HAMM- 100 YEARS OF INNOVATION & EXPERIENCE

It was in 1911 when Hamm developed the first road compaction equipment with a diesel engine - since then our innovative team has been designing trend-setting machinery. Today, HAMM is the world‘s major producer of asphalt rollers and soil compactors.

HAMM is famous worldwide for powerful and user-friendly compaction machines for a wide variety of jobs associated with road construction and earth works. Moreover, Hamm rollers are convincing because of their ergonomic and innovative design. HAMM has been awarded a total of 20 design prizes for all its innovations.

Wirtgen India, a 100% subsidiary of the Wirtgen Group, has maintained a strong presence in India since 1995, with 22 local Sales and Service offices. Theyoffer a broad range of services in all areas of road construction and refurbishment. With passion and dedication our highly motivated team ensures your success at the construction site.

Market-leading products and top service with tried and tested quality standards give you the confidence you need in your fiercely competitive environment. The Wirtgen Group’s successful brands of long standing will safely keep you on the road to success.

TECHNICAL DATA

|

| |

Unit |

HD 99 VV |

| WEIGHTS |

| Operating weight with sunroof |

kg |

9 170 |

| Operating weight, max. |

kg |

9 800 |

| Static linear load, front/rear |

kg/cm |

27,7 / 26,9 |

| French classific., data/class |

|

22,5 / VT1 |

|

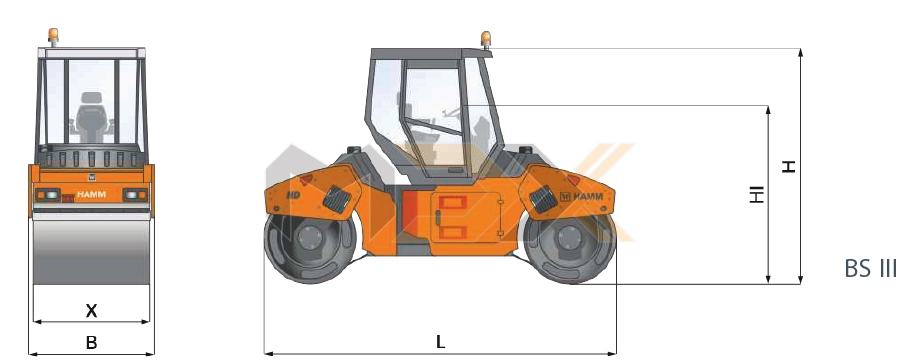

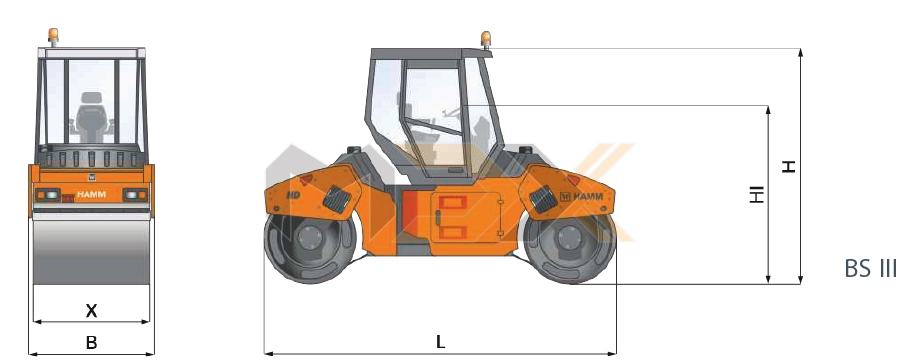

| MACHINE DIMENSIONS |

| Total length (L) |

mm |

4 600 |

| Total height with cab (H) |

mm |

3 050 |

| Height, loading, min. (HI) |

mm |

2 660 |

| Wheelbase |

mm |

3 400 |

| Total width (B) |

mm |

1 810 |

| Max. working width |

mm |

1 780 |

| Kerb clearance, left/right |

mm |

710 / 710 |

| Turning radius, inside |

mm |

3 961 |

| DRUM DIMENSIONS |

| Drum width, front/rear |

mm |

1 680 / 1 680 |

| Drum diameter, front/rear |

mm |

1 200 / 1 200 |

| Drum thickness, front/rear |

mm |

17 / 17 |

| Drum type, front |

|

Smooth |

| Drum type, rear |

|

Smooth |

| Track offset, left/right |

mm |

100 |

| DIESEL ENGINE |

| Manufacturer |

|

CUMMINS |

| Type |

|

4BT AA 3.9 |

| Number of cylinders |

|

4 |

| Power rat. ISO 14396 |

kW/PS/rpm |

74 / 100 / 2 200 |

| Power rating SAE J1349 |

kW/HP/rpm |

74 / 99 / 2 200 |

| Emission standard |

|

CEV Stage III |

| DRIVE |

| Speed, working gear |

km/h |

0 - 7 |

| Speed, transportation gear |

km/h |

0 - 14 |

| Climbing ability, vibration on/off |

% |

30 / 40 |

| VIBRATION |

| Vibration frequency, front, I/II |

Hz |

42 / 50 |

| Vibration frequency, rear, I/II |

Hz |

42 / 50 |

| Amplitude, front, I/II |

mm |

0,66 / 0,37 |

| Amplitude, rear, I/II |

mm |

0,66 / 0,37 |

| Centrifugal force, front, I/II |

kN |

75 / 60 |

| Centrifugal force, rear, I/II |

kN |

75 / 60 |

| STEERING |

| Oscillation angle +/- |

° |

10 |

| Steering, type |

|

Articulated steering |

| SPINKLER SYSTEM |

| Water sprinkler, type |

|

Pressure |

| TANK CAPACITY / FILL CAPACITY |

| Fuel tank, capacity |

L |

170 |

| Water tank, capacity |

L |

700 |

| SOUND LEVEL |

| Acoustic power LW(A), sticker |

db(A) |

|

| Acoustic power LW(A), measured |

db(A) |

110 |

EQUIPMENTS

Note: standard or optional equipment depends on the standard of each country. Please contact us for the answer.

EQUIPMENT: Handrails, Operator’s platform with entry from both sides, Seatoperating unit, rotatable, 1 drive lever, Amplitude switchable: large/small, Vibration front and rear, switchable single and doubled, Battery isolation switch, Water level display, Safety belt with belt retractor.

OPTIONAL EQUIPMENT: Edge pressing and cutting equipment, HAMM Compaction Meter (HCM), HAMM Temperature Meter (HTM), Telematics interface, Version with additional fuel prefilter.

HIGHLIGHTS

| Overview of the technical highlights |

|

| 1. FRP canopy as standard equipment for more comfort. Canopy can be manually retracted for transport in no time. |

2. Comfortable driver’s seat on the vibrationisolated operator’s platform, many adjustment options and also adjustable steering column rake. |

| 3. The special kinematics ensure even weight distribution, first-class directional stability for safe maneuvering and outstanding driving stability even on uneven ground. |

4. Robust, water-cooled 4-cylinder engines. Comply with CEV BS III exhaust emission standards. Highly fuel efficient, has a low noise level and provides environmentally friendly operation. Additional fuel pre-filter available as an option. |

| 5. Safety alarm and indication of high cooling water temperature as well as engine cut-off in event of low lubricant oil pressure. |

6. Efficient oil and water cooling. The volume flow of cooling air adapts to the required cooling capacity. This reduces both power consumption and noise emissions. |

| 7. All standard filters have been arranged on RHS of machine. The air filter, hydraulic and fuel filter cartridges can easily be changed by hand. |

8. Operator’s display designed with clear symbols ensures easy operation even without language skills. Display comprehensibly shows the state of the machine and indicates fault signals. Machine equipped with cover to prevent vandalism as part of standard scope of supply. |

| 9. Large capacity fuel and water tanks permit longer operation and fewer refueling stops. Water tanks made of opaque PE to prevent algae. |

10. Two frequencies enable wide variety of asphalt mixes and gravel to be compacted. |

| 11. Powerful front lights with low-beam and highbeam function, additional rear working light and a tail lamp ensure optimum sight and visibility, even at night time or when working under poor lighting conditions. |

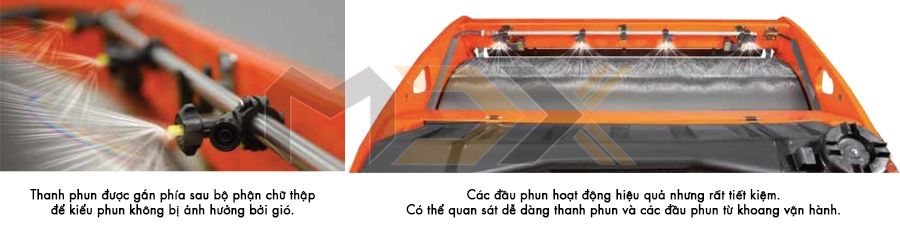

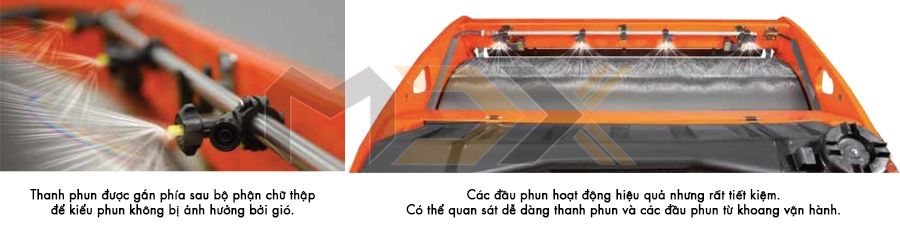

12. One spray bar per roller drum. Arranged in such a way that the spray bars can be seen by the driver. A redundant pump system ensures reliable sprinkling. Even in strong winds spraying remains constant as the spray bars are shielded by the frame. Simple mounting and removal of spray nozzles and spray bars. |

| 13. Available with two vibrating drums (VV). Track offset of 100 mm to both sides. |

14. Option. Enables precise road edges. Pressing rolls and cutting wheels available in many versions. |

| 15. Option. HAMM Compaction Meter (HCM) for the evaluation of rigidity when compacting asphalt. HAMM Temperature Meter (HTM) for the measurement and display of asphalt surface temperature |

16. Option. ICS minimizes the number of passes, records the output and prevents the danger of over compaction. It also includes the temperature meter for measurement and display of asphalt surface temperature. |

Robust power train

Hamm HD 99 VV roller is powered by robust 4-cylinder Cummins diesel engines. They generate ample output with which to operate all components, even in difficult working conditions. They comply with the CEV BS III exhaust emission standards, making them environment-friendly with low fuel consumption.

Thanks to the intelligent airflow, the cooling capacity is very high. It enables the rollers to be operated even at high ambient temperatures. Operational reliability can be further increased with an additional fuel filter. This filter removes excess water from the diesel fuel, thereby ensuring reliable operation.

Many options for countless applications

Unobstructed view for safe working

Hamm HD 99 VV tandem roller provides remarkably good visibility from the large operator’s platform. Drivers see everything in the immediate working area around the roller as well as in the general environment of the construction site. The sprinkling system, too, is always in their field of vision. The good visibility thus ensures high-quality compaction and a high level of safety.

All service items are readily accessible via large doors in the engine compartment.

In the 9 t weight class HD 99 VV tandem roller covers a huge spectrum of asphalt compaction applications. The roller can be tailor-made with edge pressing and cutting equipment and many convenience and safety solutions. In terms of compaction technology, there is a choice of double vibration rollers.

Excellent driving and steering characteristics

Precise steering, safe driving

The 3-point articulation in HD 99 VV offers drivers exceptionally good driving stability and steering characteristics, providing unrivalled directional stability with great driving comfort. Moreover, the 3-point articulation ensures uniform weight distribution over the front and rear sections, even at full steering lock. This results in very smooth asphalt surfaces, because asphalt movement and lateral deformations are prevented from the outset. In addition, the risk of tipping in tight curves is significantly reduced due to the 3-point articulation.

Small turning circle for maximum agility

The articulated tandem rollers can also compact swiftly in tight curves thanks to their extremely small turning circle - under 4 m, according to model.

Optional the drum tracks can be offset to the right or left. This function is available in all driving situations. It enables complete and thorough compaction right up to the edge. When rerolling and finishing, the wider working width ensures a high surface quality.

The powerful water sprinkling system of the HD 99 VV is perfectly visible, easy to operate and maintain.

Dependable water sprinkling system

Hamm HD 99 VV roller brings a very powerful water sprinkling system with it to the construction site. It begins with the large water tanks. Their volume permits long working days without refilling stops. The tanks are made of opaque plastic in order to prevent algae formation.

The water delivery intervals are preset on the dashboard. Furthermore, a foot switch enables the driver to supply additional water in a matter of seconds should the need arise.

Two pumps are fitted in the rollers to generate the spray pressure. The redundant design guarantees reliable operation and a high level of availability.

The spray bars are mounted in an easily accessible position on the cross member. They can be removed for cleaning, replacement or frost protection in next to no time.

Equipped for comfort

Excellent working conditions included

The HD series tandem rollers offer drivers an excellent working environment with plenty of space at the operator’s platform. Steps are provided on both sides. The seat can be moved backwards or forwards and the rake of the steering column with dashboard is also adjustable. In short: every driver will find their optimum sitting position here.

Dashboard, steering column and drive lever are linked with the driver’s seat in a seat-operating unit. This means that the driver always has the dashboard in view, even when he swivels the seat.

And of course, there are compartments for the storage of the machine documentation and personal items.

Systematic operation

HAMM makes life easy for roller drivers: other than the steering wheel and the two drive levers, there is just one clearly laid-out dashboard on the steering column. The switches on this dashboard are grouped together in a logical arrangement, so that the functions are discernible at a glance without any need for explanation.

Drive control is by means of two drive levers. They contain the activation switches for the vibration. This means that the two most frequently used functions can be controlled with one hand. On the dashboard, drivers will find all the status displays that are of importance for operation. They are explained by simple, internationally understandable symbols. The driver is thus always fully informed about the current operating status of the machine - an important prerequisite for high-quality compaction of asphalt surfaces.

TECHNOLOGIES

3-POINT ARTICULATTION

3-point articulation is different to conventional joints due to its geometric arrangement and connection of the three individual joints and one additional connecting link between the two conventional upper joints. This allows optimum steering, excellent driving safety and maximum driving comfort.

See more at: HERE