|

| Frame |

| Torsion-resistant, all-welded structure of high strength steel. Connected to carrier by single-row, ball-bearing slewing ring with external gearing for 360° continuous rotation. Central lubricating system. |

| Superstructure engine |

| Mercedes-Benz 4 cylinder model OM 924 LA (Euromot III B / EPA Tier 4i), water cooled diesel engine. Rated at 143 kW (194 HP) at 1800 min-1. Torque 800 Nm (82 kpm) at 1200 - 1600 min-1. Engine rating according to 80 / 1269 / EWG. Fuel tank 250 l. AdBlue-tank 8 l |

| Hydraulic system |

| Three circuit diesel hydraulic system with 1 power controlled axial piston double pump (hydraulically adjustable) and 1 double gear pump, oil cooler. |

| Controls |

| Electrical, 2 joy-stick levers for simultaneous operation of crane motions. |

| Telescopic boom |

|

| 7 sections, made of high tensile, fnegrained steel, consisting of 1 base section and 6 telescoping sections extended by means of a single telescopic cylinder. All telescope sections extendable under partial load. 13.2 m to 68.0 m long. Boom head with 7 sheaves. |

| Derricking system |

| 1 double acting hydraulic cylinder with integral brake and holding valve. |

| Main winch |

| Axial piston motor, winch drum with integrated planetary reduction and hydraulically controlled spring-loaded multiple disc brake and integrated free rotation (no sagging of load when hoisting). Hoist cable with 'Super-Stop' easy reeving system. |

| Slewing system |

| Axial piston motor with three-stage planetary gear equipped with automatic service and a parking brake. Closed hydraulic circuit with free slewing function. Speed infnitely variable 0 - 1.2 min-1 |

| Counterweight |

| Total 71 t divisible, assembled and disassembled by hydraulic cylinders controlled from superstructure cab. |

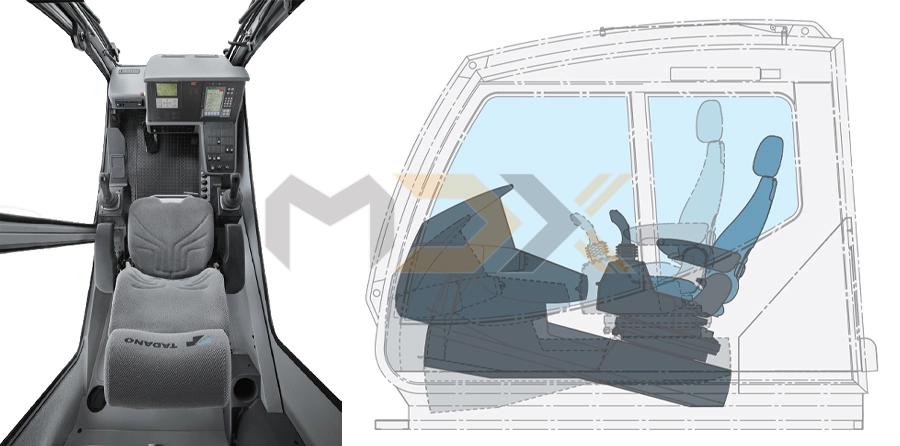

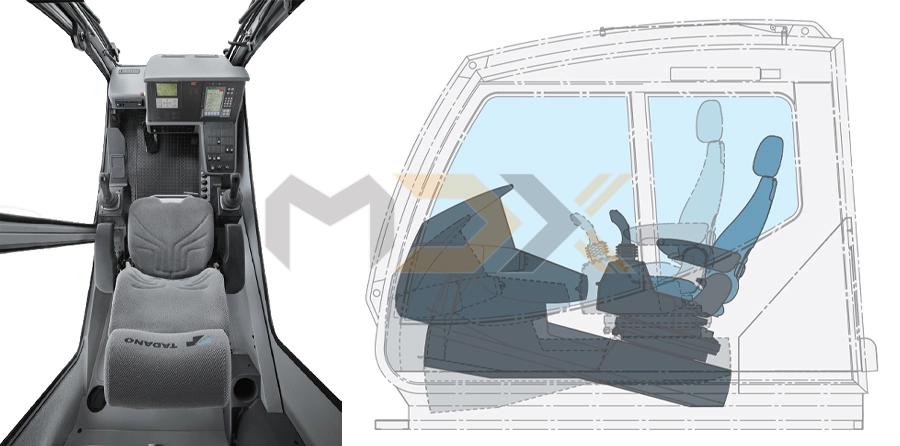

| Superstructure cab |

|

|

| Spacious panoramic cab of composite structure with safety (tinted) glass windows, tiltable cockpit with hydraulically cushioned adjustable seat with heater, engine dependent water heater engine independent water heater (with engine pre-heat), air conditioning, radio/CD player. Complete controls and instrumentation plus LCD graphic display for crane operation. |

| Electrical system |

| 24 volt DC system, 2 batteries |

| Safety devices |

| 'Lift Adjuster', load moment device (LMD), anemometer, working area limitation, hoist limit switch, lower limit switch and drum turn indicator, safety valves against pipe and hose rupture, holding valves on hydraulic cylinders |

| OPTIONS |

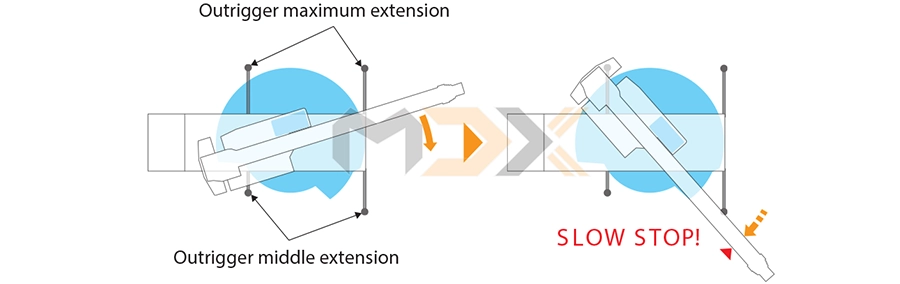

| Boom extensions 13.2 m to 37.2 m, offsets 0°, 20° and 40° or hydraulically 0°- 40° (5.4 m integrated heavy duty jib + 7.5 m tip section + 4 inserts à 6.12 m x 0.64 m x 1.10 m/ weight 440 kg), boom extensions HTLJ 1.85 m + 8.5 m to 1.85 m + 21 m (hydraulically offsets and telescopable 5° - 60°), LMD-programme for 12 t, 23.5 t, 35 t and 47 t counterweight, 10 t swivel hook, selection of hook blocks 32 t - 160 t, auxiliary winch (same as main winch), additional oil cooler, outrigger load display, special painting and lettering. Further optional equipment available upon request. |

|