

Adjustable Steering Column

The steering wheel is tiltable and to suit operator of all builds for comfortable operation.

Bi-Level Auto Air Conditioner and Pressurized Cab

The bi-level air conditioner allows air conditioning at foot space and overhead simultaneously. Airflow volume and direction can automatically be adjusted according to the temperature setting. The pressurized cab shuts out dust and debris even in dusty environment.

Front / Rear Defrosters

With the front and rear defrosters, airflow comes out from three front air outlets and two rear outlets to protect respective windows from fogging, keeping clear vision even in rain and cold weather.

Shock-Dampened Cab

The cab rests on fluid-filled elastic mounts to absorb shocks and vibration, and reduce resonance.

Hat (Resin Cab Roof)

The hollow hat is provided atop the cab to form an air space. This greatly helps reduce the temperature rise in the cab, and increases the cooling efficiency of the air conditioner.

Low Noise Design

The cab is well sealed, and the new low noise engine is utilized to reduce sound, along with the following measures:

- Hydraulically operated cooling fan with heat-sensing system

- Hitachi Silent (HS) fan

- Sound-absorbing materials inside engine cover and cab

An Array of Standard Accessories

Durability is enhanced with a number of advanced mechanisms for long, continuous operation.

Durable Axles

Front and rear axles are improved for durability. The axle housing is thickened for tough operation at quarries

Robust Differential Gears

Differential gears are thickened to increase rigidity.

Improved Braking Ability

The brake is a wet-type multi-plate brake, and housed in the axle.

Hydraulically Operated Cooling Fan with Heat- Sensing System

Fan speed can be adjusted depending on fluid temperature to effectively cool down coolant and hydraulic oil. The result is extended component service life and reduction in fuel consumption. The fan is also separate from the engine for easy servicing.

Capacious Hydraulic Oil Cooler

The ample cooling capacity of the hydraulic oil cooler helps reduce oil temperature fluctuation, and extend service life of components.

Aluminum Radiator and Oil Cooler

The radiator and oil cooler are made of aluminum instead of conventional steel or copper for corrosion prevention.

LED Indicators and Instruments

On the indicators, monitors and alarms, many LEDs are utilized for longer service life resulting in less failure, enhancing the reliability.

O-Ring Seal (ORS) Joints and Water-Resistant Electric Connectors

Numerous elaborate components are utilized for higher durability and reliability. The proven ORS joints and high-pressure hydraulic lines are utilized in the hydraulic system, and water resistant wiring connectors in the electrical system.

Robust Frame

The box-section frame is thickened and strengthened to resist torsion and increase durability. Center pins are widely spaced for higher resistance to torsion.

Protected Fuel Tank

The large counterweight is arranged to protect the fuel tank from collisions with obstacles during operation.

Running and maintenance costs are reduced greatly with concentrated inspecting points and durable components.

HN Bushings

The HN bushing containing high viscosity oil is provided at each joint to reduce grease consumption, extend lubrication intervals (100 to 500 hours), and increase durability.

The HN bushing, another example of innovative technology developed by Hitachi, features long life and high durability. High-viscosity oil is vacuum impregnated in sintered high-hardness metal. During operation oil oozes from the pores of the bushing into the clearance between pins and bushing providing lubrication.

Easy-to-Read Monitor

With the easy-to-read monitor, the operator can see instructions for scheduled servicing and maintenance.

- Monitor Indication Items:Clock, service intervals, travel speed, mileage, hour meter

- Replacement Alerting: Engine oil / filter, fuel filter, hydraulic oil / filter, transmission oil / filter, Axle oil.

Hydraulically Operated Cooling Fan

The rotation of the hydraulically operated cooling fan with heat-sensing system is equipped as standard. The fan itself can swing open for easy cleaning.

Flat Cab Floor

The cab floor is stepless (flat) for ease of cleaning.

Strategically Located Fuel Supply Port

The fuel supply port is located for convenient fuel supply from the ground.

Dirt-Less (DL) Front Frame

The DL front frame is shaped for easy removal of dirt, stones and snow

Easy-to-Replace Air Conditioning Filters

The fresh air filter can easily be replaced from the cab, and circulation air filter also replaced by detaching the drink holder.

Conveniently Located Filters

Fuel filter, fuel pre-filter with sedimentary function and engine oil filter are strategically located for the convenient daily inspection and servicing.

Extended Engine Oil Replacement Intervals (Up from 250 to 500 Hours)

Engine oil capacity and filter capacity are increased for longer filter replacement intervals, reducing maintenance time and downtime.

Easy Draining

The engine oil drain port is located for the convenience of maintenance. No need for reaching under the machine.

Achieving a High-Level of Safety in the Working Environment with an Array of Advanced Mechanisms.

ROPS / FOPS Cab

The ROPS / FOPS cab is provided to protect the operator from injury in an accident.

- ROPS: Roll-Over Protective Structure: ISO3471

- FOPS: Falling Object Protective Structure: ISO3449

Highly Reliable Dual-Line Brake System

The dual-line hydraulic brake system is utilized: even if one line fails, the other can work for braking. The brake is an enclosed wet single-plate type for reliable braking.

Full Fan Guard

The cooling fan is enclosed by a full guard (metal net) to protect service technicians from injury during servicing and maintenance.

Emergency Steering System

The emergency electric pump delivers the necessary oil pressure for power steering even in the case of an emergency. This allows normal steering at all times even if the engine fails.

Mis-Operation Protection:

- Starting Engine: The engine will start only when the Forward / Reverse lever in neutral.

- Starting: The transmission is disabled when the parking switch is in the ON position, even if selecting Forward or Reverse.

- Leaving from Operator Seat: Control levers and Forward / Reverse lever are locked to prevent accidental operation.

- Stopping Engine: The spring-set/hydraulic-released parking brake is automatically applied even if failing to apply it.

Other Safety Features

- Retractable Seat Belt

- Inclined Ladder

The ZW Series is equipped with a clean but powerful engine to comply with Tier 3 and Stage III A. An engine emission regulations effective in the U.S. EPA and European Union from 2006. Exhaust gas is partly re-combusted to reduce particulate matter (PM) output and lower nitrogen oxide (NOx) levels.

Common Rail Type Fuel Injection System

In this fuel injection system complying with the Emission Regulations, one fuel pump runs to generate high pressure for distributing fuel to each injector per cylinder through a common rail. By electronic control, fuel injection volume and timing can be precisely regulated for efficient combustion and higher horsepower. This also reduces PM* (diesel plume), fuel consumption and vibration.

*Particulate matter

Important: The use of fuels other than diesel fuel (EN590) is prohibited. Otherwise, the engine may be damaged.

A Recyclable Machine

Approximately 95% of the ZW Series can be recycled. The resin parts are marked to facilitate recycling. The machine is completely lead-free. The radiator and oil cooler are made from aluminum and all wires are lead-less. In addition, bio-degradable hydraulic oil is available for jobsites where special environmental care is required.

A number of features make this machine quieter. First, isochronous control of the engine speed means a restriction of engine speed during no-load and light-duty operation to suppress sound. A fan with curved blades reduces air resistance and airflow noise. Third, a time-tested muffler suppresses engine noise significantly and reduces emissions. This advanced low noise design complies with the 2000 / 14 / EC, Stage II, directive effective in the European Union from 2006.

Hitachi Silent (HS) Fan

The HS fan is capable of reducing air resistance and air flow sound are utilized at the radiator and oil cooler for quieter operation.

Low Noise Engine

Engine noise is effectively reduced by increasing engine mechanical strength with rigid cylinder block, and by utilizing the elaborate gear train on the flywheel side.

Tags: wheel loader, caterpillar wheel loader, hitachi wheel loader, Komatsu wheel loader, Doosan caterpillar wheel loader, wheel loader specifications, wheel loader Komatsu, wheel loader for sale, wheel loader capacity, wheel loader vs excavator, wheel loader caterpillar, wheel loader liugong, kubota wheel loader, volvo wheel loader, compact wheel loader, bobcat wheel loader, wheel loader volvo, wheel loader jcb, hitachi wheel loader dealers, hitachi wheel loader models, hitachi wheel loader specifications, hitachi wheel loader zw80, hitachi wheel loader parts, hitachi wheel loader zw180, used hitachi wheel loader, hitachi wheel loaders usa, hitachi 310 wheel loader, hitachi 220 wheel loader, hitachi 140 wheel loader, hitachi 370 wheel loader, hitachi 310 wheel loader specs, hitachi zw140 6 wheel loader specs