ZAXIS EMPOWER YOUR VISION

Hitachi Excavator ZX470-5G

A ZAXIS hallmark – industry-leading hydraulic technologies, and performance no other can beat. New ZAXIS provides reliable solutions: impressive fuel economy, swift front movements, and easy operation. You'll also find Hitachi technological prowess and expertise, such as the optimized hydraulic system and engine.

New ZAXIS features the key benefits of high quality, low fuel consumption, and high durability, all of which serve to ensure low running costs. New ZAXIS, which is empowered by comprehensive evolution, will realize customers’ visions and dreams, and pioneer your colorful future.

Key Benefits for Low Running Costs: High Quality, Low Fuel Consumption, High Durability.

TECHNICAL DATA

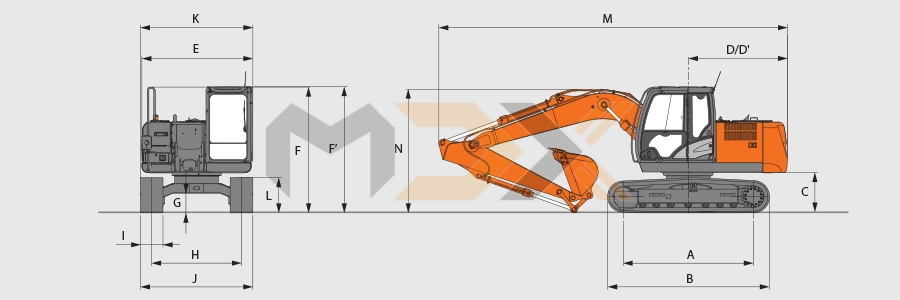

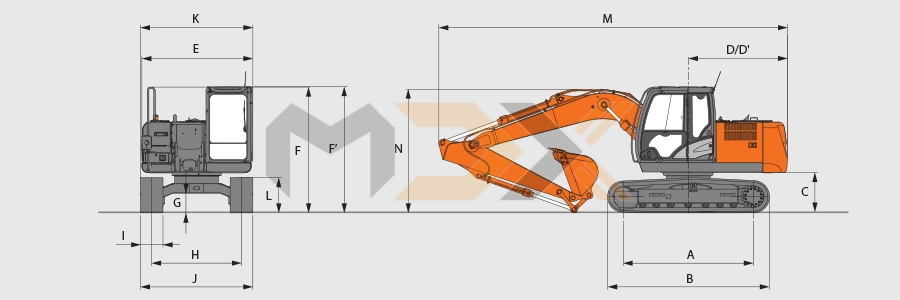

| DIMENSIONS |

|

| |

|

ZX470-5G |

| A Distance between tumblers |

mm |

4 040 |

| B Undercarriage length |

mm |

5 040 |

| C Counterweight clearance (*) |

mm |

1 230 |

| D Rear-end swing radius |

mm |

3 670 |

| D’ Rear-end length |

mm |

3 660 |

| E Overall width of upperstructure |

mm |

3 480 |

| F Overall height of cab |

mm |

3 170 |

| G Min. ground clearance |

mm |

495 |

| H Track gauge |

mm |

2 740 |

| I Track shoe width |

mm |

600 / 750 |

| JUndercarriage width |

|

|

| with 600 mm shoe |

mm |

3 340 |

| with 750 mm shoe |

mm |

3 490 |

| K Overall width |

mm |

3 820 |

| L Overall length |

mm |

12 050 |

| M Overall height of boom |

mm |

4 660 |

| N Track height |

mm |

1 150 |

*1 Excluding track shoe lug

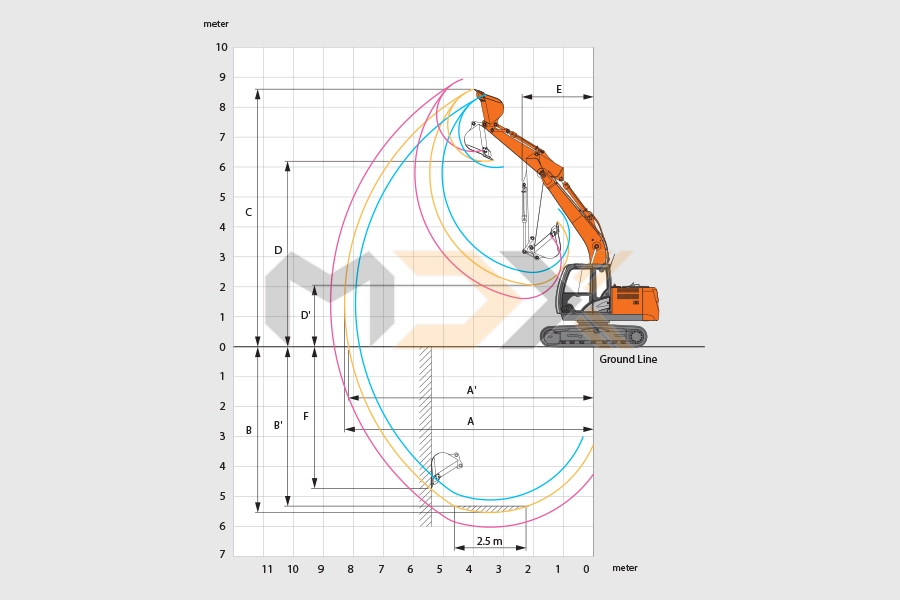

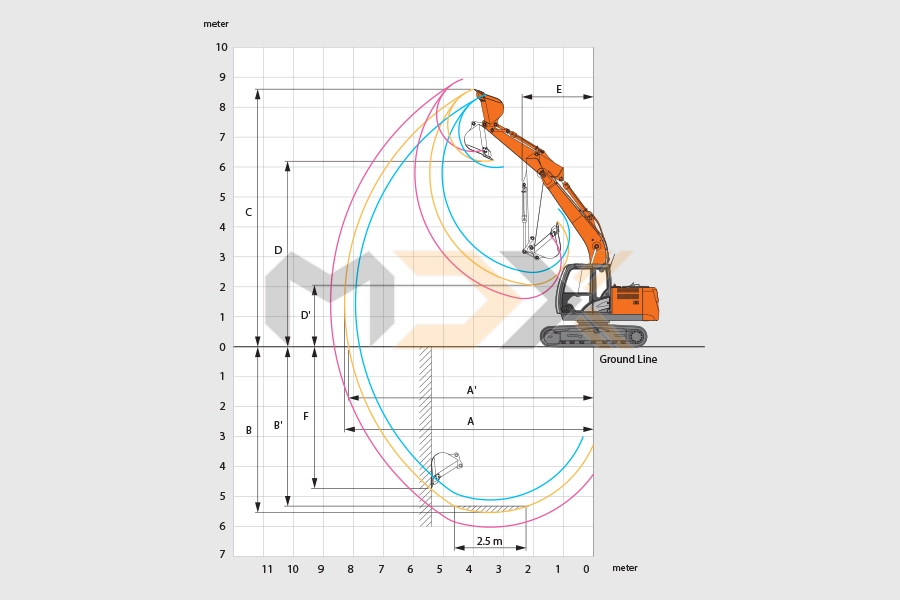

| WORKING RANGES |

|

| |

|

6.3 m BE-boom |

7.0 m H-boom |

| Arm length |

m |

2.5 m BE-arm |

2.9 m BE-arm |

2.9 m BE-arm |

3.4 m H-arm |

3.9 m Arm |

4.9 m Arm |

| A Max. digging reach |

mm |

10 460 |

10 850 |

11 400 |

12 060 |

12 490 |

13 260 |

| A’ Max. digging reach (on ground) |

mm |

10 240 |

10 640 |

11 200 |

11 860 |

12 300 |

13 080 |

| B Max. digging depth |

mm |

5 920 |

6 360 |

7 400 |

7 890 |

8 390 |

9 230 |

| B’ Max. digging depth (8' level) |

mm |

5 740 |

6 200 |

7 200 |

7 750 |

8 270 |

9 110 |

| C Max. cutting height |

mm |

10 530 |

10 760 |

10 130 |

10 920 |

11 040 |

11 420 |

| D Max. dumping height |

mm |

7 190 |

7 210 |

6 900 |

7 530 |

7 650 |

8 390 |

| D’ Min. dumping height |

mm |

3 550 |

3 030 |

3 320 |

2 820 |

2 320 |

1 490 |

| E Min. swing radius |

mm |

3 930 |

3 920 |

5 020 |

4 840 |

4 810 |

4 850 |

| F Max. vertical wall |

mm |

4 380 |

5 150 |

5 390 |

6 710 |

7 100 |

8 470 |

| Excluding track shoe lug |

| SPECIFICATIONS |

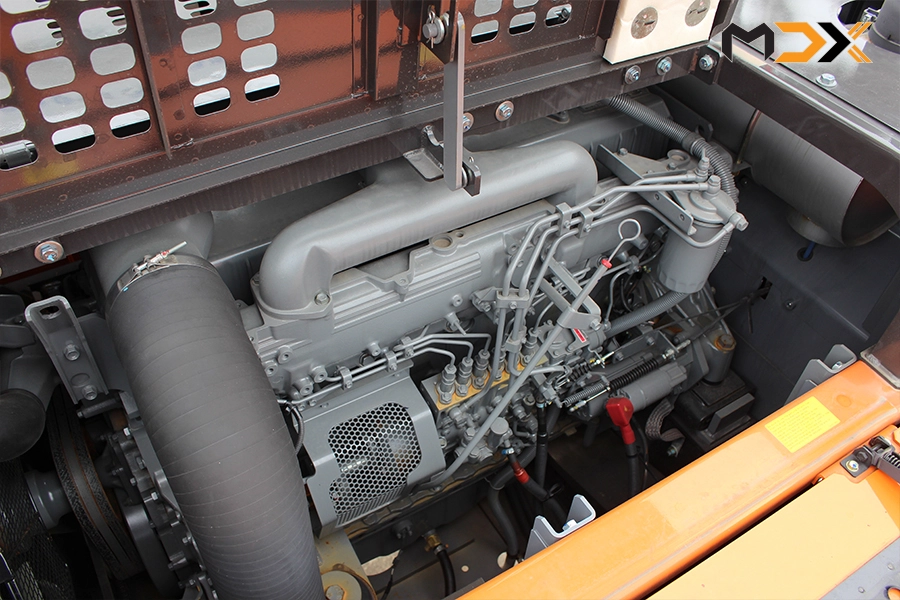

| ENGINE |

| Model |

Isuzu AA-6WG1TQA |

| Type |

4-cycle water-cooled, direct injection |

| Aspiration |

Turbocharged |

| No. of cylinders |

6 |

| Rated power |

|

|

| ISO 9249, net, H/P mode: (With Fan) |

kW |

235 kW (315 HP) at 1 800 min-1 (rpm) |

| SAE J1349, net, H/P mode: (With Fan) |

kW |

231 kW (310 HP) at 1 800 min-1 (rpm) |

| Maximum torque |

Nm |

15.681 L |

| Piston displacement |

L |

6.494 |

| Bore and stroke |

mm |

147 mm x 154 mm |

| Batteries |

|

2 x 12 V / 170 Ah |

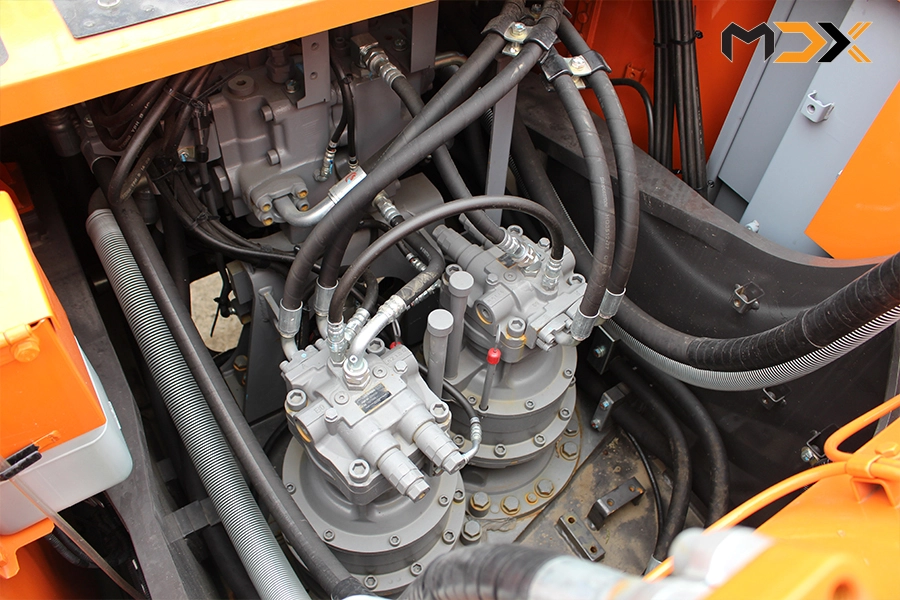

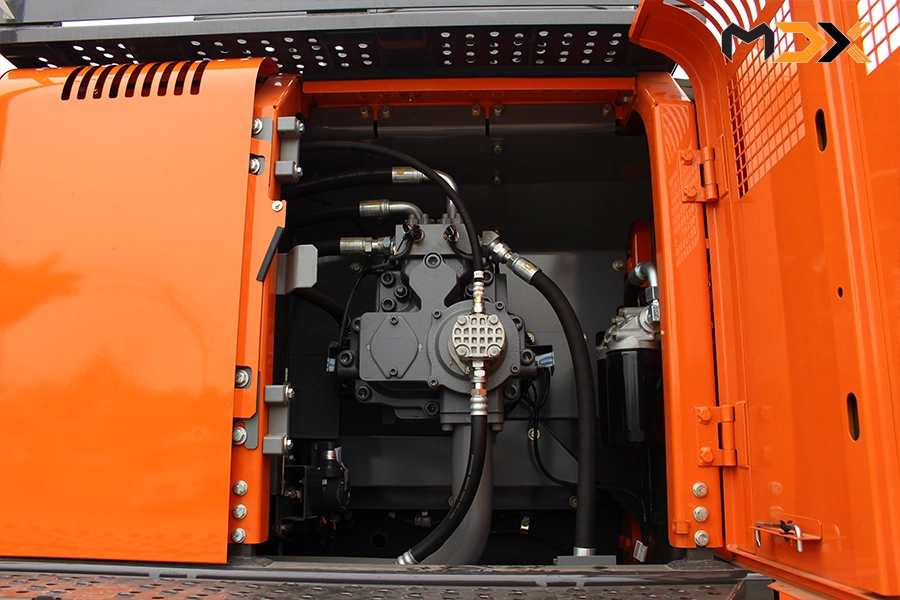

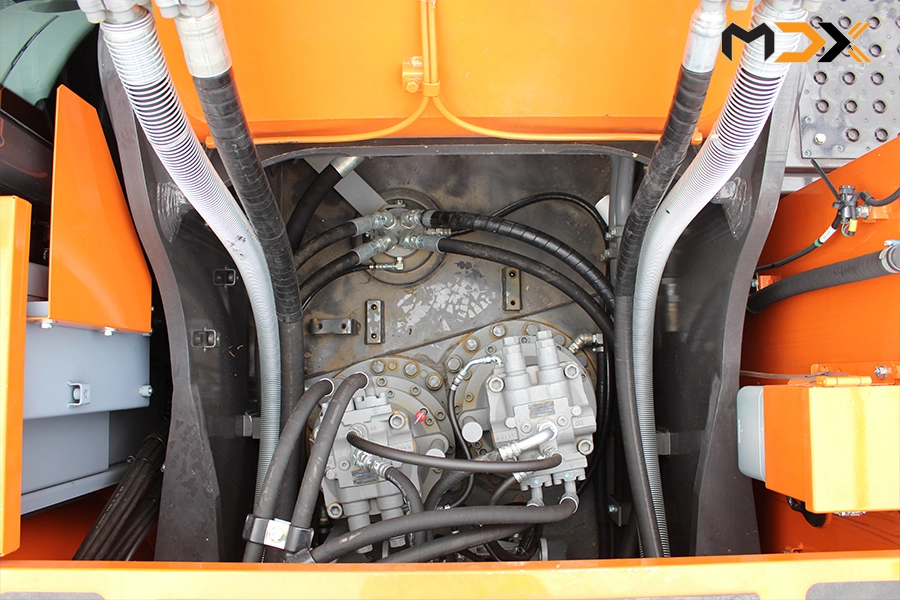

| HYDRAULIC SYSTEM |

| Hydraulic Pumps |

|

|

| Main pumps |

2 variable displacement axial piston pumps |

| Maximum oil flow |

L/min |

2 x 360 |

| Pilot pump |

1 gear pump |

| Maximum oil flow |

L/min |

30 |

| Hydraulic Motors |

|

|

| Travel |

2 variable displacement axial piston motors |

| Swing |

1 axial piston motor |

| Relief Valve Settings |

|

|

| Implement circuit |

MPa (kgf/cm2) |

31.9 (325) |

| Swing circuit |

MPa (kgf/cm2) |

28.4 (290) |

| Travel circuit |

MPa (kgf/cm2) |

35.3 (360) |

| Pilot circuit |

MPa (kgf/cm2) |

3.9 (40) |

| Power boost |

MPa (kgf/cm2) |

35.3 (360) |

| UNDERCARRIAGE |

| Tracks |

Track shoes with triple grousers made of induction-hardened rolled alloy. Heat-treated connecting pins with dirt seals. Hydraulic (grease) track adjusters with shock-absorbing recoil springs. |

| Numbers of Rollers and Shoes on Each Side |

|

|

| Upper roller |

2 |

|

Lower rollers

|

8: ZX470-5G / ZX470H-5G

9: ZX470LC-5G / ZX470LCH-5G

|

|

Track shoes

|

49: ZX470-5G / ZX470H-5G

53: ZX470LC-5G / ZX470LCH-5G

|

| Idler track guard |

1: ZX470-5G / ZX470LC-5G |

| Track guard |

1: ZX470-5G

2: ZX470LC-5G

Full track guard : ZX470H-5G / ZX470LCH-5G

|

|

Travel Device

|

Each track driven by axial piston motor through reduction gear for counterrotation of the tracks. Parking brake is spring-set/hydraulicreleased disc type. |

| Automatic transmission system |

High-Low |

|

Travel speeds

|

km/h

km/h

|

High : 0 to 5.1 km/h

Low : 0 to 3.8 km/h

|

| Maximum traction force |

kN (kgf) |

329 kN (33 600 kgf) |

| Gradeability |

% (degree) |

70 (35) |

| SERVICE REFILL CAPACITIES |

| Fuel tank |

L |

705.0 |

| Engine coolant |

L |

61.0 |

| Engine oil |

L |

55.0 |

| Swing device |

L |

6.5 |

| Travel device (each side) |

L |

11.0 |

| Hydraulic system |

L |

510.0 |

| Hydraulic oil tank |

L |

310.0 |

| UPPERSTRUCTURE |

| Revolving Frame |

D-section frame skirt for resistance to deformation |

| Swing Device |

Swash plate piston motor with planetary reduction gear is bathed in oil. Swing circle is single-row. Swing parking brake is spring-set/hydraulicreleased disc type. |

| Swing speed |

min-1 |

9.0 |

| Operator's Cab |

ZX470-5G / ZX470LC-5G: Independent spacious cab, 1 025 mm wide by 1 675 mm high, The OPG top guard ftted Level I conforms to the related requirements of the International Organization Standardization (ISO) 10262.

ZX470H-5G / ZX470LCH-5G (H/R cab): Independent spacious cab, 1 025 mm wide by 1 817 mm high, The OPG top guard ftted Level II conforms to the related requirements of the International Organization Standardization (ISO) 10262

|

| HYDRAULIC CYLINDERS |

| |

|

Quantity |

Bore |

Rod diameter |

| Boom |

mm |

2 |

170 |

115 |

| Arm |

mm |

1 |

190 |

130 |

| Bucket |

mm |

1 |

170 |

120 |

| WEIGHTS AND GROUND PRESSURE |

| Shoe type |

Shoe width |

Boom type |

Arm type |

kg |

kPa(kgf/cm 2) |

Triple or double grouse |

600 mm |

7.0 m H |

3.4 m H |

45 600 |

85 (0.87) |

| Bucket capacity |

1.9 m3 |

| 6.3 m BE |

2.5 m BE |

46 000 |

86 (0.87) |

| Bucket capacity |

2.5 m3 |

Triplegrouser

|

750 mm |

7.0 m H |

3.4 m H |

46 300 |

69 (0.70) |

| Bucket capacity |

1.9 m3 |

| 6.3 m BE |

2.5 m BE |

46 700 |

70 (0.71) |

| Bucket capacity |

2.5 m3 |

| BUCKET AND ARM DIGGING FORCES |

| |

6.3 m BE-boom |

7.0 m H-boom

|

| Arm length |

2.5 m BE-arm |

2.9 m BE-arm |

2.9 m BE-arm |

3.4 m H-arm |

3.9 m arm |

4.9 m arm |

| Bucket digging force* ISO |

285 kN ( 29 130 kgf) |

285 kN ( 29 130 kgf) |

285 kN ( 29 130 kgf) |

286 kN ( 29 230 kgf) |

286 kN ( 29 230 kgf) |

238 kN ( 24 290 kgf) |

| Bucket digging force* SAE : PCSA |

257 kN ( 26 240 kgf) |

257 kN ( 26 240 kgf) |

254 kN ( 25 940 kgf) |

256 kN ( 26 140 kgf) |

256 kN ( 26 140 kgf) |

213 kN ( 21 720 kgf) |

| Arm crowd force* ISO |

294 kN ( 30 050 kgf) |

256 kN ( 26 140 kgf) |

259 kN ( 26 450 kgf) |

222 kN ( 22 640 kgf) |

201 kN ( 20 480 kgf) |

177 kN ( 18 110 kgf) |

| Arm crowd force* SAE : PCSA |

285 kN ( 29 130 kgf) |

249 kN ( 25 420 kgf) |

252 kN ( 25 730 kgf) |

215 kN ( 21 920 kgf) |

196 kN ( 19 970 kgf) |

175 kN ( 17 800 kgf) |

| * At power boost |

HIGHLIGHTS

More Production with Less Fuel

|

|

| 8%* Reduction in Fuel Consumption

New ZAXIS is a fuel-thrifty excavator that can reduce fuel consumption by 8%*, compared to the conventional ZX450-3/ ZX450-3F family, thanks to the HIOS IIIB hydraulic system and engine control system, thereby reducing CO2 emissions.

*PWR mode vs. conventional model's P mode

More Fuel Reduction in the ECO mode

The ECO mode, a new economical mode, can further cut fuel consumption by 9% compared to the PWR mode, without sacrifcing digging force by optimal matching of operations. |

|

| Swift Front Movements with HIOS* III Hydraulics

Operating speed increases with less fuel consumption thanks to the HIOS III hydraulic system, developed by industry-leading hydraulic technologies and a wealth of experience. Actuators work quickly by boom weight, without needing a regenerative circuit and pressure oil.

*Human & Intelligent Operation System

Improved Arm Controllability

Improved arm controllability for level luffng and level crowding for front movements, including swing operations. The boom regenerative circuit using the boom weight and the newly adopted variable orifce of the swing circuit help ensure hydraulic oil can be effectively allocated and pressure loss can be reduced. |

|

| Enhanced Basic Performance

The new ZAXIS offers enhanced basic performance, in addition to a sophisticated hydraulic control system like HIOS IIIB. For example, the boom circuit of the control valve was changed to an external flow combining circuit from the internal one to reduce energy loss when raising or lowering the boom. In addition, the powerboosting pressure function was enhanced to increase basic performance.

- 8% increased in swing torque

- 3% increased in traction force

- 3% increased in boom lifting capacities

- 3% increased in arm digging force*

- 3% increased in bucket digging force*

(compared to the conventional ZX450-3 / ZX450-3 family)

*At power boost

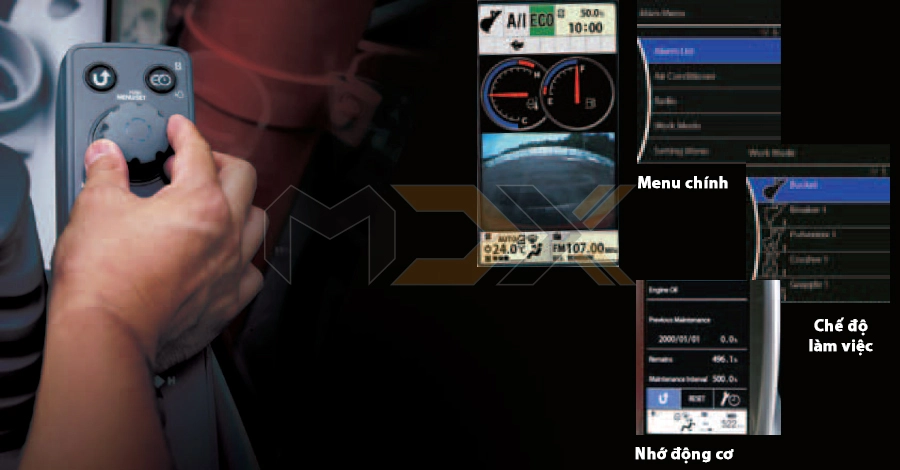

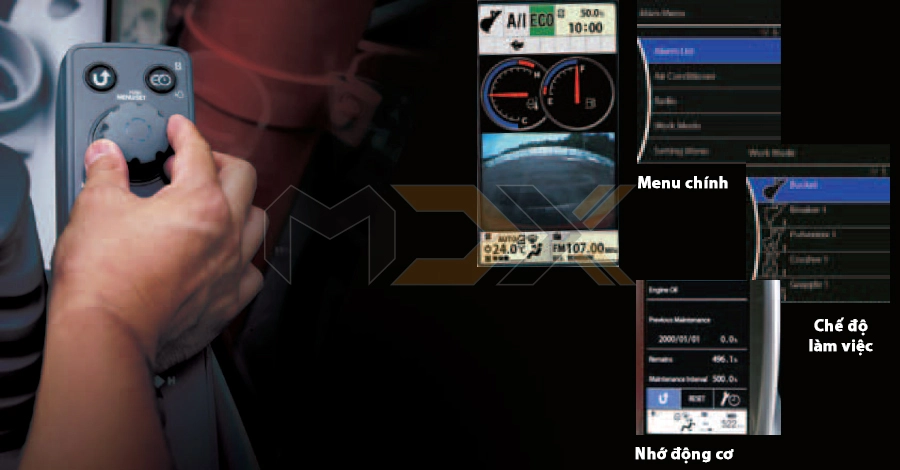

Easy-to-Use Attachments

The operator can change over valves, adjust extra circuit flow, and check settings from the multifunction monitor next to the operator seat. What’s more, 11 jobs, including flow rate setting, can easily be selected by their identifed names. |

Pursuits of Performance and Durability

|

|

|

Prestige R&D and Quality Control

Hitachi has earned praise for technological prowess and product performance around the world. R&D Division has a track record – including excellent design, stress analysis expertise using CAE system, and abundant production data base. What’s more, a large-scale durability test field (427 hm2) allows for a series of stringent testing of new machines. Production Division strives to automatize production processes, including robotic welding, machining, painting, assembling and transferring.

|

|

|

|

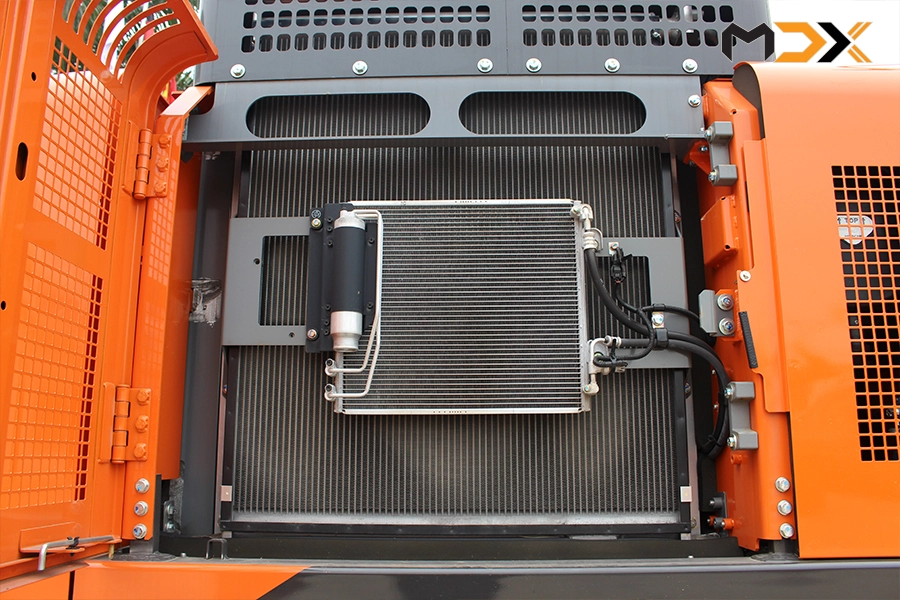

Durable, Reliable Engine

This engine has a track record showing impressive durability at countless tough job sites around the world. The engine - associated with a rugged design, a direct fuel injection system and an elaborate governor - goes green, and complies with EU Stage II and US EPA Tier 2 emissions regulations.

A simple cooling system, consisting of a radiator and oil cooler, facilitates smooth cooling air flow for improved cooling effciency. The combination of a 235 kW (315 HP) engine and the new HIOS IIIB hydraulic system meets requirements, in terms of both output and fuel consumption. |

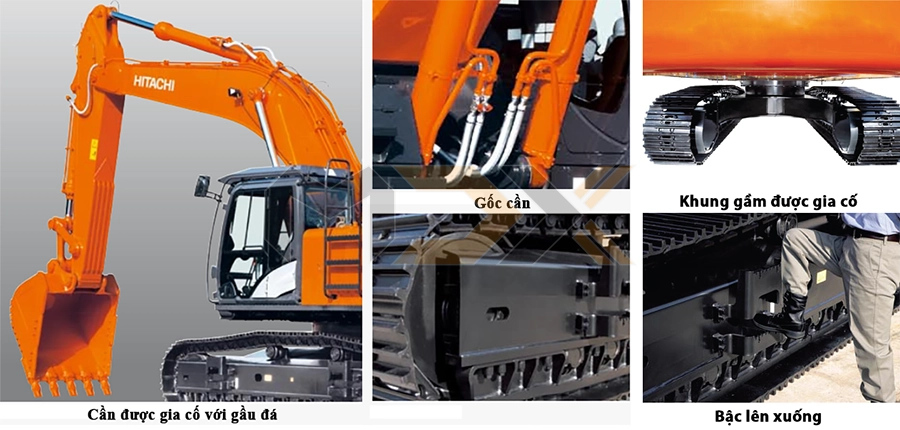

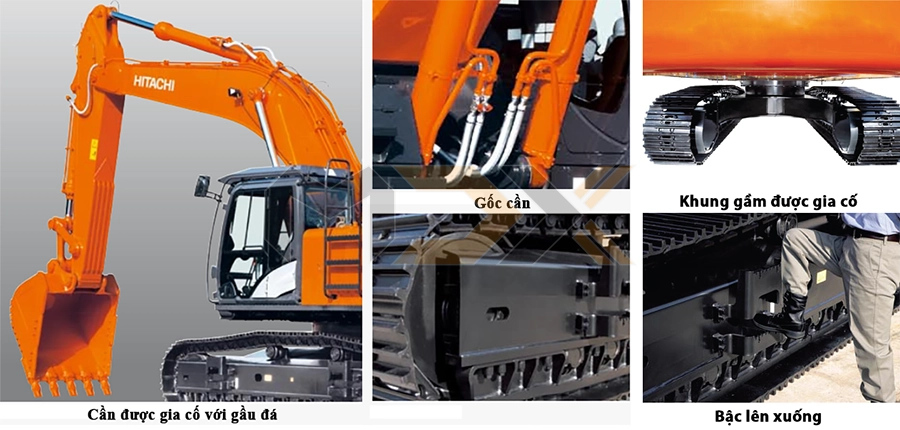

| Rock-Solid, Durable Front Attachment

The new ZAXIS adopts the boom and arm used for heavy-duty versions of the conventional ZAXIS series to the ZX470-5G/ ZX470LC-5G standard models to increase the strength, allowing it to function optimally at tough job sites such as mines / quarries, where an endless stream of operations are required. It also has a wide applicable scope by using a bucket for civil engineering work or one for quarrying, depending on the intended use.

The arm cylinder, boom cylinders and bucket cylinder for the retract side cushion shocks at the stroke ends to reduce noise and extend the service life. |

|

| Strengthened Fixed Gauge Undercarriage

The new undercarriage is an integral construction, the track center and side frame of which are welded together. The lower center of gravity of the body improves stability. For idler brackets, where stress is concentrated in transit, the box-structure and reinforcing plates limit deformation and enhance travel stability. An enhanced twostep side step ladder is also provided to facilitate entering/alighting from the cab.

Proven Upperstructure

The upperstructure frame is reinforced with the proven D-section skirt to increase rigidity against damage by obstacles. A large door catch is added to reduce shocks and jolts of the cab and upperstructure |

No Compromise on Operator Comfort

|

|

|

| Comfortable Operating Environment

You'll feel comfortable and confident, with plenty of leg space and excellent visibility when entering the cab. The new compact console gives more leg space. The new door pillar is shifted rearward by 70 mm to widen an entry space for easy access. A new LED room light, interlocked with the door, turns on when the door opens. The front window is easily removed and stored overhead using slide rails. The overhead window is openable for ventilation. Lots more air vents for air conditioner are located strategically for uniform air circulation inside the cab. The control panel and control levers are arranged within easy reach of the operator. AM/FM radio and AUX port (optional) for a mobile music player are available for a long work day with less fatigue. All these designs focus on operator comfort.

Comfort-Designed Operator Seat

The luxury cloth seat is fitted with a headrest and arm rests for operator comfort. The seat can be adjusted in multiple ways, sliding and reclining, to suit operator’s size and preferences. The seat can slide rearward by 40 mm more for added leg space. The air suspension seat with a heat pad is optional.

Robust Cab The robust cab, meeting the OPG (Top Guard Level 1), protects the operator from falling objects. The pilot control shut-off lever is provided with a neutral engine start system that permits engine starting only when the pilot control shut-off lever is in Lock position. |

|

|

New, Easy-to-Use Multifunction Monitor

The new multi-language, multifunction monitoring system comprises a 7-inch highresolution color monitor and a multifunction controller. The monitor allows the operator to check varying operating variables: coolant temperature, fuel level, work mode, full-auto air conditioner, AM/FM radio, rear view monitor camera (optional), maintenance support, and attachment flow adjustment. Menu items can be selected and adjusted by a multifunction controller on the control panel. A new rear view monitor camera always displays the view behind the machine

|

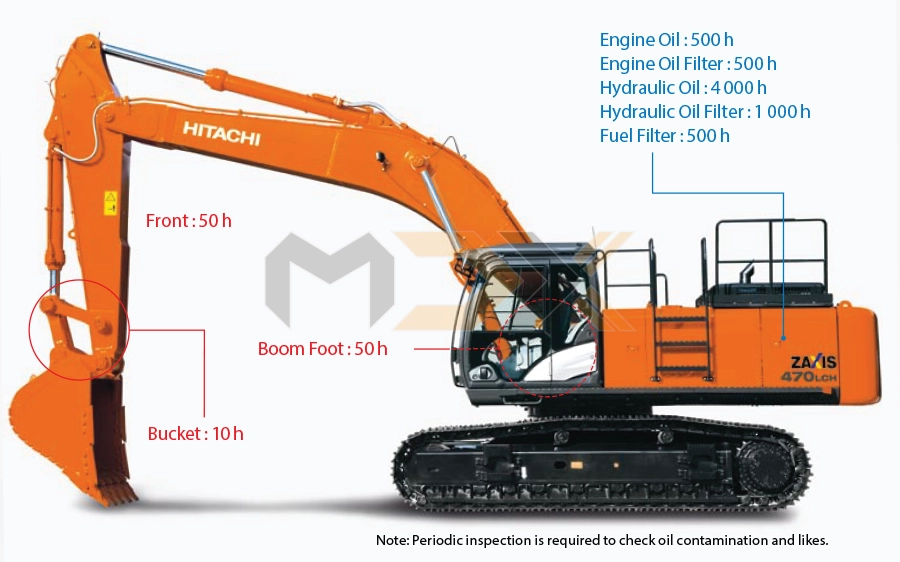

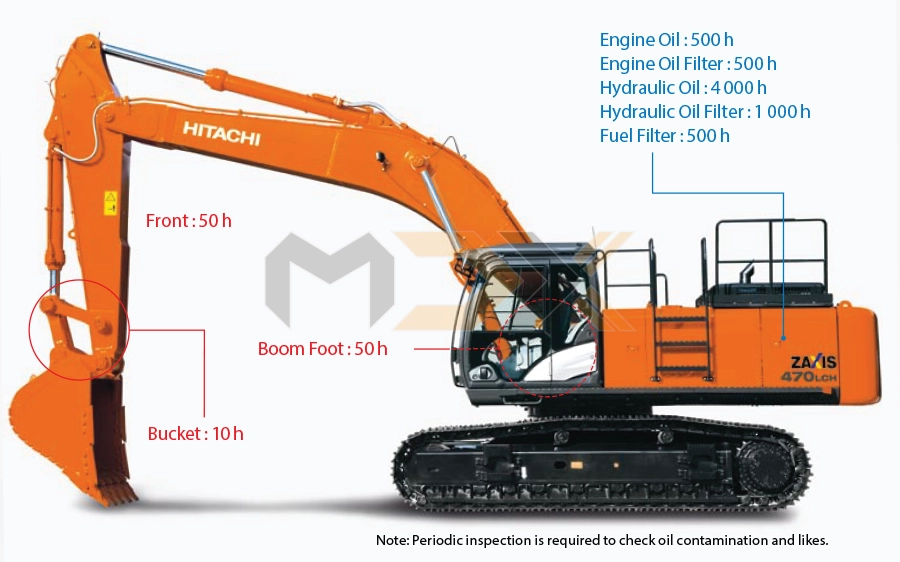

Simplified Maintenance

|

|

| Grouped Remote Inspection Points

Service points are concentrated inside left and right covers that are readily accessible from ground level for convenient servicing and inspection, including water draining from the fuel tank, replenishment of coolant, and replacement of filters. The fuel tank is anti-corrosion coated on its inside, and has a large cleaning port at the bottom. These wise designs effectively keep fuel clean, and ease servicing. Handrails are provided at convenient locations for easy riding on the upperstructure. Plenty slip-resistant plates are located for safe maintenance.

Fast Lubrication

The arm and boom have their own centralized greasing points for fast lubrication. An optional electric grease gun with hose-reel or an auto-grease lubricator is also available for faster greasing / lubrication. |

|

Easy-Access to the Upperstructure

A large sidewalk is provided on the left side of the cab, making it easy to access the engine from the ladder while handrails are provided and suffcient slip-resistant plates for safety

|

|

| Low Life Cycle Costs

Service intervals are long enough to slash maintenance costs

705 L Large Capacity Fuel Tank

Equipped with a large capacity fuel tank for longer operations.

|

Hitachi Support Chain

Hitachi Support Chain is a full customer support system offered after buying a Hitachi machine

|

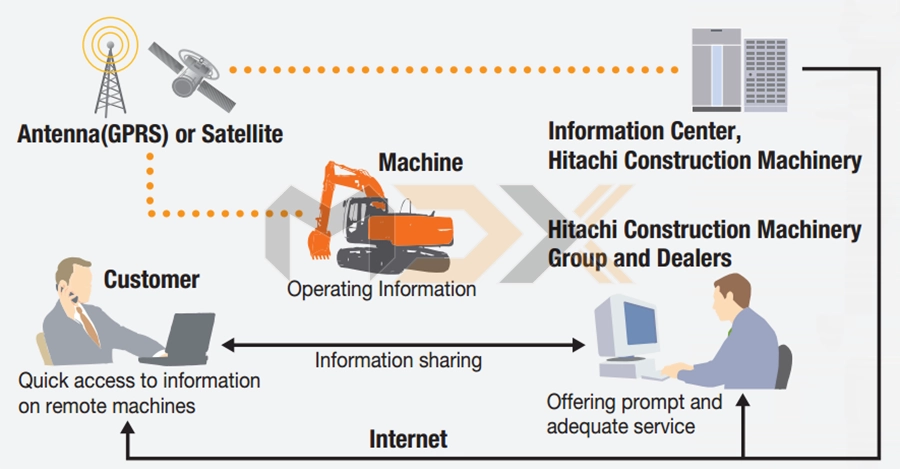

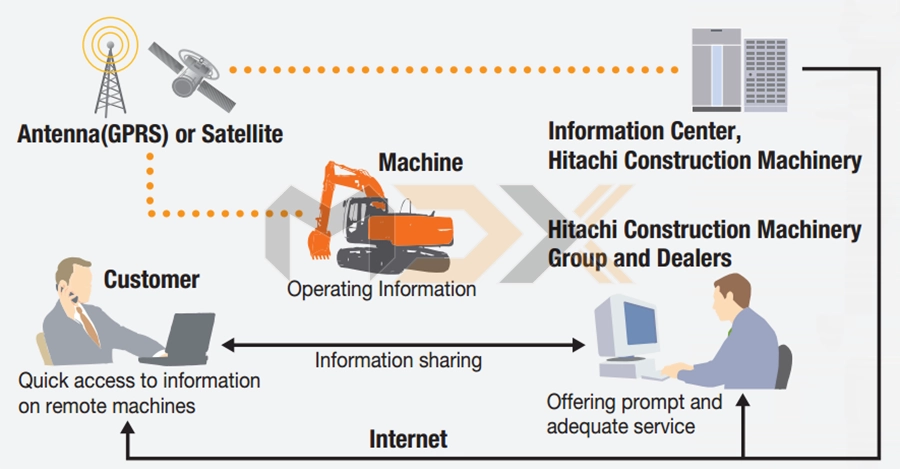

| Remote Fleet Management with Global e-Service |

Easy Access to On-Site Machines through the Internet

This on-line fleet management system allows you to access each on-site machine from a PC in your office. You can get its operating information and location to increase productivity of the fleet and reduce downtime. Operating data and log are sent to a Hitachi server for processing, and then to customer and dealers around the world. This system is available 24 hours a day, all the year around.

Note: In Some Regions, Global e-Service Is Not Available by Local Regulations |

|

| Main Features of Global e-Service

Functions

Global e-Service provides easy access to a machine on site, conveying operating information and log, including daily operating hours, fuel level, temperatures, pressures, and likes.

Maintenance

Maintenance data and log are displayed on a easy-to-read monitor screen, suggesting recommended maintenance for efficient fleet management. |

Parts and Service

Hitachi full customer support is available every area on the globe for full customer satisfaction through Hitachi local dealers. |

| Parts

Hitachi Global Online Network, a parts supply system, is linked with Japan Parts Center, overseas depots and over 150 dealers abroad to deliver on-line parts information, including in-stock parts, order receptions, shipments and delivery period of over one million parts and components.

Genuine Hitachi Parts

Genuine Hitachi parts, meeting Hitachi stringent quality standards, are guaranteed according to Hitachi warranty standards. The use of genuine Hitachi parts, including engine, fuel, hydraulic oil and filters, may slash running costs, and extend machine life.

Ground Engaging Tools (GETs)

Hitachi provides an array of Hitachi Ground Engaging Tools developed and built for a variety of applications. Using high-quality, well-maintained GETs will help you get customers' trust.

Note: Some dealers do not handle Hitachi GETs.

Remanufactured Components

Hitachi components are remanufactured according to the stringent remanufacturing standards at four factories around the world. They have high quality equivalent to new ones, and backed up by Hitachi warranty system.

Note: Some dealers do not handle Hitachi Remanufactured Components.

|

| Service

Extended Warranty - HELP

Hitachi Standard Warranty System is available on all new Hitachi machines. In addition, Hitachi offers Hitachi Extended Life Programs (HELPs) to suit customer expectations - protecting machines under tough operating conditions, avoiding unexpected downtime, and reducing repair costs.

Note: Warranty conditions vary by equipment.

Diagnostic Tools - Maintenance Pro

Electronic control system needs quick on-site solutions, apart from mechanical repairs. Hitachi’s Maintenance Pro can diagnose machine failures in a short time by plugging a PC into a failed machine.

Technical Training

On-site servicing matters despite locations to keep the machine at peak performance and reduce downtime. Technical Training Center (TTC), located in Japan, educates and trains service technicians and service support personnel coming from Hitachi dealers and factories on the globe according to the international training programs |

EQUIPMENTS