THE INDIVIDUAL RICH LINEUP OF THE COMPACT ALL TERRAIN CRANES

Tadano ATF 40G-2 is a powerful yet compact two-axle crane that is quick to deploy in a wide range of applications. Tasks such as rigging other cranes and lifting smaller objects are its main applications. Reliable, flexible and economical, the AFT 40G-2 can be driven on-road in its 12 t axle load configuration with a 1.4 t counterweight, 445/95 R 25 tires and 9.0 m boom extension.

The sophisticated drive concept of the all terrain crane means that it can be transported for use by road in an incredibly cost-efficient manner while still maintaining optimal good terrain mobility on construction sites. Every single TADANO all terrain crane available worldwide is developed and manufactured on our site in Lauf an der Pegnitz and therefore has the "Made-in-Germany" quality seal.

TECHNICAL DATA

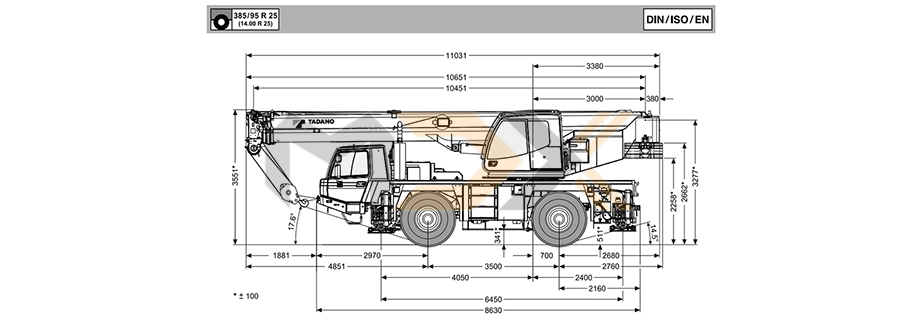

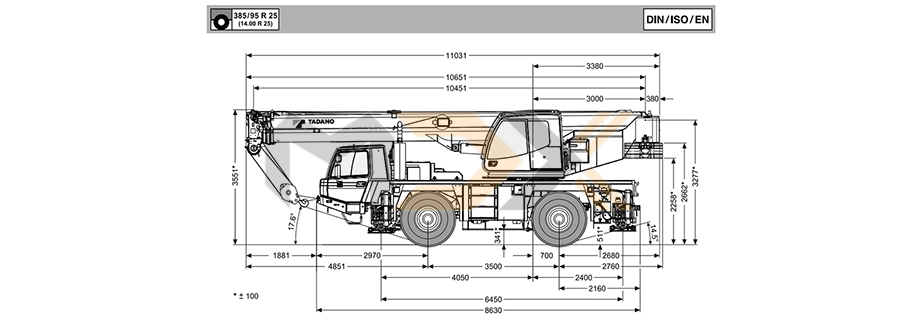

| Dimensions |

|

|

|

| Maximum lifting capacity |

boom |

40 t x 2.5 m |

| Maximum lifting height |

boom& |

35.5 m |

| boom+jib& |

45.0 m |

|

Maximum load radius:

|

boom& |

32.0 m |

| boom+jib& |

38.0 m |

| Maximum boom length |

& |

10.45 m - 35.2 m |

HIGHLIGHTS

|

| Frame& |

| Torsion-resistant, welded construction made from high strength, fne-grained steel |

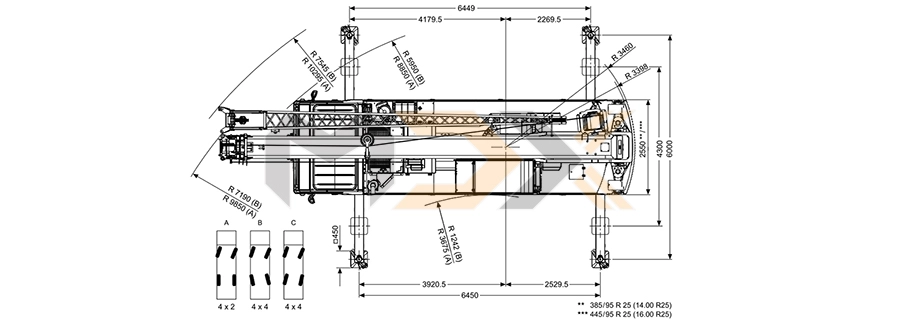

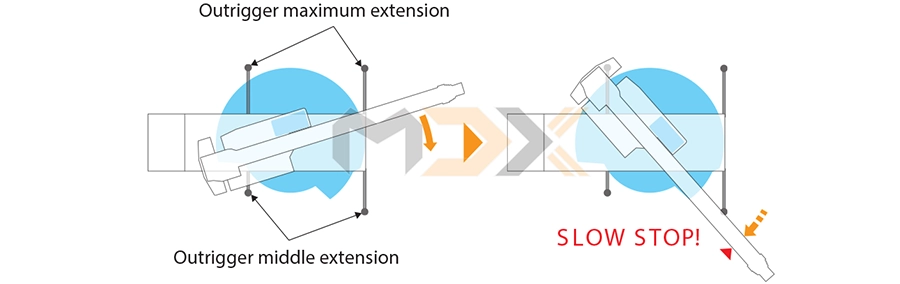

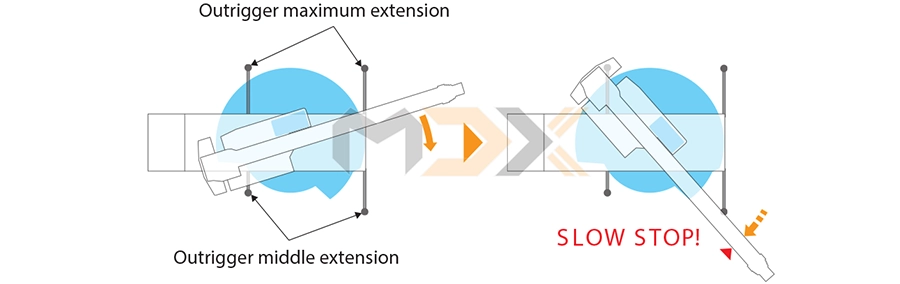

| Outriggers |

|

|

4 point, telescopic hydraulic outriggers with controls on both sides of carrier and in superstructure cab.

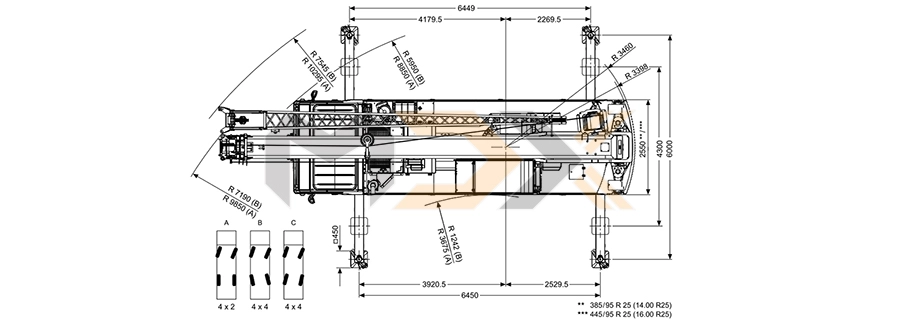

Outrigger base 6.0 m (4.3 m mid extension) x 6.45 m

|

| Carrier engine |

|

| Mercedes-Benz 6 cylinder model OM 906 LA (Euromot III A/ EPA III), water-cooled diesel engine. Rated at 205 kW (279 HP) at 2200 min-1. Torque 1100 Nm (112 kpm) at 1200 - 1600 min-1. Engine rating according to 80 / 1269 / EWG. Fuel tank 300 l. |

| Transmission |

|

ZF Powershift transmission 6 WG 210 with integrated transfer case, hydrodynamic torque converter (with "lock-up" from 1st gear) and with 6 forward gears and 1 reverse gear.

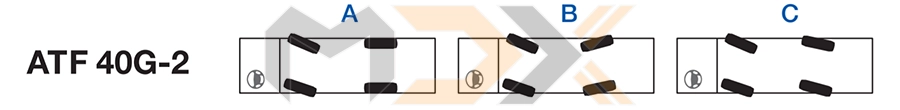

Drive 4 x 4

|

| Axles |

|

1st axle: steered, driven, with differential lock.

2nd axle: steered, driven, with differential lock.

|

| Suspension |

| Hydro-pneumatic with levelling adjustment |

| Brake system |

| Service brakes: dual circuit compressed air system with ABS. Parking brake: spring loaded type acting on 1st and 2nd axles. Auxiliary brakes: engine exhaust brake and constant throttle engine brake system |

| Tyres |

| (4) 385/95 R 25 (14.00 R 25). |

| Steering system |

|

| ZF-Servocom, dual circuit hydraulic steering, mechanical steering of front axle with hydraulic assistance and emergency steering pump. Steering of both axles possible. All axles steered hydrostatically from superstructure cab. |

| Carrier cab |

|

|

| Two man full width cab of composite (steel sheet metal and fbre-glass) structure, with safety glass, air-cushioned adjustable seats, engine dependent hot-water heater. Complete controls and instrumentation for road travel. Speed control |

| Electrical system |

| 24 volt DC system, 2 batteries, Electrical system conforms with EEC regulations. |

| OPTIONS |

| Towing attachment, eddy current retarder brake, engine independent additional heater with engine pre-heat, air conditioning, 445/95 R 25 (16.00 R 25) tyres, spare wheel and tyre, special painting and lettering. Further optional equipment available upon request. |

|

| Frame |

| Torsion-resistant, all-welded structure of high strength steel. Connected to carrier by single-row, ball-bearing slewing ring with external gearing for 360° continuous rotation. |

| Hydraulic system |

| Three circuit diesel hydraulic system with 1 double axial piston pump (hydraulically adjustable) and 1 gear pump, oil cooler. Pumps driven by carrier engine rated at 204 kW (277 HP) at 1500 min-1 (DIN 6270B) |

| Controls |

| Hydraulic, 2 joy-stick levers for simultaneous operation of crane motions. |

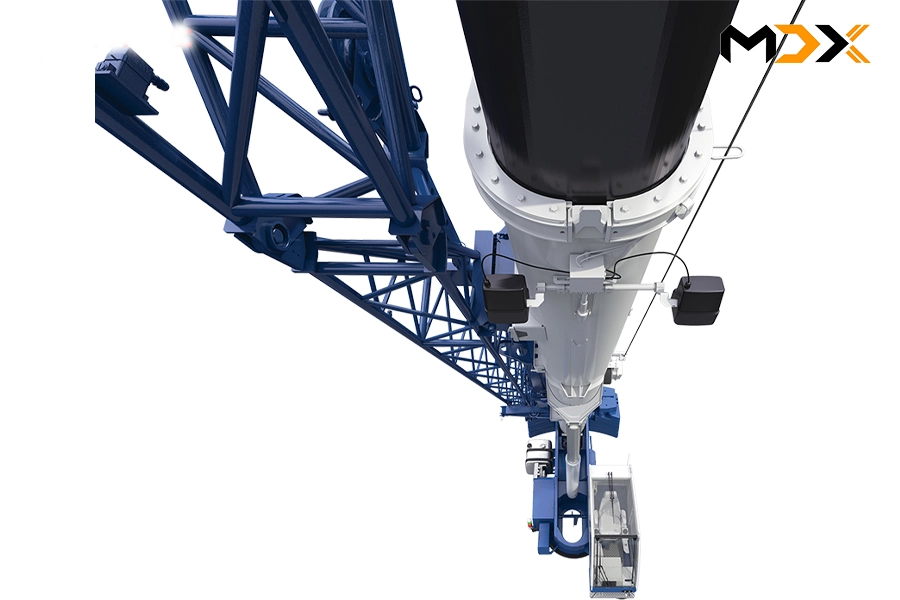

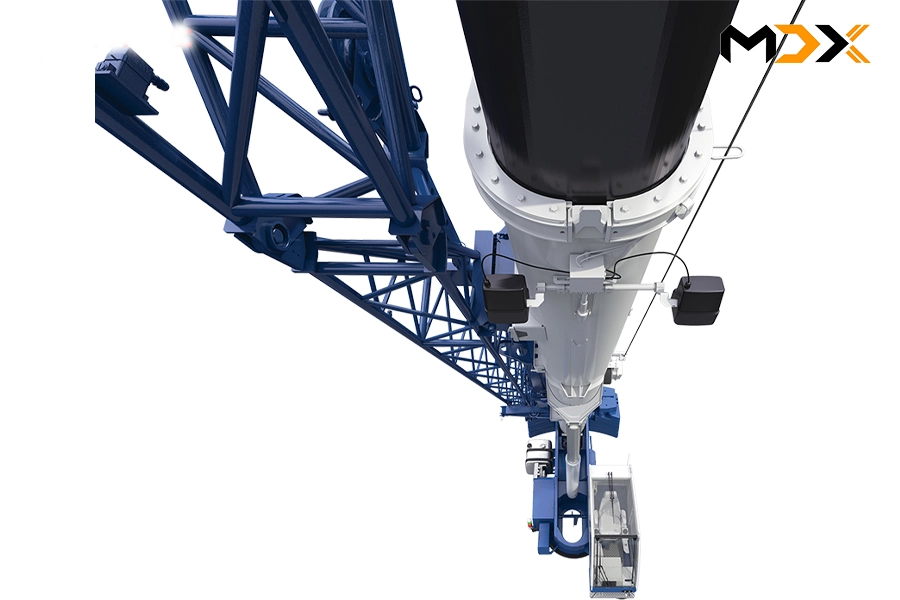

| Telescopic boom |

|

| 4 sections, made of high tensile, fnegrained steel, consisting of 1 base section and 3 telescoping sections, single telescopic cylinder and ropes. All telescope sections extendable under partial load. 10.45 m to 35.2 m long. Boom head with 5 sheaves. |

| Derricking system |

| 1 double acting hydraulic cylinder with integral brake and holding valve. |

| Main winch |

| Axial piston motor, winch drum with integrated planetary reduction and hydraulically controlled spring-loaded multiple disc brake and integrated free rotation (no sagging of load when hoisting). Hoist cable with 'Super-Stop' easy reeving system. |

| Slewing system |

| Axial piston motor with two-stage planetary reduction with a foot actuated service and a parking brake. Speed infnitely variable 0 - 2 min-1. |

| Counterweight |

| Standard 1.4 t |

| Superstructure cab |

|

|

| Spacious panoramic cab of composite structure with safety (tinted) glass windows with hydraulically cushioned adjustable seat, engine independent hot-water heater, air conditioning. Complete controls and instrumentation for crane operation, on-site travelling and outriggers. |

| Electrical system |

| 24 volt DC system |

| Safety devices |

| Load moment device (LMD), working area display, working area limitation, hoist limit switch, lower limit switch, drum turn indicator, safety valves against pipe and hose rupture. Holding valves on hydraulic cylinders. |

| OPTIONS |

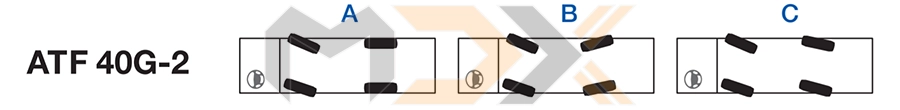

| Boom extension 9.0 m, offsets 0°, 20° and 40°, additional counterweight 5.1 t, counterweight variation 3.5 t, selection of hook blocks, working and slewing area limiter, additional oil cooler, special painting and lettering. Further optional equipment available upon request. |