Compact dimensions, easy handling and excellent value for money - that’s what the new VÖGELE SUPER 1303 wheeled paver has to offer. A member of the Classic Line, it features a range of functions which is focussed on the essentials required by paving teams for successful operations.

The SUPER 1303 can be combined with the AB 340 Extending Screed with tamper (T version), vibrators (V version) or with tamper and vibrators (TV version).

| Conveyor and augers | |

| Conveyor | 2, with replaceable feeder bars, direction of conveyor temporarily reversible |

| Drive | separate hydraulic drive provided for each conveyor |

| Speed | up to 25 m/min., infinitely variable (manual or automatic) |

| Augers | 2, with replaceable auger blades, auger rotation reversible |

| Diameter | 300 mm |

| Drive | separate hydraulic drive provided for each auger |

| Speed | up to 80 rpm, infinitely variable (manual or automatic) |

| Auger height | |

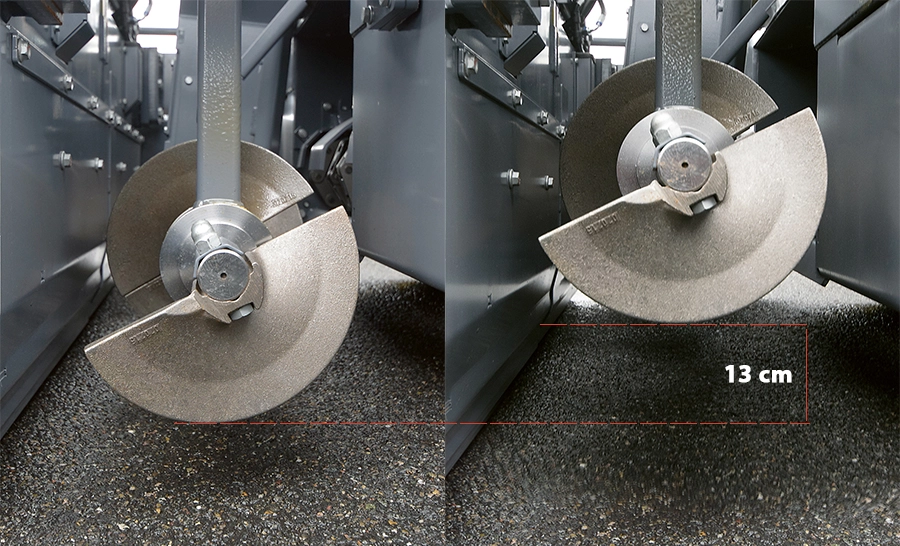

| Standard | infinitely variable by 13cm, mechanical |

| Option | infinitely variable by 13cm, hydraulic |

| Screed | Type | Basic Width | Maximum Width | Compacting Systems |

| AB 340 (More) | 1.8 m | 4.5 m | V, TV | |

| Layer thickness (up to) | 25 cm | |||

| Heating | electric | |||

| Power Supply | Three-phase AC generator | |||

| DIMENSIONS AND WEIGHT |

||

| Operating weight | Screed | Total weight |

| AB 340 TV | 10 200 kg | |

| Length | Screed | Total length |

| AB 340 | 4.95 m | |

| Maximum laydown rate | 250 t/h | |

Small size, high efficiency: be it extremely confined job sites outside of town or winding inner-city alleyways, the highly manœuvrable Vögele paver can negotiate tight spots with ease while delivering top performances.

The slim paver design, with no protruding edges and a compact overall length, makes it very easy to work and manœuvre on tight job sites.

The clearance width of just 1.85m allows Vögele Super 1303 to easily get in and out of confined spaces such as narrow alleys. The push-rollers automatically fold up together with the hopper sides.

For transport, the hardtop, made of a glass fibre-reinforced polymer material, and the exhaust pipe can be folded down in just a few swift moves, readying the paver for transport quickly and easily.

With their combination of compact dimensions and top performance, road pavers in the Vögele Compact Class can handle a wide variety of applications.

Whether it is a combined footpath and cycle path, a farm track or minor roads and small areas, Super 1303is more than up to the task, thanks to its wide range of pave widths from 0.75m to 3.9m and its innovative drive concept.

Vögele’s modern drive concept guarantees full power whenever it is needed and, thanks to its superior technology, this Compact Class paver is exceedingly economical in everyday use.

This is achieved by means of intelligent engine management with ECO mode and a variable-speed fan. These features significantly reduce Vögele wheeled paver Super 1303 fuel consumption and noise emissions

The high-traction crawler tracks on Super 1303 perfectly combine high performance paving with maximum mobility during transport.

Modern drive technology

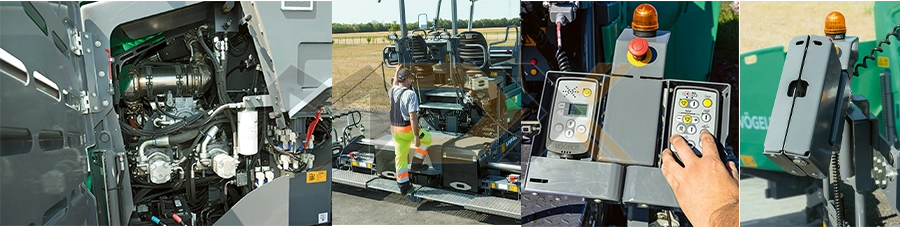

Three main components form the power unit of Vögele Super 1303: the large cooler assembly, an advanced, liquid-cooled diesel engine and a splitter gearbox flanged directly to the engine.

The driving force behind this Vögele powerhouse is a powerful diesel engine. The 4-cylinder engine delivers 74.4 kW at 2,000 rpm. Yet the fuel-saving ECO mode is sufficient for many applications. And even then, Vögele S1303 still has a full 68.7 kW at its disposal. Moreover, the machine operates particularly quietly when running at just 1,600 rpm.

A large cooler assembly ensures that the power unit always delivers its full output. With innovative air routing and a variable-speed fan, temperatures are always maintained within the optimum range, significantly extending the service life of both the diesel engine and the hydraulic oil. Another advantage is that the machine can be operated without difficulty in all climatic regions around the world.

All hydraulic consumers are directly supplied with hydraulic oil via the splitter gearbox. Hydraulic pumps and valves are centrally located, making them optimally accessible for servicing.

The large cooler assembly is made up of four parts. It ensures that charge air, engine coolant, fuel and hydraulic oil are maintained at optimum temperature

Powerful diesel engine develops 74.4 kW at just 2,000 rpm.

ECO mode, which delivers 68.7 kW at 1,600 rpm, is not only perfectly adequate for many applications, it also cuts operating costs and supports super-quiet operation.

A powerful three-phase A.C. generator with generator management controls output in line with the selected pave width and minimizes the time required to heat the compacting systems up to operating

temperature.

The high-traction SUPER 1303 wheeled paver perfectly combines high performance paving with maximum mobility during transport, thanks to powerful separate hydraulic drives integrated in the powered wheels. They provide for maximum traction.

Rapid transport under its own power at up to 20 km/h - a feat Super 1303 is optimally equipped for. The paver can optionally be equipped with a lighting system approved for use in traffic. As a result, this machine meets the basic requirement for driving on public roads.

Maximum power transmission thanks to separate, hydraulic drives in both rear wheels and optionally in two front wheels.

Optimum traction is assured, even on difficult terrain, by Electronic Traction Management and an electronic limited slip differential acting on the drives of the rear wheels.

Highly manœuvrable thanks to Pivot Steer. With Pivot Steer activated, the rear inside wheel is automatically slowed down hydraulically. This minimizes the outside turning radius to no more than 3.8m for positioning manœuvres and paving. The function can be activated in “Pave” and “Positioning” modes, greatly increasing the manœuvrability of the machine on confined job sites.

A continuous flow of mix is key to ensuring uninterrupted and high-quality paving. That is why we attach such importance to professional material management when designing our pavers. All our development efforts focus on simple operation and the best possible overview for the paving team.

Despite the paver’s slim profile, its material hopper holds 10 t. The paver comes with oscillating push-rollers to ensure the shock-free docking of feed vehicles.

Separately folding hopper sides ensure smooth feeding with mix even when paving across asymmetrical widths and a convenient mix supply even when paving along boundaries.

Oscillating push-rollers for convenient and shock-free docking also of large feed vehicles.

The large material hopper has a capacity of 10 t so that a sufficient quantity of mix is available for paving at all times, even in situations where feeding is difficult, such as when paving under bridges.

01 The amply dimensioned conveyor tunnel and powerful, separate hydraulic drives for conveyors and augers support laydown rates of up to 250 t/h, which are extraordinarily high for a paver in this class.

02 Separate drives and controls are installed for each conveyor and auger. When operating in Automatic mode, conveyors and augers are subject to continual monitoring. Proportional control provides for a constant head of mix in front of the screed.

03 Separately folding hydraulic hopper sides for smooth feeding with mix, paving along boundaries and a targeted mix supply even when paving across asymmetrical widths.

The conveyance and even spreading of mix in front of the screed are optimal thanks to the large conveyor tunnel, proportional control of conveyors and powerful augers.

What is more, the height-adjustable augers and folding limiting plates for the auger tunnel allow the paver to be repositioned without a need for conversion, a benefit that saves time and money.

The conveyance and even spreading of mix in front of the screed are optimal thanks to the arge conveyor tunnel, proportional control of conveyors and powerful augers.

What is more, the height-adjustable augers and folding limiting plates for the auger tunnel allow the paver to be repositioned without a need for conversion, a benefit that saves time and money

The height of the augers is infinitely variable by 13 cm for uniform spreading of mix across the entire pave width.

The amply dimensioned conveyor tunnel and powerful, separate hydraulic drives for conveyors and augers support laydown rates of up to 250 t/h, which are extraordinarily high for a paver in this class.

Separate drives and controls are installed for each conveyor and auger. When operating in Automatic mode, conveyors and augers are subject to continual monitoring. Proportional control provides for a constant head of mix in front of the screed.

The ErgoBasic operating concept was developed on the basis of the proven ErgoPlus operating system which is installed in our Premium Line pavers, but was tailored specifically to the needs and requirements of Vögele Classic Line users.

The goal was to develop an operating system that an be operated just as quickly, accurately and intuitively as the ErgoPlus 3 system on the “Dash 3” machines.

This makes Vögele the only manufacturer to offer a standardized operating concept for all paver classes.

Everything at a glance: the functions are arranged in a clear, logical and practical layout that has clearly been inspired by the ErgoPlus operating console. The type of controls and the symbols used are all in line with those on an ErgoPlus console.

Given the limited number of functions, there is no need for a display.

The status of all settings is indicated as a percentage on LED strips immediately next to the relevant functions.

Additional LEDs indicate the set speeds of the augers and the compacting systems as well as the fill level of the diesel tank.

Function and status indicators

The function and status indicators mean that the operator always has full control over his machine, even without a display. he can, for instance, read the fill level of the fuel tank directly and identify whether there are any functional faults.

Choice of operating modes for the paver

All the main paving and machine functions can be controlled directly by individual push-buttons on the paver operator’s ErgoBasic console. The paver changes between operating modes at the push of a button in the following order: “Pave”, “Positioning”, “Job Site” and “neutral”. An LED indicates which mode is selected. On leaving ”Pave” mode, the memory function stores all the last settings, which means that the paving parameters last used are retrieved immediately after repositioning the machine on the job site, for instance.

Speed of the augers

In automatic mode, the maximum speed of the augers can be adapted to the pave width separately for the left and right using the plus and minus keys. The set value is displayed as a percentage on the LED strip.

Safe operation during the night

The paver operator‘s ErgoBasic console features glarefree backlighting so that the paver operator can also work safely on night-time jobs.

Compacting effort

The speed of the compacting systems can be set directly on the paver operator's ErgoBasic console. The LED strips from 0 to 100% indicate the speed settings for the tamper and vibrators, enabling them to be

adjusted immediately if required.

Steering at a pre-set angle

The machine is steered by means of an easy-grip rotary controller which enables the driver to manœuvre the machine easily and precisely even in the tightest spots. For long bends with a constant radius, the desired steering angle can be preselected using arrow keys. The paver then automatically follows the set path until the function is deactivated, allowing the driver to monitor the paving process undisturbed.

No-load function

The no-load function is provided for the warm-up or cleaning of conveyors, augers and tamper.

Safe operation during the night

The paver operator's ErgoBasic console features glarefree backlighting so that the paver operator can also work safely on night-time jobs.

The safe and easy handling of all screed functions s a key factor in high-quality pavement construction. That’s why an ErgoBasic remote control unit for the screed was developed specifically for the new Classic

Line pavers.

Its keypad is laid out logically according to the functional processes. Designed for robustness, it is well able to withstand tough job-site conditions.

Operation is easy to understand and can be learned intuitively in a very short space of time, not least because the symbols used in the proven ErgoPlus operating system are found here, too.

The ErgoBasic remote control unit for the screed allows all paving-related functions to be set quickly and easily. This includes direct access to the material handling systems and the sonic sensors for the augers.

All the main paving functions can be controlled via the two handy screed remote control units. Simple, language-neutral symbols allow the machine to be operated intuitively.

1. Conveyor, automatic/manual

2. Horn

3. Auger, automatic/manual/ reverse

4. Screed floating on/off

5. Screed width control, one side

6. Adjustment of screed tow point ram

Vögele have also developed a System for Automated Grade and Slope Control to match the ErgoBasic operating concept: the Niveltronic Basic. It is completely integrated into the machine control system and therefore perfectly adapted to the respective paver model. Another outstanding aspect of Niveltronic Basic is its particularly simple and intuitive handling, a feature which makes it easy even for less experienced operators to learn their way around the system. This creates ideal conditions for the Classic Line pavers to work true to line and level on any base.

Each side of the screed is operated by a separate compact and exceedingly robust Niveltronic Basic remote control unit.

A variety of sensor types is available for Niveltronic Basic, in keeping with the machine‘s large and varied range of uses. The selection extends from mechanical sensors to non-contacting sonic sensors. The System for Automated Grade and Slope Control can simultaneously be connected to two grade sensors and one slope sensor. The type of sensor used is detected automatically.

The kind of reference – ground, tensioned wire or transverse slope – can be easily set on the remote control unit.

The remote control units cover all the functions required for high-precision grade and slope control. Clear symbols support intuitive machine operation.

1. deviation from specified values

2. Niveltronic Basic on/off

3. Setting: Sensor sensitivity

4. Selecting: kind of reference (ground, tensioned wire, transverse slope)

5. Quick set-up

6. Setting: Specified value

7. Sensor calibration

1. The comfortable paver operator’s platform gives an unobstructed view of all crucial areas on the paver such as material hopper, steering guide or screed. The paver operator is thus ideally positioned to monitor the material feeding process right from his seat.

2. Working comfortably: The operating console can be shifted across the entire working width so that operators can work comfortably and in an ergonomic position on either side of the machine.

3. A place for everything and everything in its place The paver operator’s platform is streamlined and well organized, offering the paver operator a professional workplace. The paver operator’s console can be protected by a shatter-proof cover to prevent wilful damage.

4. Hardtop provides excellent protection The modern hardtop, made of a glass fibre-reinforced polymer material, protects the operator. It can easily be collapsed to quickly prepare the paver for transport.

5. Cost-efficient and service-friendly design The paver operator has convenient access to all service points on the machine. All hydraulic pumps connected to the transfer gearbox are extremely easy to service thanks to their clear arrangement and easy accessibility. Durable components made of highly wear-resistant materials for a long service life minimize machine downtimes.

6. Safe and comfortable ascent: The walkway and comfortable middle ascent on the screed ensure safe and convenient access to the paver operator’s platform.

7. Safe and simple operation of all screed functions: All paving-related functions can be set quickly and easily on the ErgoBasic remote control unit for the screed.

8. Protection against theft and vandalism: Once work has been completed, the remote control unit for the screed can be collapsed and secured.

Tags: Super 1303, Wheeled Paver, Vögele paver, Vögele super 700, asphalt paver machine, asphalt paver price, asphalt paver parts, small asphalt paver, mini asphalt paver, volvo asphalt paver, caterpillar asphalt paver, tracked paver, asphalt paver, wheel asphalt paver, asphalt paver specs, asphalt paver machine specifications, cat paver