-

Your shopping cart is empty!

Currently, motorized machines and especially excavators are an indispensable part in the field of civil, industrial and irrigation construction. In the market with many famous machine manufacturers such as Hitachi excavators, Catterpillar excavators, Kobelco excavators,... Besides, it would be remiss not to mention Komatsu crawler excavators.

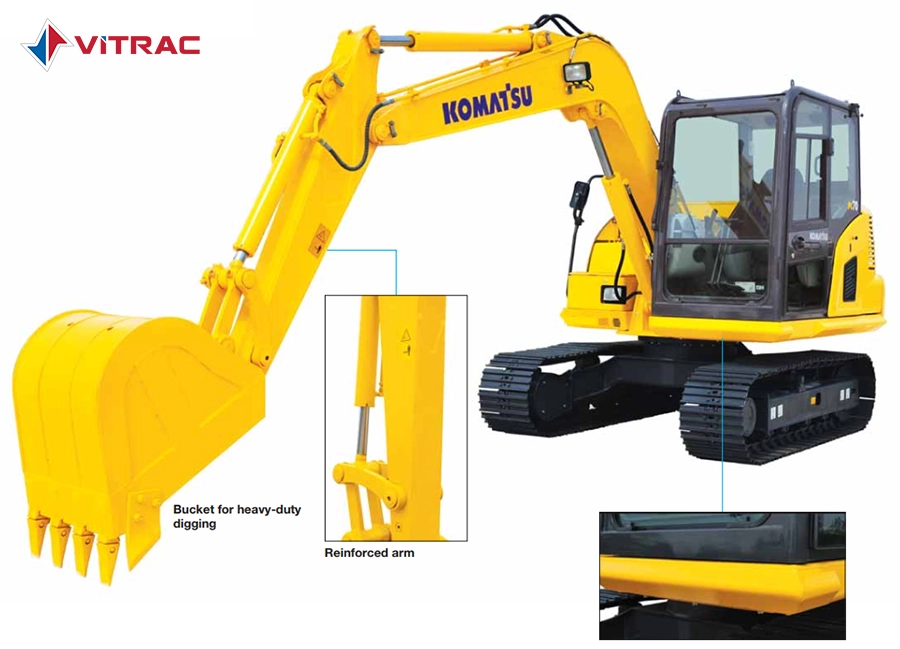

Komatsu crawer excavator PC70-8

Komatsu is the world's second largest supplier of construction and mining equipment, after Caterpillar. However, Komatsu has a larger market share than Caterpillar in some regions such as Japan and China. The company currently has many factories and branches in Japan, Asia, America and Europe and is still planning to continue to expand.

Komatsu excavator brand originated from Japan, appeared on the market since 1917. It can be said that this is one of the world's leading brands of excavators, currently competing fiercely with rivals. as big as Hitachi or Catterpillar. Komatsu excavator is considered as a machine with high durability, good working performance and common use. Perhaps that is also the reason why Vietnam and other countries around the world are very fond of the Komatsu line.

Komatsu excavators are specially designed for heavy duty applications. With a powerful engine, sturdy boom and bucket design, bearing iron material ensures workability and productivity in all cases. Along with compact structure and superior features, the company's machine can be widely applied such as: bridge construction, road construction, construction work in residential areas. The machine has many working modes with different engine speed and hydraulic system pressure to meet different conditions. In the fuel-saving mode, the machine still works effectively, in the heavy-duty mode, the machine can operate with the largest capacity, helping the digging and lifting force of the machine can be increased many times.

Below is the detailed product information of Komatsu crawler excavator PC70-8:

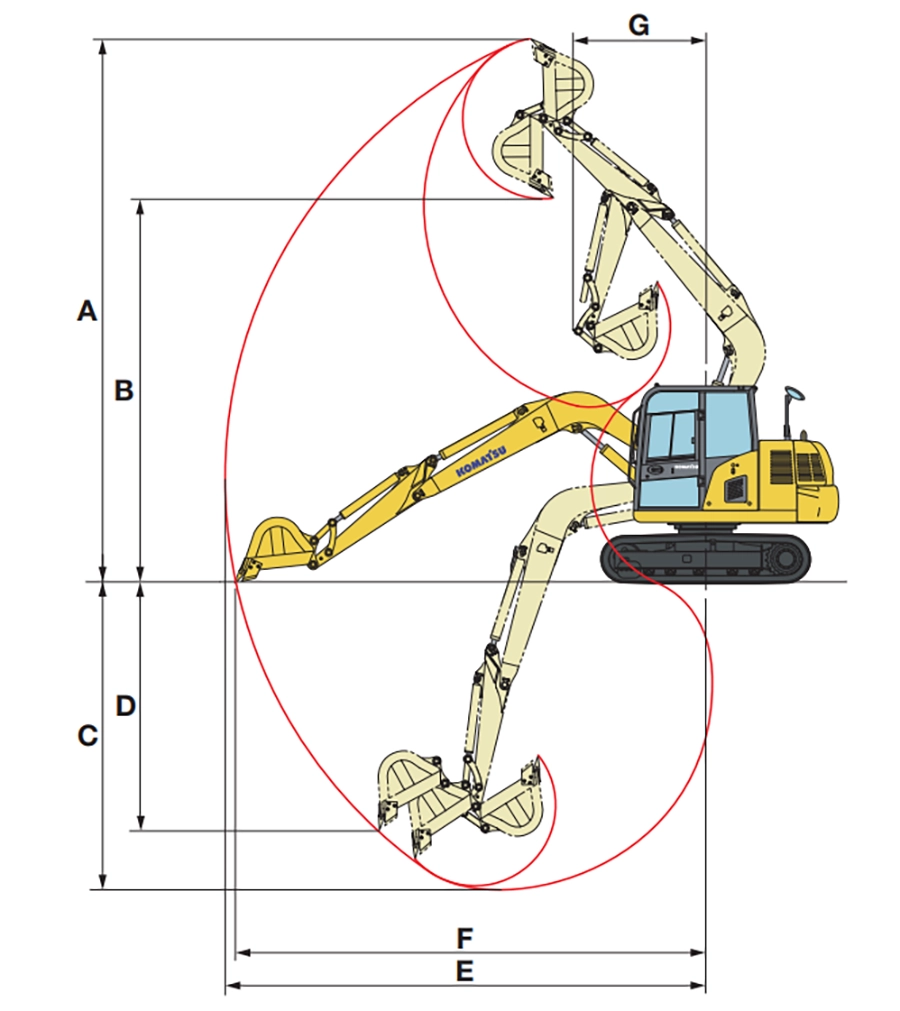

| WORKING RANGE | ||

|

||

| A Max. digging height | mm | 7150 |

| B Max. dumping height | mm | 5 015 |

| C Max. digging depth | mm | 4 100 |

| D Max. vertical wall digging depth | mm | 3 505 |

| E Max. digging reach | mm | 6 360 |

| F Max. digging reach at ground level | mm | 6 220 |

| G Min. swing radius | mm | 6 220 |

| SAE 1179 Rating | ||

| Bucket digging force | kN (kg) | 54.8 (5 590) |

| Arm crowd force | kN (kg) | 38.2 (3 900) |

| SO 6015 Rating | ||

| Bucket digging force | kN (kg) | 00.0 (0000) |

| Arm crowd force | kN (kg) | 00.0 (0000) |

| Gầu STD (ISO 7451 heaped) | m3 | 0.30 |

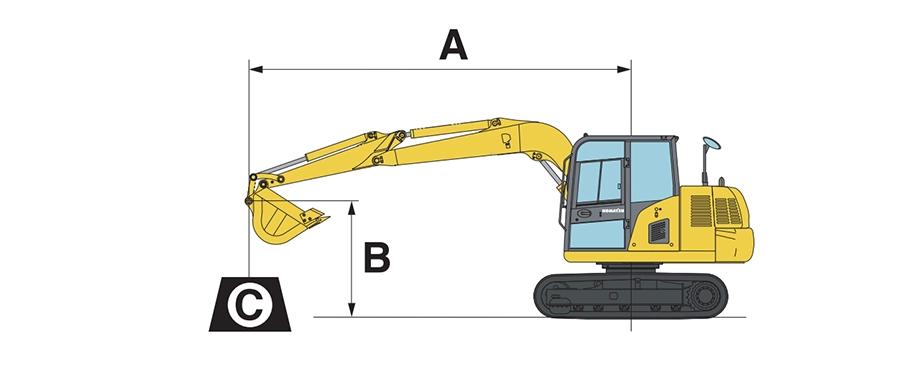

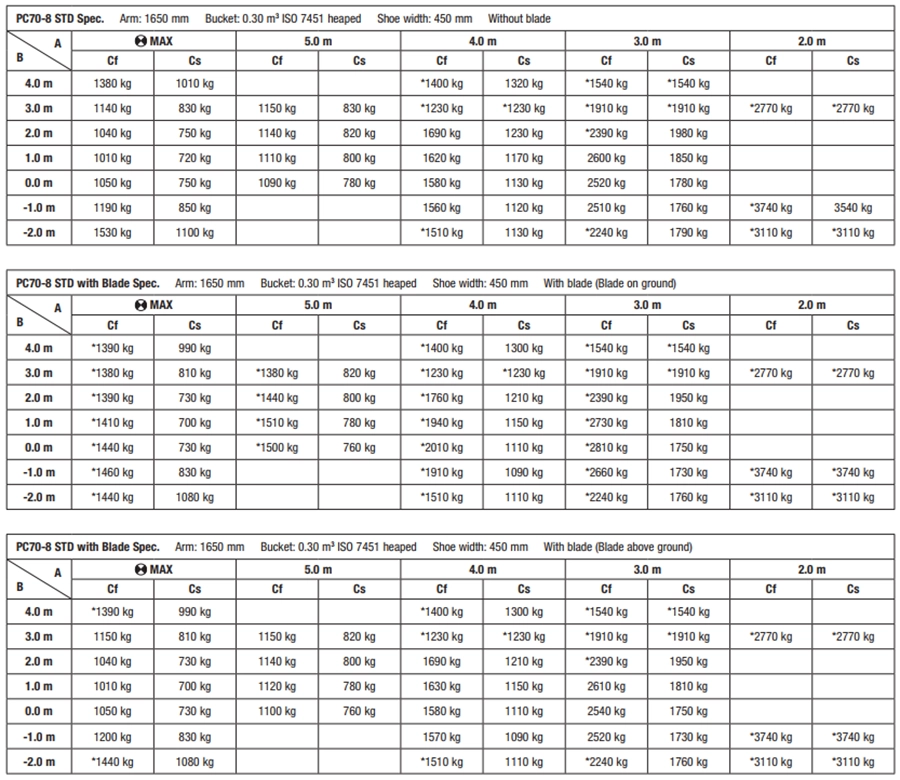

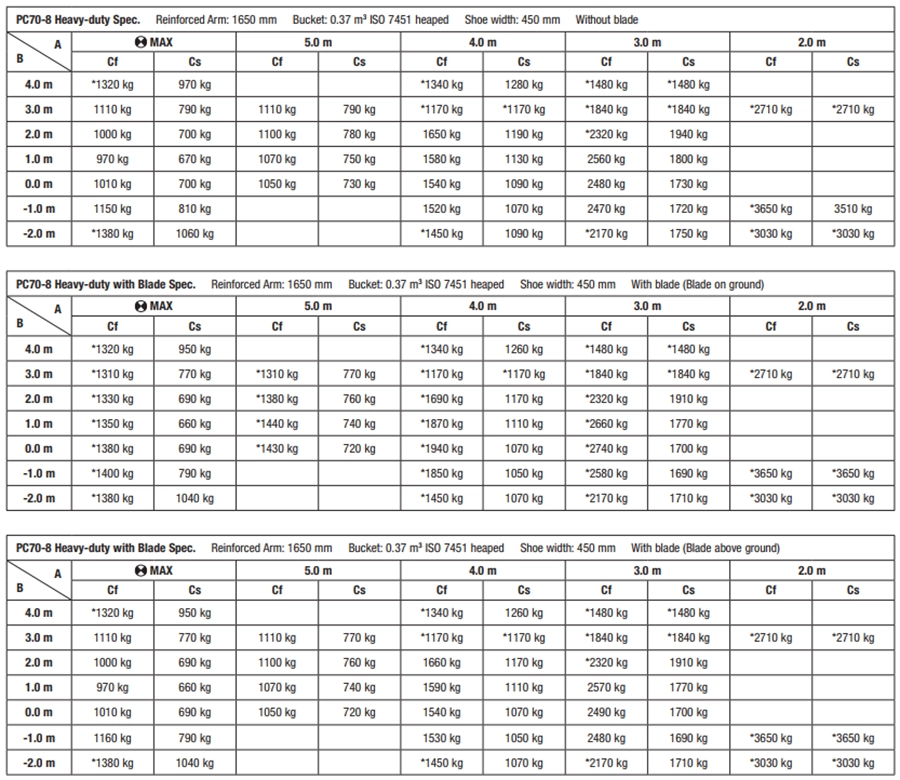

LIFTING CAPACITY WITH LIFTING MODEA: Reach from swing center B: Bucket hook height C: Lifting capacity Cf: Rating over front Cs: Rating over side Rating at maximum reach |

|

|

|

| SPECIFICATIONS | ||

| ENGINE | ||

| Model | Komatsu SAA4D95LE-5 | |

| Type | Water-cooled, 4-cycle, direct injection | |

| Aspiration | Turbocharged, and air-to-air aftercooled | |

| Number of cylinders | 4 | |

| Horsepower | ||

| SAE J1995, Gross | kW | 50.7 kW (68 HP) at 1 950 rpm |

| ISO 9249 / SAE J1349, Net | kW | 48.5 kW (65 HP) at 1 950 rpm |

| Fan drive method for radiator cooling | Mechanical | |

| Piston displacement | l | 3.26 |

| Bore x Stroke | mm | 96 x 115 |

| Governor | All-speed control, electronic | |

| HYDRAULIC SYSTEM | ||

| Type | Closed-center system with load sensing valves and pressure-compensated valves | |

| Main pump | Variable displacement, axial piston | |

| Maximum flow | l/min | 172 |

| Hydraulic motors | ||

| Travel | Variable displacement, axial piston | |

| Swing | Fixed displacement, axial piston | |

| Relief valve setting | ||

| Implement circuits | MPa (kgf/cm2) | 24.5 (250) |

| Travel circuit | MPa (kgf/cm2) | 21.1 (215) |

| Swing circuit | MPa (kgf/cm2) | 24.5 (250) |

| Pilot circuit | MPa (kgf/cm2) | 3.1 (32) |

| UNDERCARRIAGE | ||

| Track frame | Box-section | |

| Shoe type | Triple grouser shoe | |

| Track adjuster | Hydraulic | |

| Number of shoes (Each side) | 38 | |

| Number of carrier rollers (Each side) | 1 | |

| Number of track rollers (Each side) | 5 | |

| DRIVES AND BRAKES | ||

| Steering control | Two levers with pedals | |

| Drive method | Fully Hydrostatic | |

| Hydraulic motors | Variable, displacement, axial piston motors | |

| Maximum drawbar pull | kN (kg) | 56.4 (5750) |

| Maximum travel speed | km/h |

High: 4.5 Low: 2.8 |

| Service brake | Hydraulic lock | |

| Parking brake | Hydraulic release lock | |

| COOLANT AND LUBRICANT CAPACITY (REFILLING) | ||

| Fuel tank | l | 130 |

| Coolant | l | 10 |

| Engine | l | 11.5 |

| Final drive (Each side) | l | 1.1 |

| Hydraulic tank | l | 61 |

| STANDARD EQUIPMENT AND OPTION EQUIPMENT |

|

COMFORT |

|

|

| Low-noise Cab

Cab is highly rigid and has excellent sound absorption ability. Improvement of noise source reduction and use of low noise engine, hydraulic equipment, and air conditioner allow this machine to generate a low level of noise. Excellent VisibilitySpacious cab has wide glass area to provide the operator with excellent visibility. Wide Spacious CabNewly designed large cab provides roomy work space and wide legroom. In addition, large operator’s seat has a fore-and-aft sliding and a reclining function. Automatic A/CThe automatic A/C has a bi-level control function to keep cool and warm respectively. This improved air flow function keeps the inside of the cab comfortable from top to bottom throughout the year. Defroster function keeps cab glass clear. |

|

| ROPS Cab (ISO 12117-2)

The machine is equipped with a ROPS cab (ISO 12117-2) for excavators as standard equipment. The ROPS cab has high shock-absorption performance, featuring excellent durability and impact strength. It also satisfies the requirements of OPG top guard level 1 (ISO 10262) for falling objects. Combined with the retractable seat belt, The ROPS cab protects the operator in case of tipping over and against falling objects. Large LCD Color MonitorA large user-friendly color monitor enables safe, accurate and smooth work. Improved screen visibility is achieved by the use of LCD that can easily be read at various angles and lighting conditions. The switches are simple and easy to operate. Industry first function keys facilitate multi-function operations. Displays data in 12 languages to globally support operators around the world. Indicators1. Auto-decelerator 2. Working mode 3. Travel speed 4. Engine water temperature gauge 5. Hydraulic oil temperature gauge 6. Fuel gauge 7. ECO gauge 8. Function switches menu Basic operation switches1. Auto-decelerator 2. Working mode selector 3. Traveling selector 4. Buzzer cancel 5. Wiper 6. Windshield washer Rear View MirrorRear view mirror allow Komatsu PC70-8 to meet the visibility requirements (ISO 5006). Lock LeverLocks the hydraulic pressure to prevent unintentional movement. Neutral start function allows machine to be started only in lock position. Equipment Management Monitoring SystemMonitor function: Controller monitors engine oil level, coolant temperature, battery charge and air clogging, etc. If the controller finds any abnormality, it is displayed on the LCD. Maintenance function: Monitor informs replacement time for oil and filters when the replacement interval is reached. Trouble data memory function: Monitor stores abnormalities for effective troubleshooting. |

SPECIAL SPECS. |

|

|

|

|

Komatsu Genuine Attachment Tool Komatsu-recommended attachment tools for hydraulic excavators. A wide range of attachment tools are provided to suit customers’ specific applications Hydraulic breaker The hydraulic breaker is an attachment tool used for crushing rock beds and paved surfaces, demolishing concrete structures, etc. The large gas chamber, ideal gas pressure ratio, and long-stroke piston deliver Crusher This attachment tool is used for demolishing concrete structures. Since it does not have a striking mechanism and features low noise and low vibration, it is suitable for work in urban areas. The openclose cylinder is equipped with a speed-up valve for increasing work speed. |

KOMATSU TOTAL SUPPORT |

|

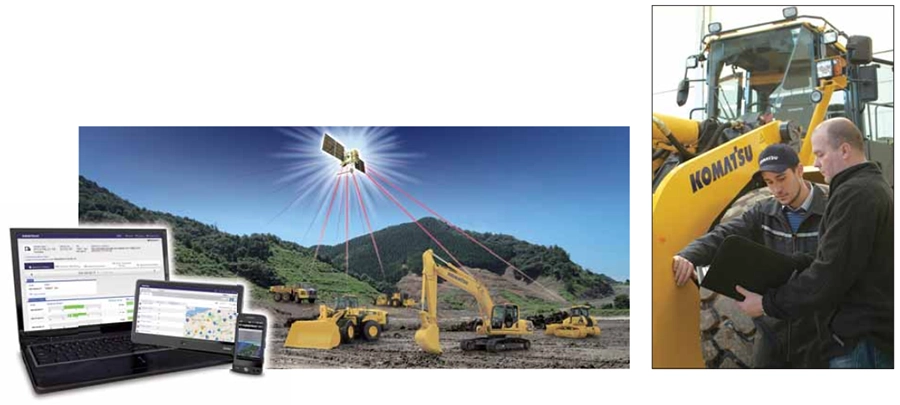

| Komatsu Total Support

To keep your machine available and minimize operation cost when you need it, Komatsu Distributor is ready to provide a variety of supports before and after procuring the machine. Technical support Komatsu product support service (Technical support) is designed to help customer. Komatsu Distributor offers a variety of effective services to show how much Komatsu is dedicated to the maintenance and support of Komatsu machine. - Preventive Maintenance (PM) clinic - Oil & Wear analysis program - Undercarriage inspection service, etc. Fleet recommendation Komatsu Distributor can study the customer’s job site and provide the most optimum fleet recommendation with detailed information to meet all of your application needs when you are considering to buy new machines or replace the existing ones from Komatsu. Product support Komatsu Distributor gives the proactive support and secures the quality of the machinery that will be delivered. Parts availability Komatsu Distributor is available for emergency inquiry by the customers for genuine, quality guaranteed Komatsu parts. Repair & maintenance service Komatsu Distributor offers quality repair and maintenance service to the customer, utilizing and promoting Komatsu developed programs. Komatsu Reman (Remanufactured) components Komatsu Reman products are the result of the implementation of the Komatsu global policy which establishes and agrees to reduce the owning, operating and total Life Cycle Costs (LCC) to Komatsu’s customer through high quality, prompt delivery and competitively priced in own remanufactured products (QDC). |

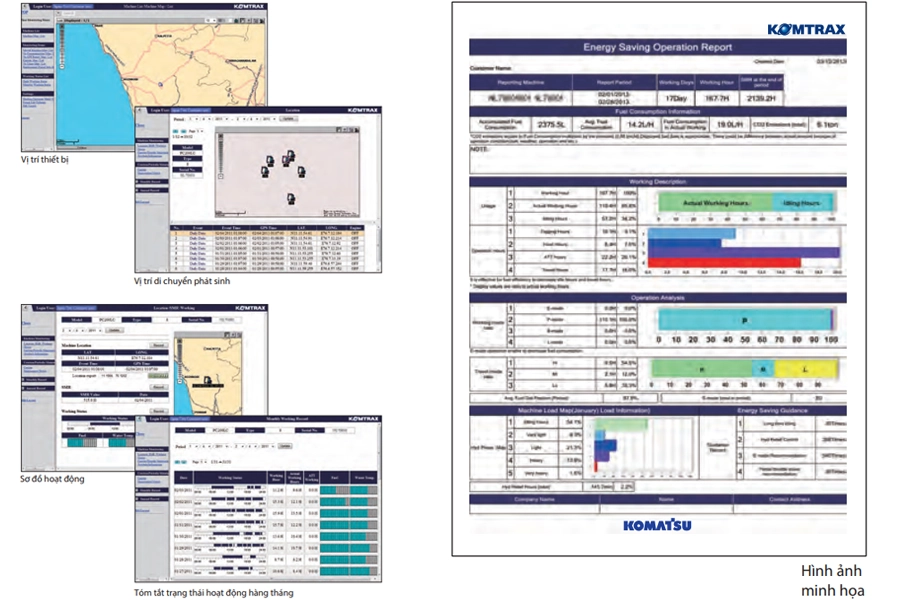

| KOMTRAX

The Komatsu remote monitoring and management technology provides insightful data about your equipment and fleet in user-friendly format. |

|

| Energy Saving Operation Report

KOMTRAX delivers the energy-saving operation report based on the operating information such as fuel consumption, load summary and idling time, which helps you efficiently run a business. Equipment Management SupportThrough the web application, a variety of search parameters are available to quickly find information about specific machines based on key factors. Moreover, KOMTRAX finds out machines with problems from your fleet and shows you through an optimal interface. |

|

| Optimal Strategy for Efficient Work

The detailed information that KOMTRAX puts at your fingertips helps you manage your fleet conveniently on the web anytime, anywhere. It gives you the power to make better daily and long-term strategic |

Tags: komatsu pc350 8, komatsu pc350 6, Komatsu 350, KOMATSU PC350 10, Komatsu PC210 6, Komatsu PC78US 6, komatsu 75 3, excavator for sale, excavator hire, excavator Komatsu, excavator hitachi, sany excavator, wheel excavator for sale, bucket wheel excavator, power wheel excavator, largest bucket wheel excavator, bucket wheel excavator price, volvo wheel excavator, bucket wheel excavator for sale, wheeled excavator, wheeled excavator for sale, wheel bucket excavator, wheel type excavator, wheeled excavator volvo, wheeled excavator hitachi